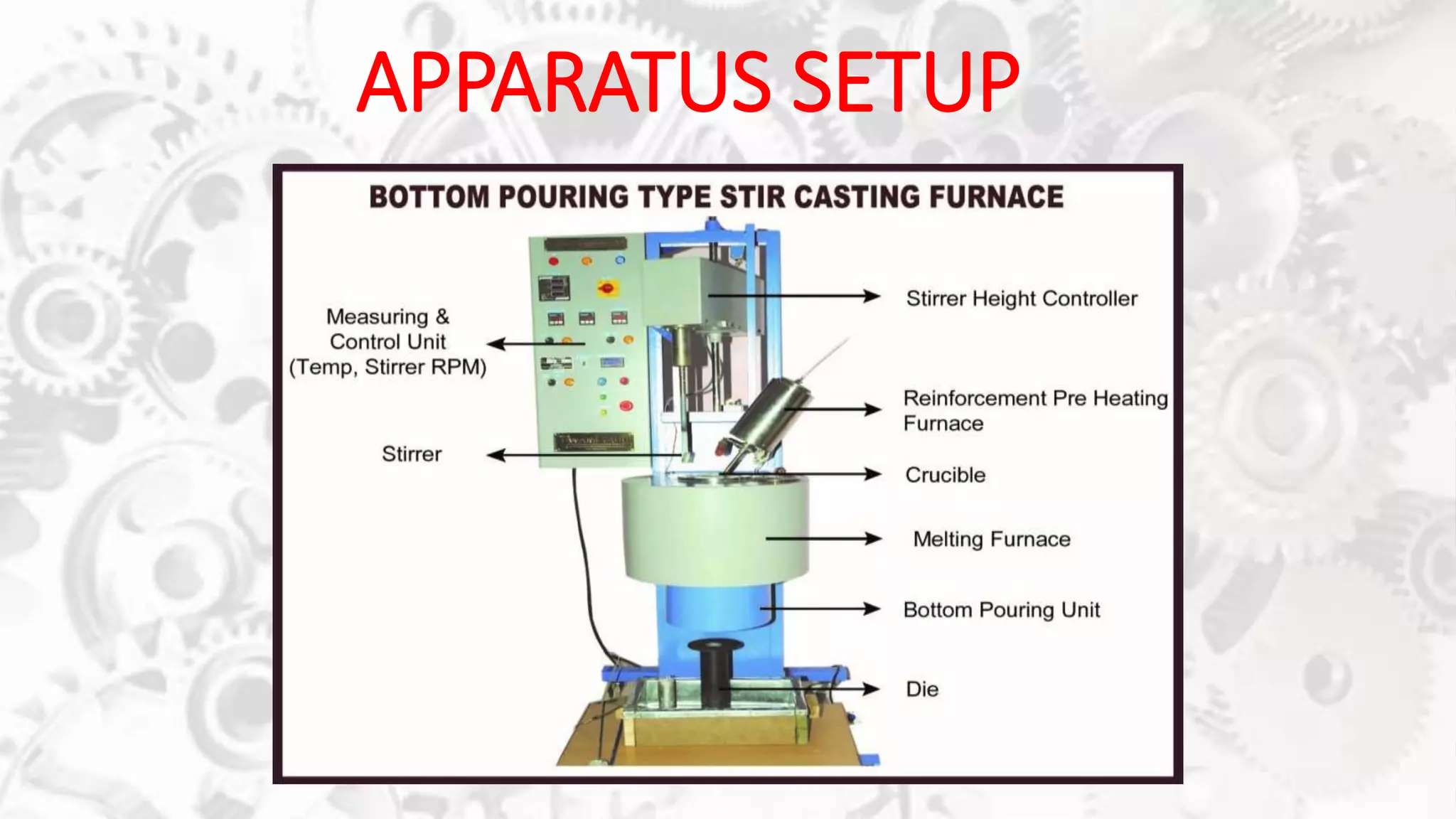

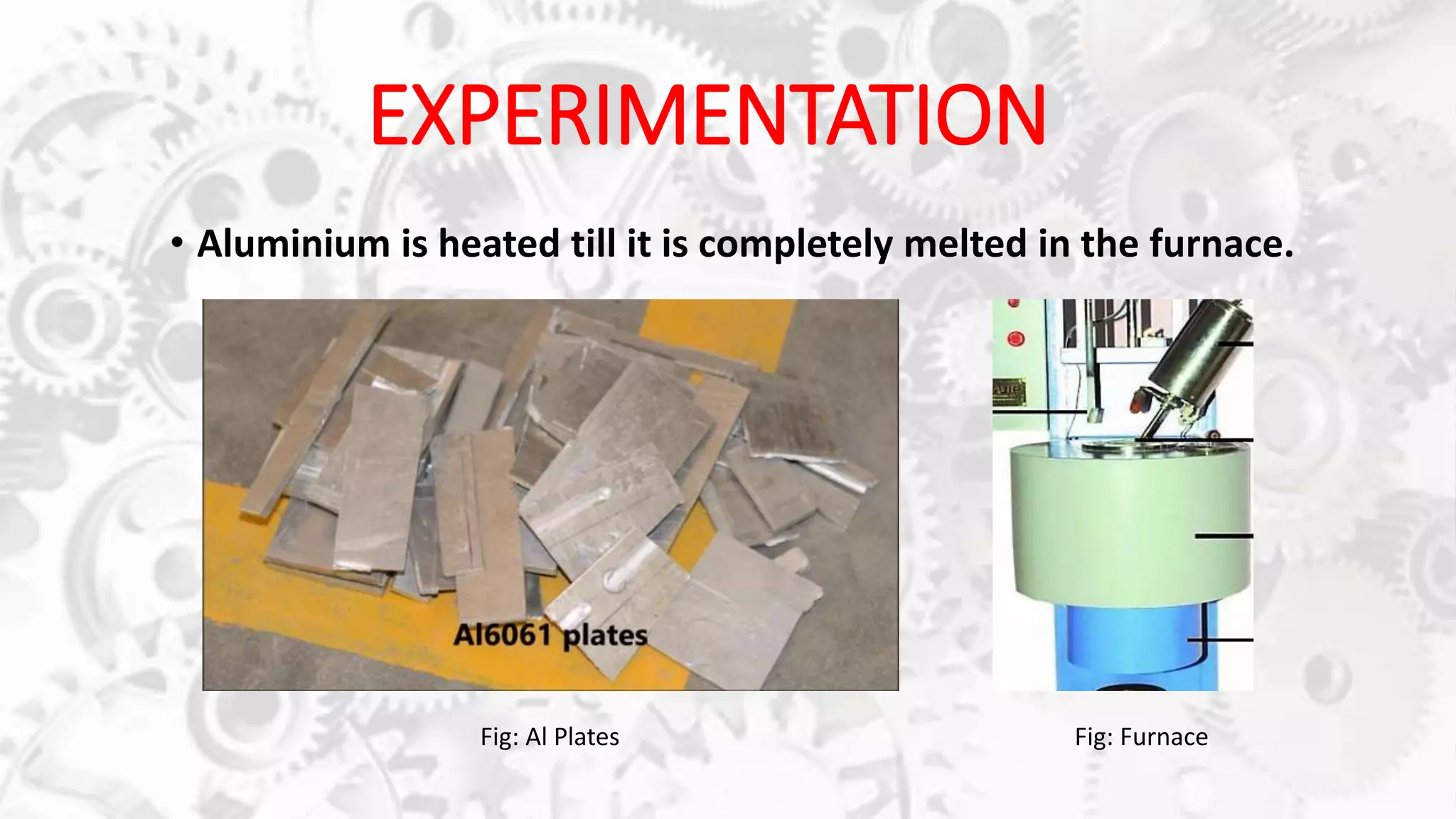

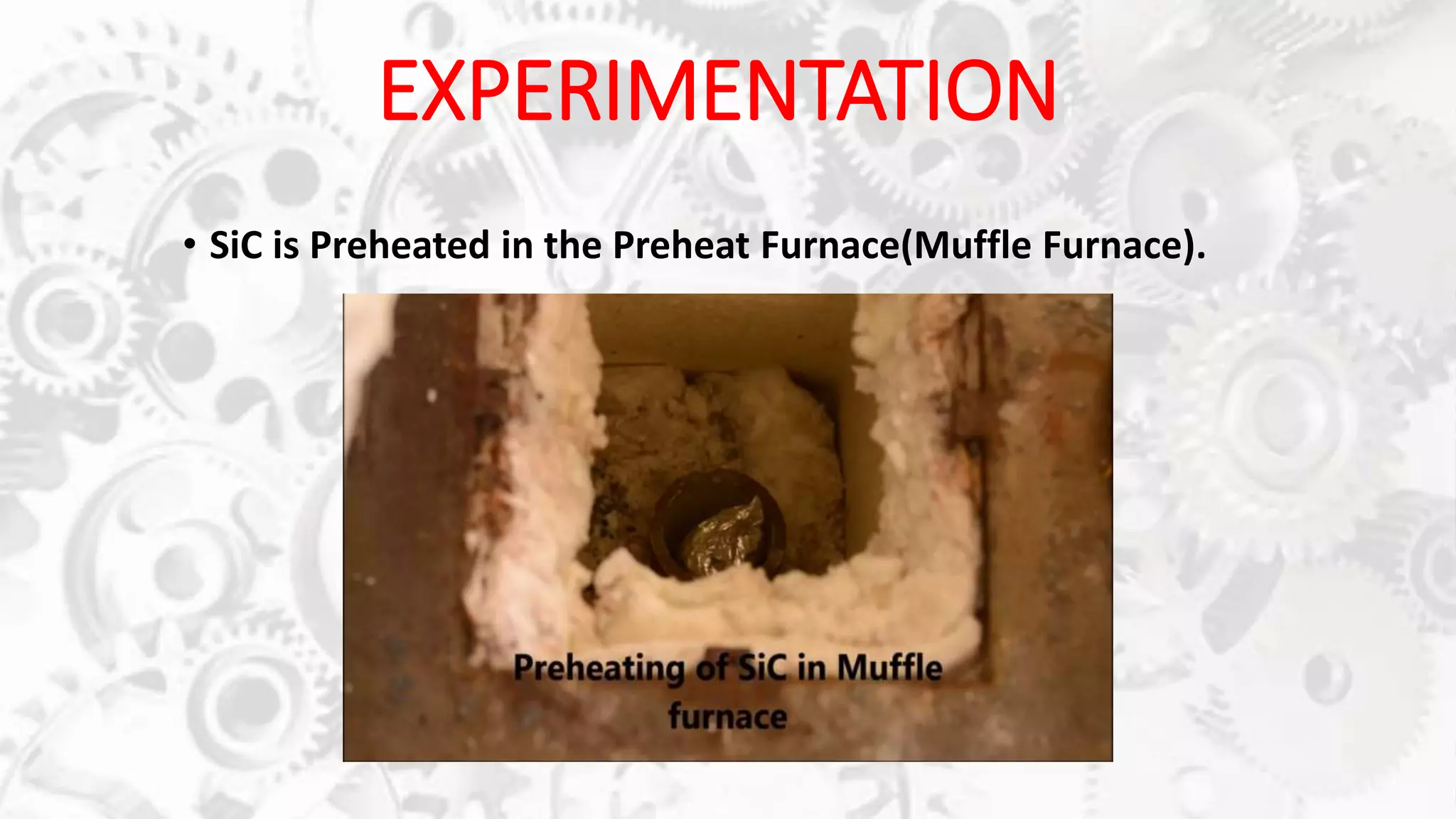

