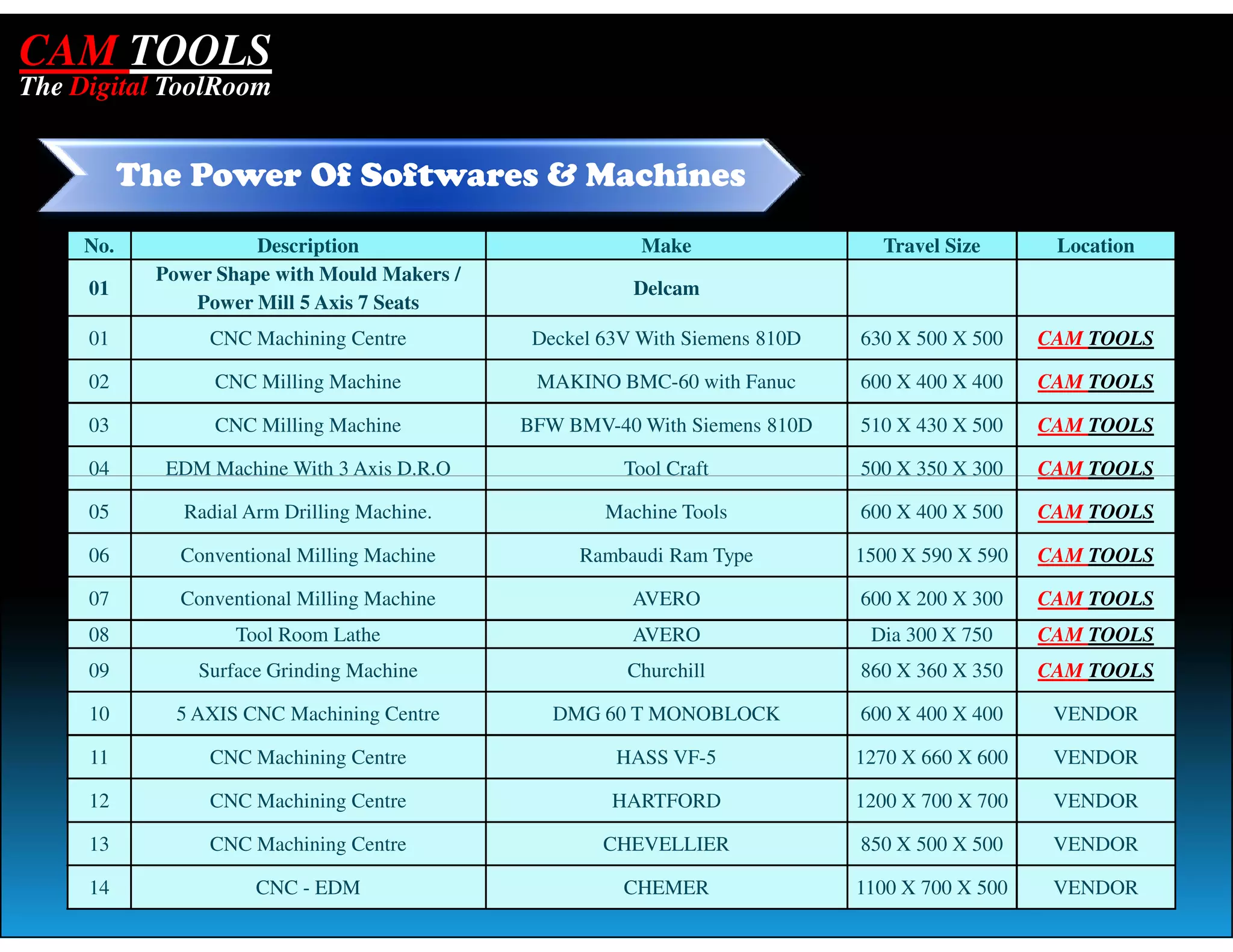

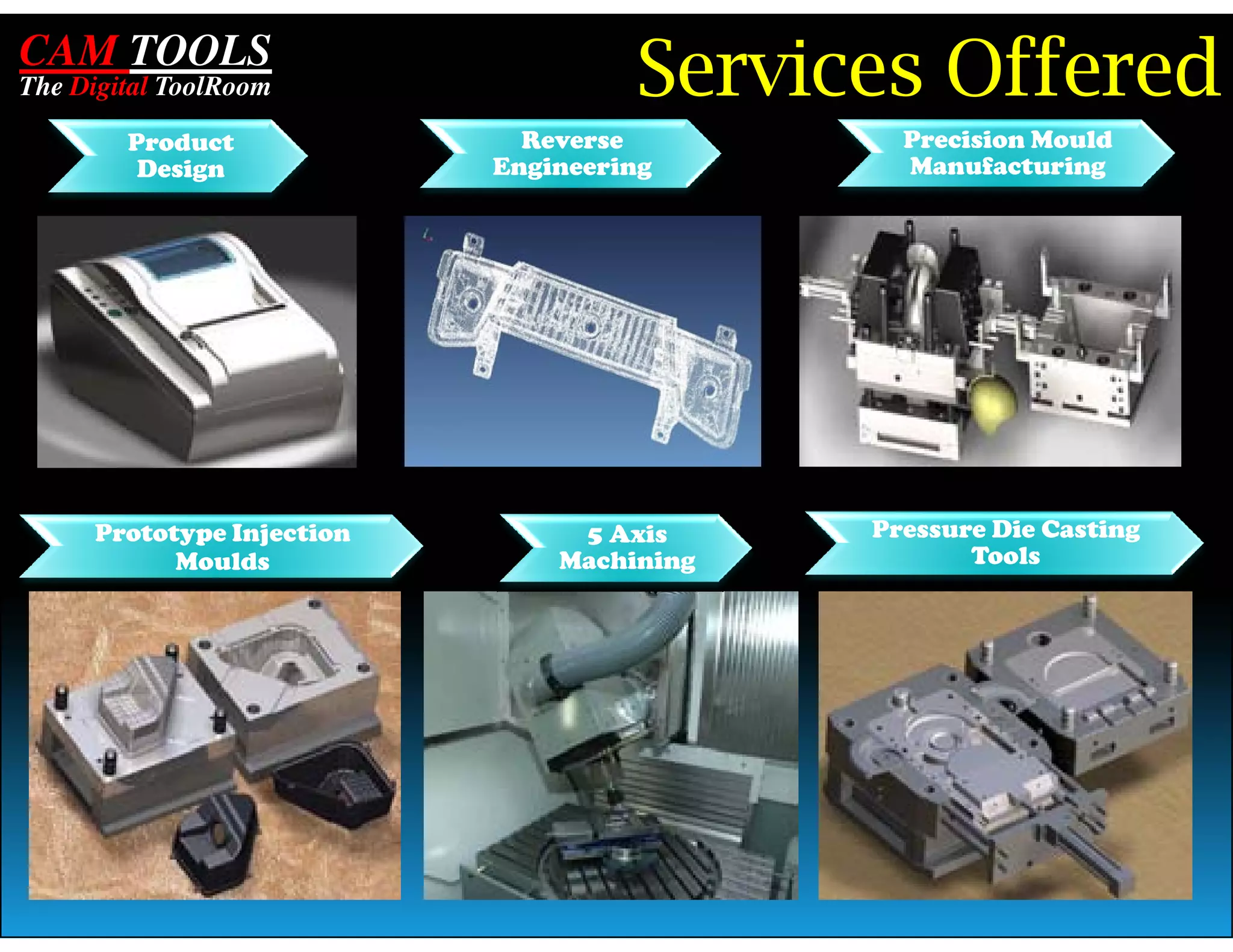

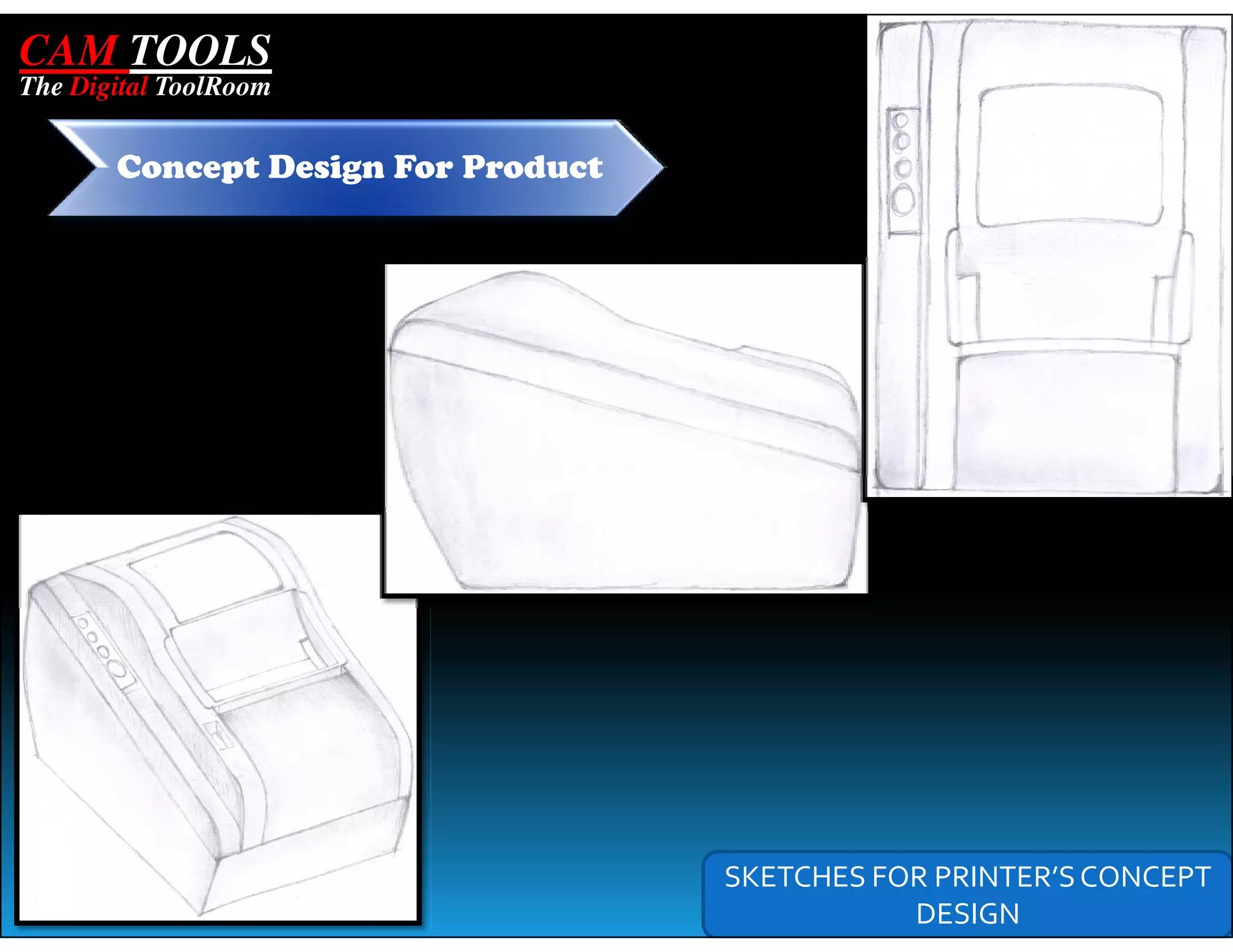

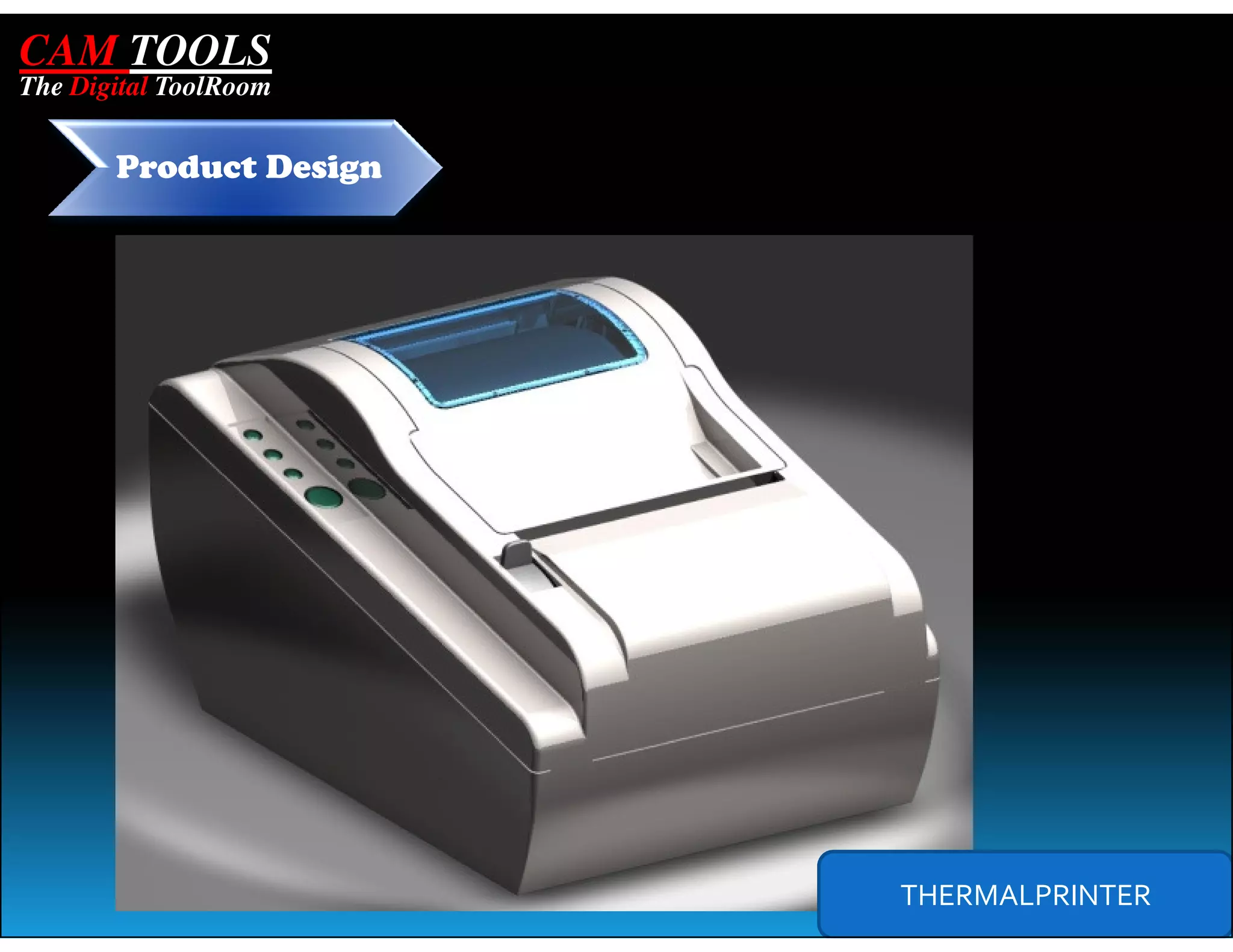

