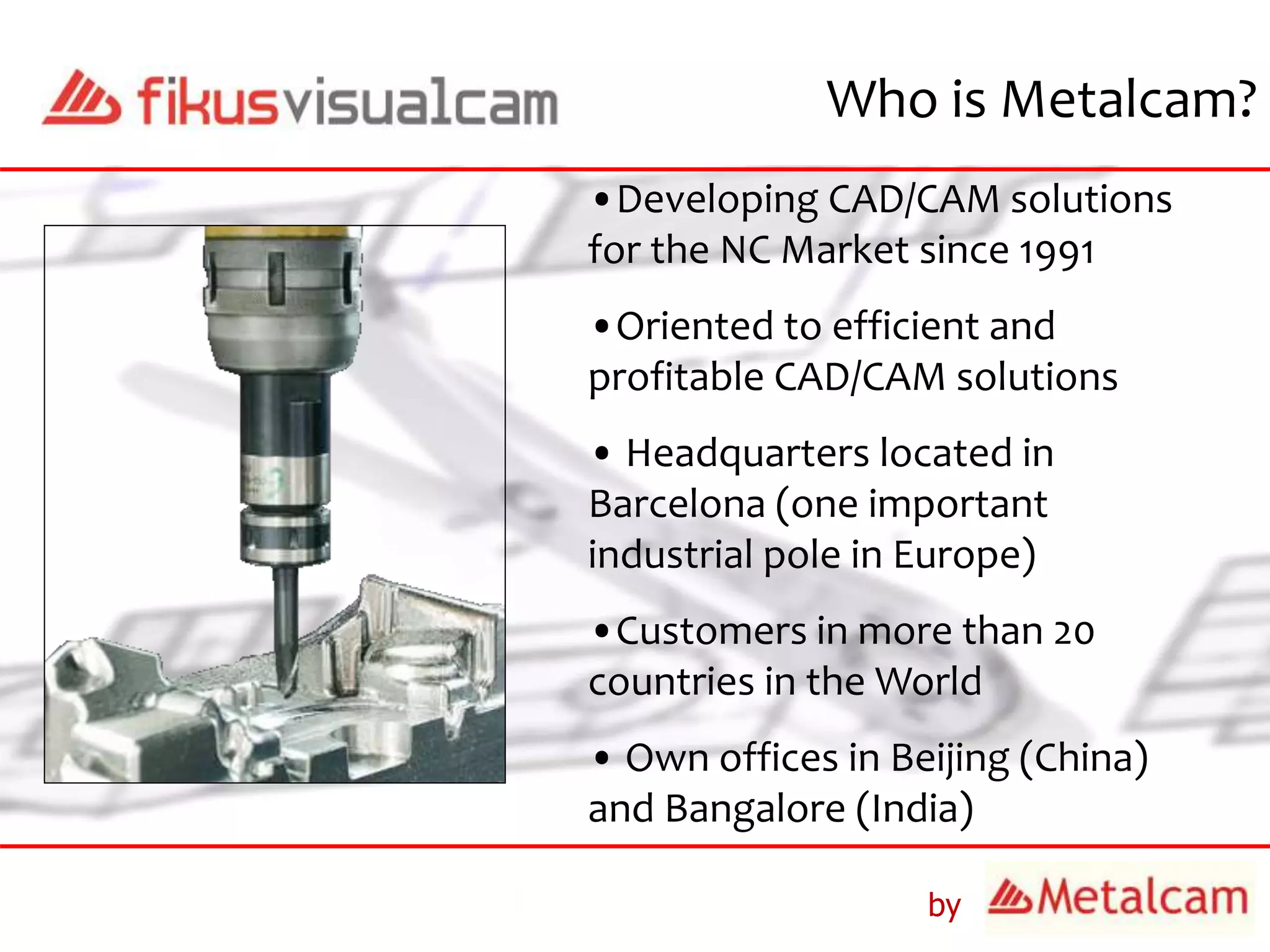

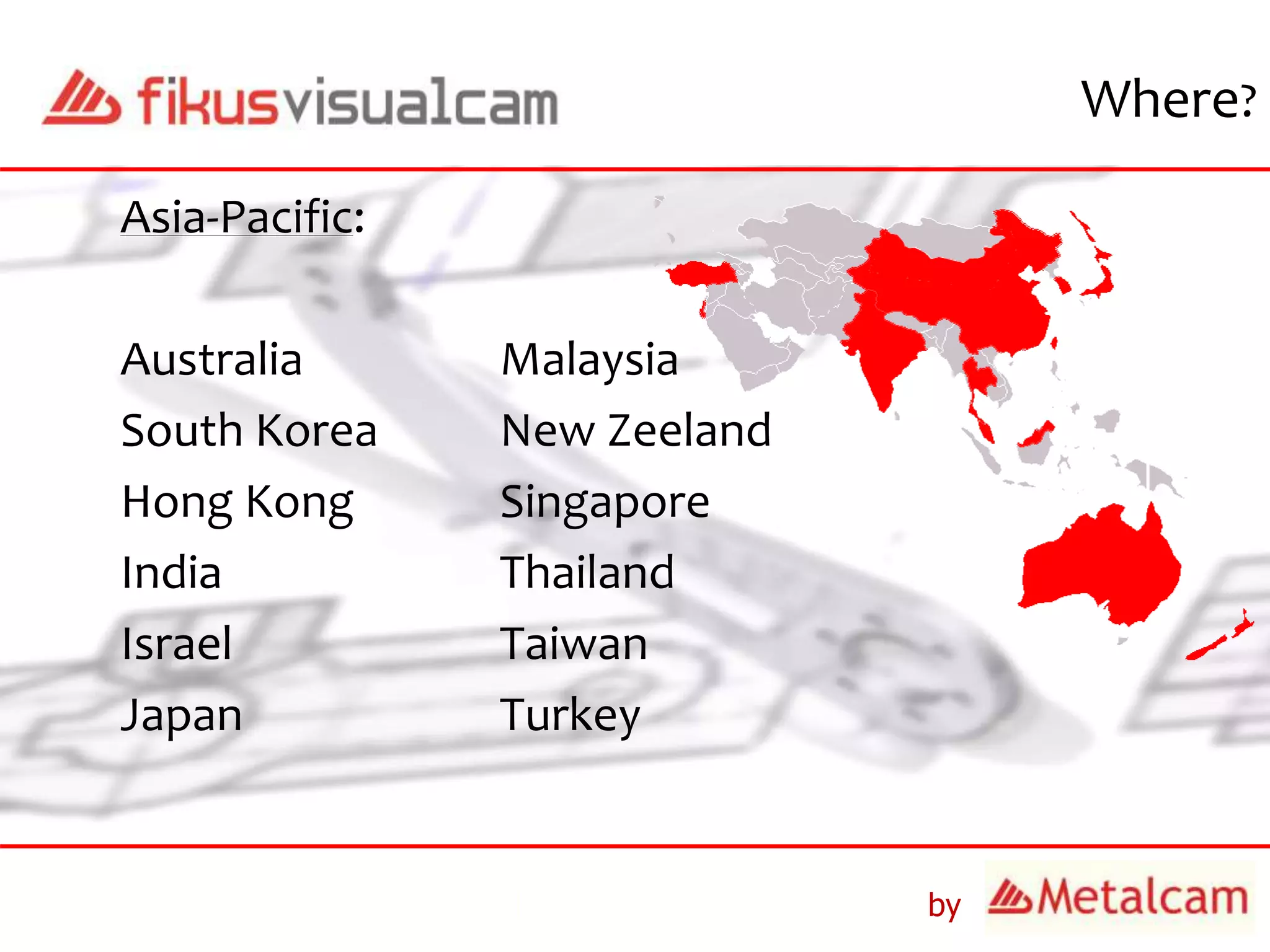

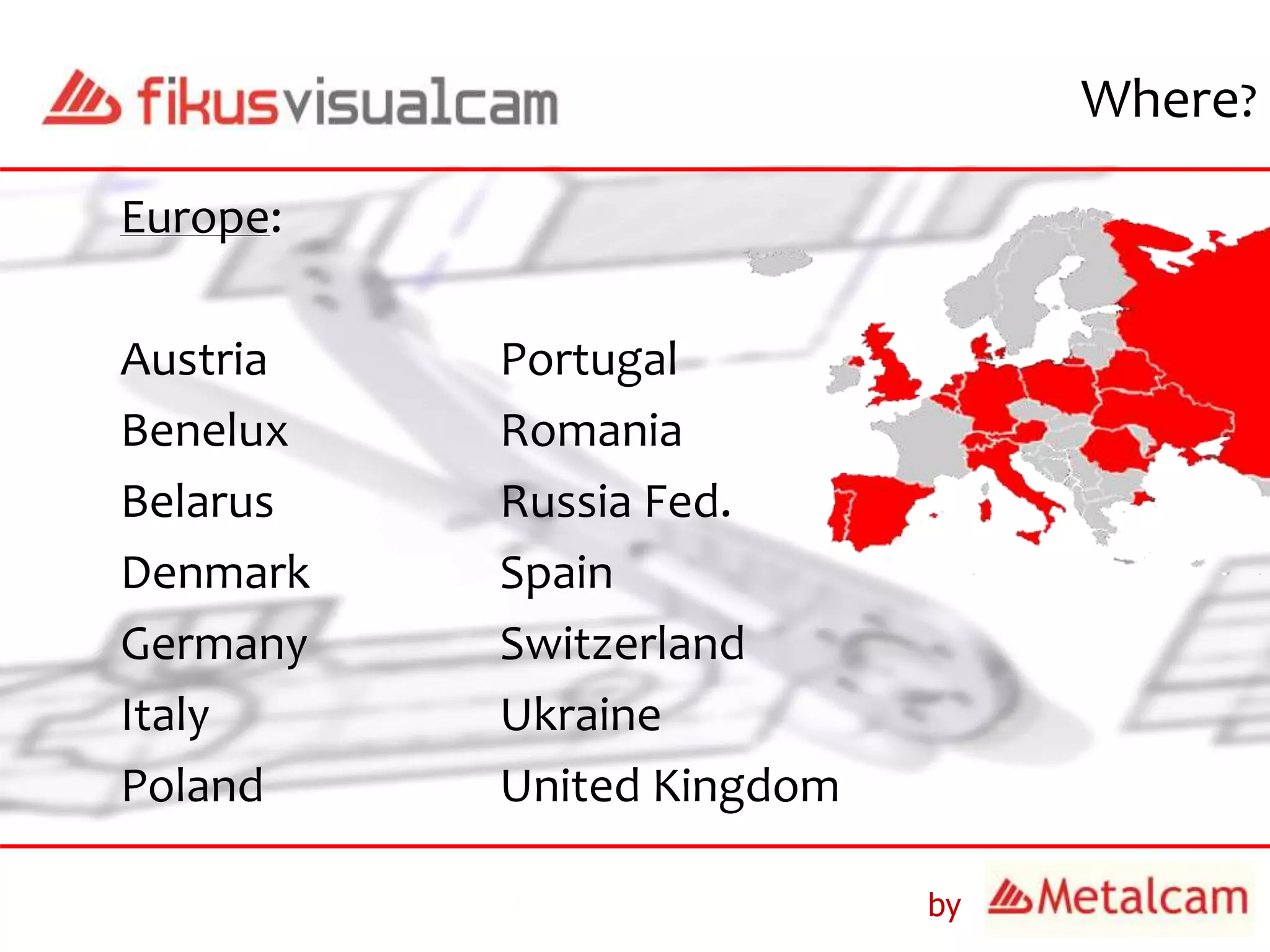

