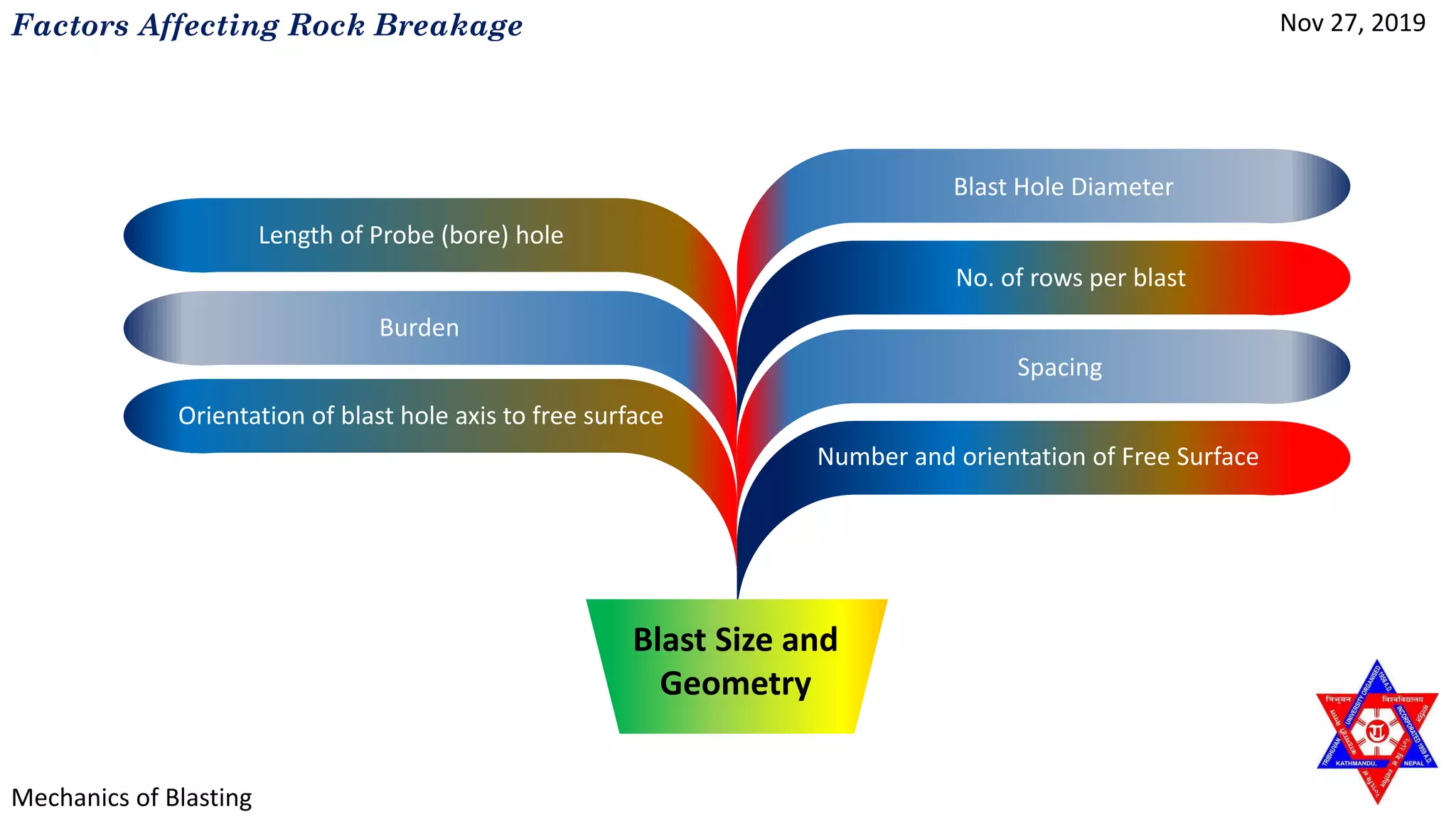

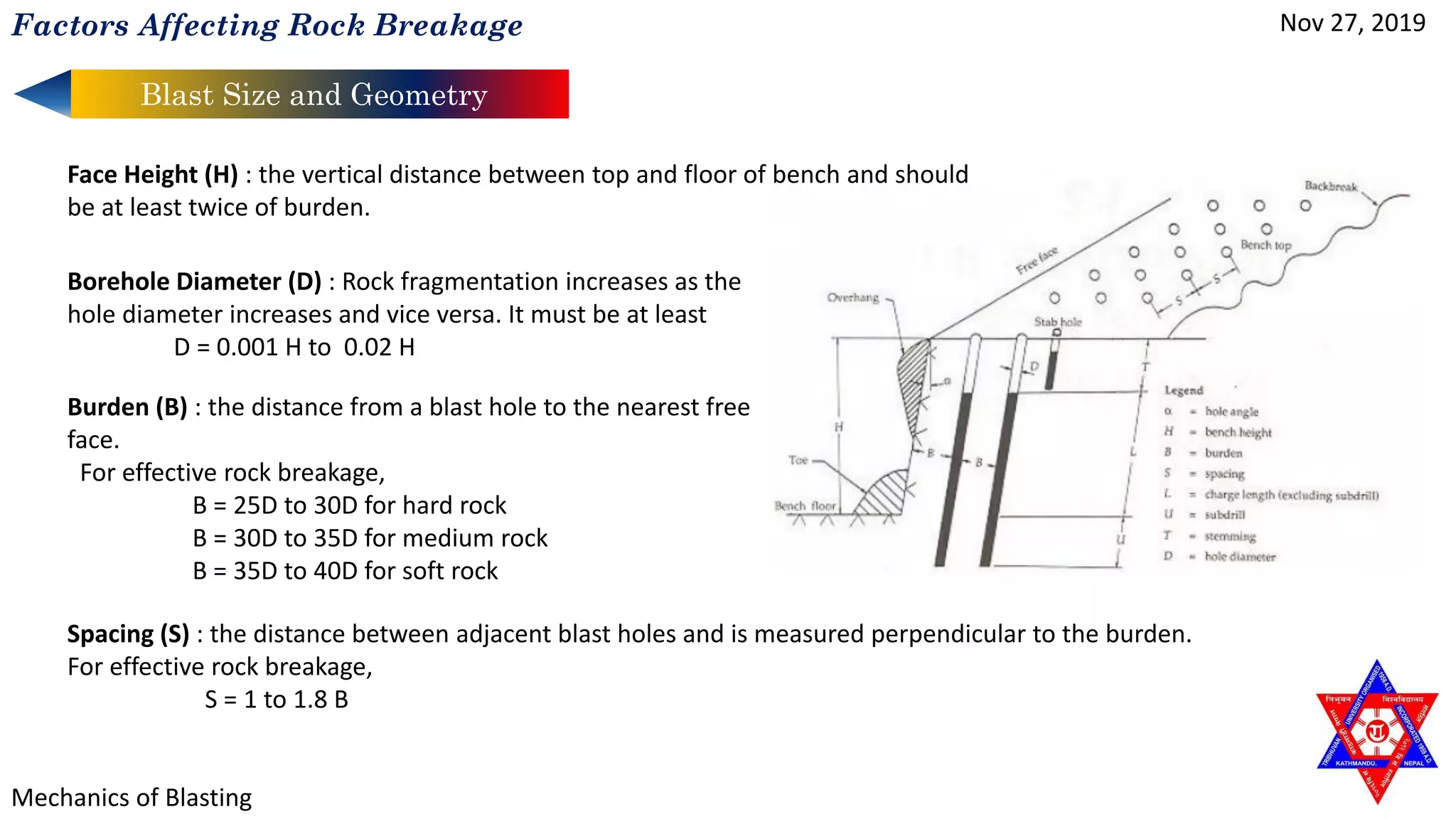

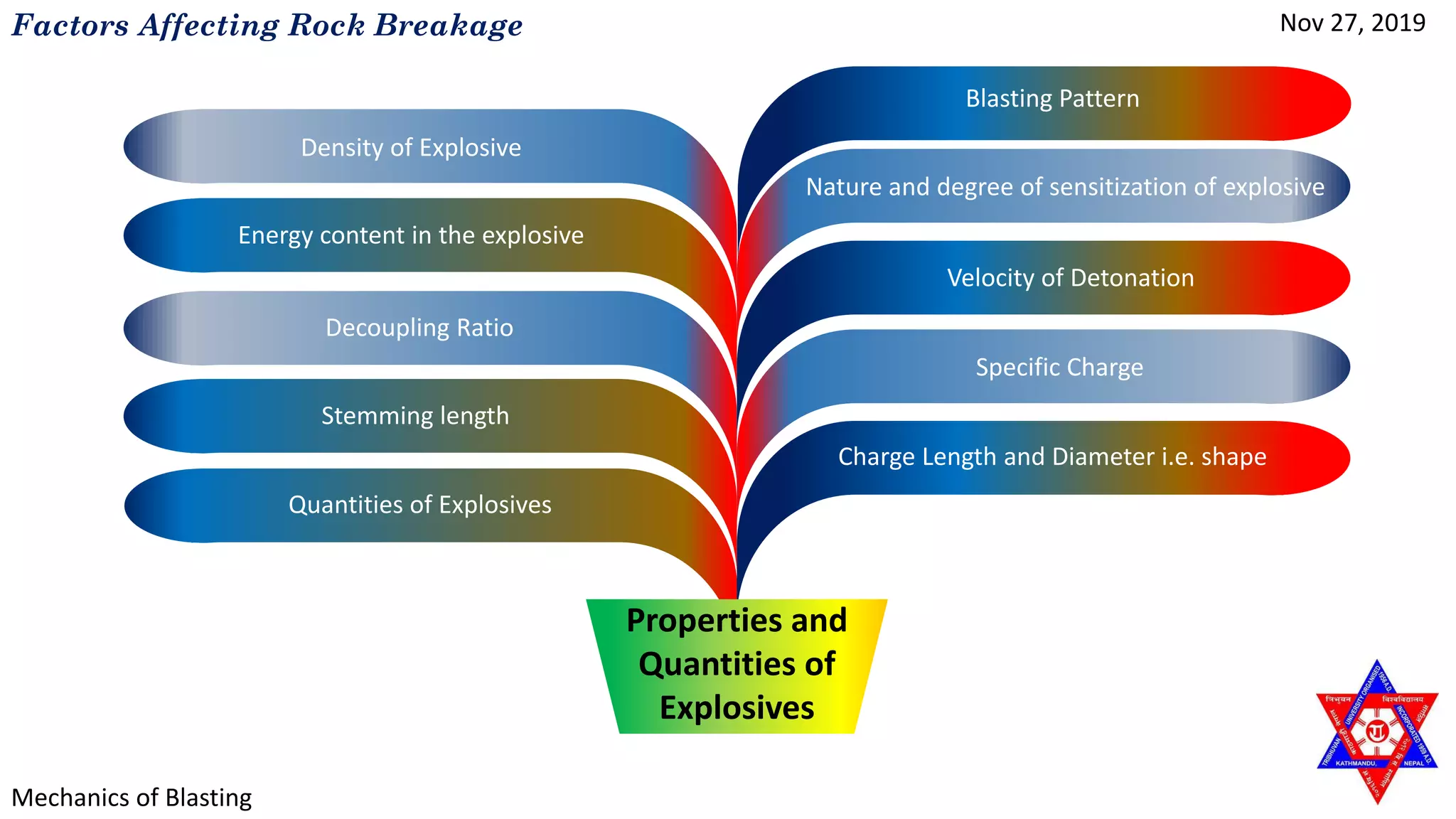

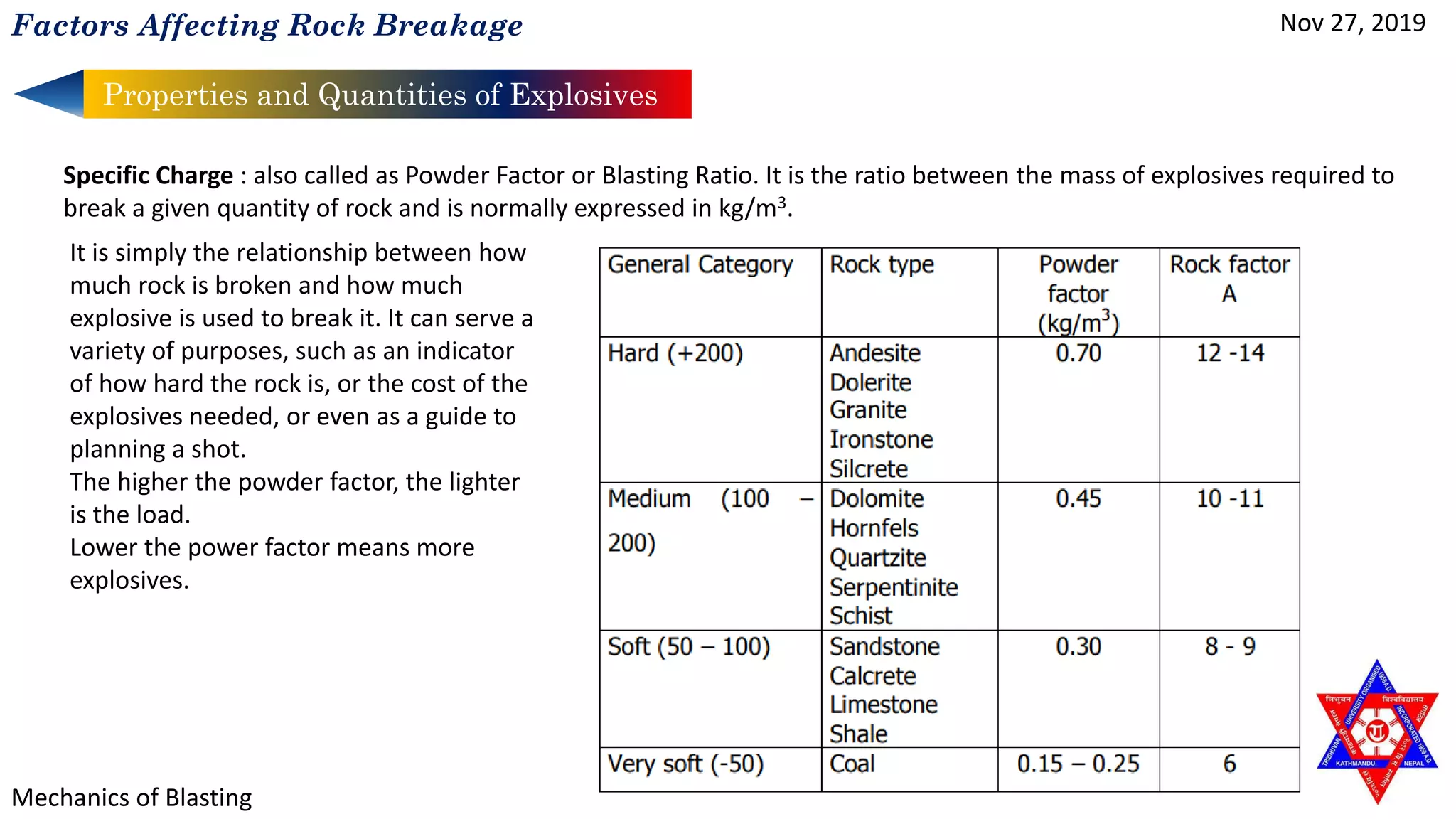

