The document provides technical details and instructions for an AF-3 filling machine. It includes:

- An overview of the machine components and operation procedures.

- Safety guidelines for transport, installation, operation and maintenance.

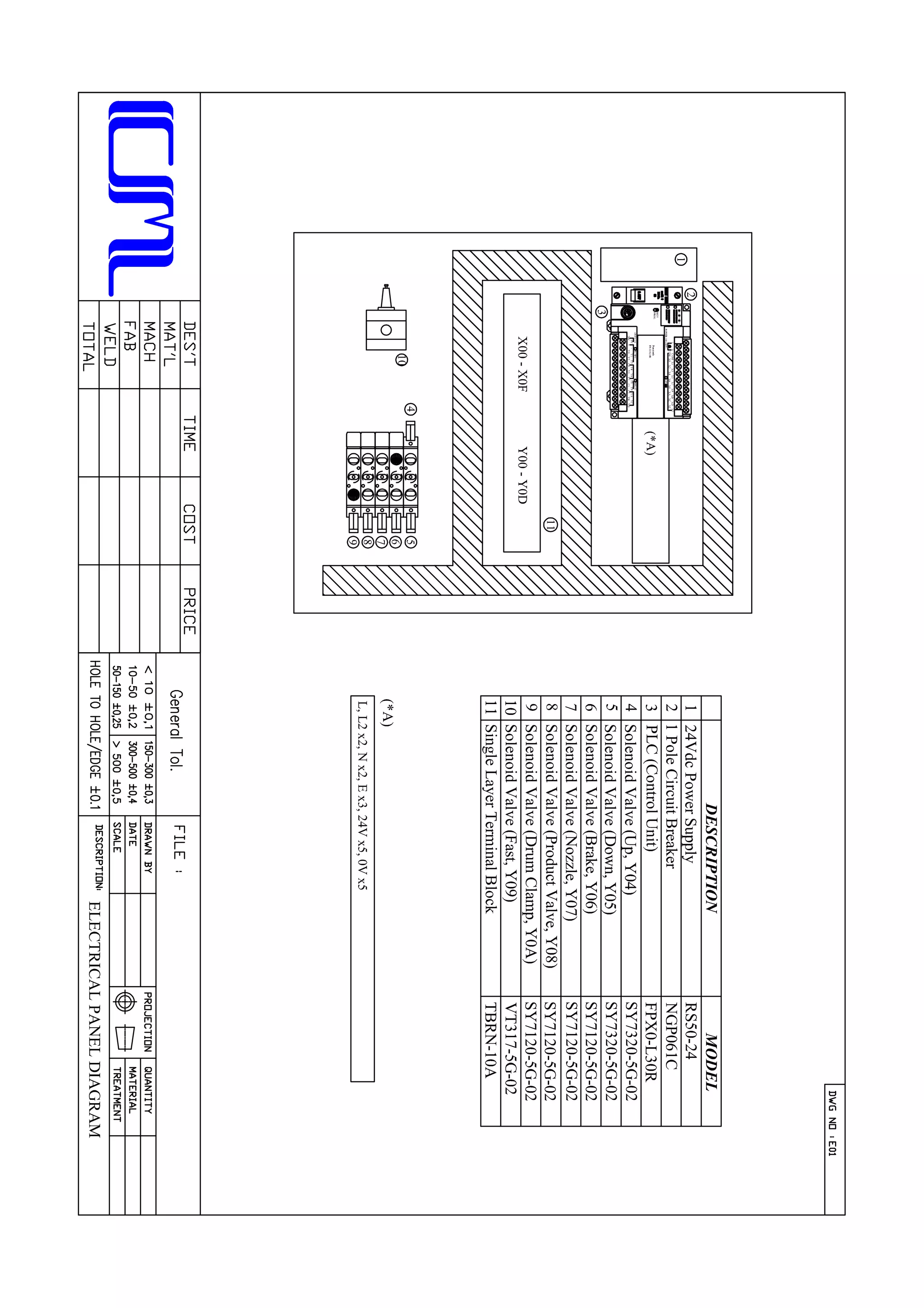

- Mechanical drawings of the major assemblies - load cell & drum clamp, nozzle, and structure - with part lists.