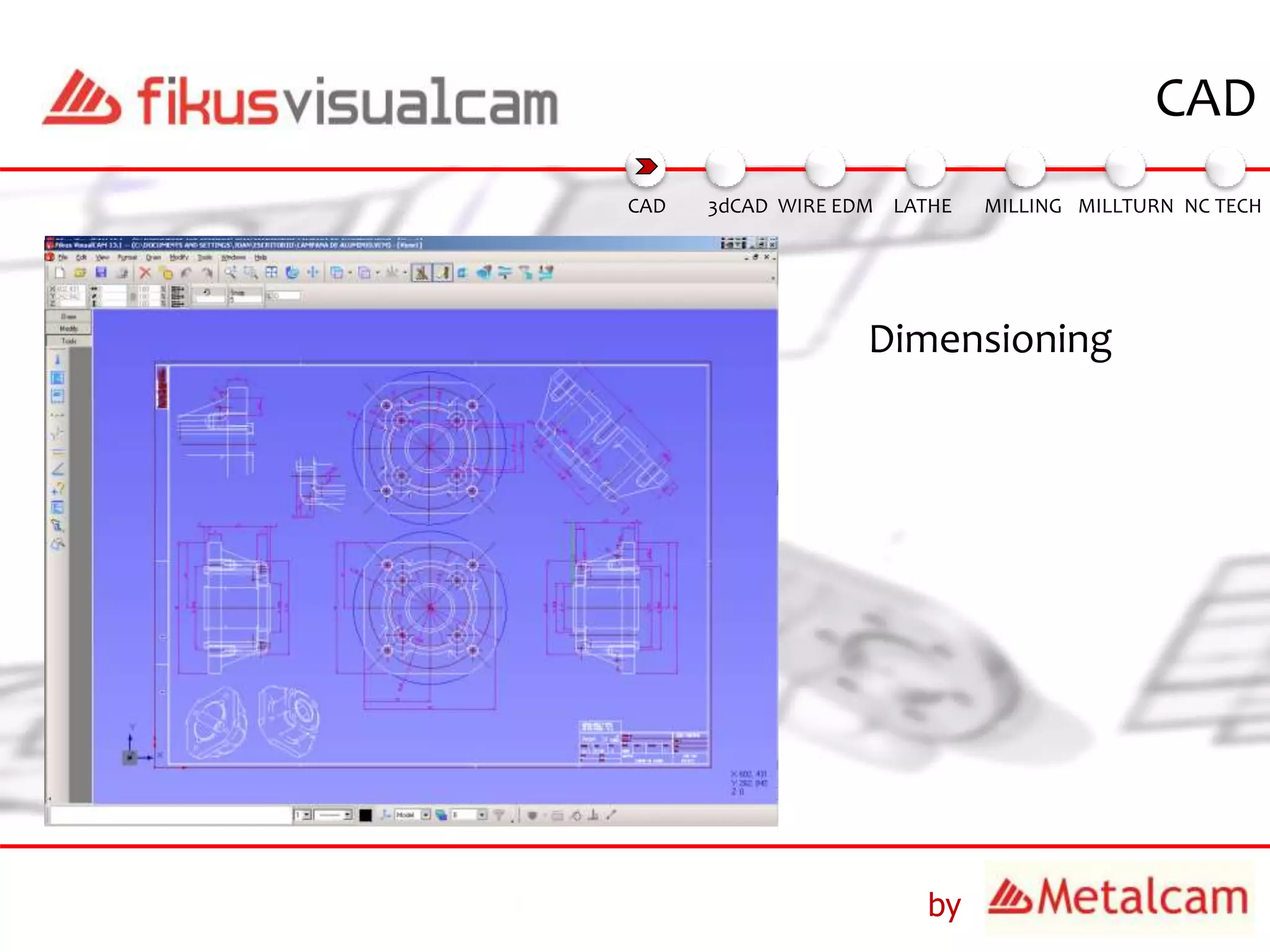

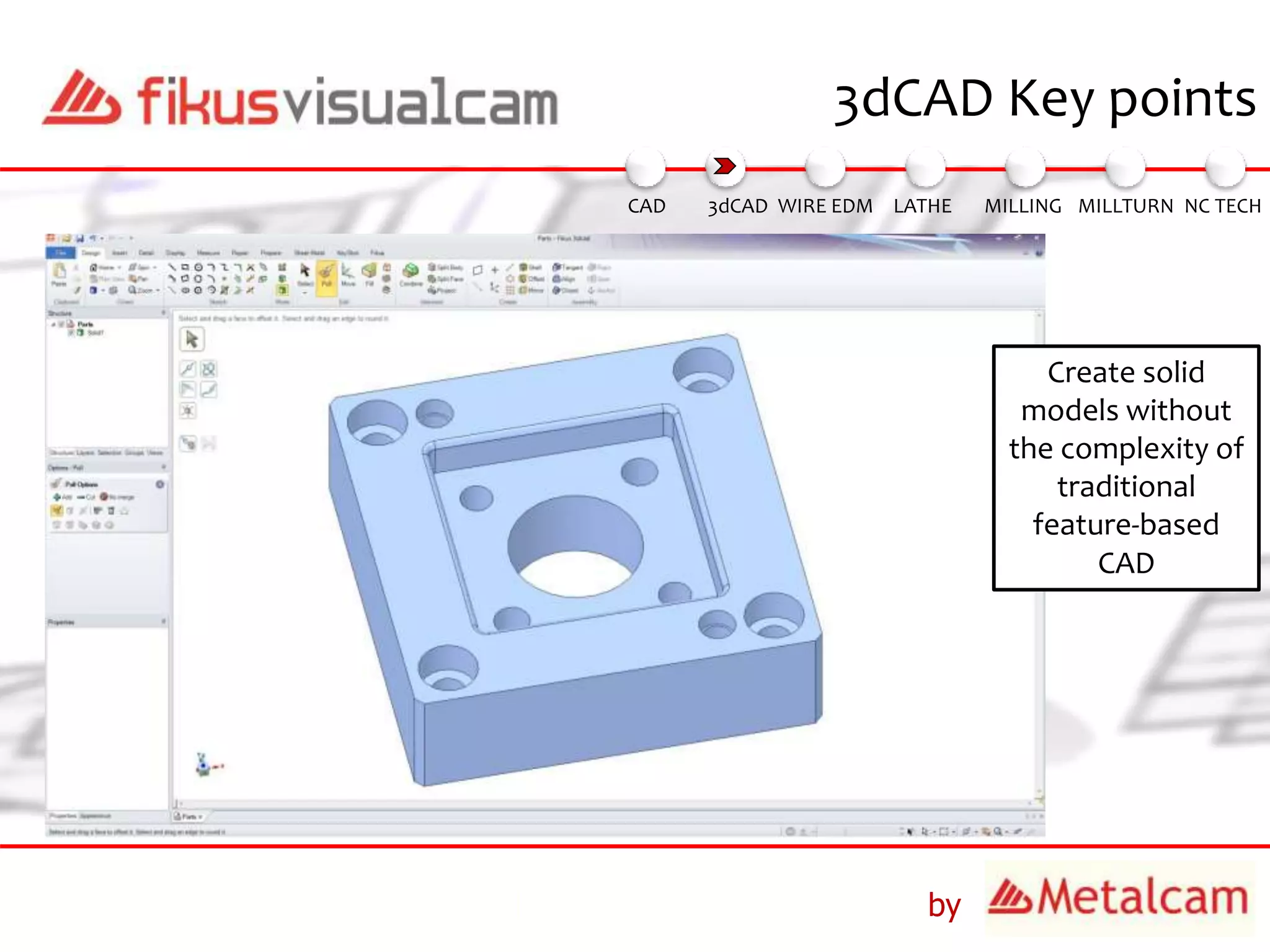

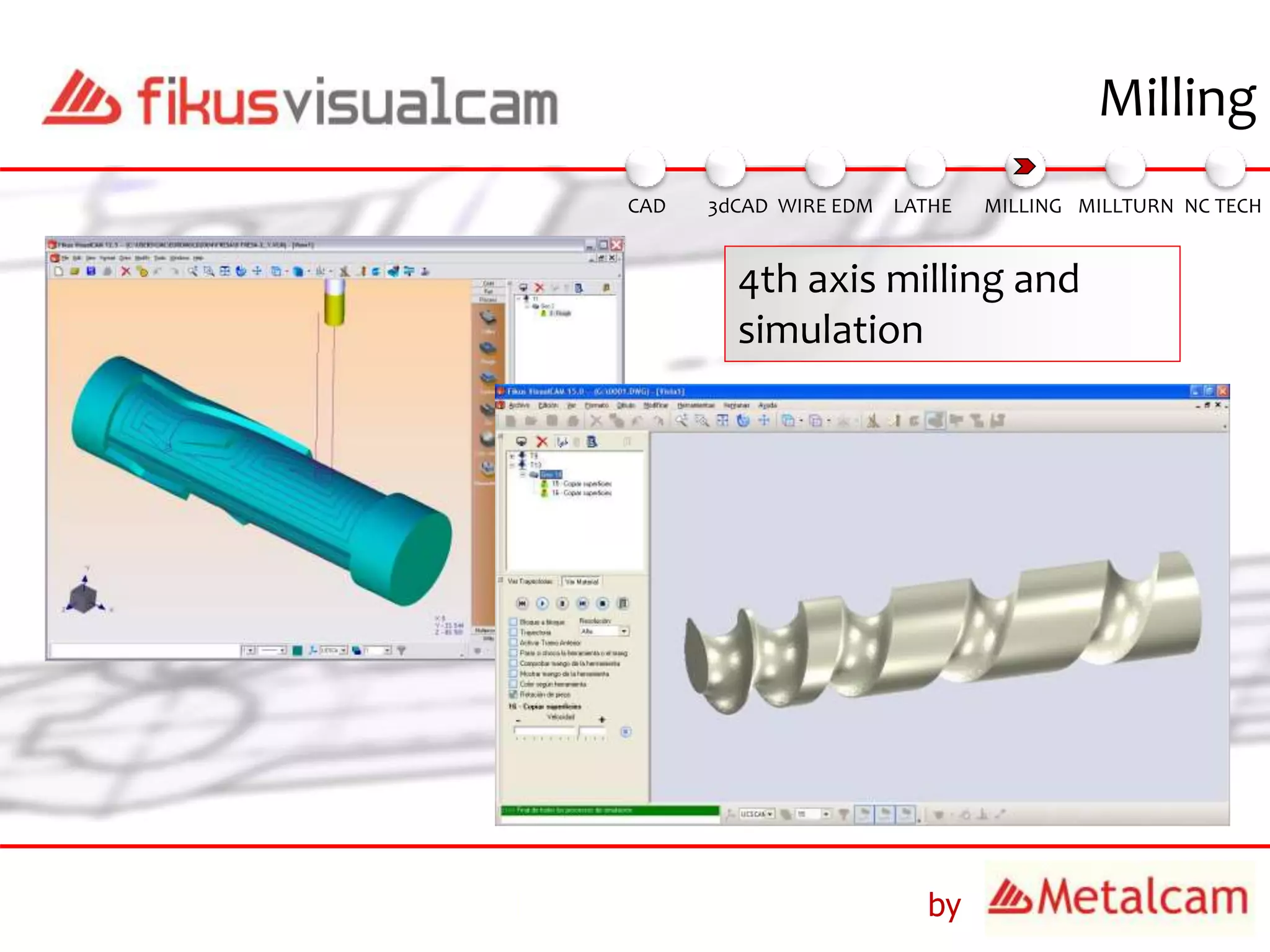

