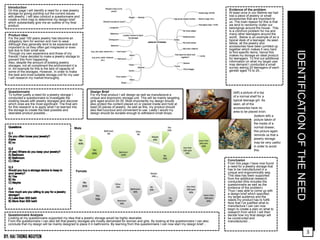

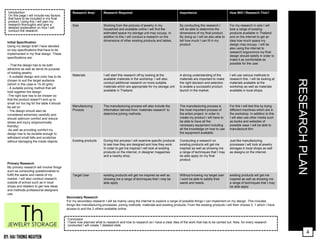

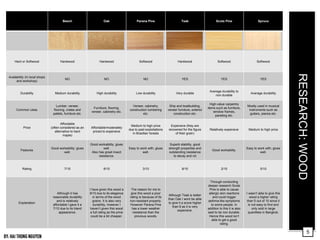

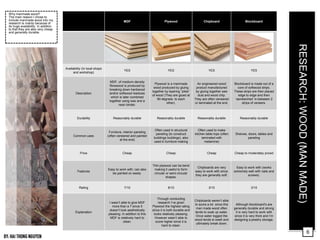

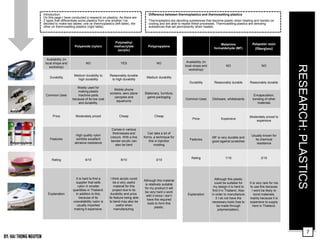

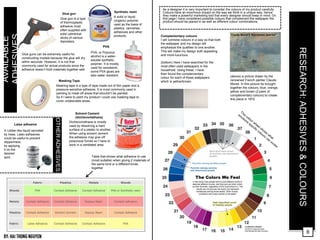

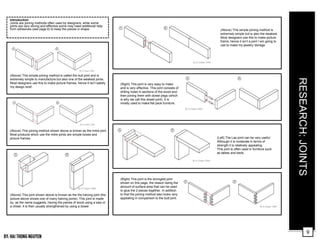

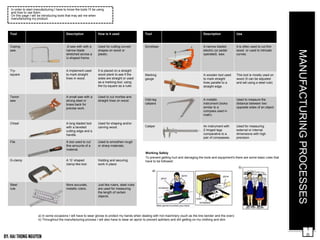

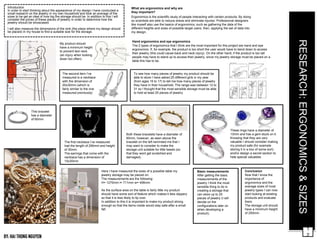

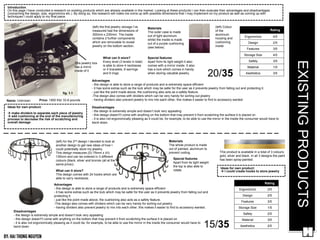

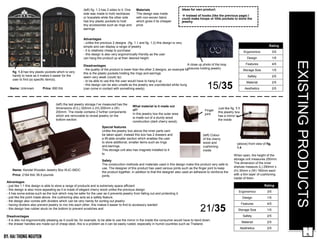

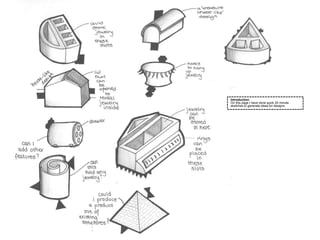

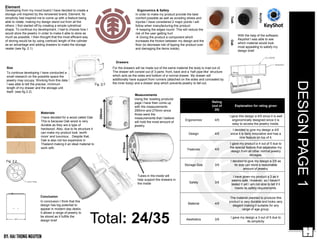

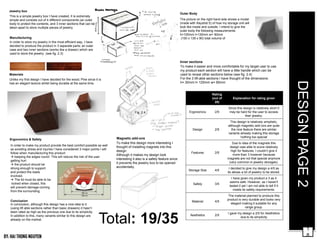

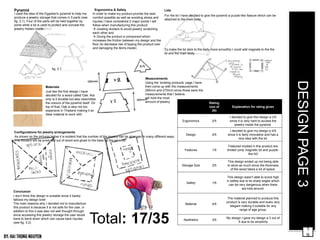

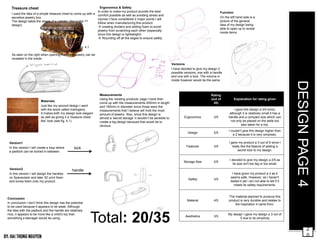

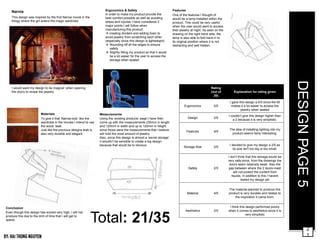

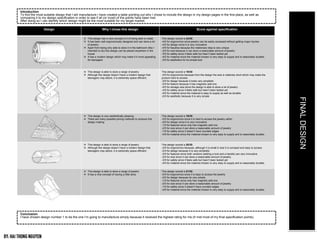

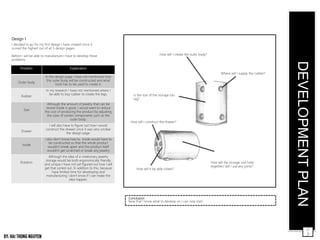

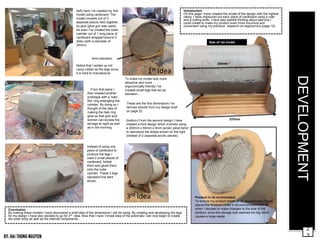

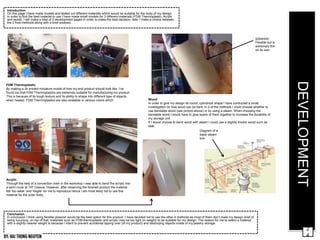