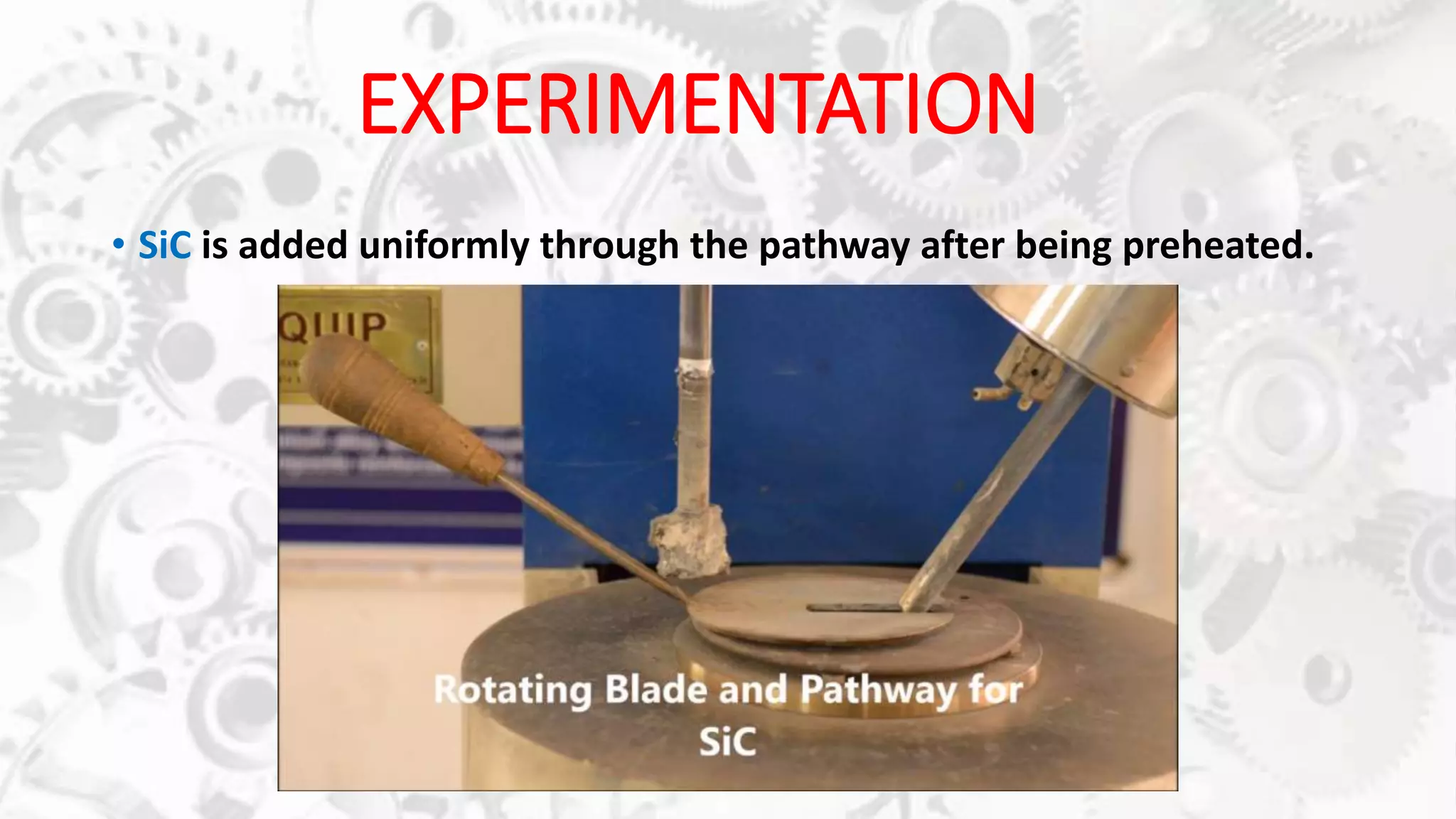

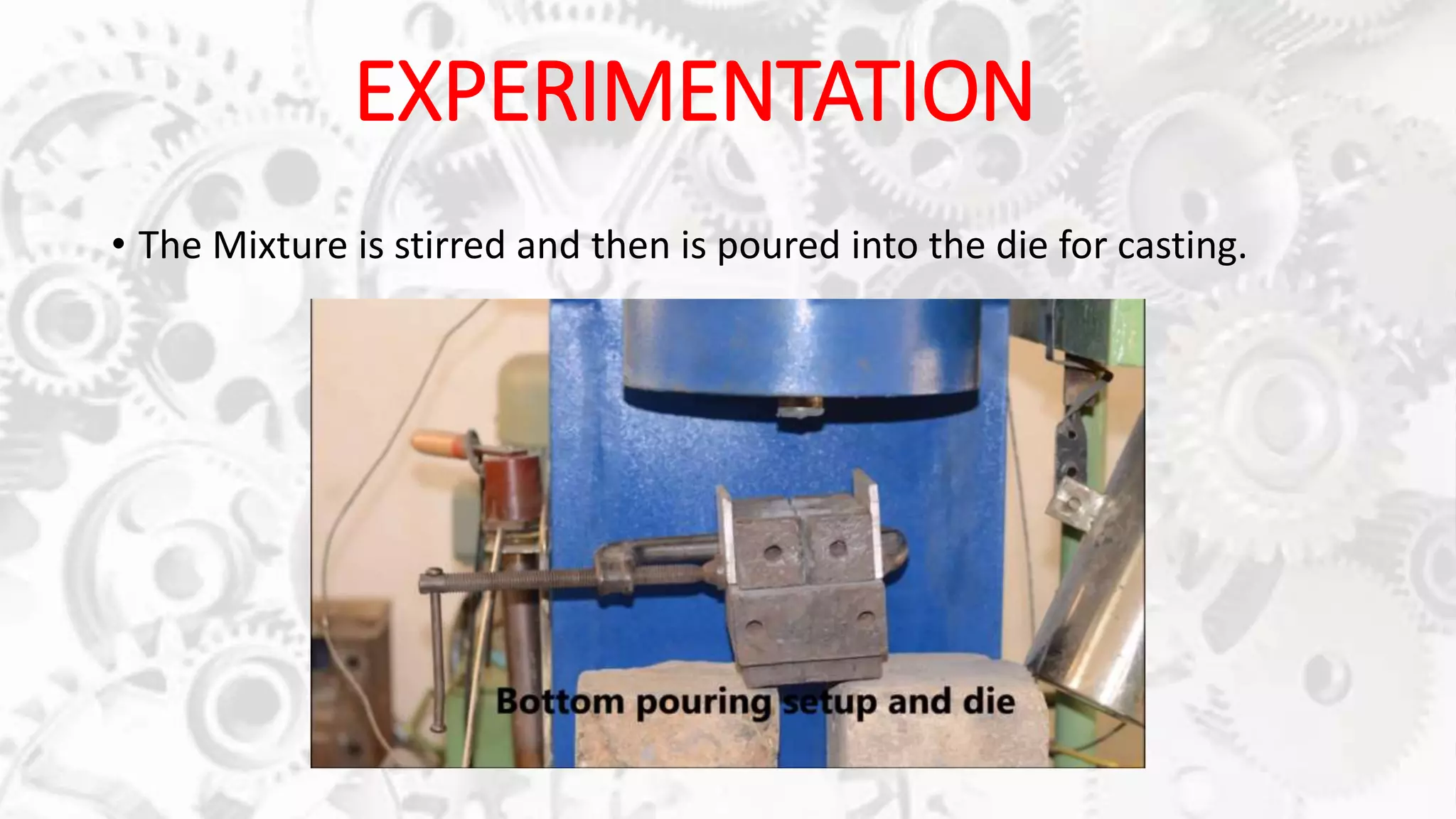

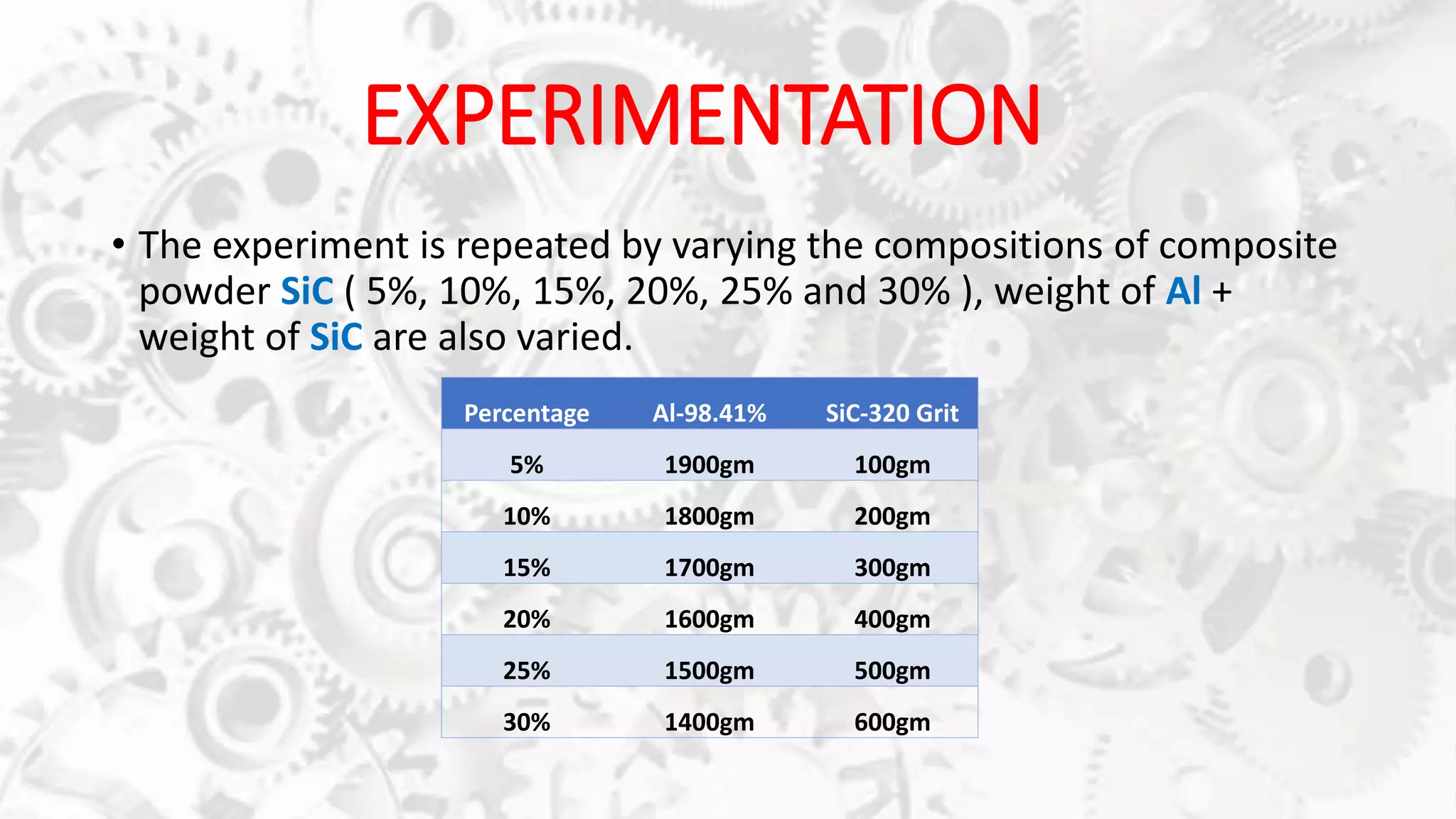

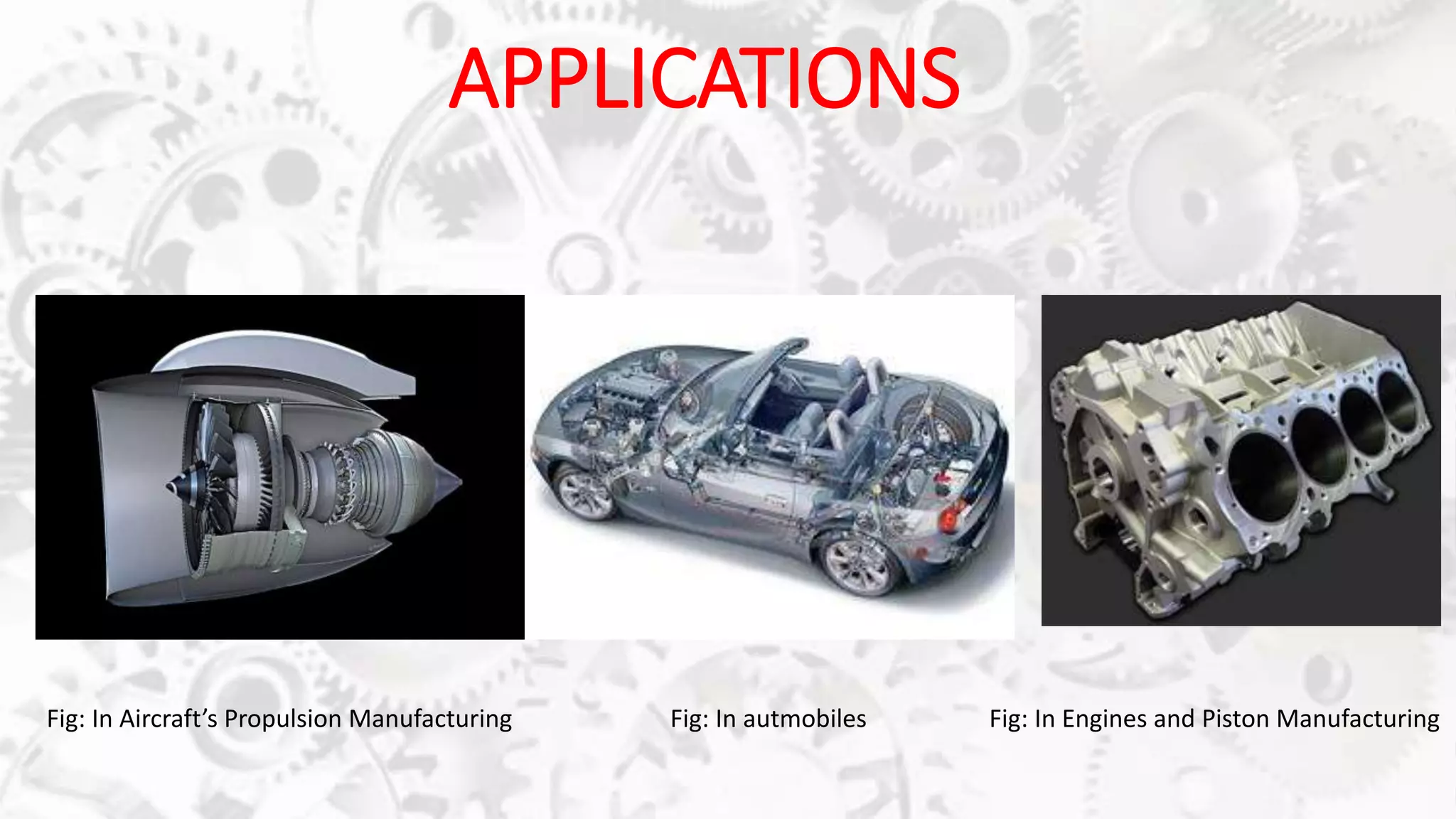

This document summarizes a project to fabricate metal-matrix composites using stir casting. The project aims to produce aluminum-silicon carbide (AlSiC) composites through stir casting to create strong, lightweight materials for use in industries like automotive and aerospace. Experiments are conducted by varying the composition of silicon carbide added to molten aluminum from 5-30% and stirring to ensure homogeneous mixing. The composites are then tested for properties like hardness and impact strength. The goal is to develop low-cost metal-matrix composite materials for industrial applications requiring high strength, stiffness, and other properties.