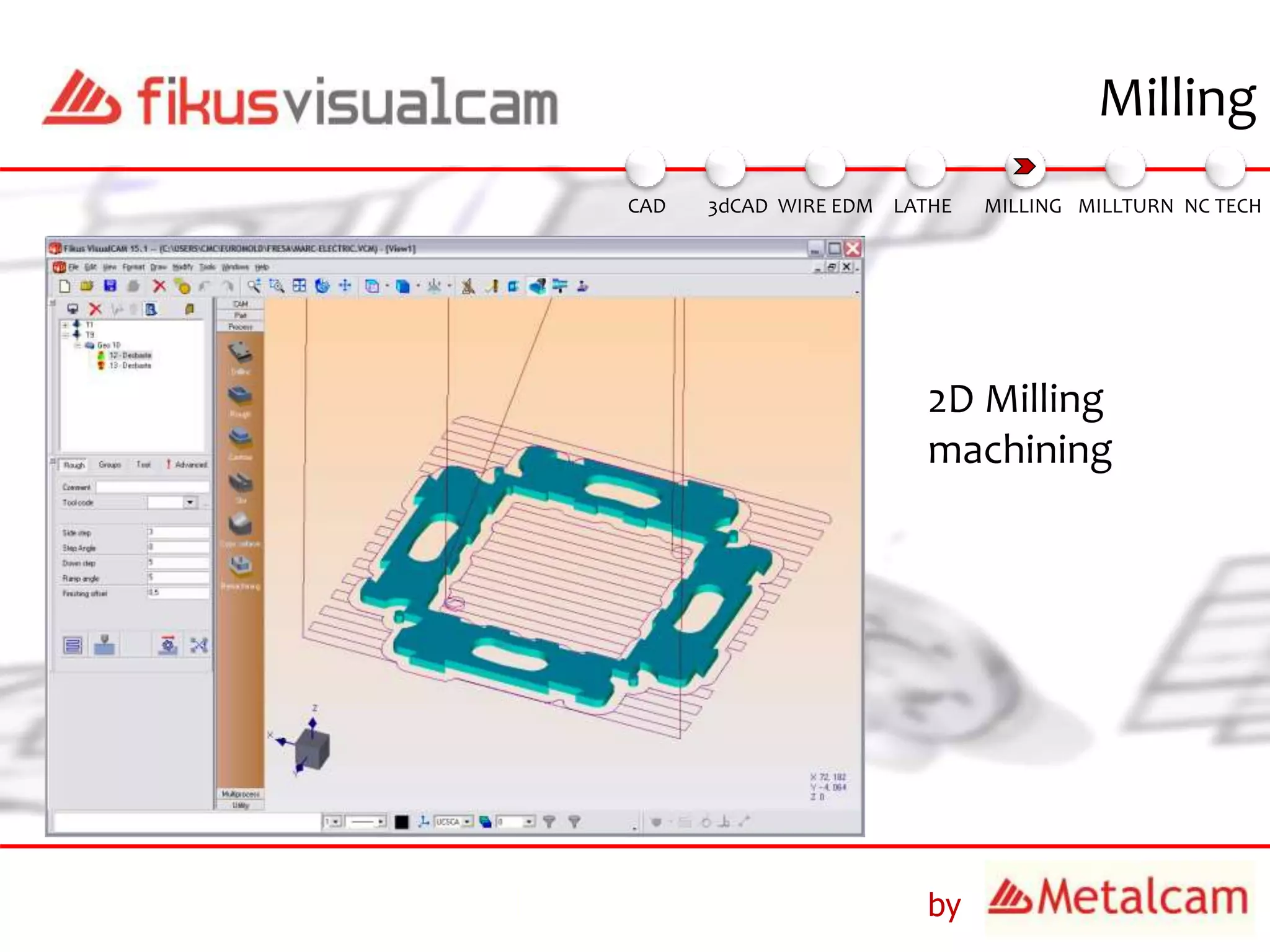

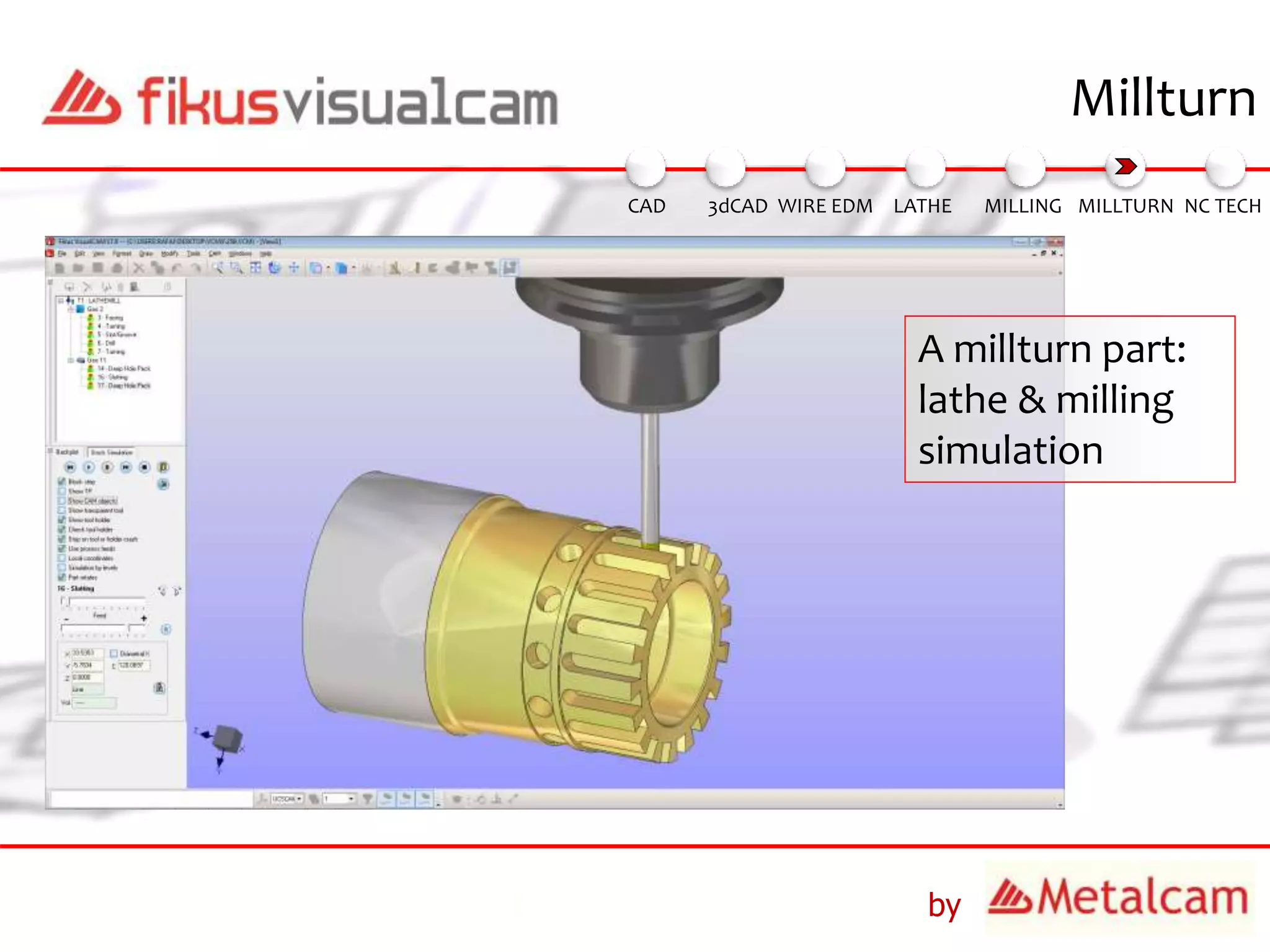

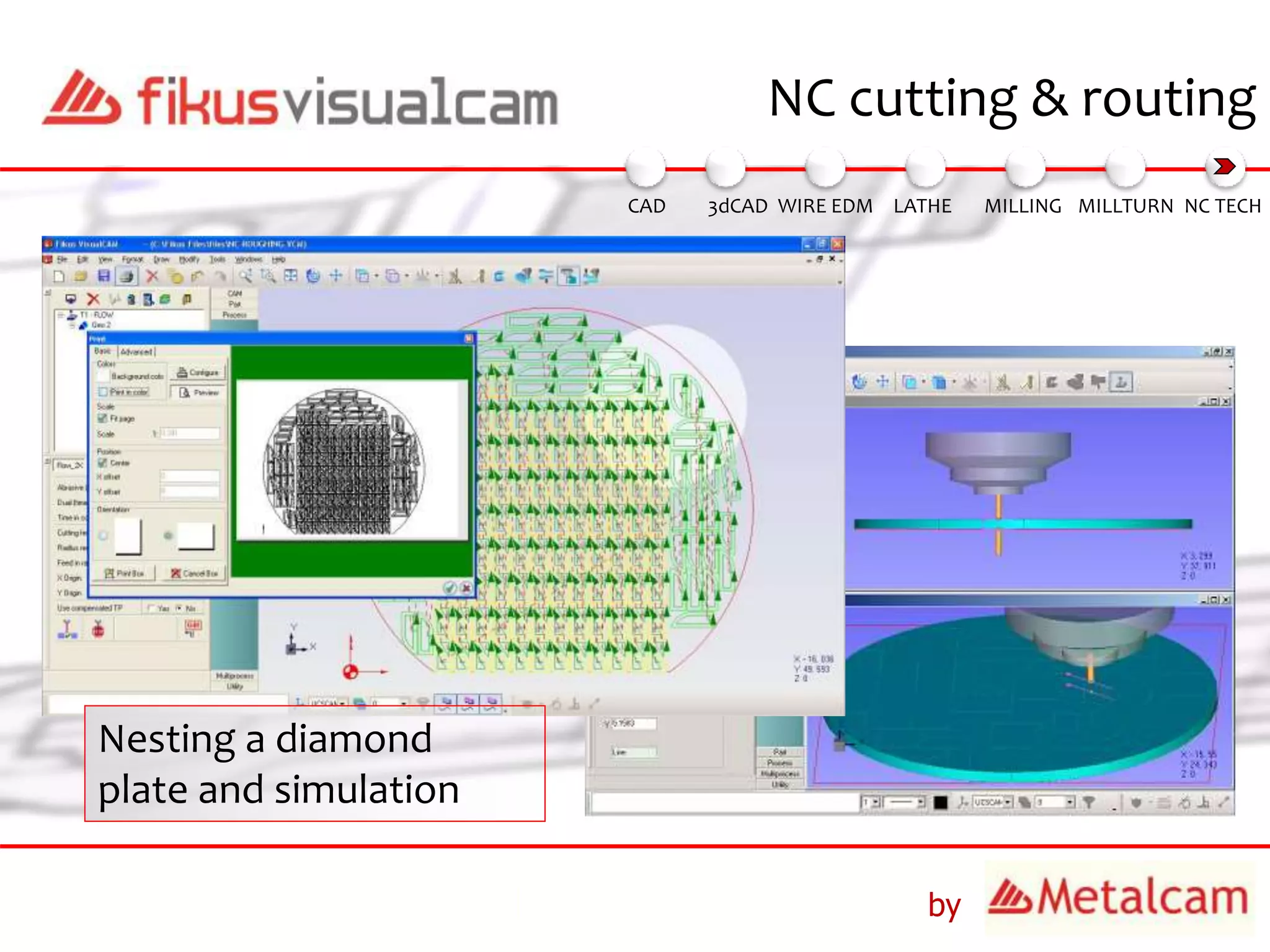

