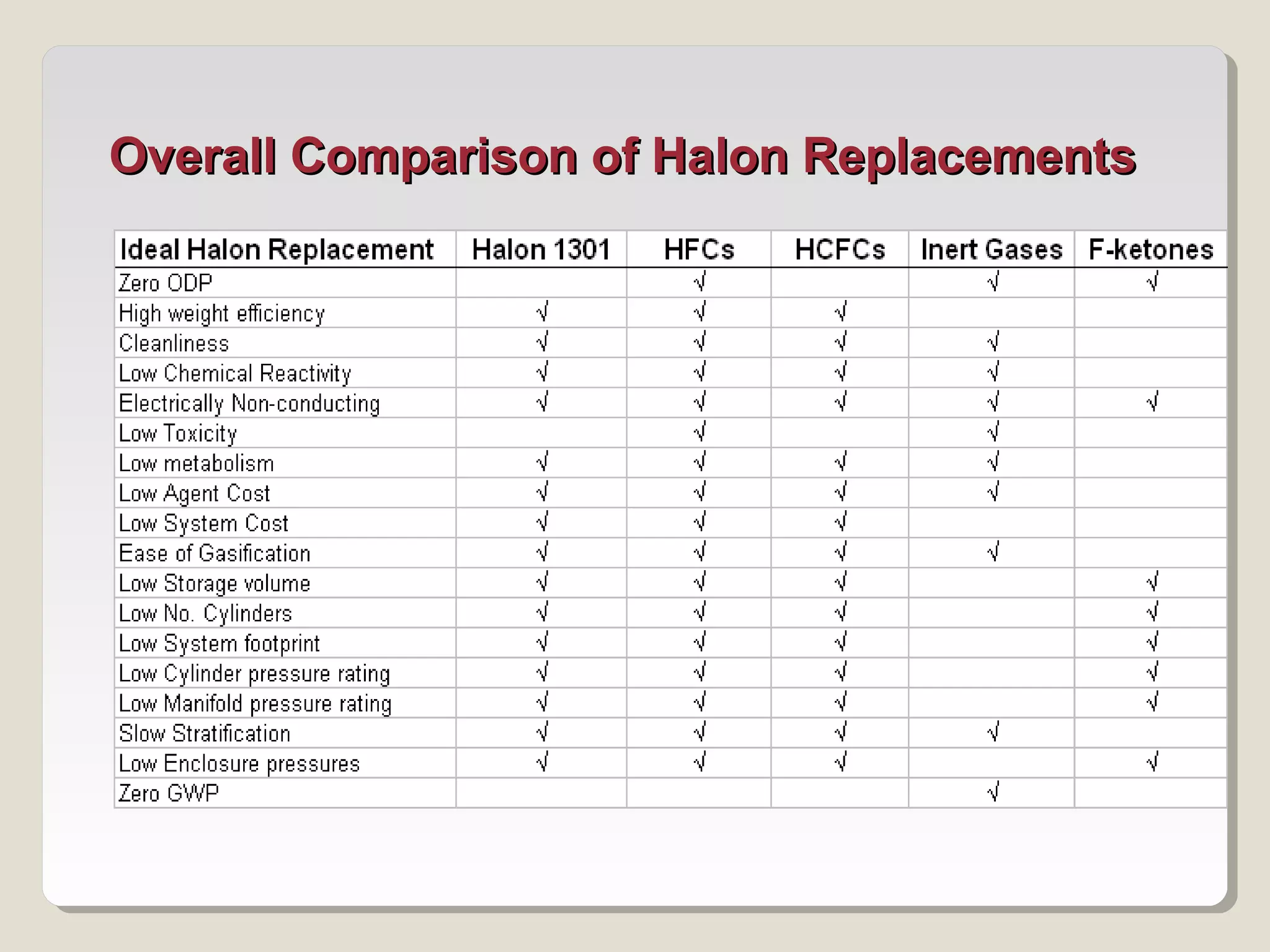

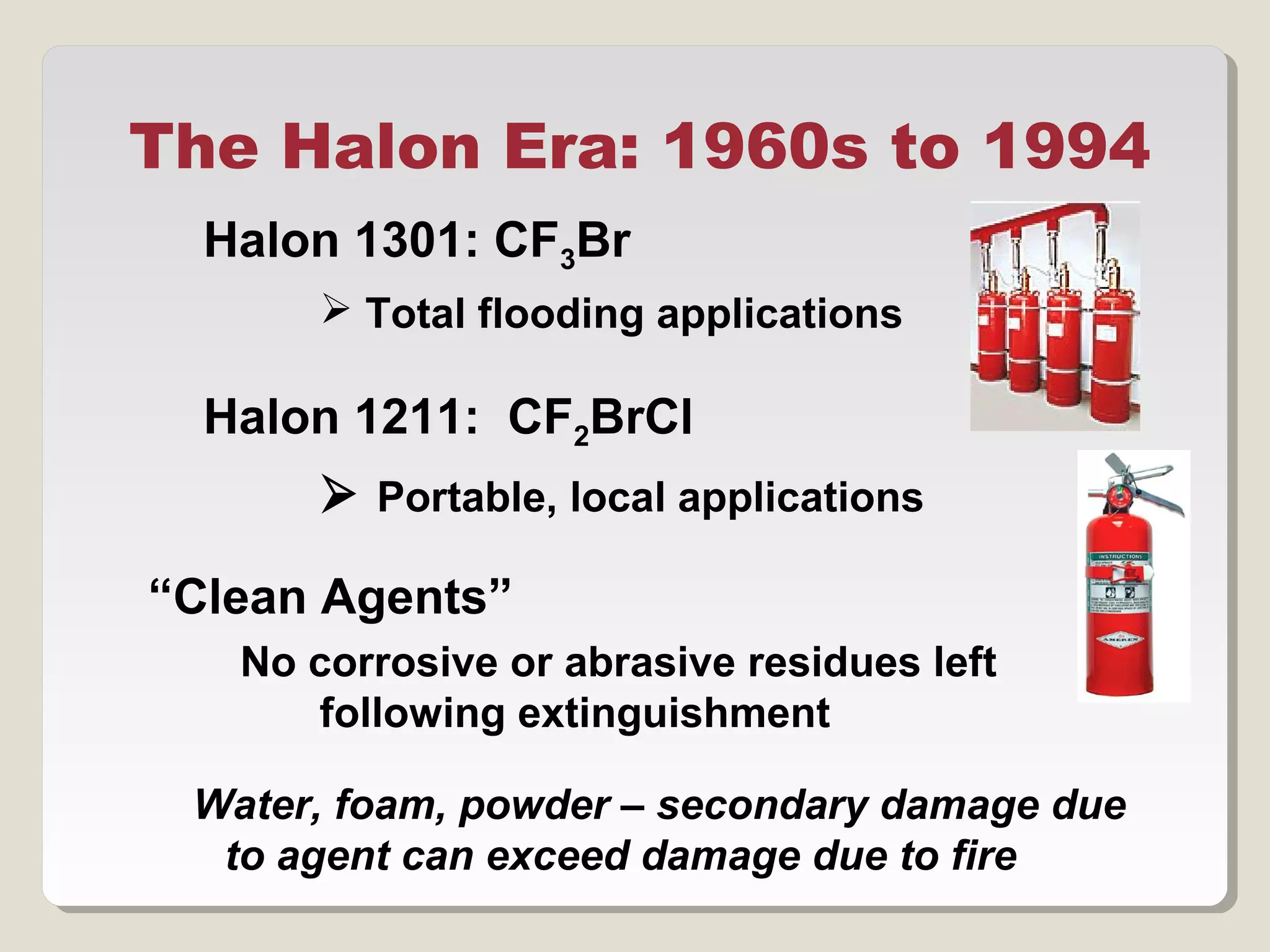

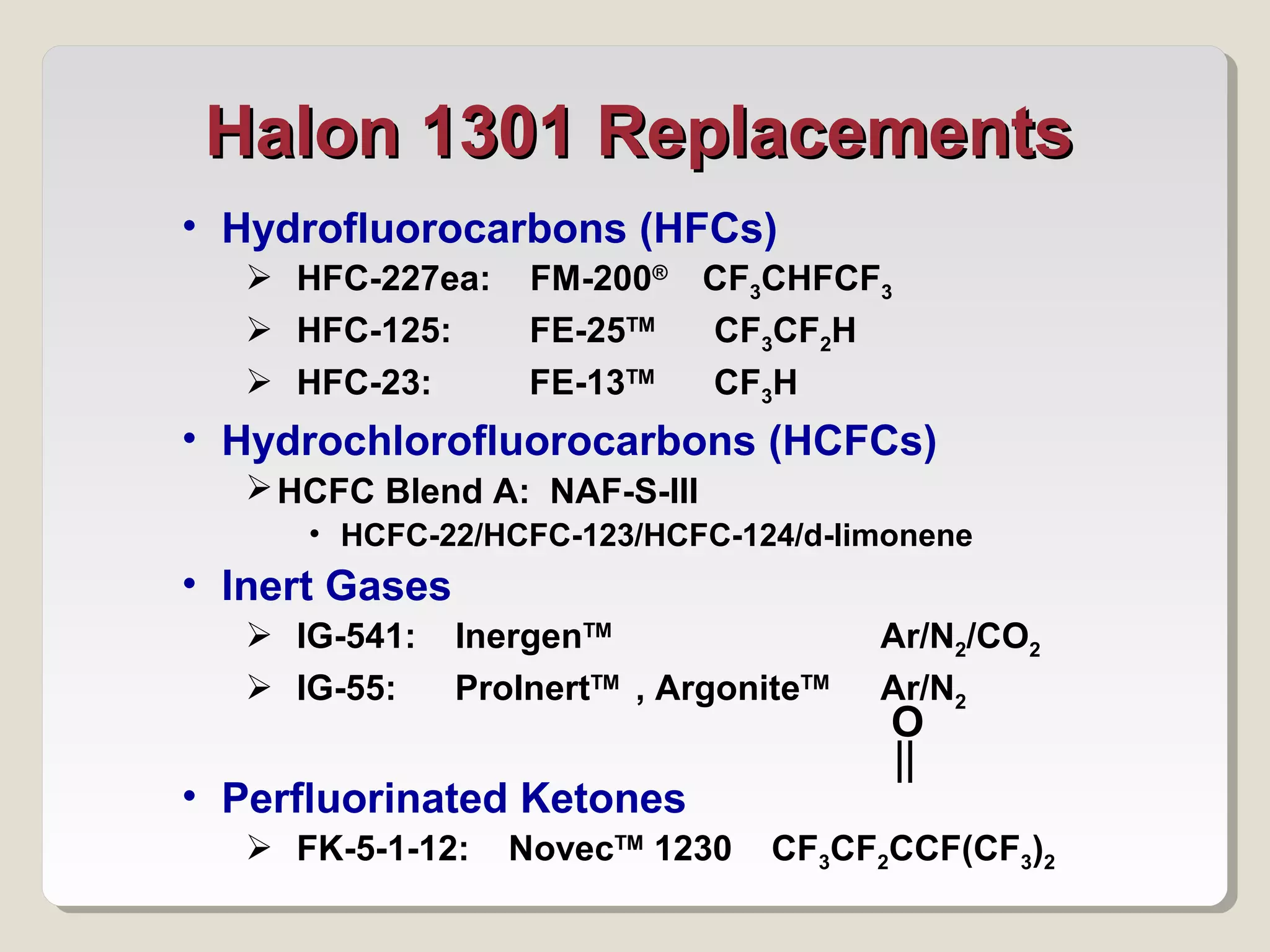

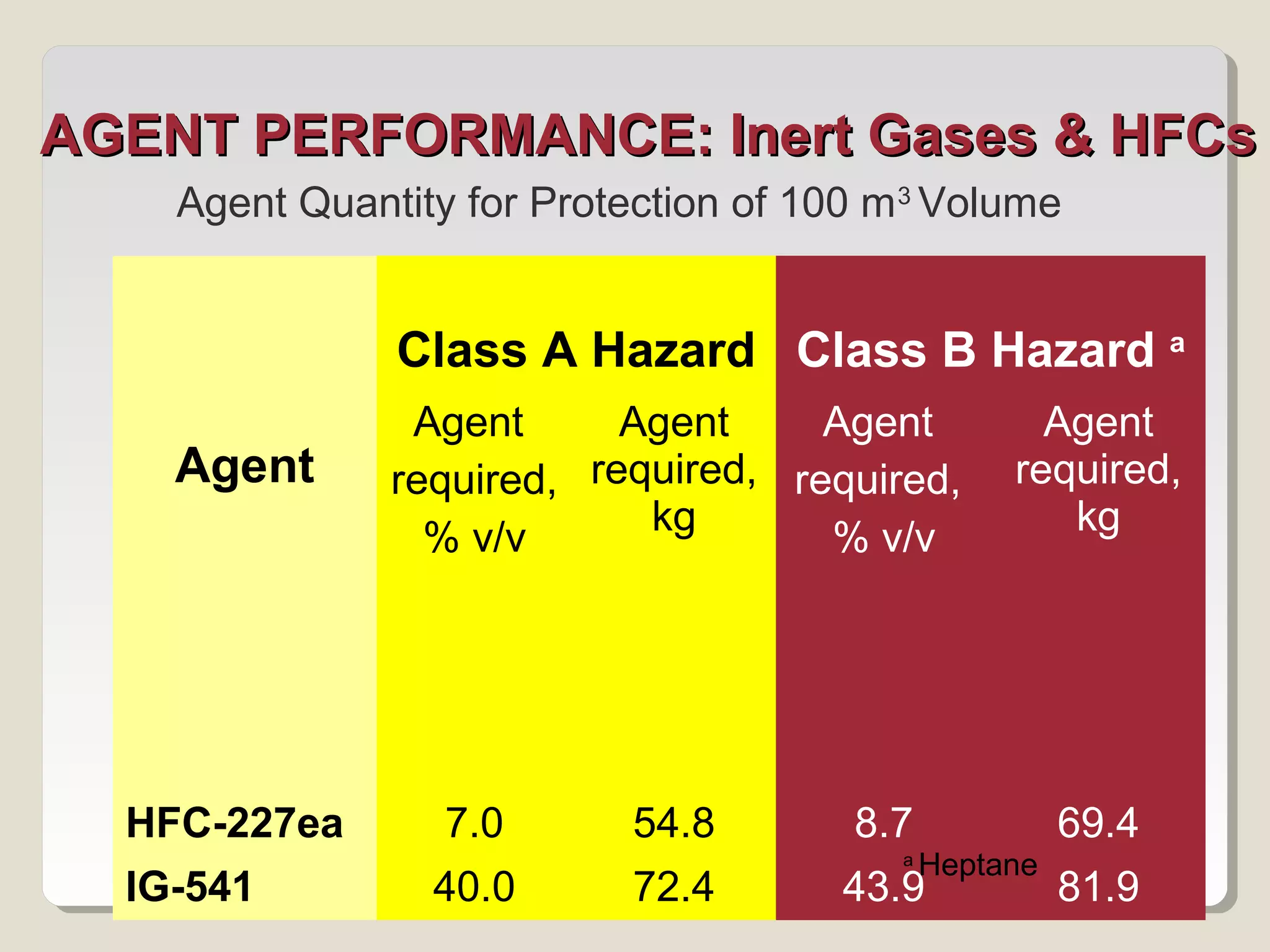

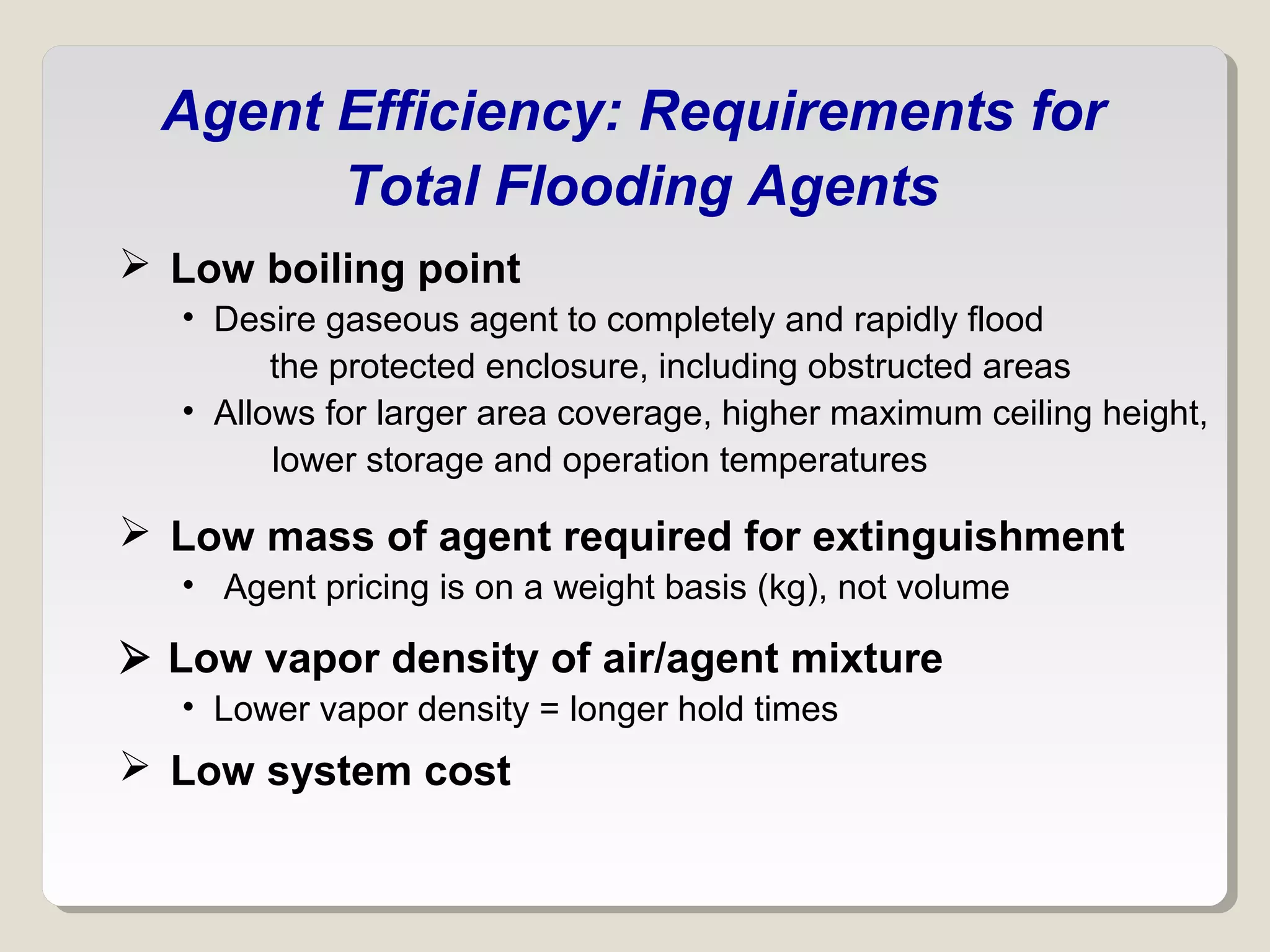

