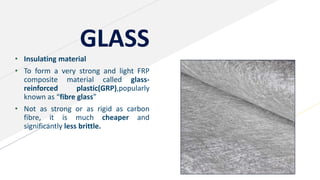

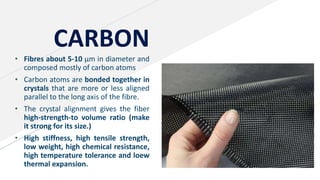

Fibre-reinforced plastic (FRP) is a composite material made of a polymer matrix reinforced with fibres like glass, carbon, aramid, or basalt. The fibres mechanically enhance the strength and elasticity of the plastic matrix. Commonly used fibres include glass for strength and light weight, carbon for high strength and stiffness, and aramid for heat resistance and strength. FRP has properties like low expansion, high strength, heat stability, and toughness making it suitable for applications in aerospace, automotive, equipment, and insulation.