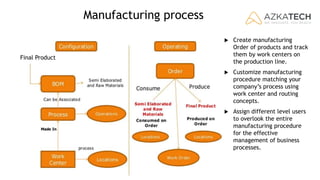

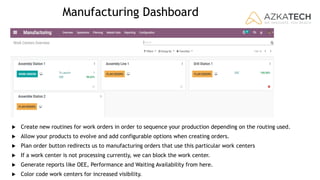

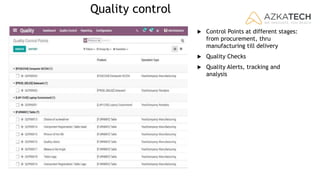

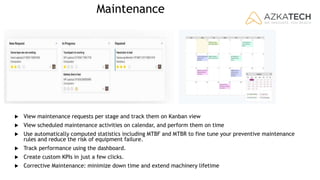

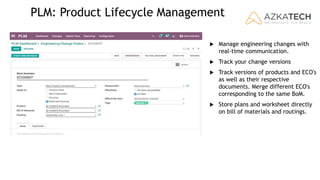

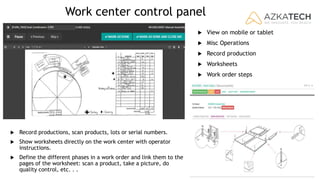

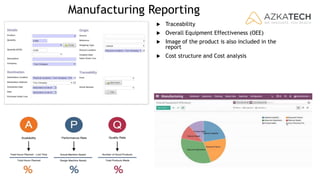

The document outlines an Odoo ERP manufacturing application that manages various processes such as manufacturing orders, work orders, and maintenance. It offers features for quality control, production tracking, and customizable workflows, including the ability to generate performance reports and manage product lifecycle effectively. The application provides a centralized dashboard for overseeing manufacturing activities and aims to enhance operational efficiency through real-time data and analytics.