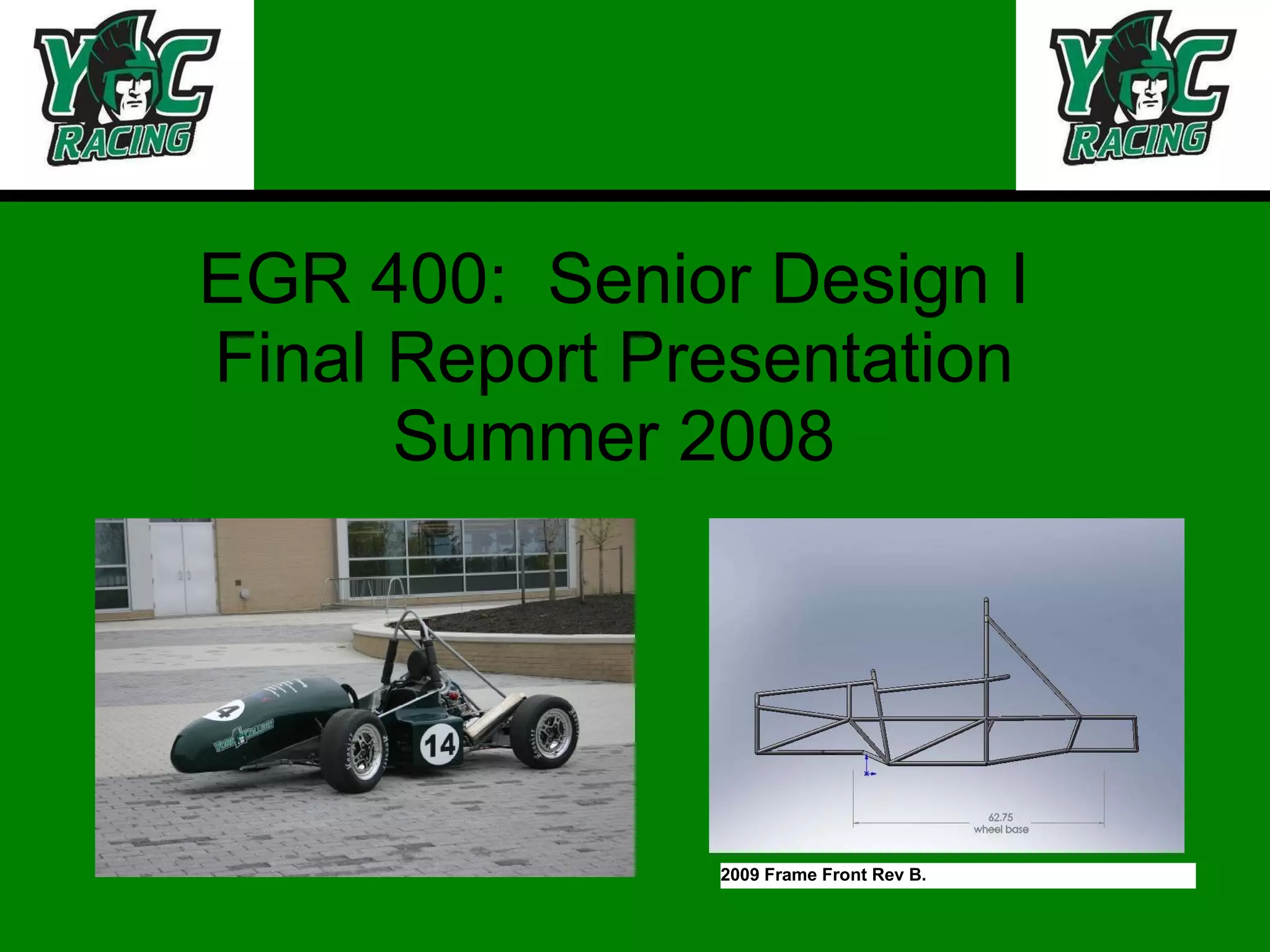

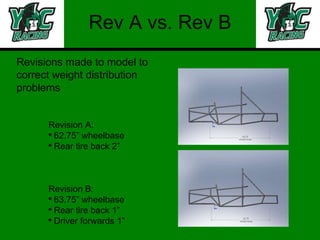

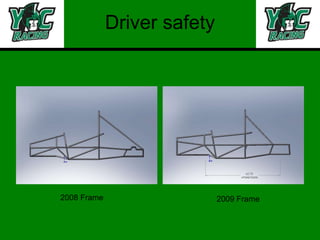

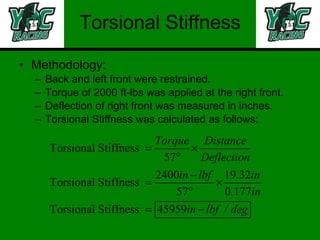

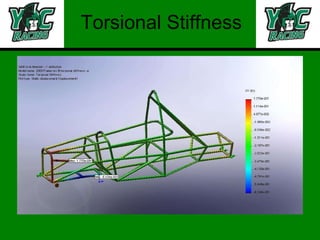

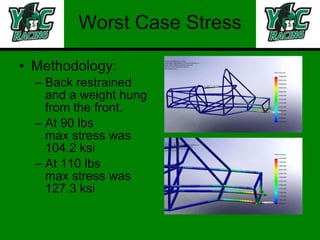

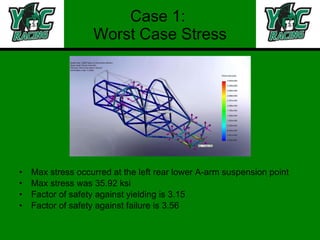

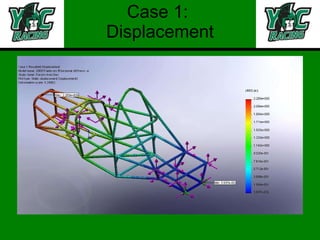

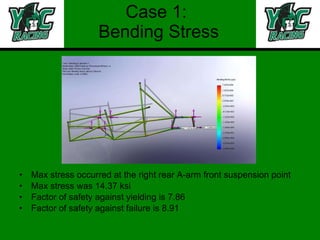

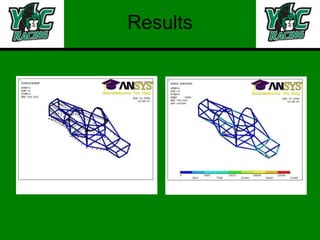

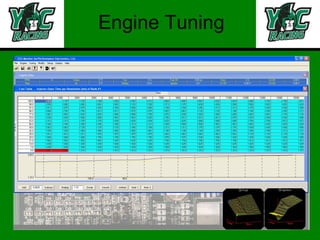

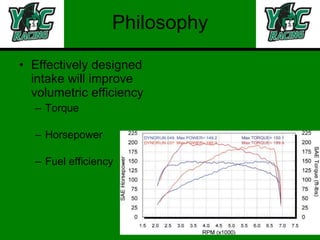

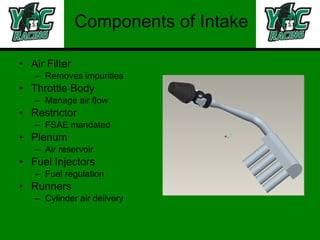

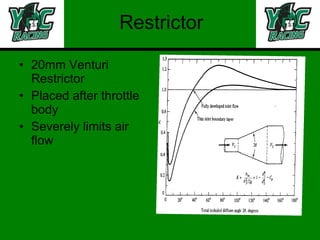

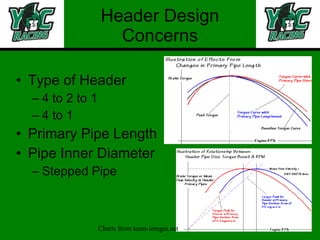

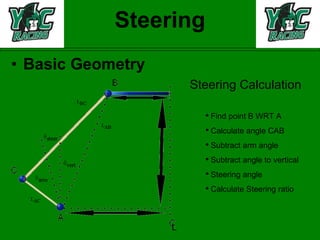

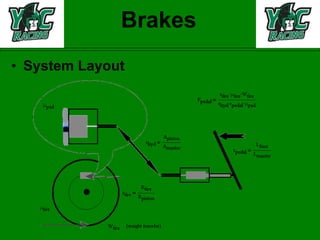

The document outlines the final report of the EGR 400 senior design project, focusing on the design, build, and competition of a formula-style race car for summer 2009. It covers various aspects including frame design, engine tuning, drive train modifications, and aerodynamics, detailing the project timeline, design revisions, and testing methodologies. Additionally, it highlights the project's goals for improving performance, safety, and efficiency while adhering to regulatory requirements.