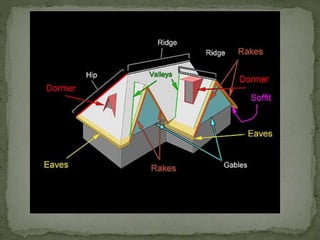

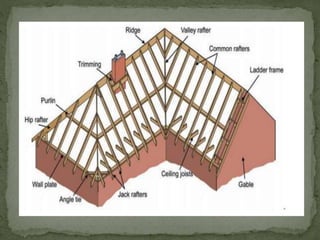

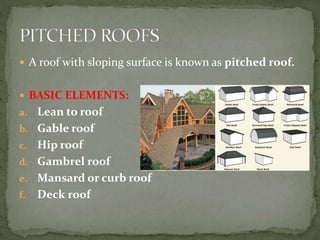

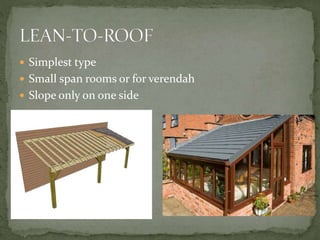

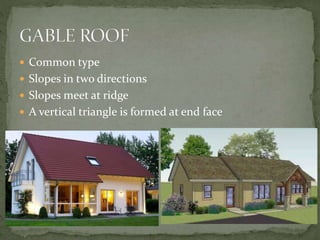

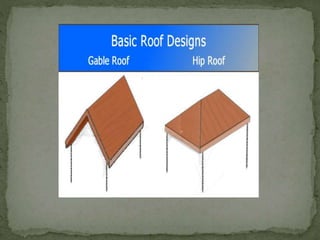

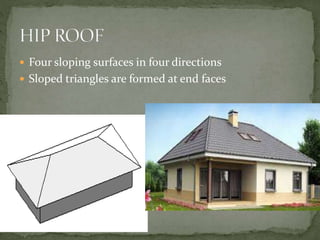

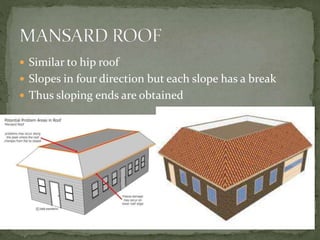

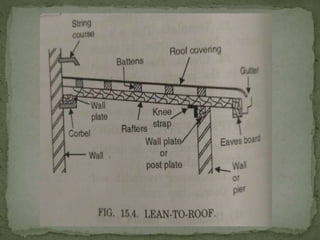

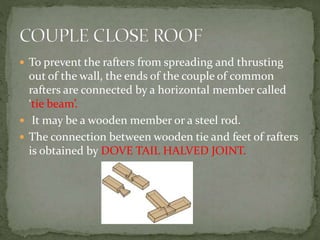

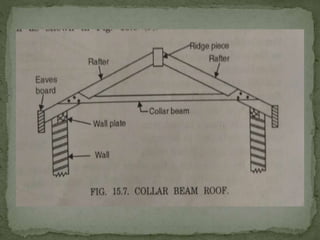

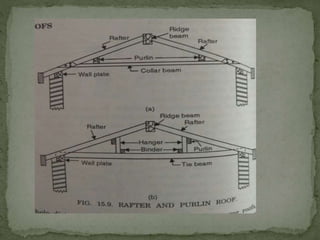

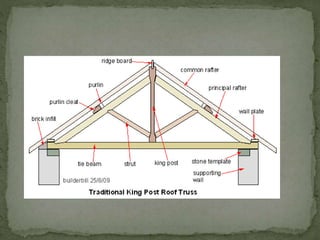

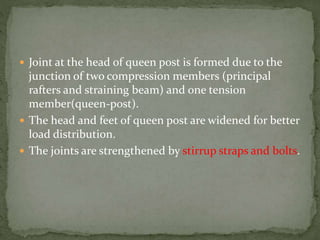

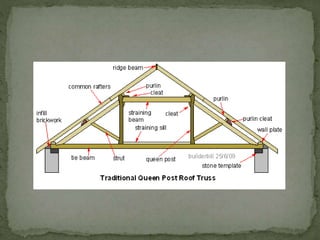

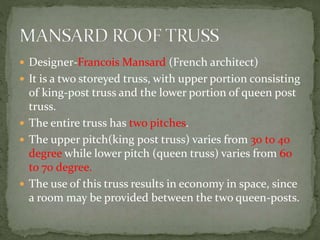

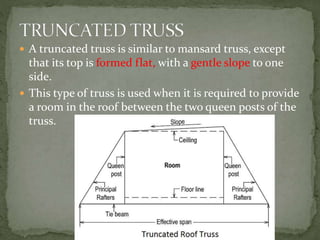

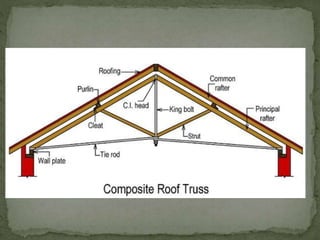

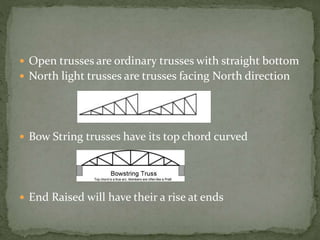

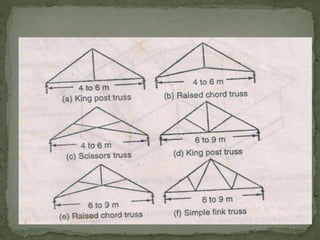

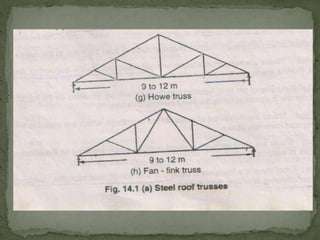

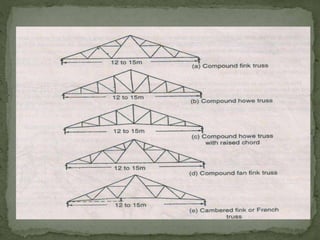

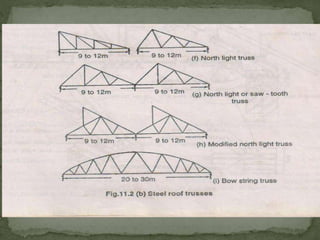

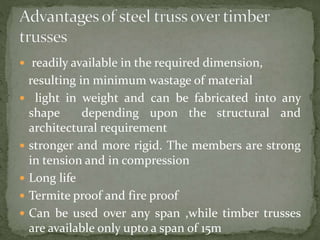

The document outlines various types of pitched roofs, detailing their basic elements such as lean-to, gable, hip, and mansard roofs, along with their suitability for different spans. It elaborates on single, double, and trussed roof types, including key components like rafters, purlins, and trusses, as well as reinforcing methods to prevent sagging and spreading. Additionally, it discusses the differences between timber and steel trusses, emphasizing the advantages of steel for longer spans due to its strength and economical fabrication.