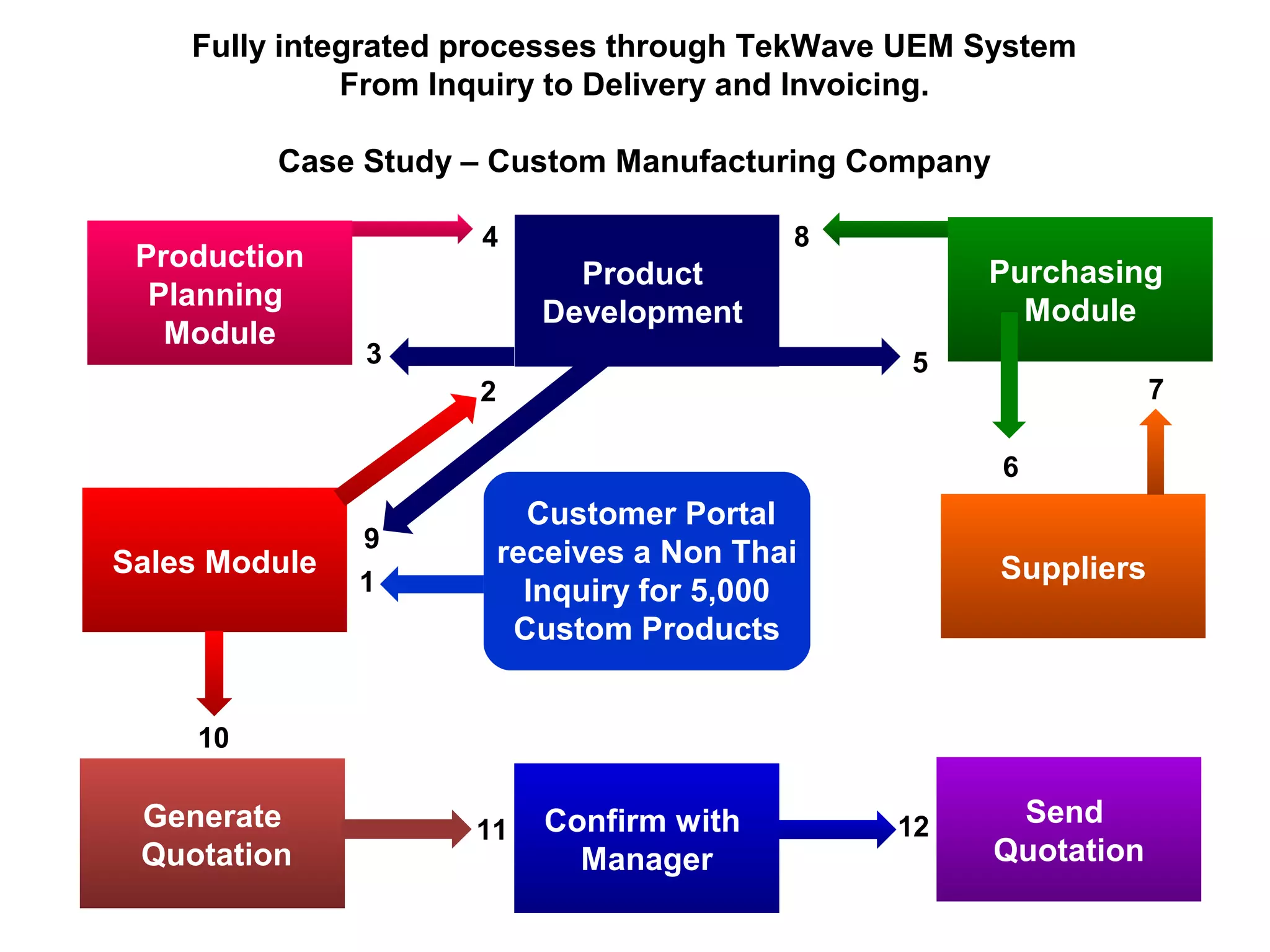

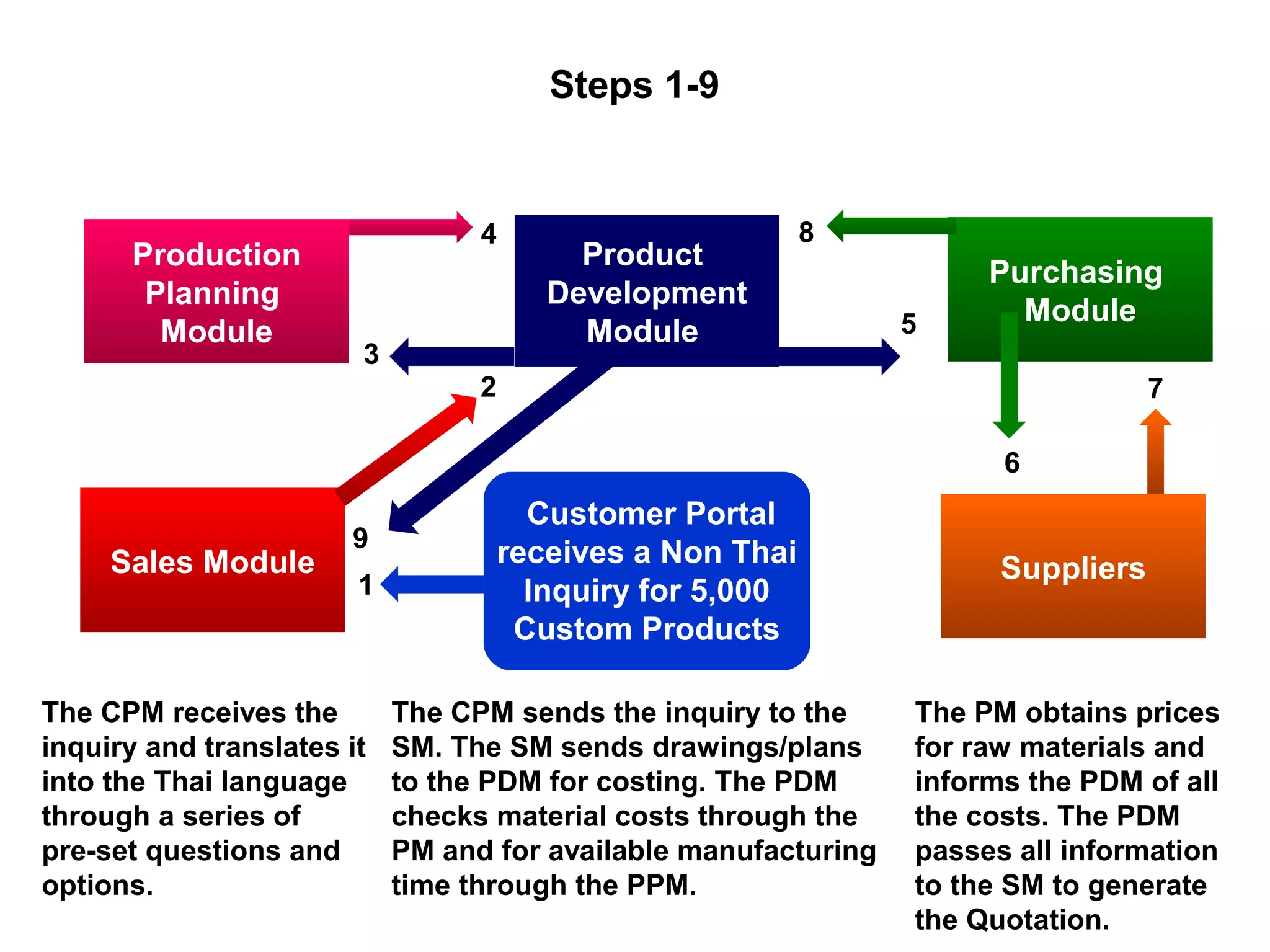

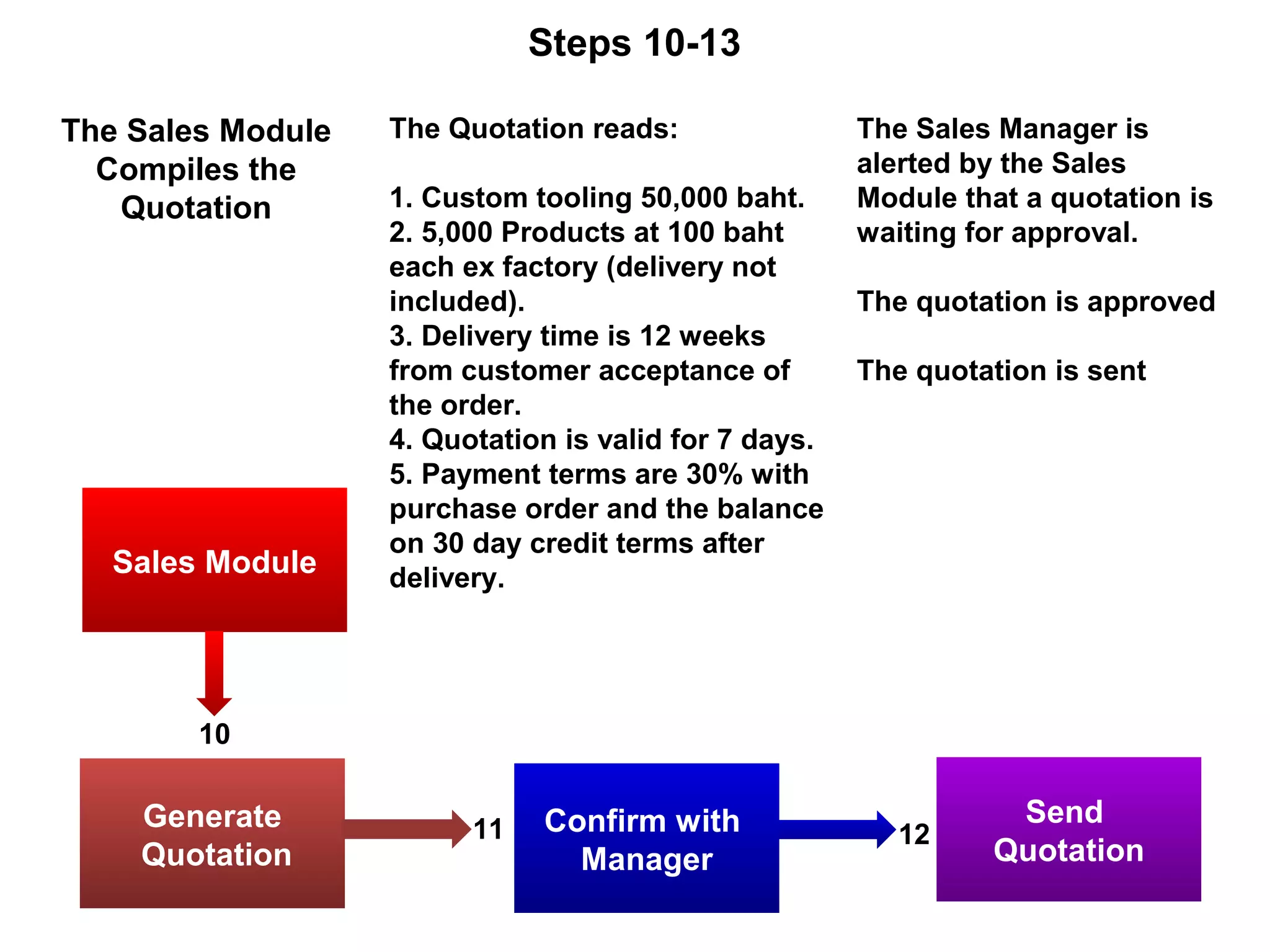

