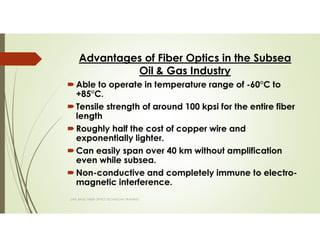

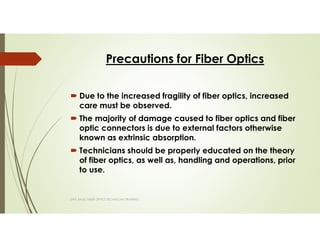

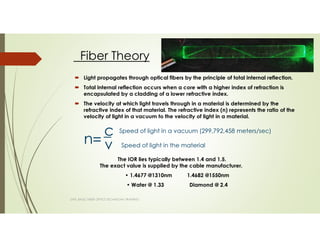

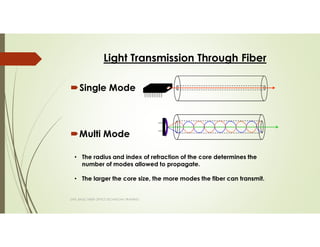

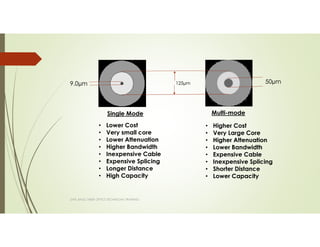

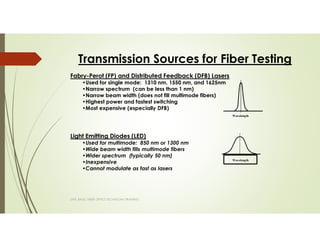

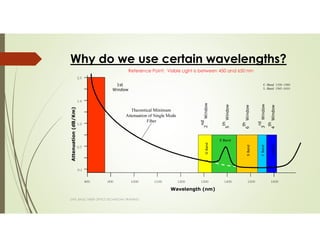

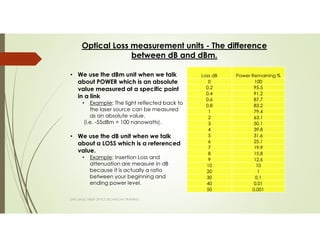

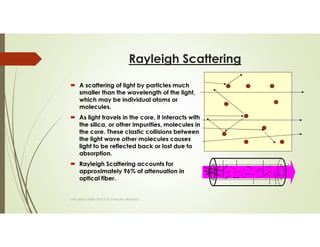

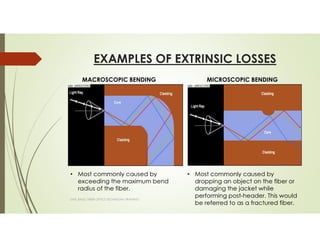

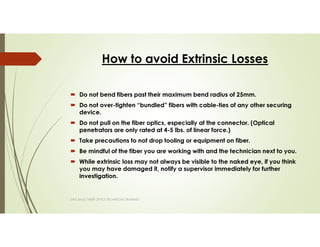

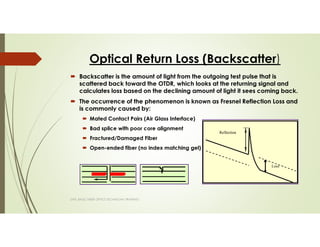

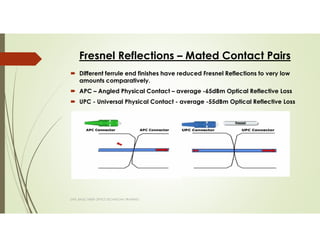

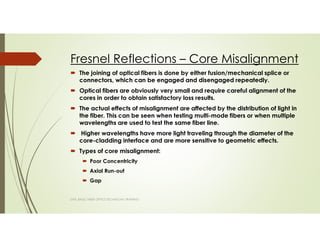

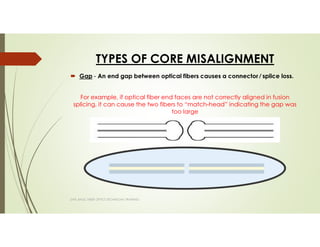

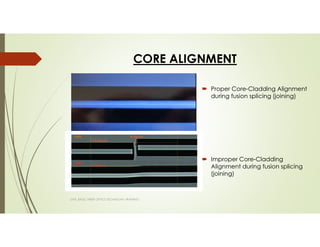

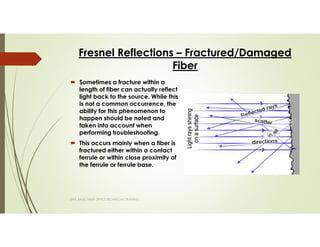

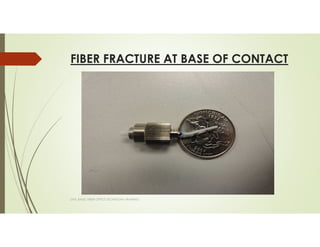

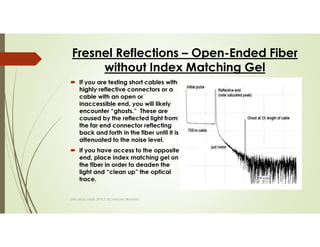

This document provides an overview of fiber optic theory and applications. It discusses the advantages of fiber optics for subsea oil and gas applications, including temperature tolerance and strength. It also covers precautions needed when working with fiber optics due to their increased fragility. The document explains light propagation through optical fibers using the principles of total internal reflection and refractive index. It provides details on single mode and multi-mode fiber types as well as intrinsic and extrinsic sources of optical loss.