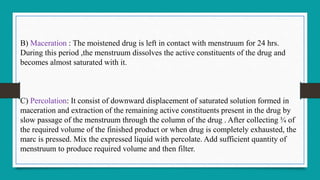

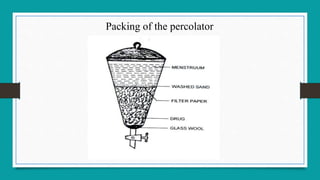

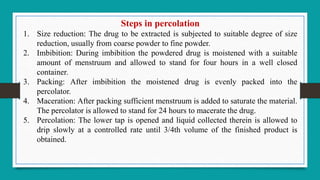

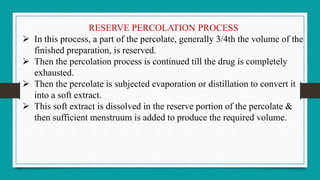

This document discusses various percolation processes used to extract drugs, including simple percolation, reserve percolation, and continuous hot percolation. Simple percolation involves imbibing powdered drug with menstruum, macerating for 24 hours, then slowly percolating menstruum through the drug column. Reserve percolation collects part of the percolate, evaporates it to an extract, then dissolves the extract in the reserved percolate. Continuous hot percolation uses a Soxhlet apparatus to continuously treat a sample with recondensing solvent over hours or days for improved extraction.