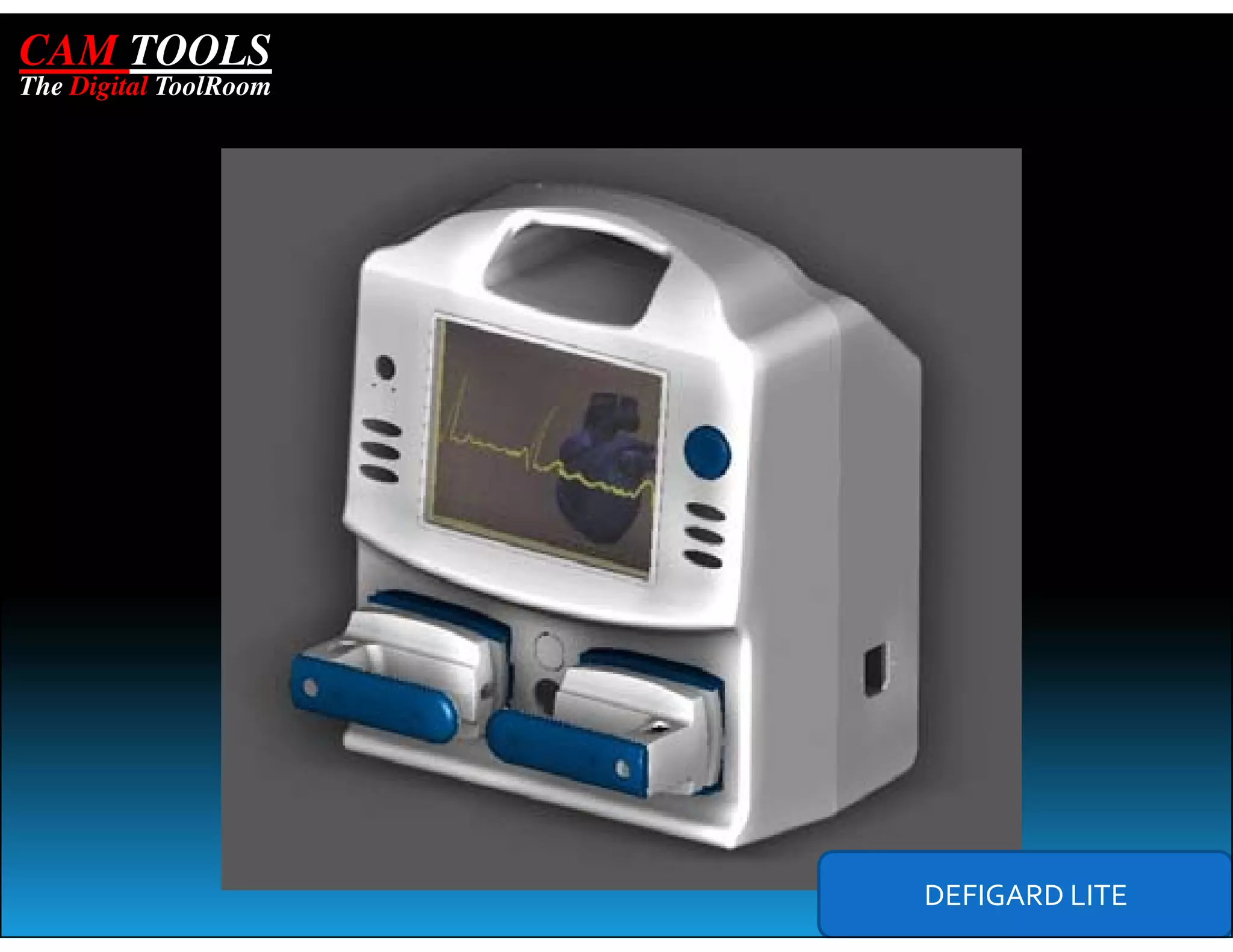

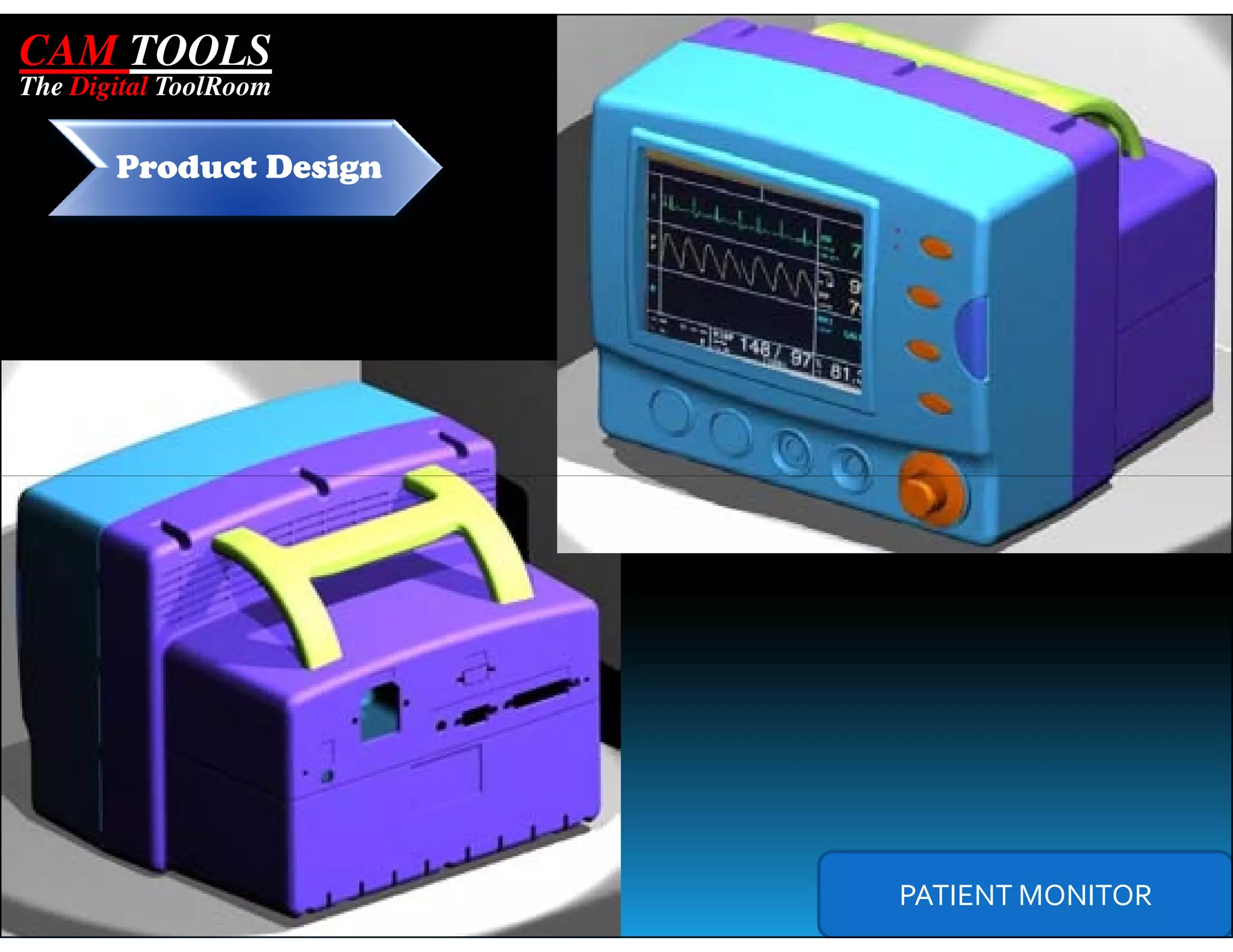

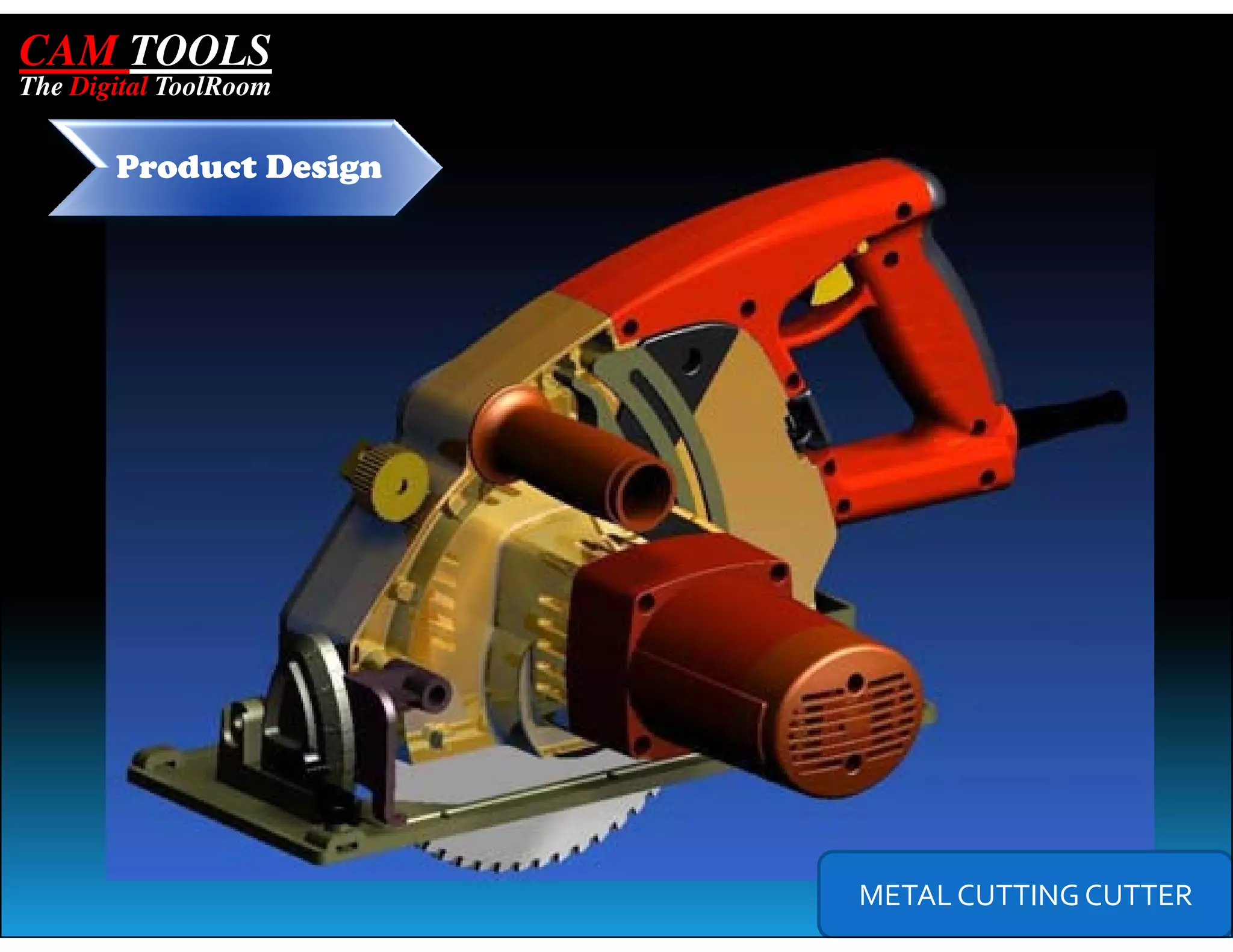

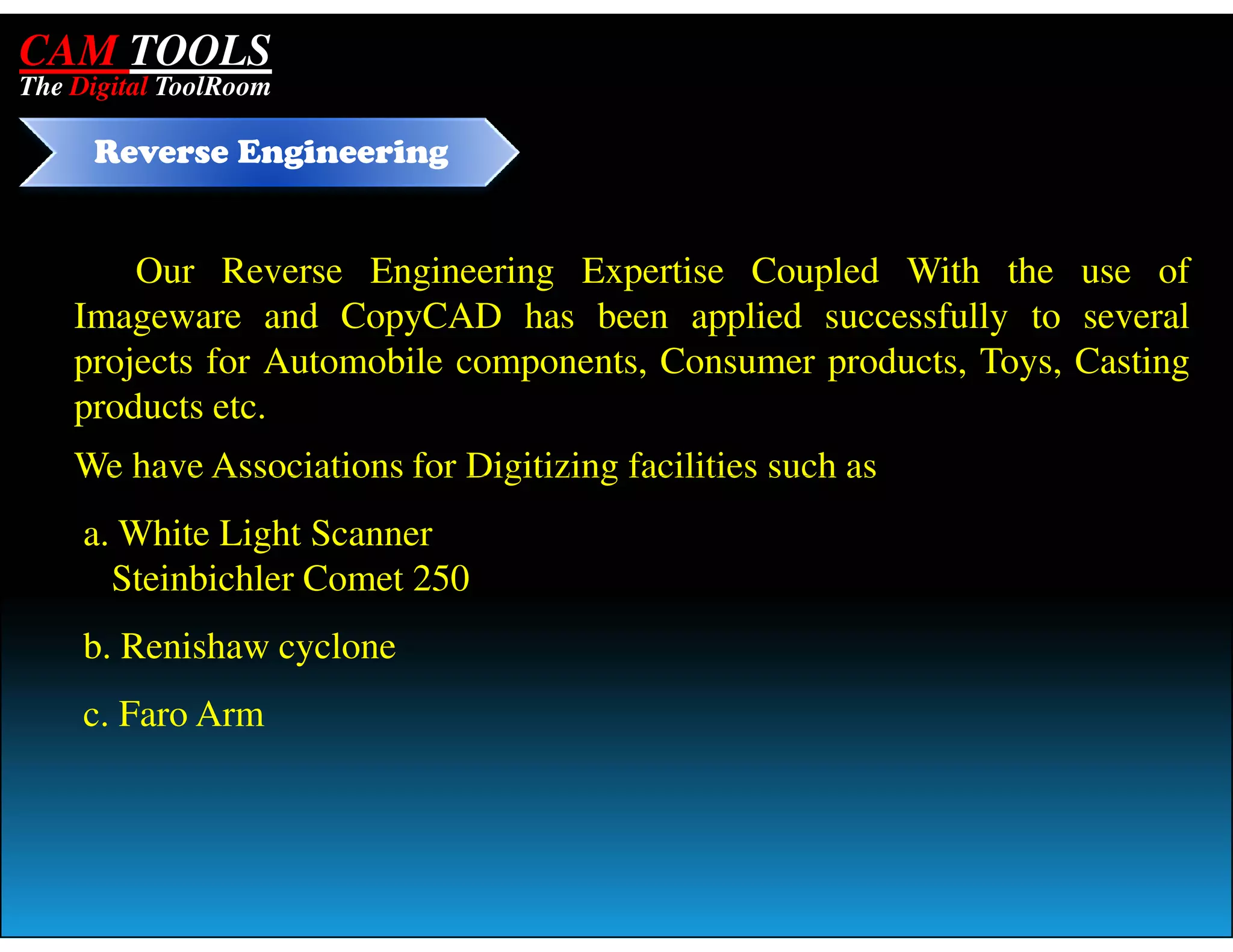