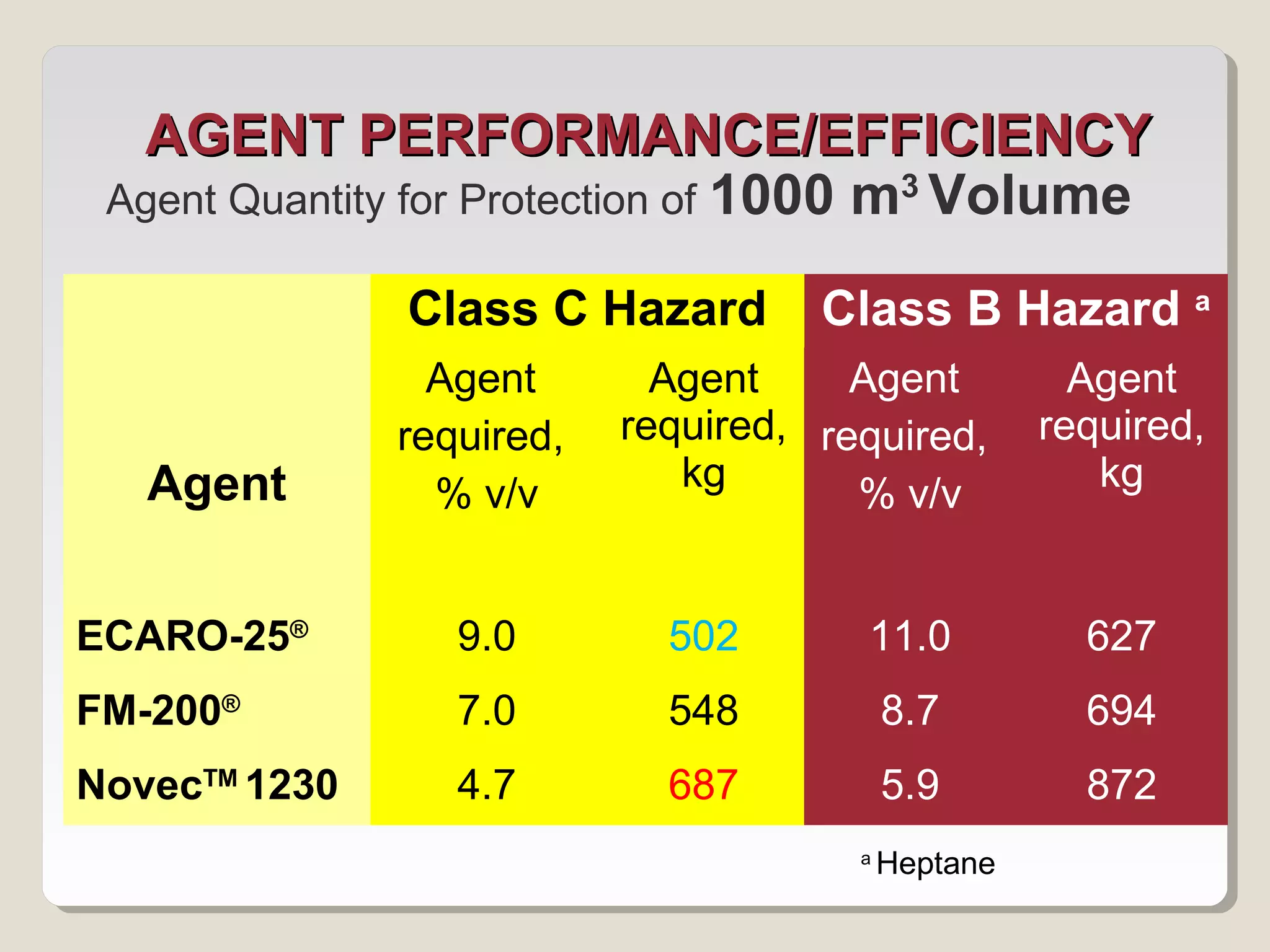

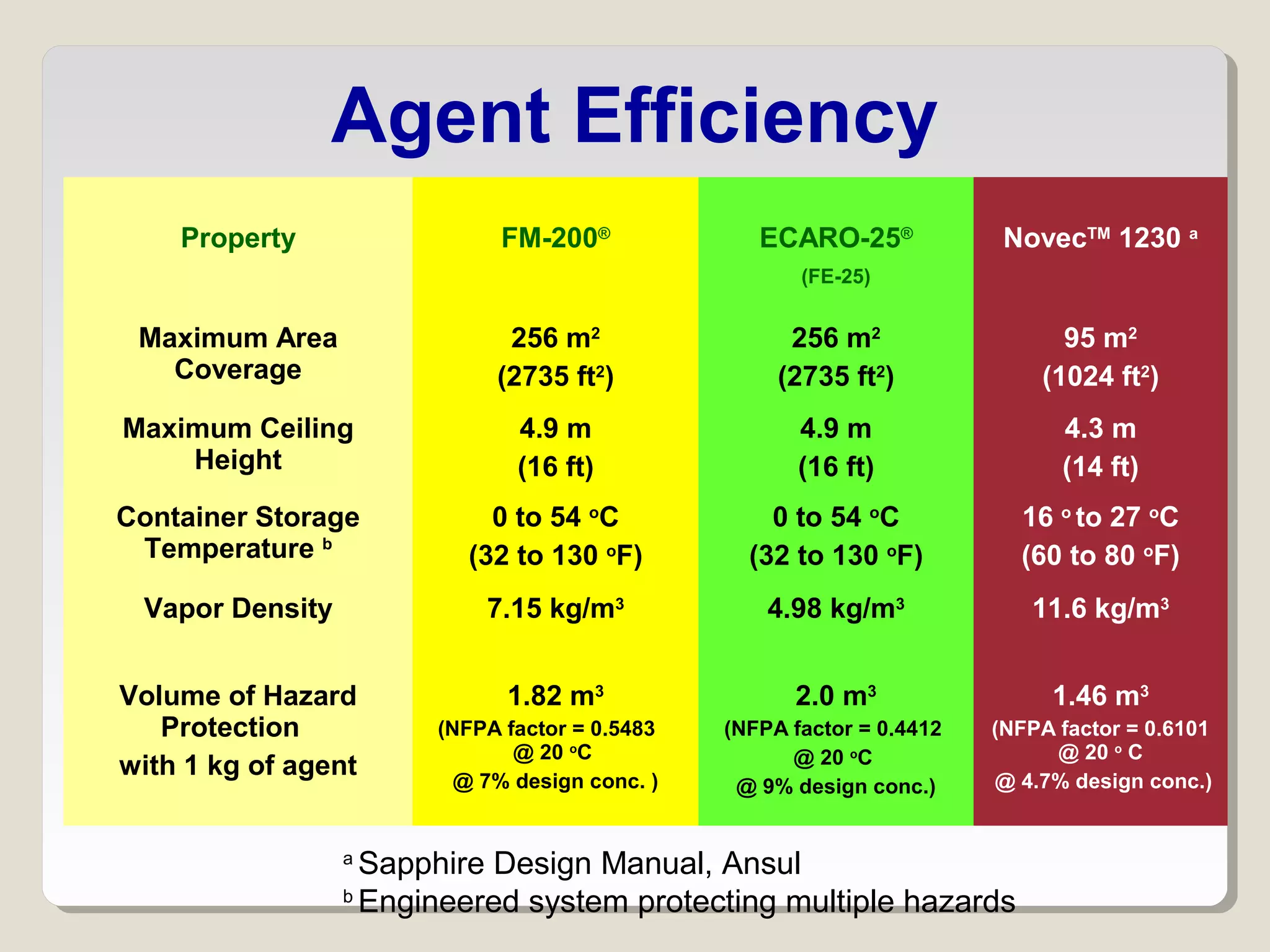

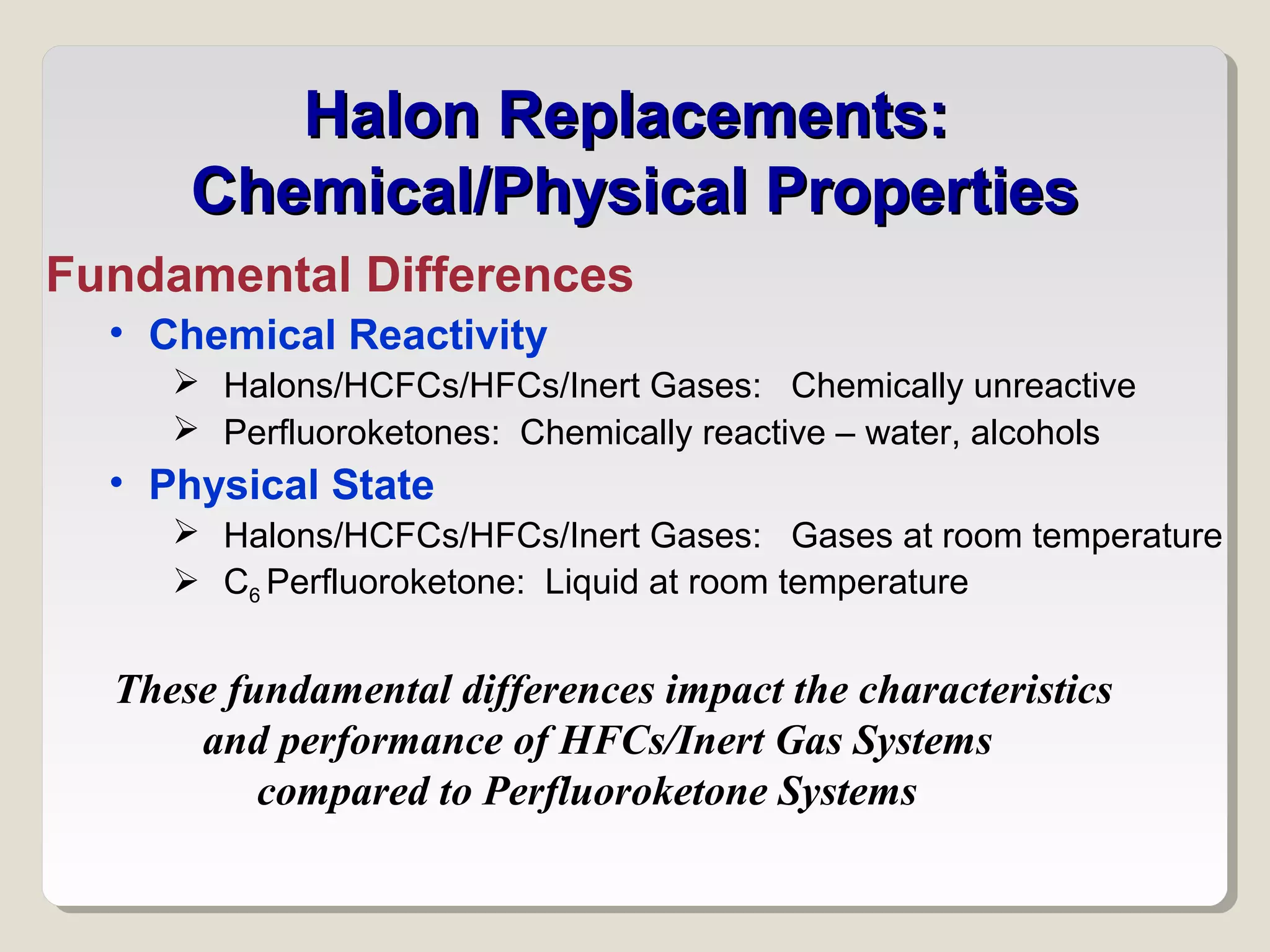

The document discusses halon total flooding fire suppression agents, highlighting