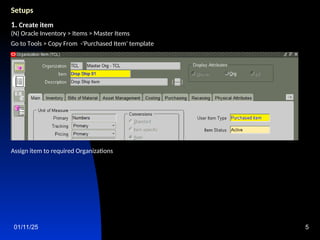

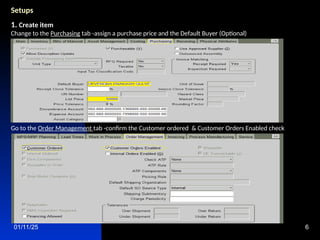

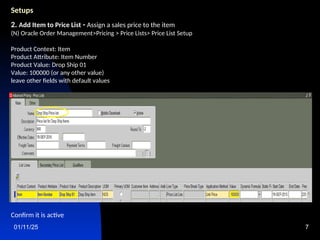

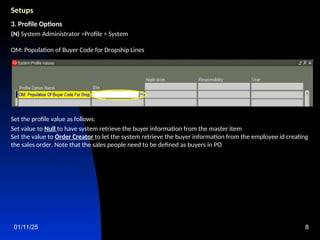

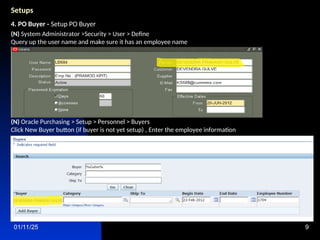

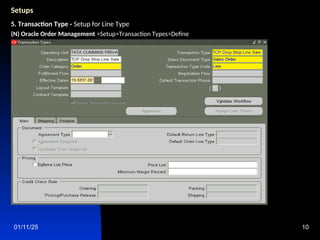

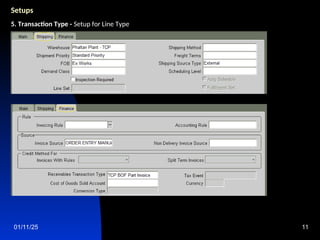

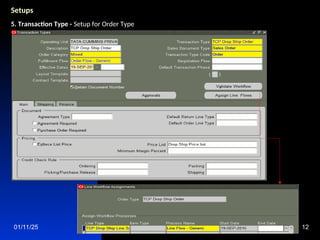

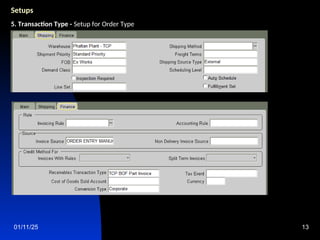

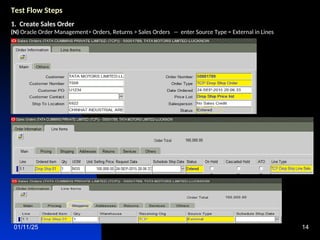

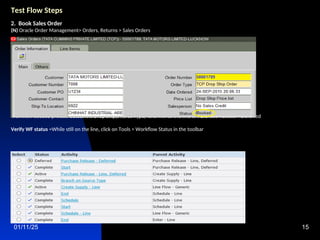

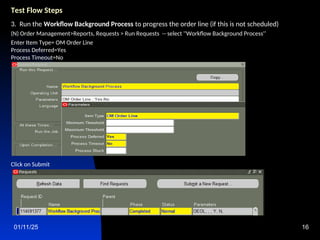

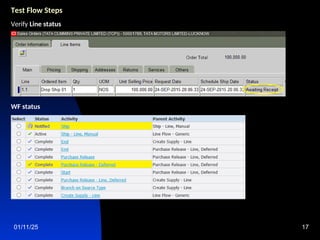

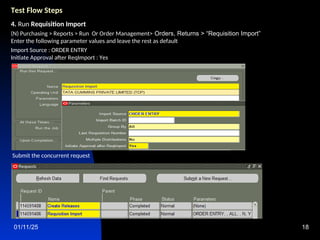

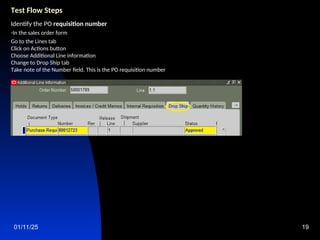

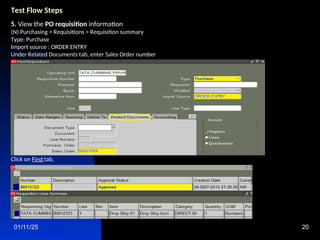

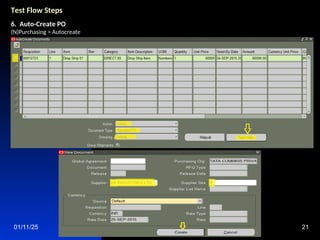

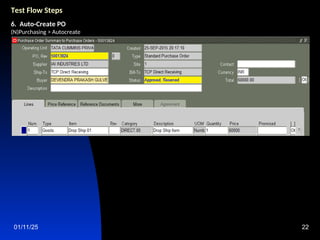

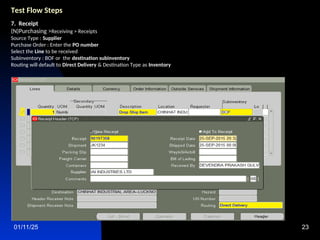

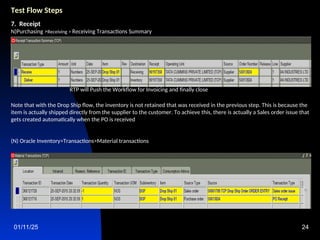

This document details the drop ship cycle in order management using the R12 system. It provides an overview of drop shipments, setup processes, and the steps involved in handling drop ship sales orders, including creating purchase requisitions, receiving items, and invoicing. The benefits of drop shipping include reduced costs and inventory requirements, while outlining the necessary configurations and workflows needed to implement the drop ship process effectively.