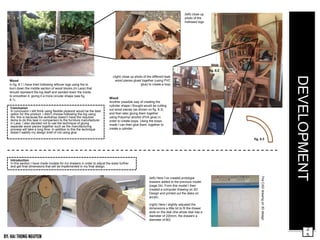

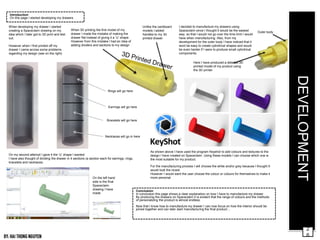

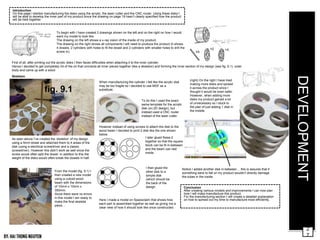

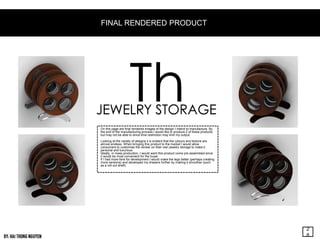

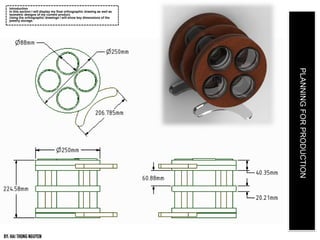

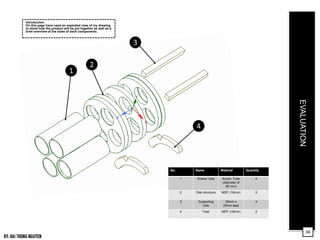

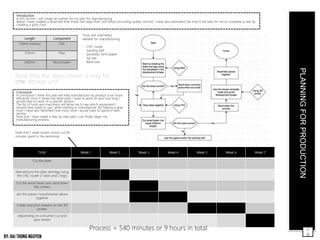

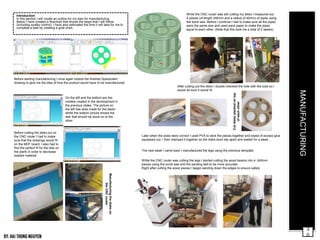

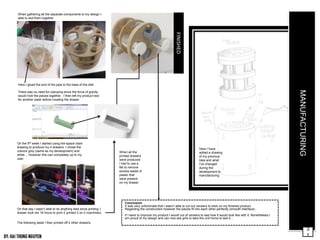

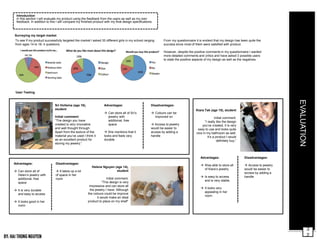

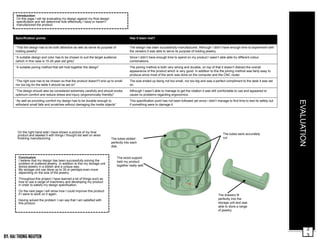

The document outlines a comprehensive research and design plan for a new jewelry storage unit targeting young women aged 20-35. It highlights the need for a unique, ergonomic, and luxurious storage solution due to the common issue of misplaced jewelry among teenagers. The plan includes conducting surveys, exploring materials, and analyzing existing products to develop a suitable, durable, and aesthetically pleasing storage design.