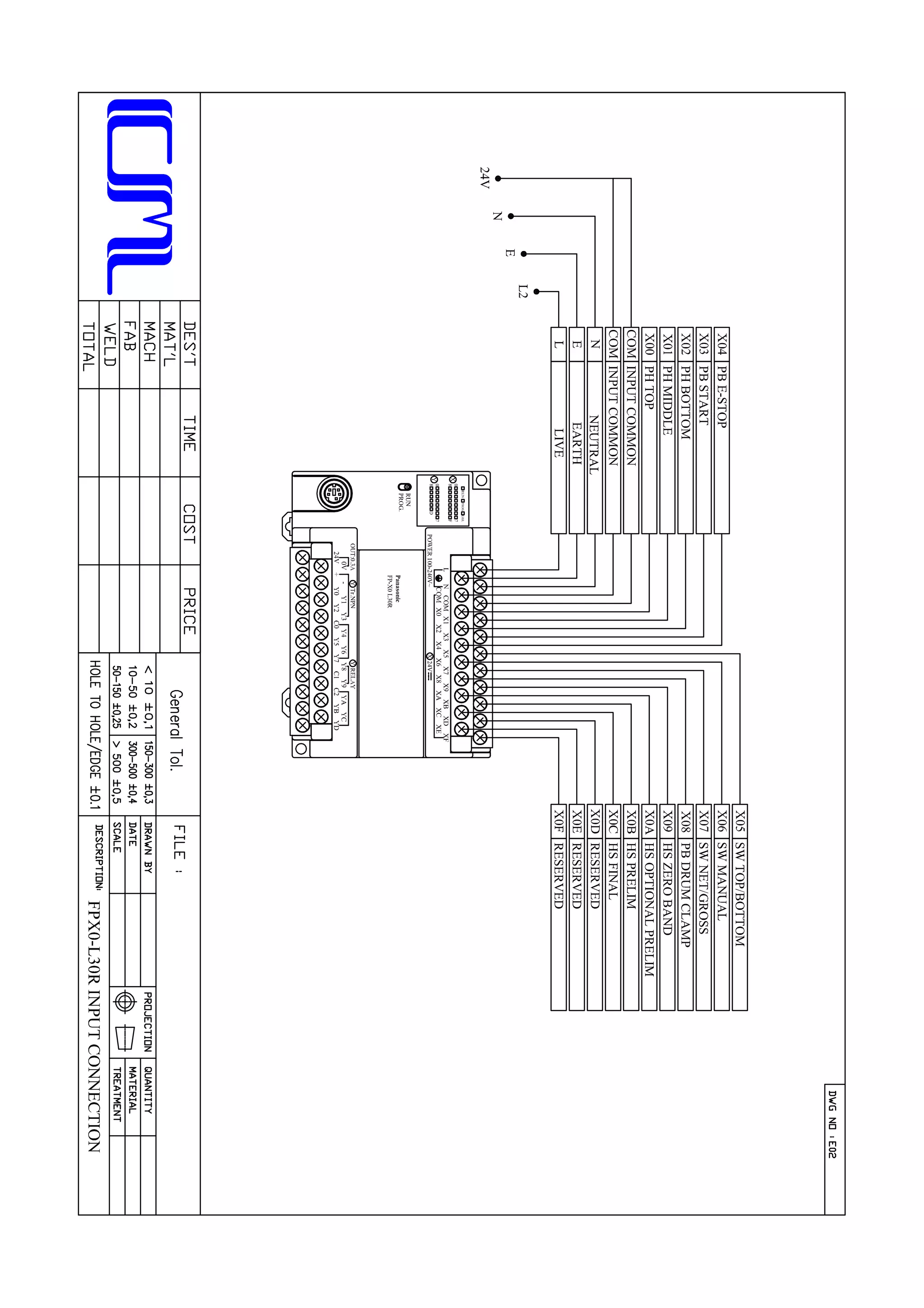

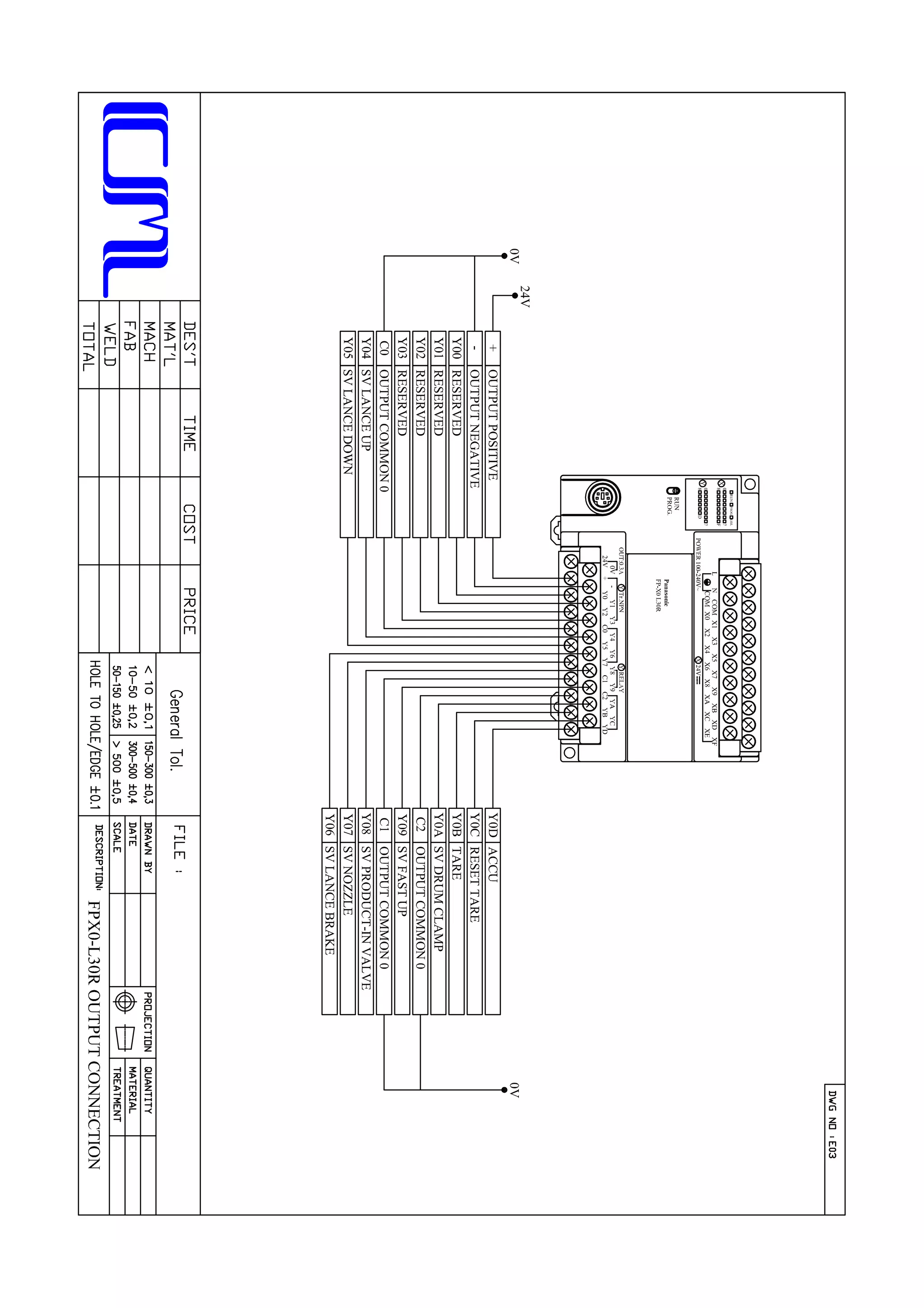

- Electrical & pneumatic diagrams showing connections, wiring and functions.

