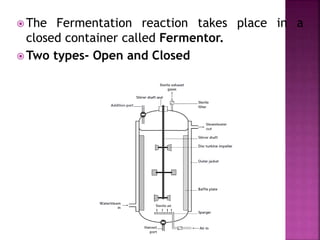

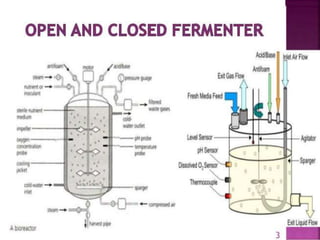

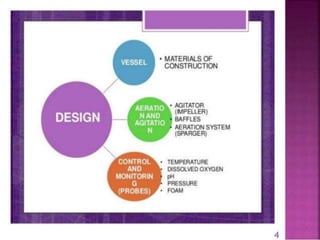

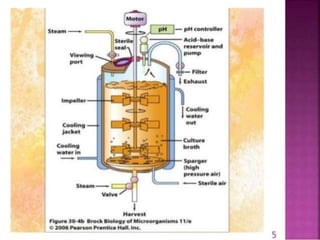

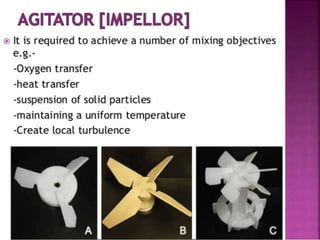

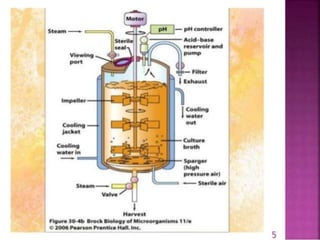

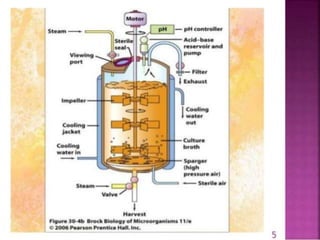

Fermentors are closed containers used for fermentation reactions. They come in two types - open and closed. Construction materials differ based on scale, with glass or stainless steel used for small scale and stainless steel, mild steel, wood, plastic or concrete for larger scales. Fermentors contain mechanically mixed impellers within a baffled cylindrical vessel to promote mixing and mass transfer. Key factors that must be controlled during fermentation include temperature, pH, dissolved oxygen, nutrient concentrations, mixing, and foam formation. Proper strain selection and sterilization of the fermentor are also important.