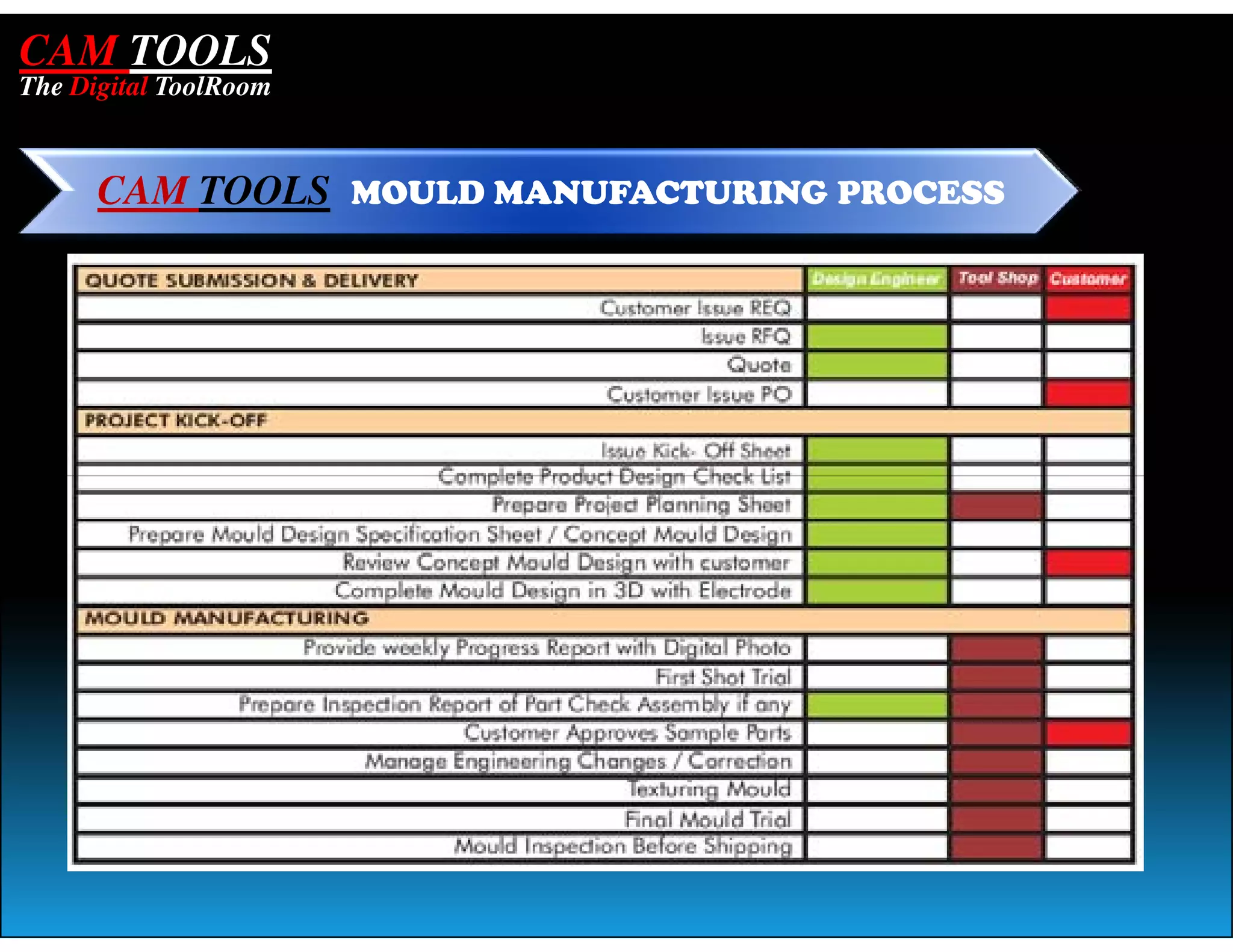

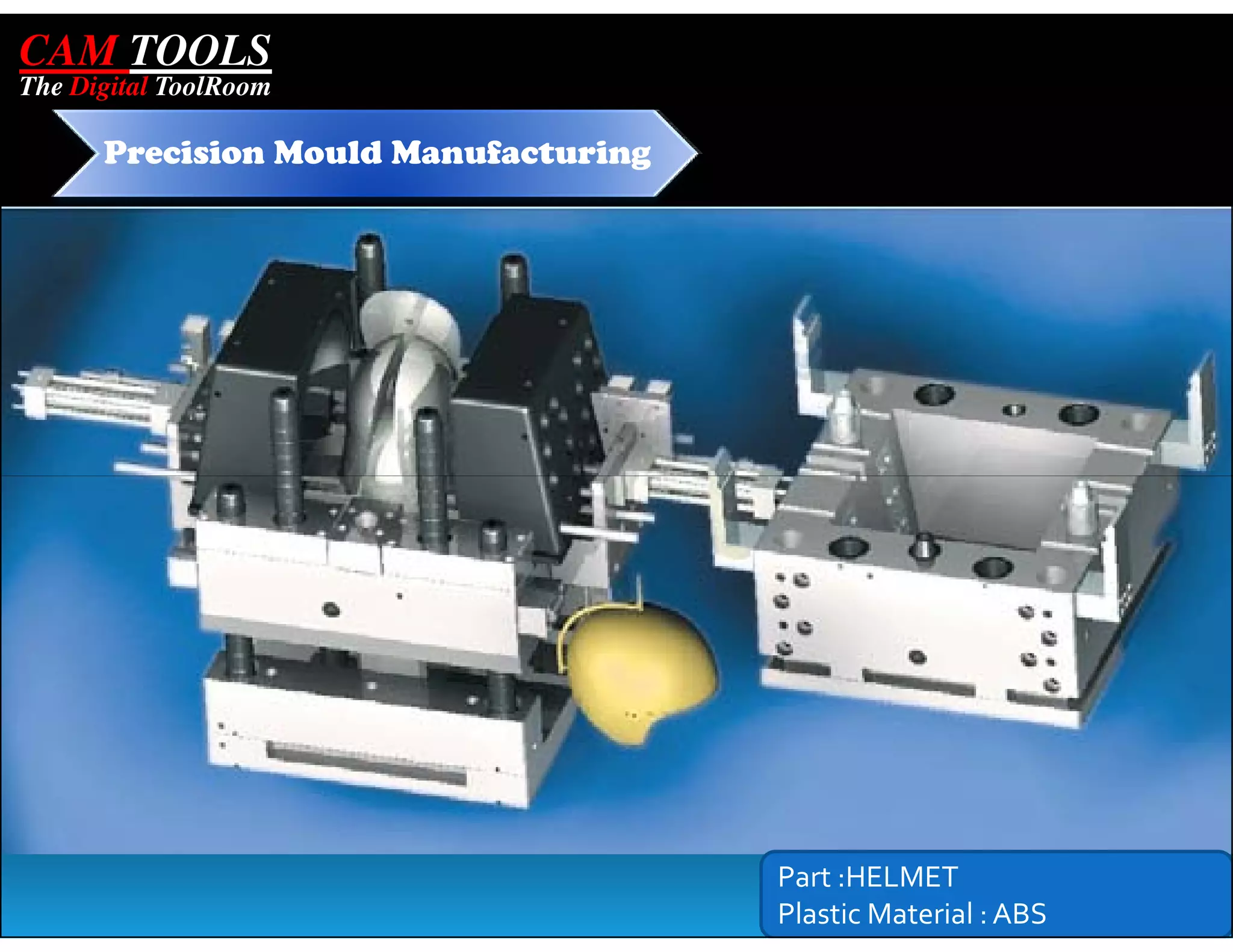

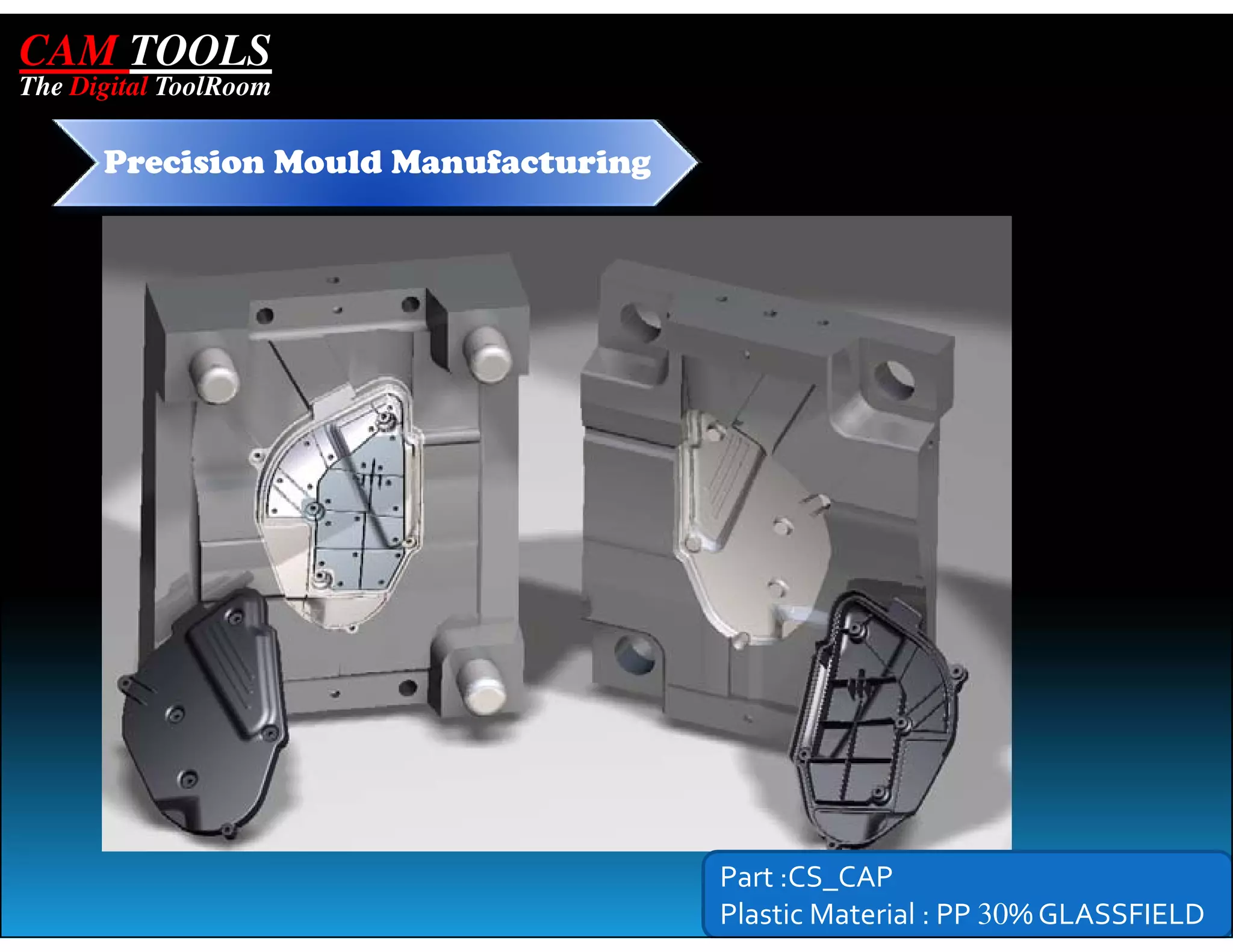

