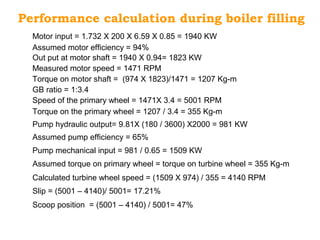

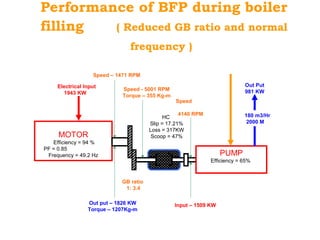

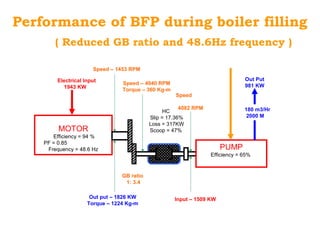

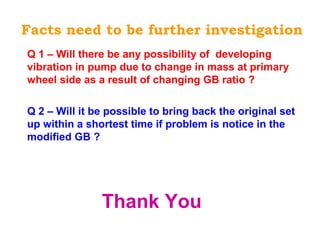

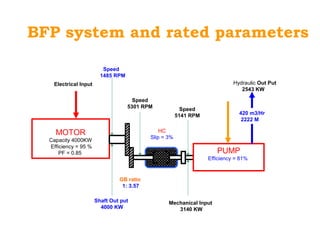

This document analyzes the feasibility of saving energy in a boiler feed pump (BFP) system by reducing the gearbox ratio. It finds that reducing the ratio from 1:3.57 to 1:3.4 could save 147 kW per BFP on average. For two BFPs, this would amount to annual savings of 1.81 million kWh in energy or 1809 tons in lignite. The simple payback period for modifying the two BFP gearboxes is estimated to be 4.15 years. Further investigation is needed to check if vibration or operational issues could arise from the gearbox ratio change and how quickly the original setup could be restored if problems occur.

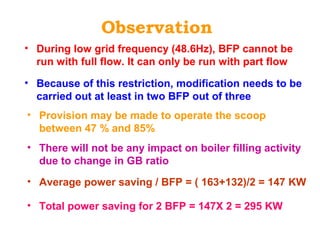

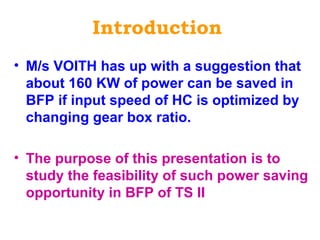

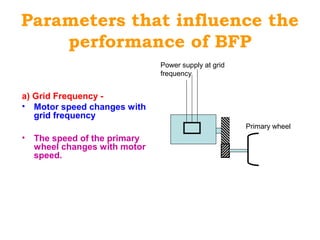

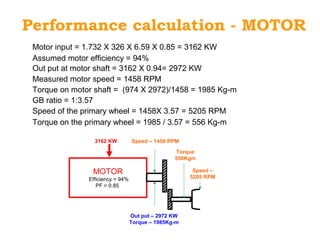

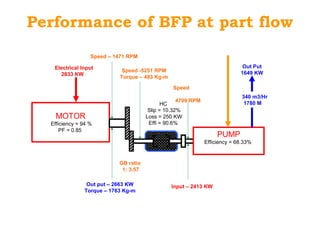

![Parameters that influence the

performance of BFP

c) HC slip -

• The percentage speed

difference between

primary and turbine

wheels is known as slip.

• The slip can be controlled

linearly by draining out oil

between two wheels with

the help of scoop tube.

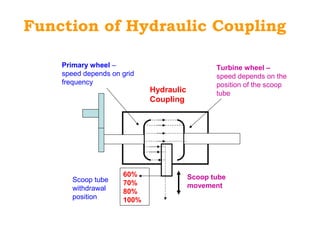

Primary wheel –

speed depends

on grid frequency

Turbine wheel –

speed depends

on the position of

the scoop tube

% SLIP = [(PW speed – TW speed) / PW speed] X100](https://image.slidesharecdn.com/feasibilitystudy-bfp-130714121601-phpapp02/85/Feasibility-study-bfp-10-320.jpg)

