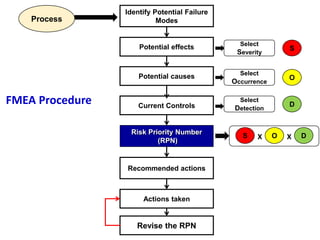

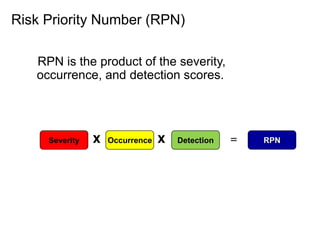

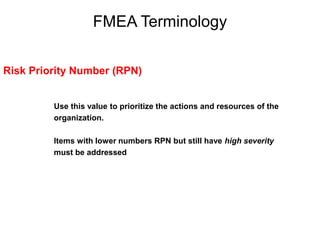

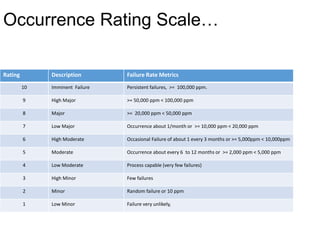

Failure Modes and Effects Analysis (FMEA) is a systematic tool used to identify potential failures, their causes, and effects. It helps prioritize issues based on a Risk Priority Number calculated from severity, occurrence, and detection ratings. FMEA was first used in the aerospace industry and has since been applied to automotive and other sectors. The analysis involves identifying failure modes, causes, and effects, then taking actions to reduce risks.