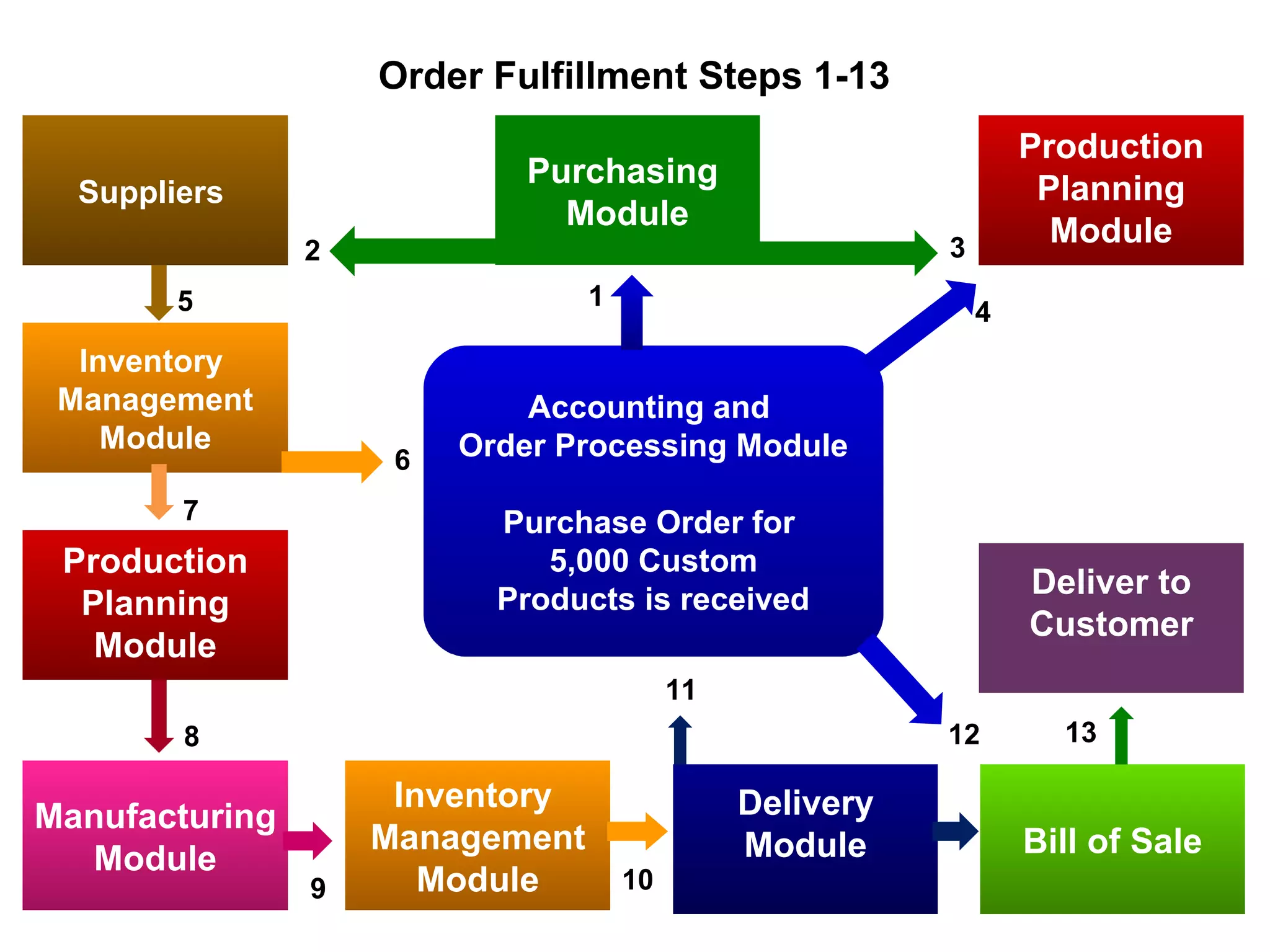

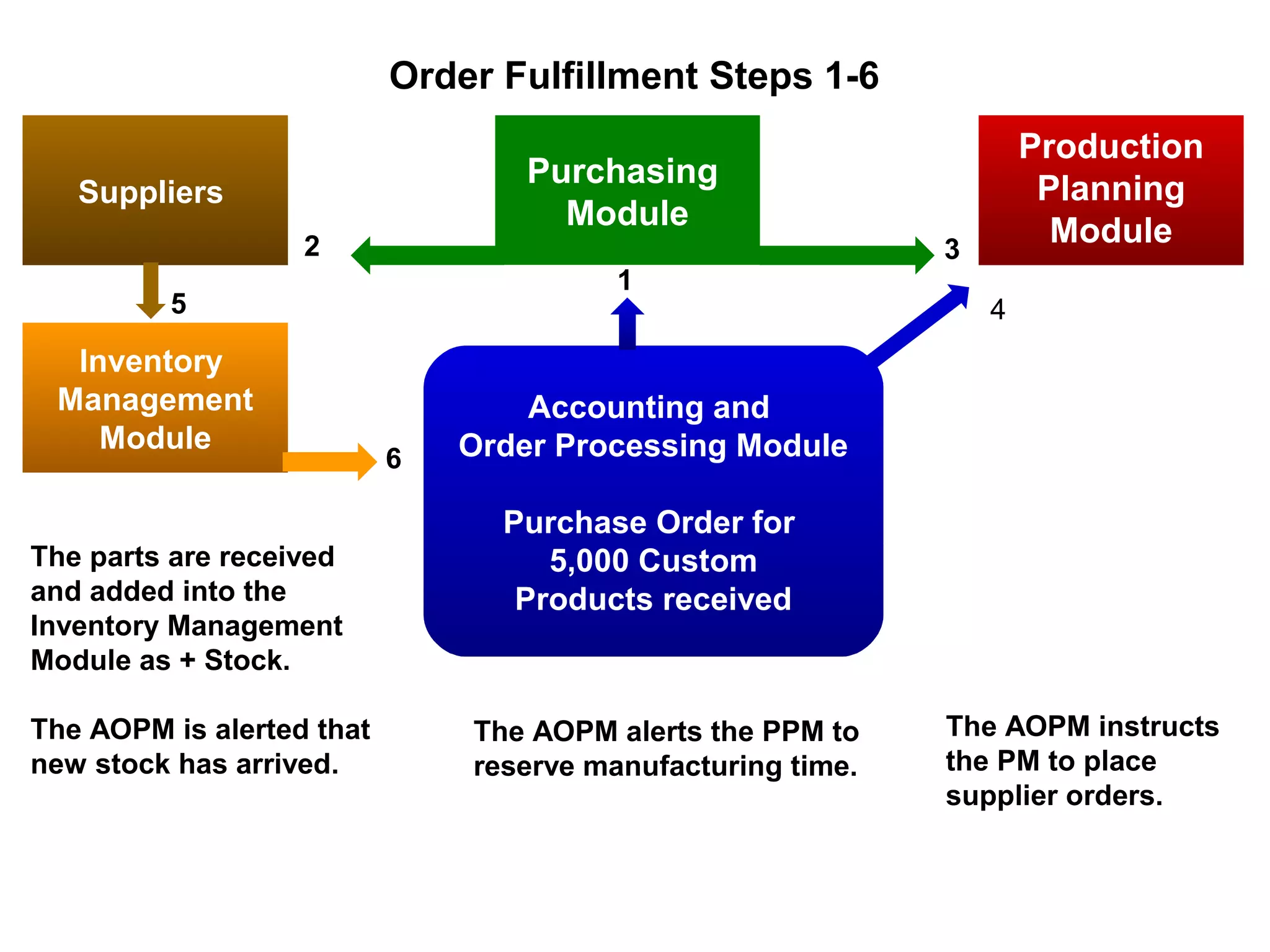