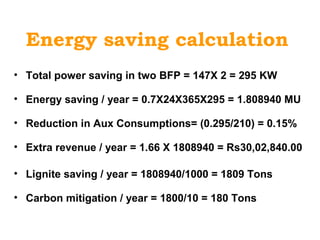

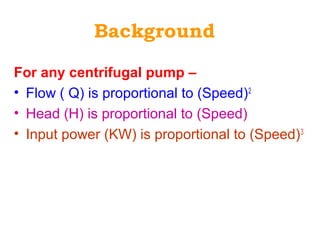

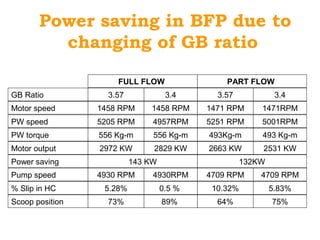

![Performance of BFP at lowest grid

frequency with reduced GB ratio

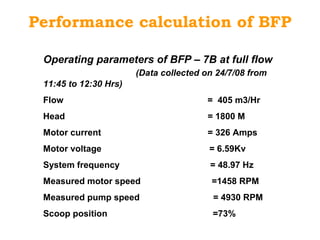

PART FLOW

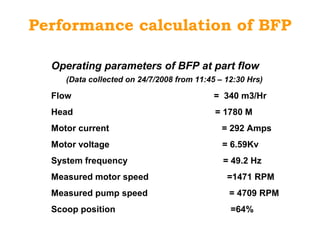

Grid frequency [ f ] 48.6 Hz

Motor syn speed [ Ns = (120 X f ) / P] 1458 RPM

Assumed motor slip [ %S] 0.3%

Motor speed [Nm = Ns(1-%S)] 1453 RPM

FULL FLOW

48.6 Hz

1458 RPM

0.7%

1448 RPM

Gear Box ratio [ R] 3.43.4

Primary Wheel speed [Np = Nm XR] 4940 RPM4923 RPM

Measured pump speed [Nt] 4709 RPM4930 RPM

HC slip [(Np – Nt) / Np] X 100 4.67%Neg. Slip

Scoop position 80%Not Possible](https://image.slidesharecdn.com/feasibilitystudy-bfp-130714121601-phpapp02/85/Feasibility-study-bfp-21-320.jpg)

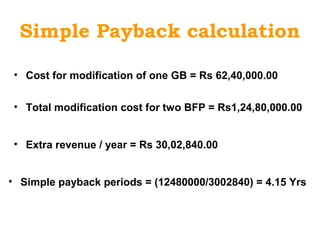

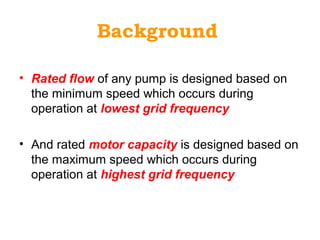

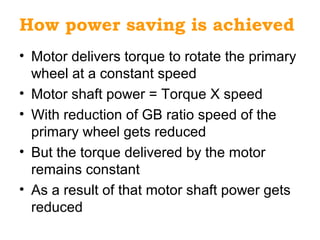

![Minimum & Maximum power saving

due to modification

PART FLOW

Grid frequency [ f ] 49.2 Hz (Ave)

Motor syn speed [ Ns = (120 X f ) / P]

1471 RPM

Assumed motor slip [ %S]

1476 RPM

Motor speed [Nm = Ns(1-%S)]

0.3%

48.6 Hz (Min)

1453 RPM

1458 RPM

0.3%

Gear Box ratio [ R] 3.43.4

Primary Wheel speed [Np = Nm XR] 5001 RPM4940 RPM

Measured pump speed [Nt] 4709 RPM4709 RPM

HC slip [(Np – Nt) / Np] X 100 5.83%4.67%

Scoop position (From graph) 75%78%

Torque on the Primary Wheel [T] 493 Kg-m493 Kg-m

Motor output [Np X T / 974] 2531 KW2500 KW

Power saving 132 KW163 KW

Motor output before modification 2663 KW2663 KW](https://image.slidesharecdn.com/feasibilitystudy-bfp-130714121601-phpapp02/85/Feasibility-study-bfp-22-320.jpg)