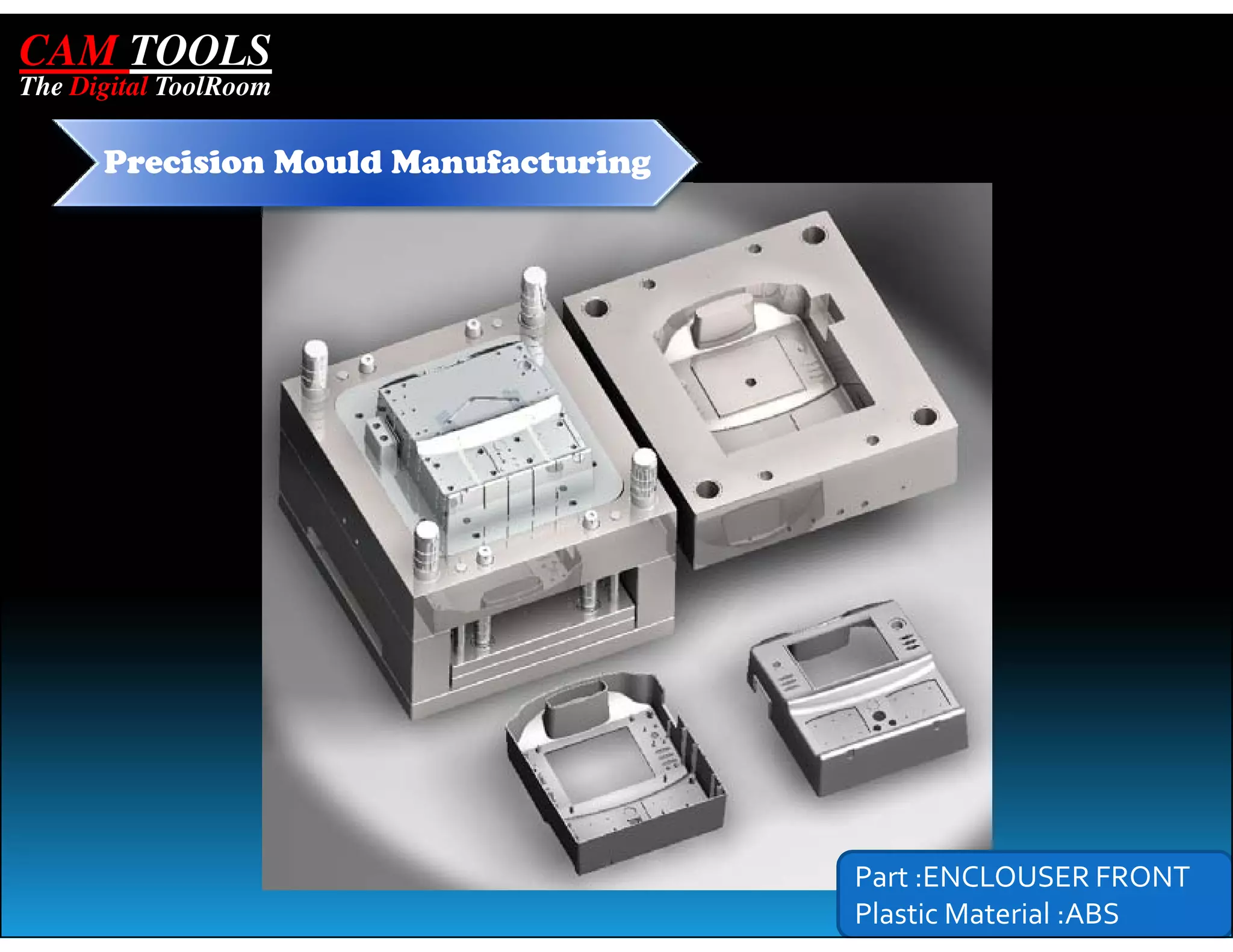

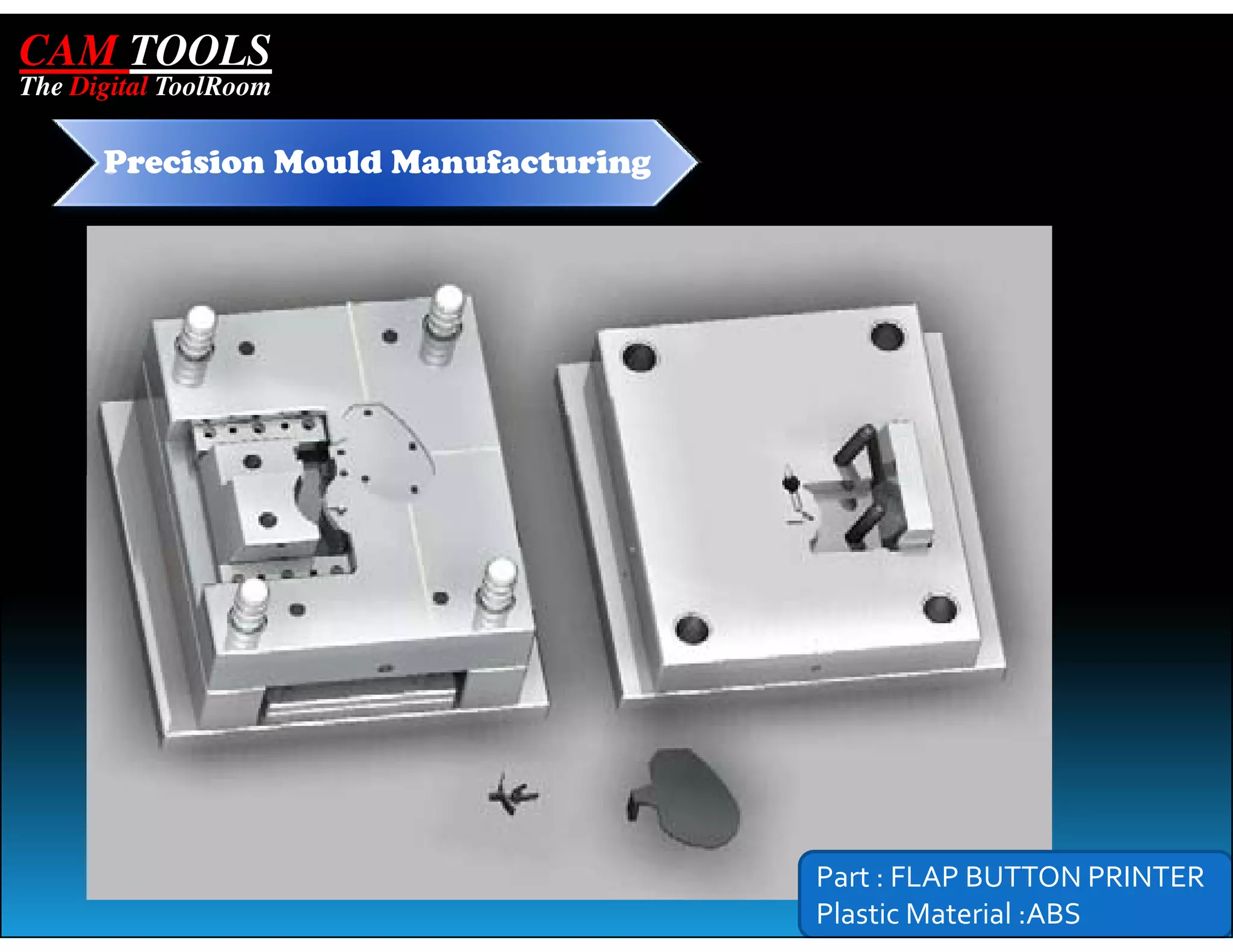

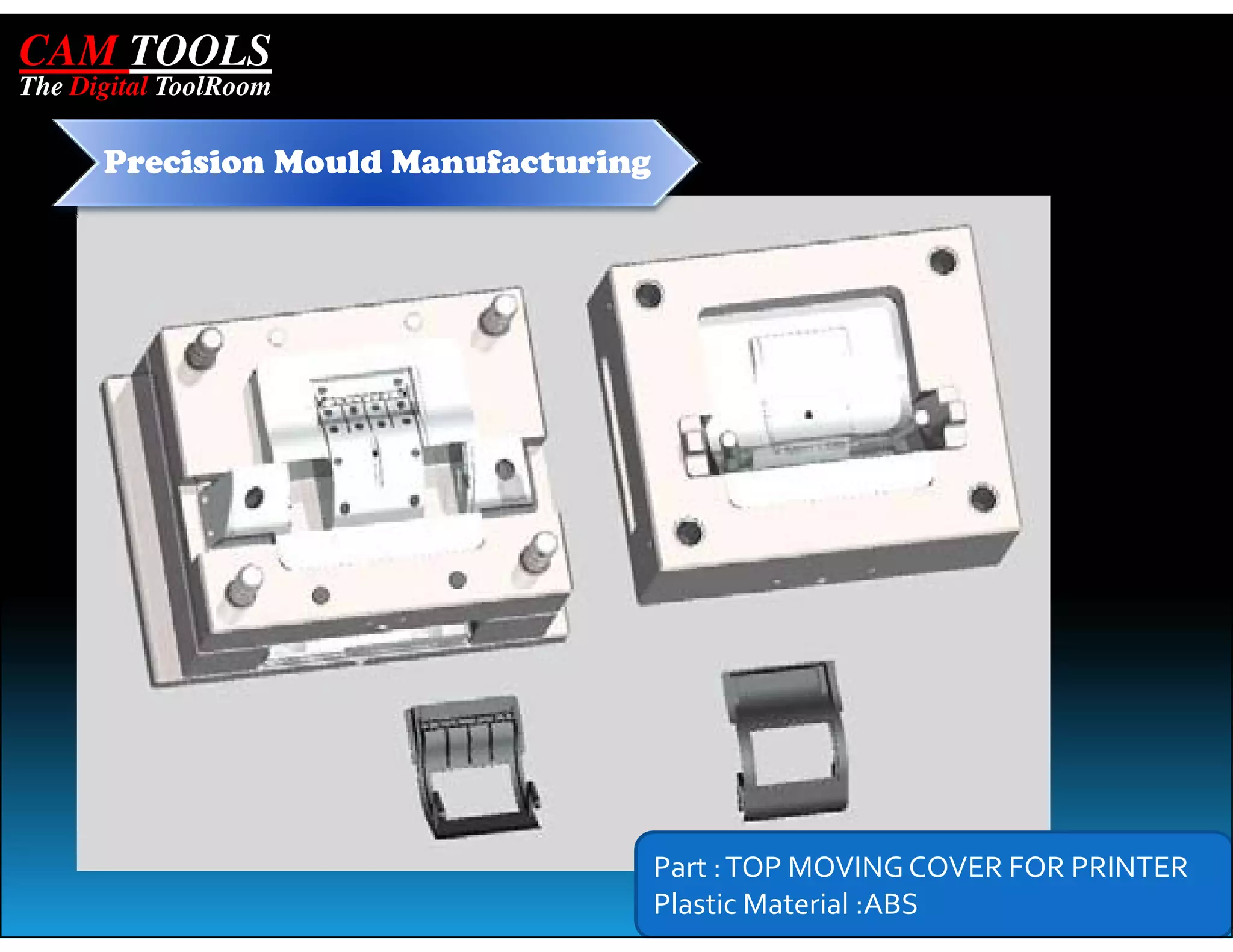

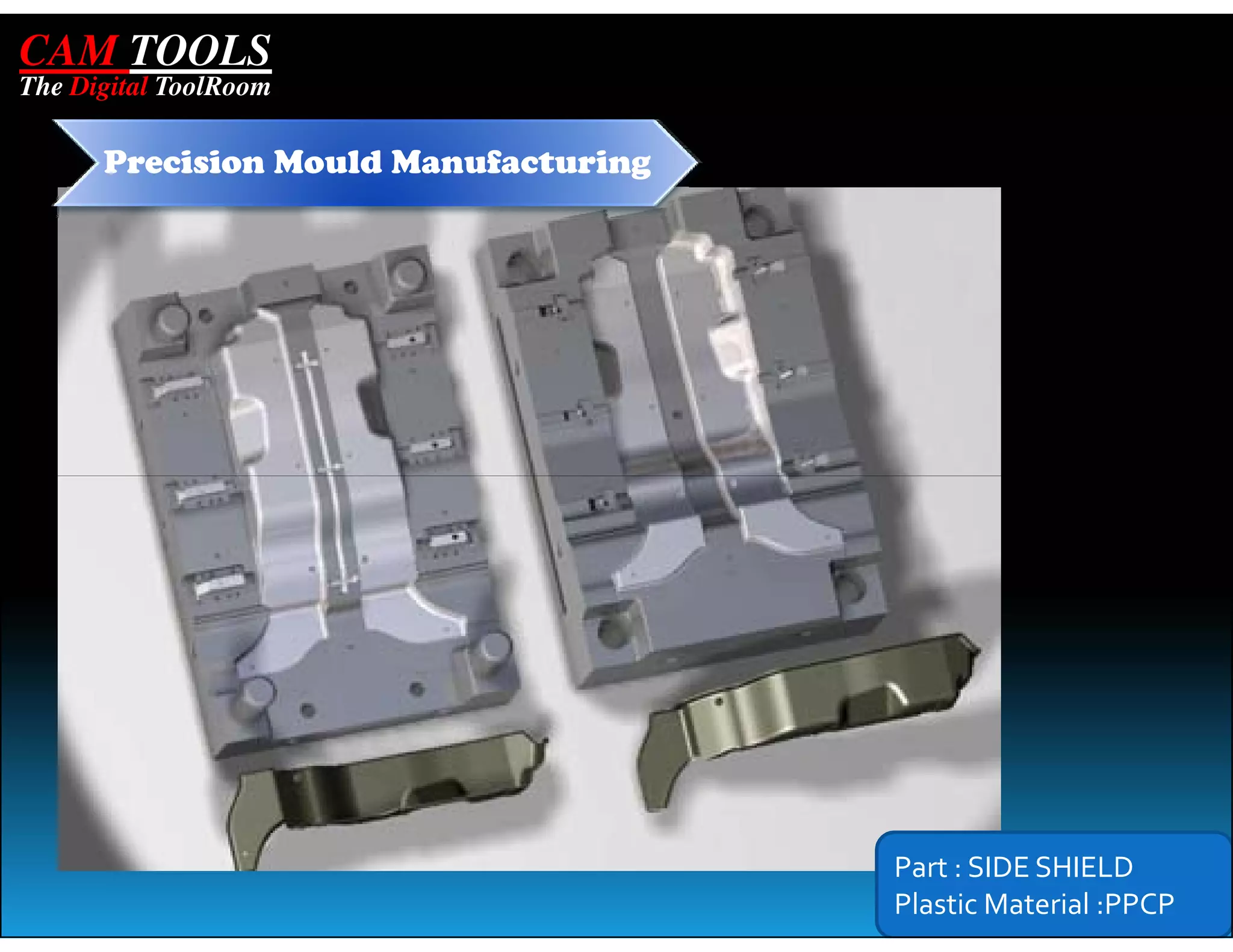