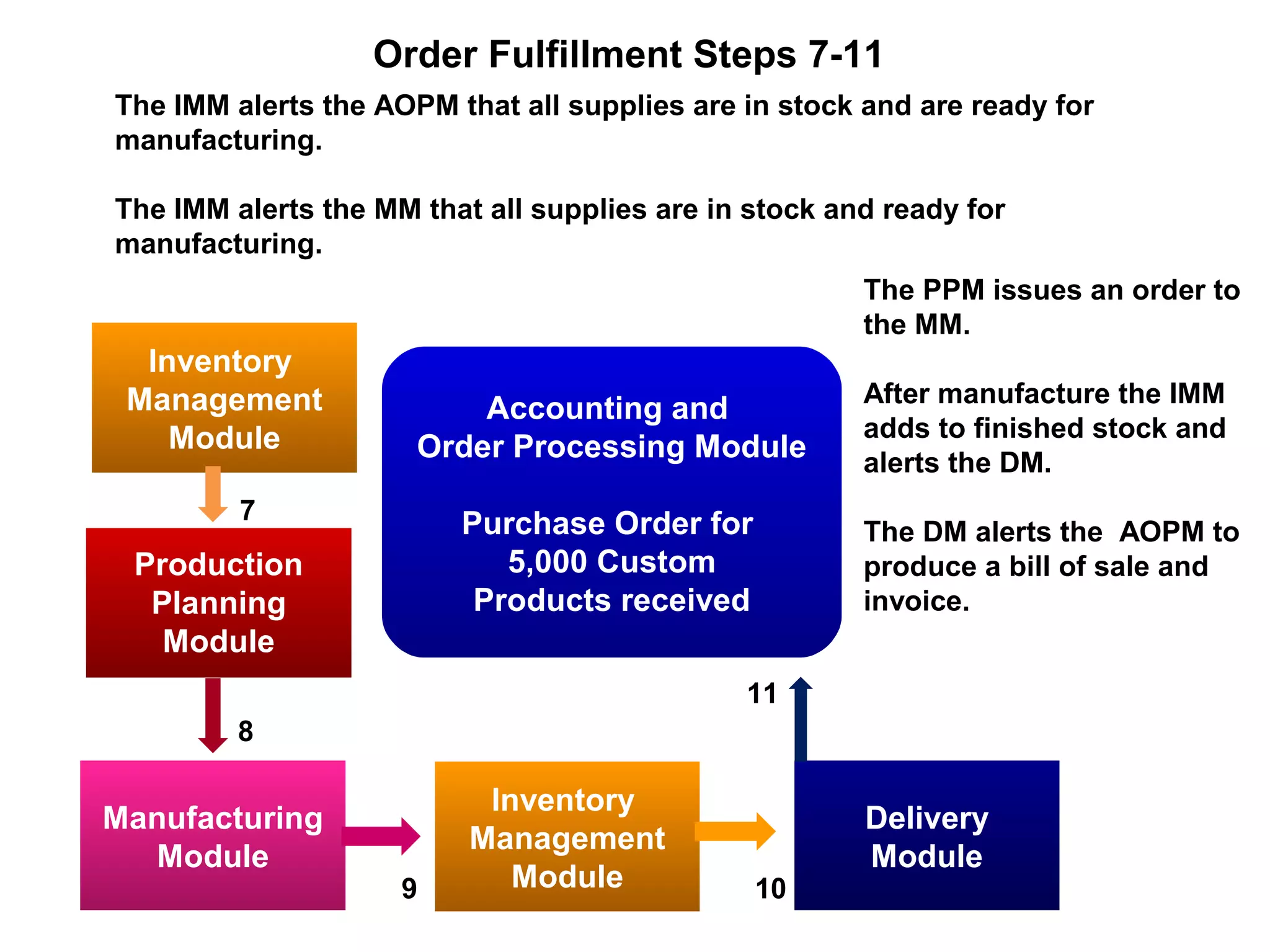

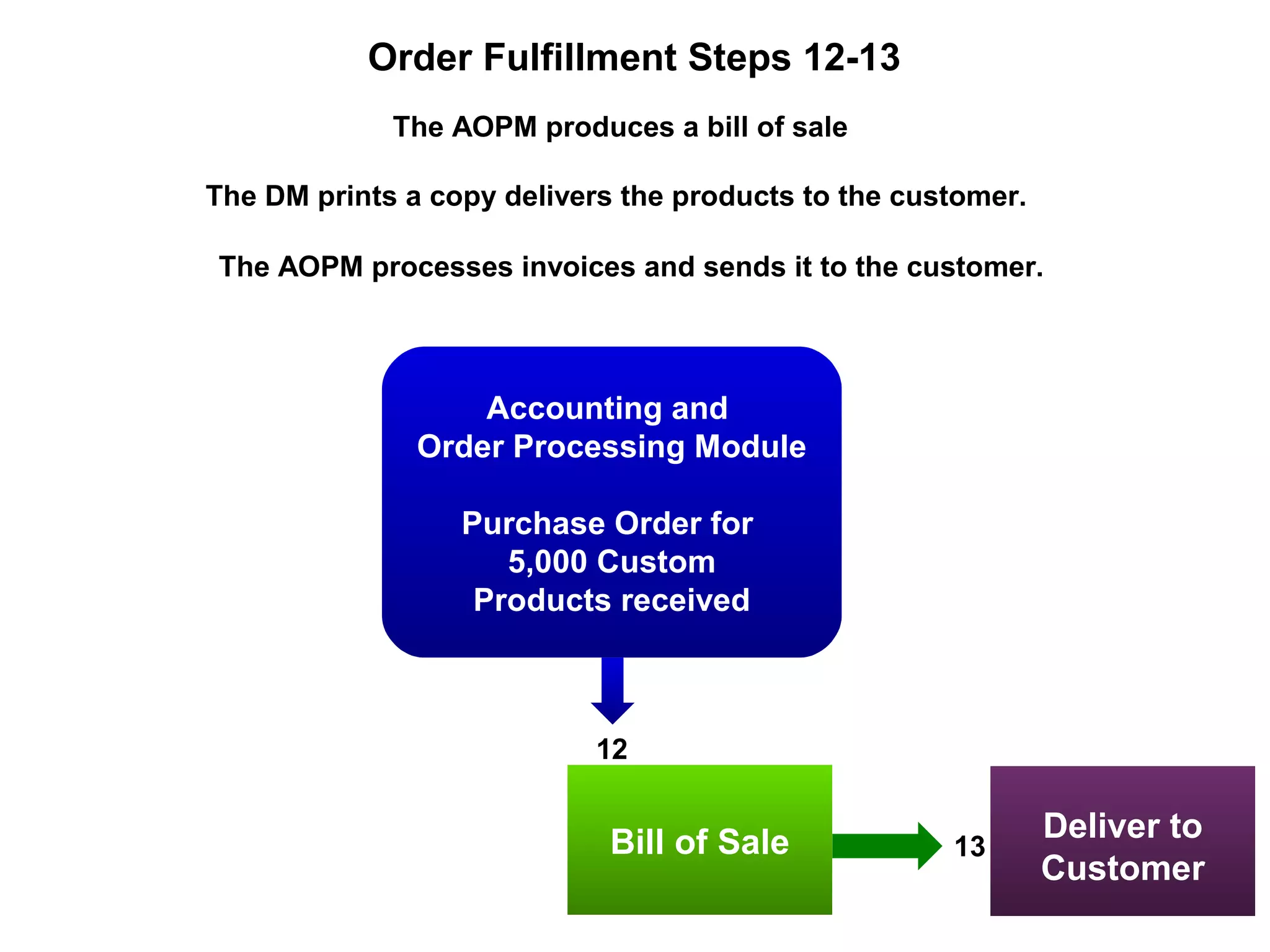

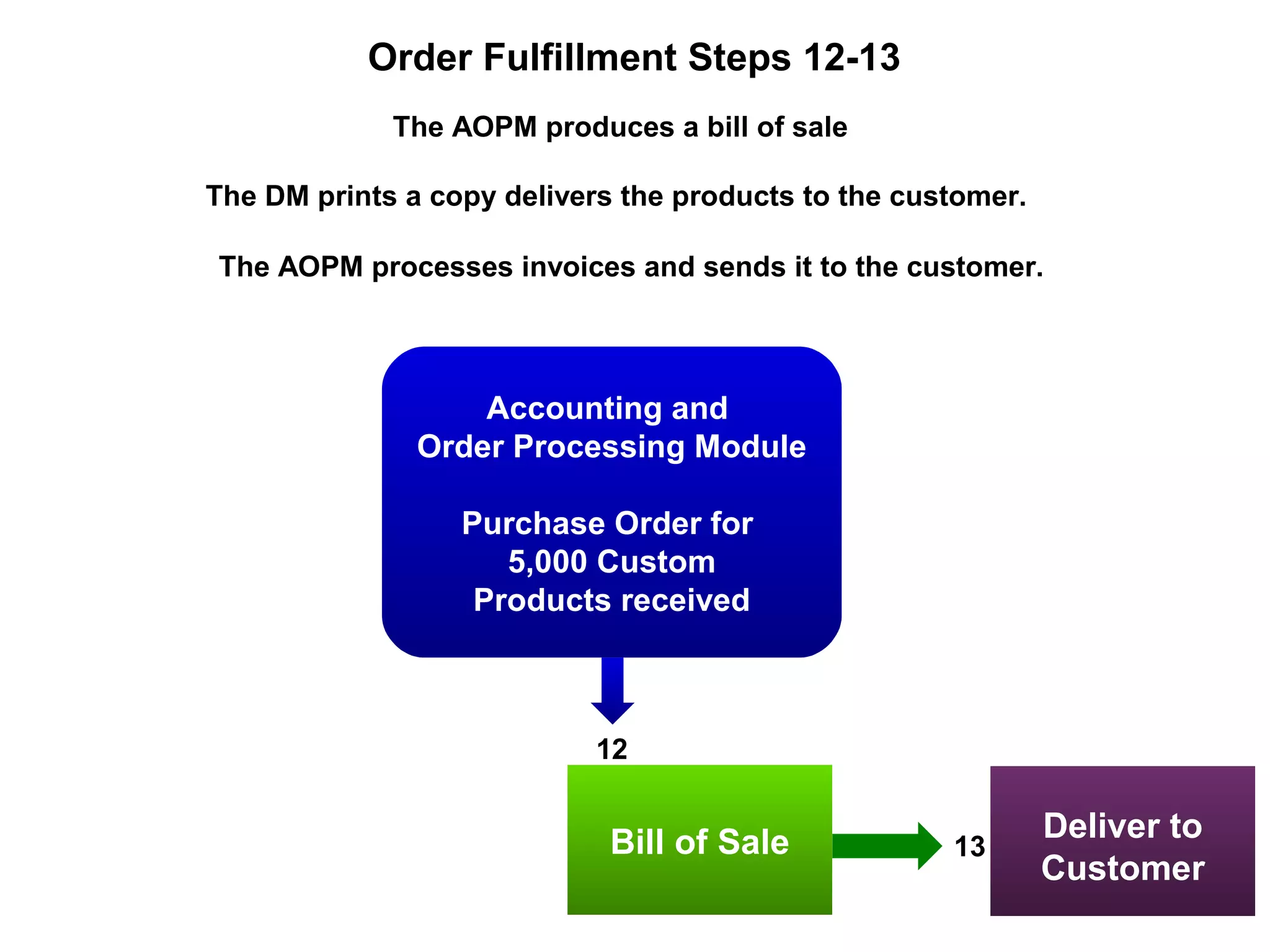

This document describes the order fulfillment process for a custom manufacturing company from inquiry to delivery and invoicing. The process involves 13 steps where a customer inquiry is converted into a quotation by the sales module. Upon receiving a purchase order, the production planning, purchasing, manufacturing, and delivery modules coordinate to fulfill the order. Inventory and accounting modules track materials and process invoices. The fully integrated system allows end-to-end order tracking and management.