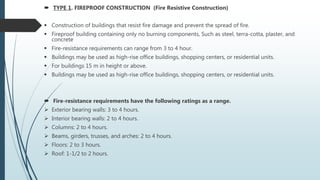

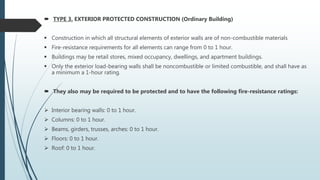

The document discusses fire guidelines for building construction. It outlines 4 types of construction based on the materials used: fireproof, noncombustible, exterior protected, and wood. Each type has different fire resistance ratings for structural elements like walls, floors, and roofs. Common building materials like concrete, brick, and gypsum are described as fire resistant due to properties like low combustibility. The document also discusses pressurization techniques to prevent smoke infiltration into stairwells and escape routes.