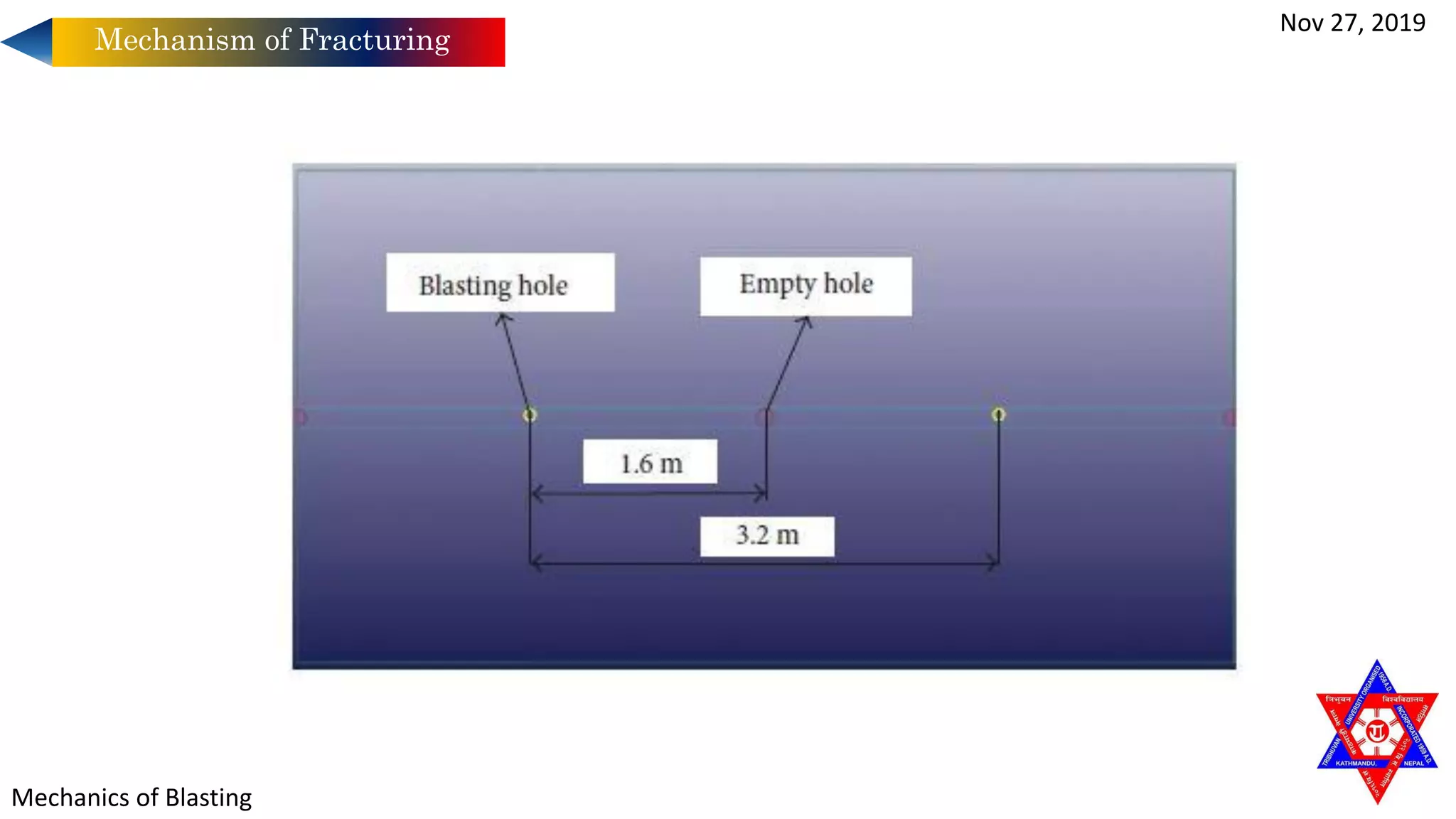

The document discusses the mechanics of blasting and the factors affecting rock breakage using explosives, focusing on parameters like blast size, geometry, and the properties of explosives. It outlines theories related to rock fragmentation, including radial cracking and flexural rupture, emphasizing the energy efficiency and effectiveness of various blasting techniques. The findings from crater theory experiments highlight the relationship between explosive usage and the volume of rock blasted, demonstrating optimal parameters for enhanced blasting performance.