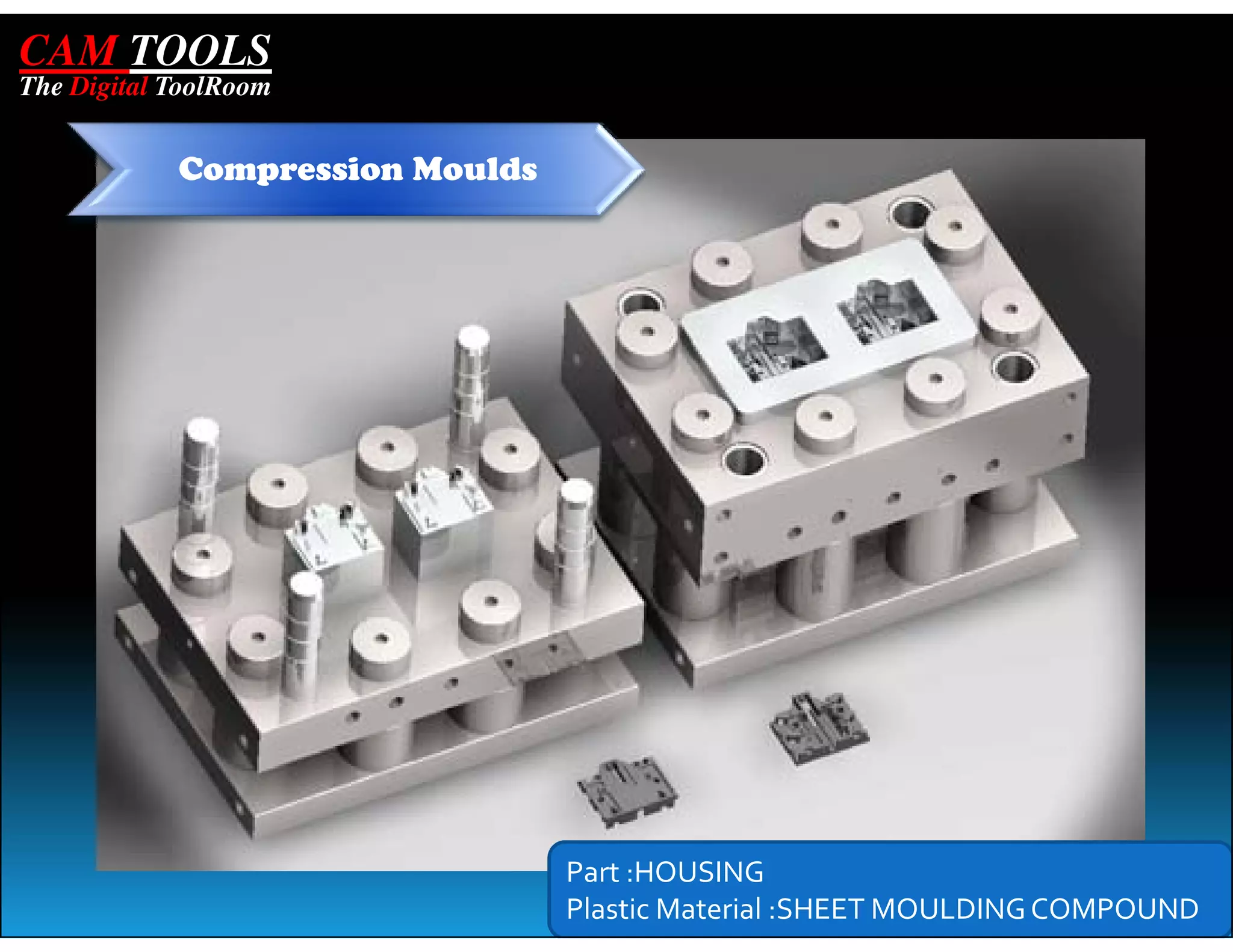

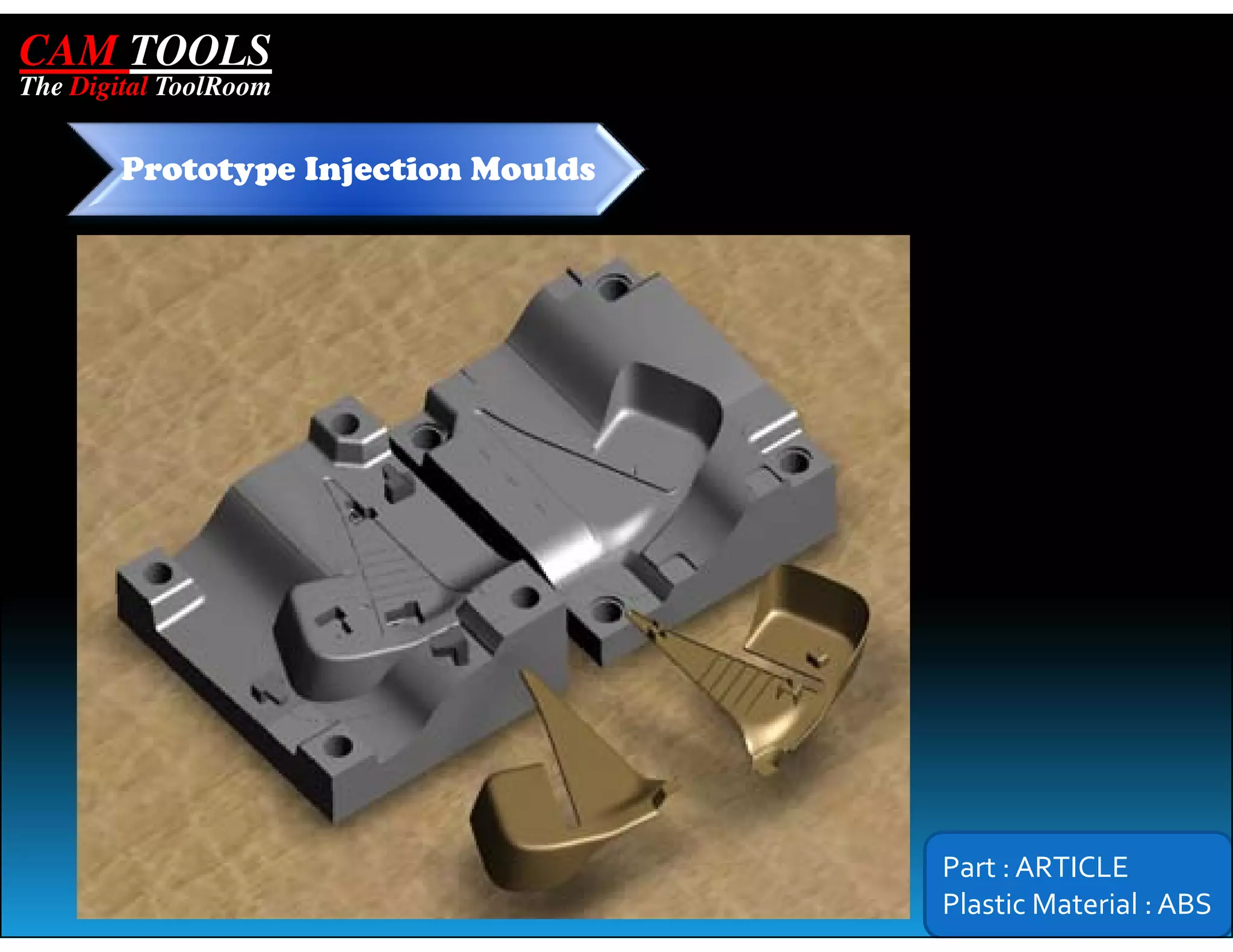

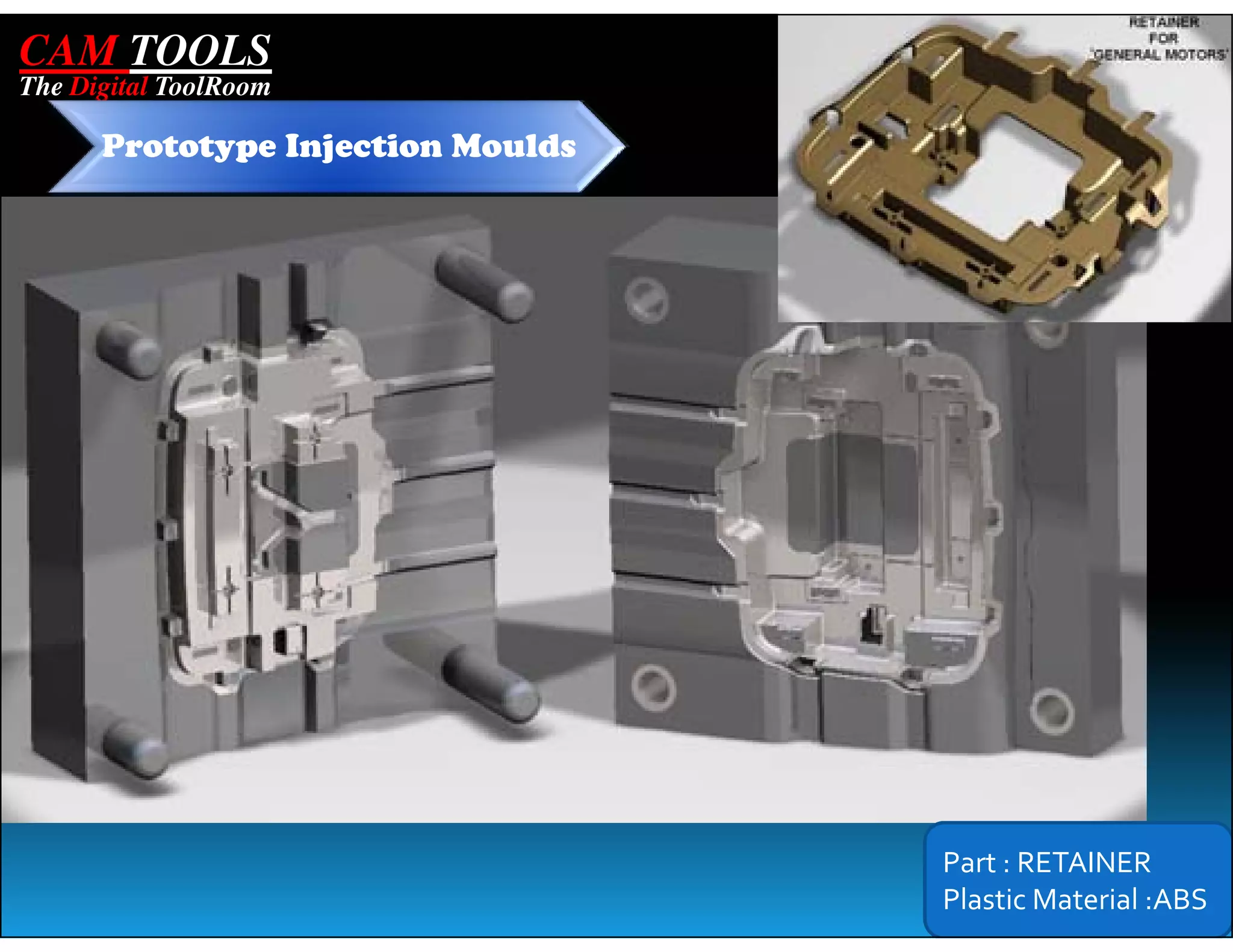

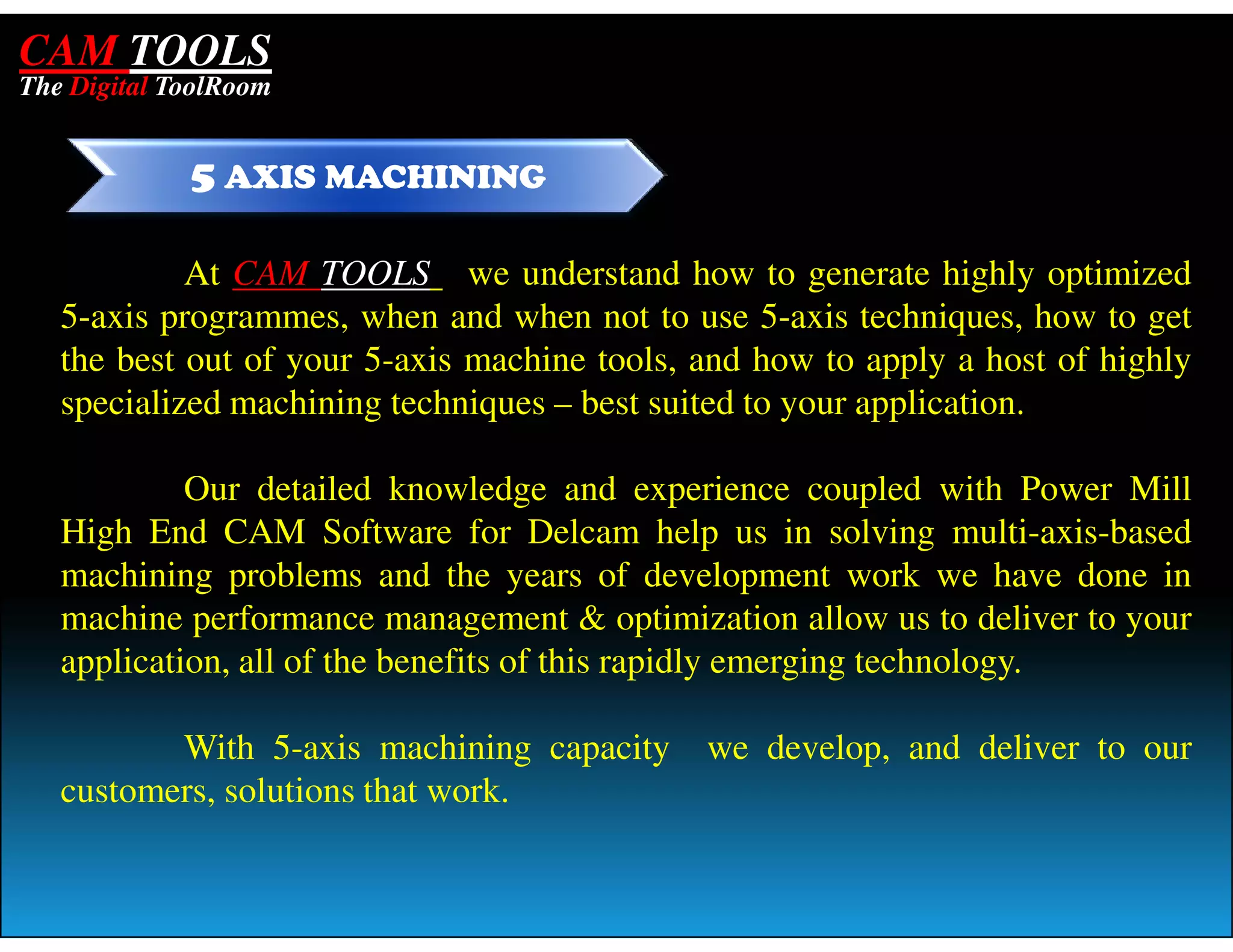