the advantages of halon 1301 and its replacements, such as hydrofluorocarbons (HFCs), hydrochlorofluorocarbons (HFCs), inert gases, and perfluorinated ketones. It outlines the configurations, performance metrics, and chemical properties of these agents, emphasizing the importance of low chemical reactivity for optimal effectiveness in fire suppression. Additionally, it addresses environmental impact, toxicity, and implications of chemical interactions of the various agents on performance and safety.

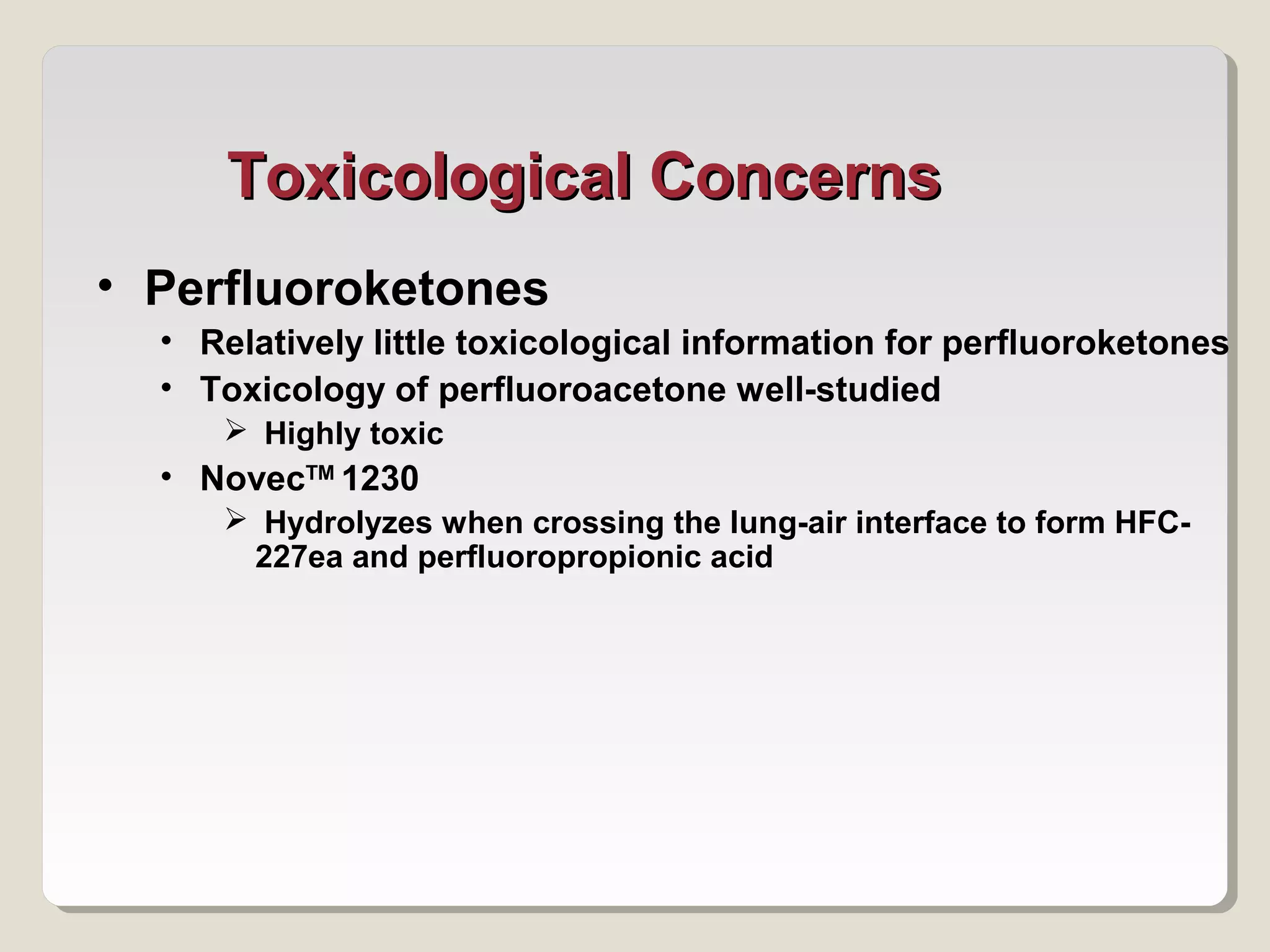

![Perfluoropropionic AcidPerfluoropropionic Acid

CF3CF2COOH

Strong Acid/Extremely Corrosive

• Is a perfluorocarboxylic acid – among strongest acids known

• Attacks steel, forming iron salt [DuPont, 2004]

Toxic [MSDS]

• Causes eye and skin burns

• May cause severe & permanent damage to digestive tract

• Causes gastrointestinal burns

• Causes chemical burns to respiratory tract

• PFCAs known tumor promoters [Env. Sci. Tech 2005, 39, 5517]

• PFCAs are known peroxisome proliferators [Ibid.]

