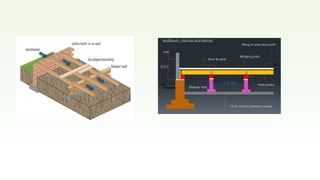

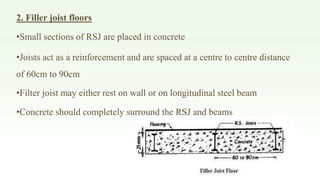

This document discusses different types of floors used in buildings. It describes basement floors, ground floors, and subfloors. The main types discussed are timber floors, composite floors, and concrete floors. Timber floors can be single joist, double joist, or framed floors and depend on the span and loads. Composite floors combine materials like steel and concrete or two layers of flagstones. Concrete floors include reinforced concrete slabs, which are widely used today.