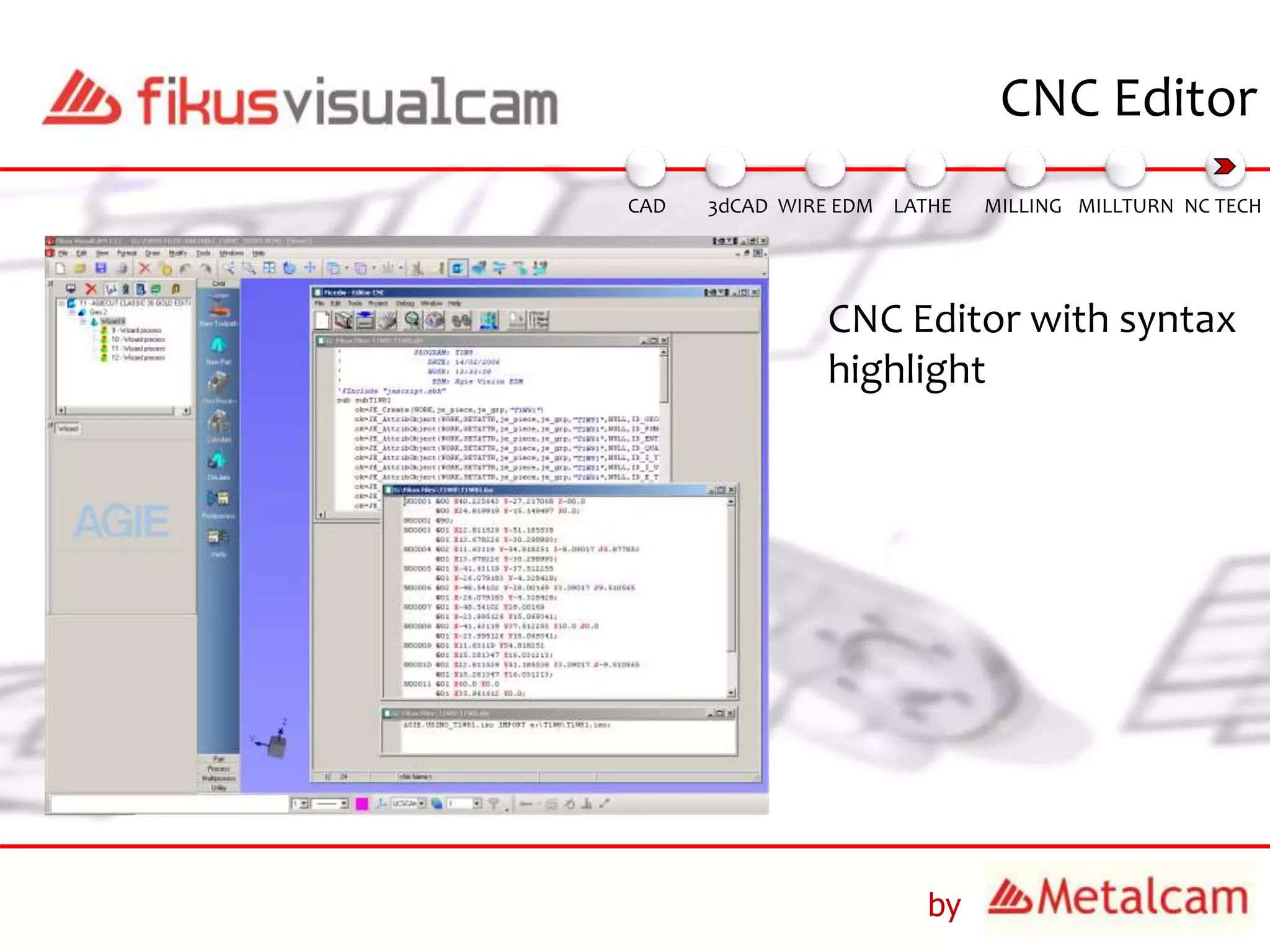

This presentation provides an overview of Metalcam, a European company that develops CAD/CAM solutions. It has been developing these solutions since 1991 and has customers in over 20 countries. The presentation describes Metalcam's mission to develop powerful and easy to use CAM systems that help customers gain a competitive advantage. It also outlines Metalcam's experience, partnerships, locations, and its flagship product Fikus Visualcam, a mature and reliable CAM system used by over 10,000 customers worldwide for programming CNC machines.