Liver damage](https://image.slidesharecdn.com/systemcomparison-fmecaro-25vsnovec1230-180117163128/75/Fire-System-comparison-fm-ecaro-25-vs-novec-1230-20-2048.jpg)

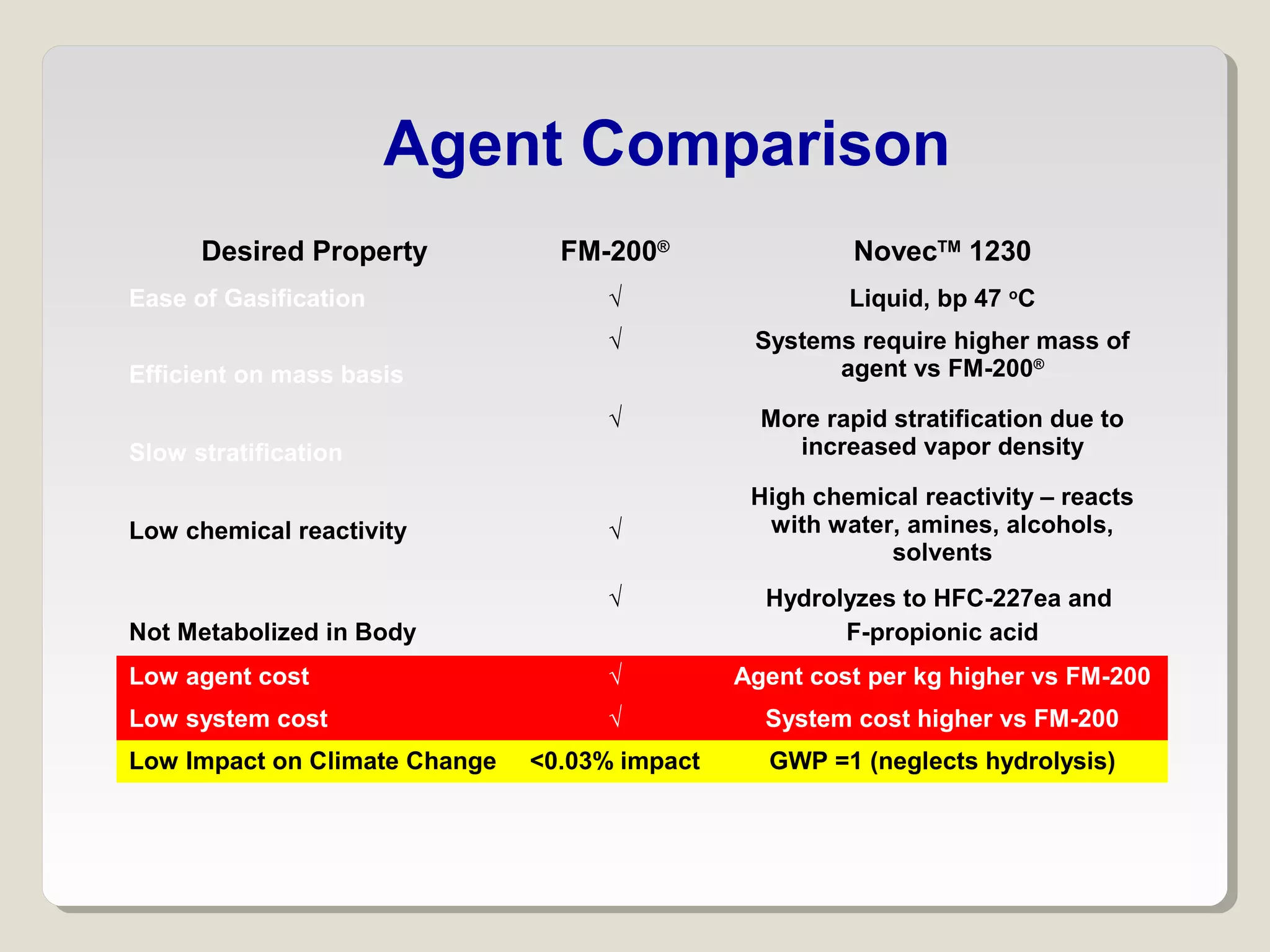

![Chemical Reactivity

Requirements FM-200®

/

ECARO-25®

NovecTM

1230

Low Chemical

Reactivity

√ Characterized by high

chemical reactivity

No reaction with

alcohols, amines √ Reacts with alcohols, amines

No reaction with

solvents √

Incompatible with polar or

hydrocarbon solvents

“Additional work is needed to assess the

reactivity of C6K [NovecTM

1230]…” a

Source: 3M: 24thIEEE SEMI-THERM Symposium, 2008, page 173.](https://image.slidesharecdn.com/systemcomparison-fmecaro-25vsnovec1230-180117163128/75/Fire-System-comparison-fm-ecaro-25-vs-novec-1230-26-2048.jpg)