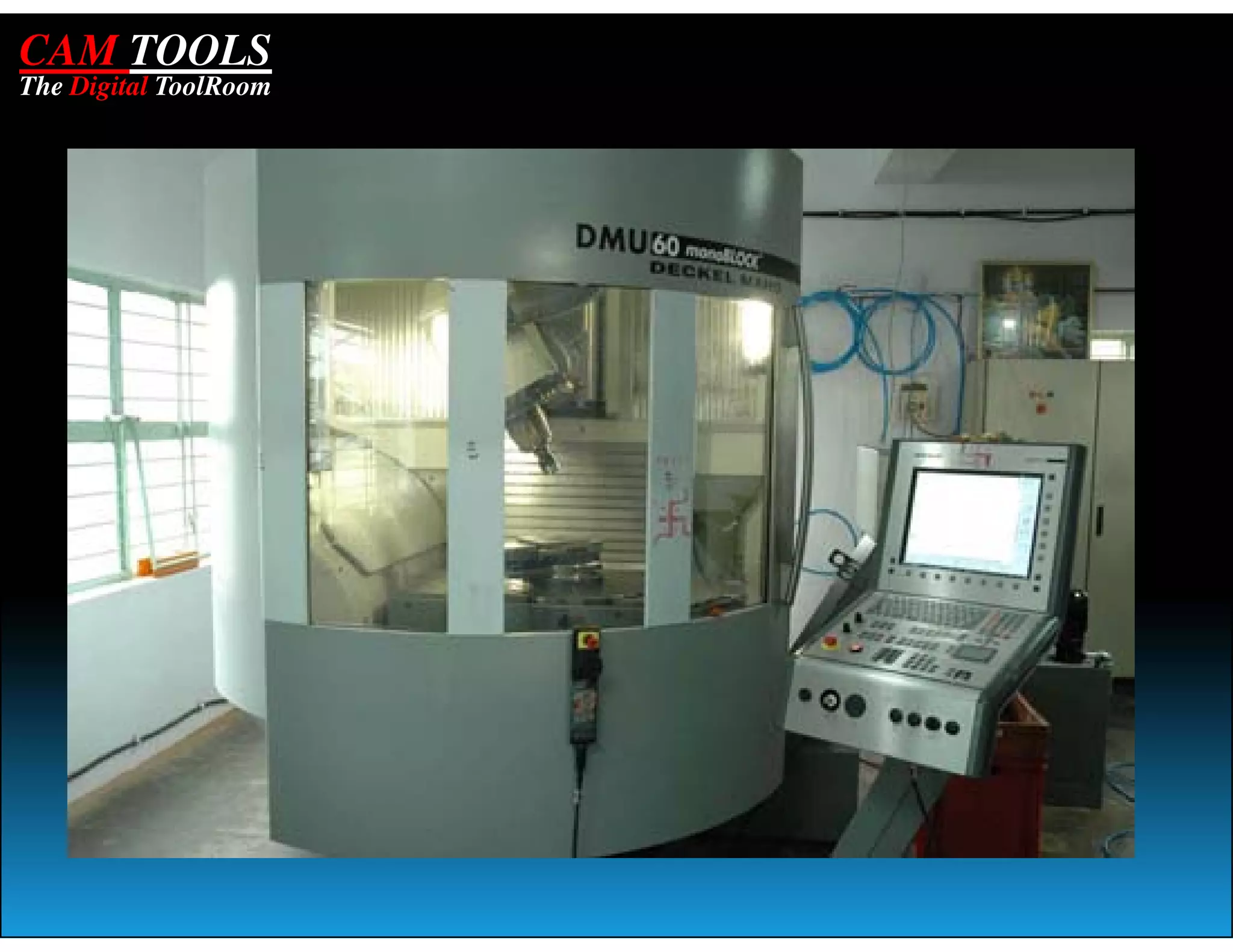

CAM Tools provides services including product design, prototyping, reverse engineering, precision mold manufacturing, 5-axis machining, and supply chain services. They have a team of engineers and technical facilities including CAD/CAM software and CNC machining centers. CAM Tools serves customers in industries like automotive, consumer products, medical, and more by offering a comprehensive set of engineering services.