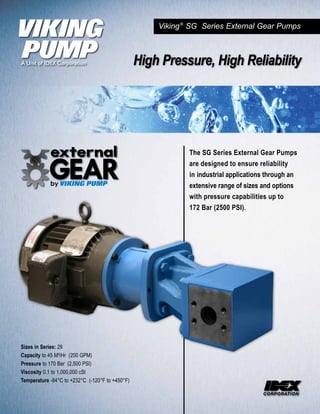

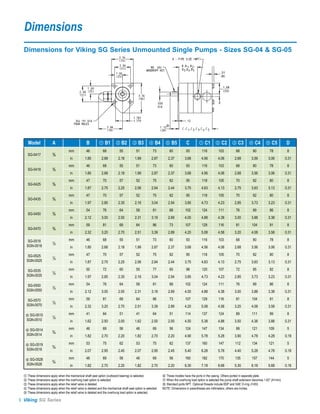

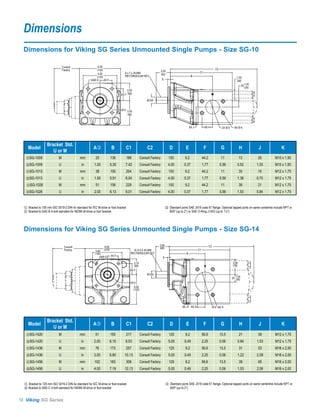

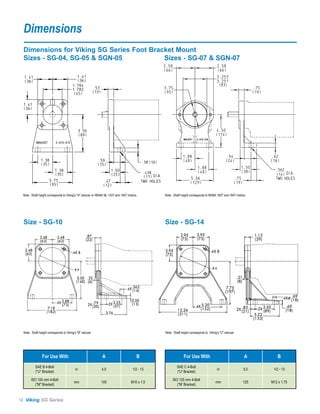

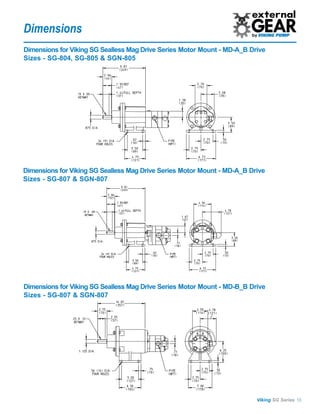

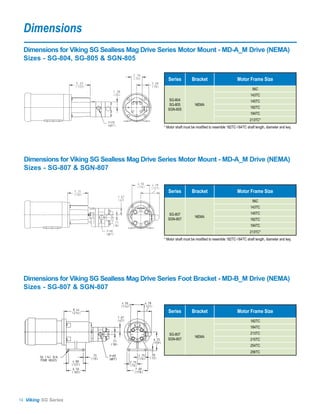

The document discusses the Viking SG Series external gear pumps. It summarizes that the pumps are designed for reliability in industrial applications with pressure capabilities up to 172 Bar and sizes ranging from 29 models with capacities up to 45 cubic meters per hour. The pumps are said to provide long seal and bearing life through designs that prevent shaft movement and wear, lowering costs of ownership compared to competitors' pumps.