- Parameter settings for the weighing indicator and maintenance instructions.

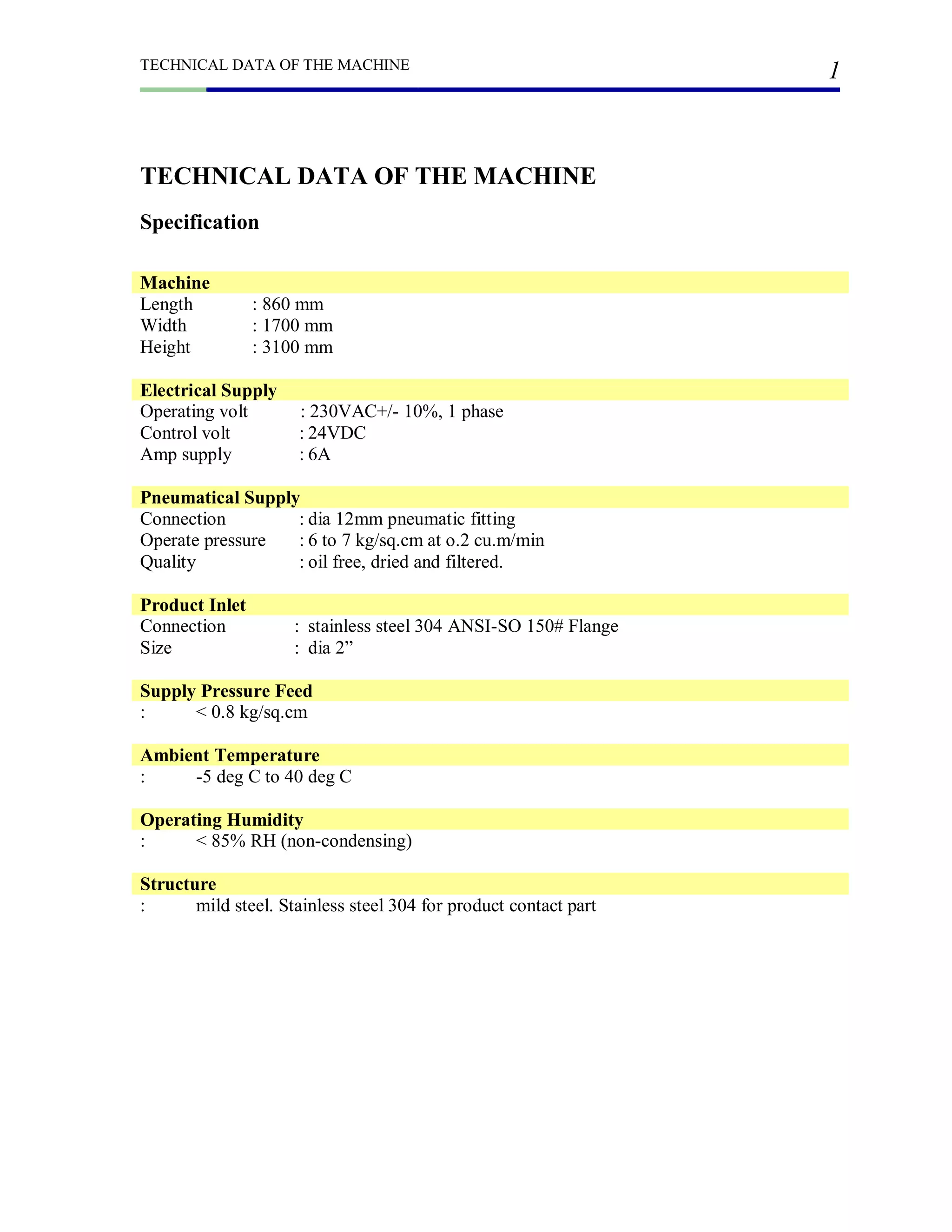

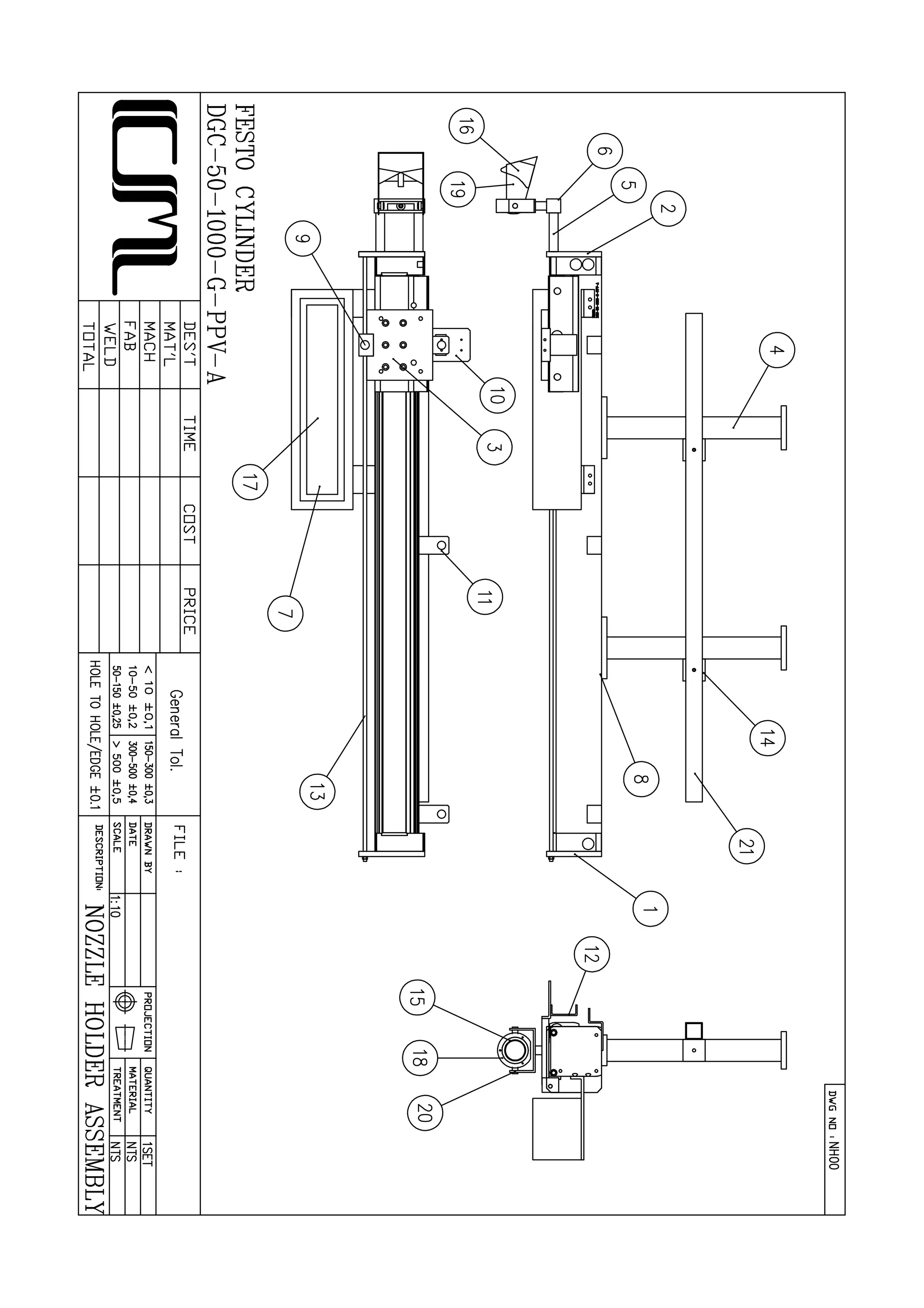

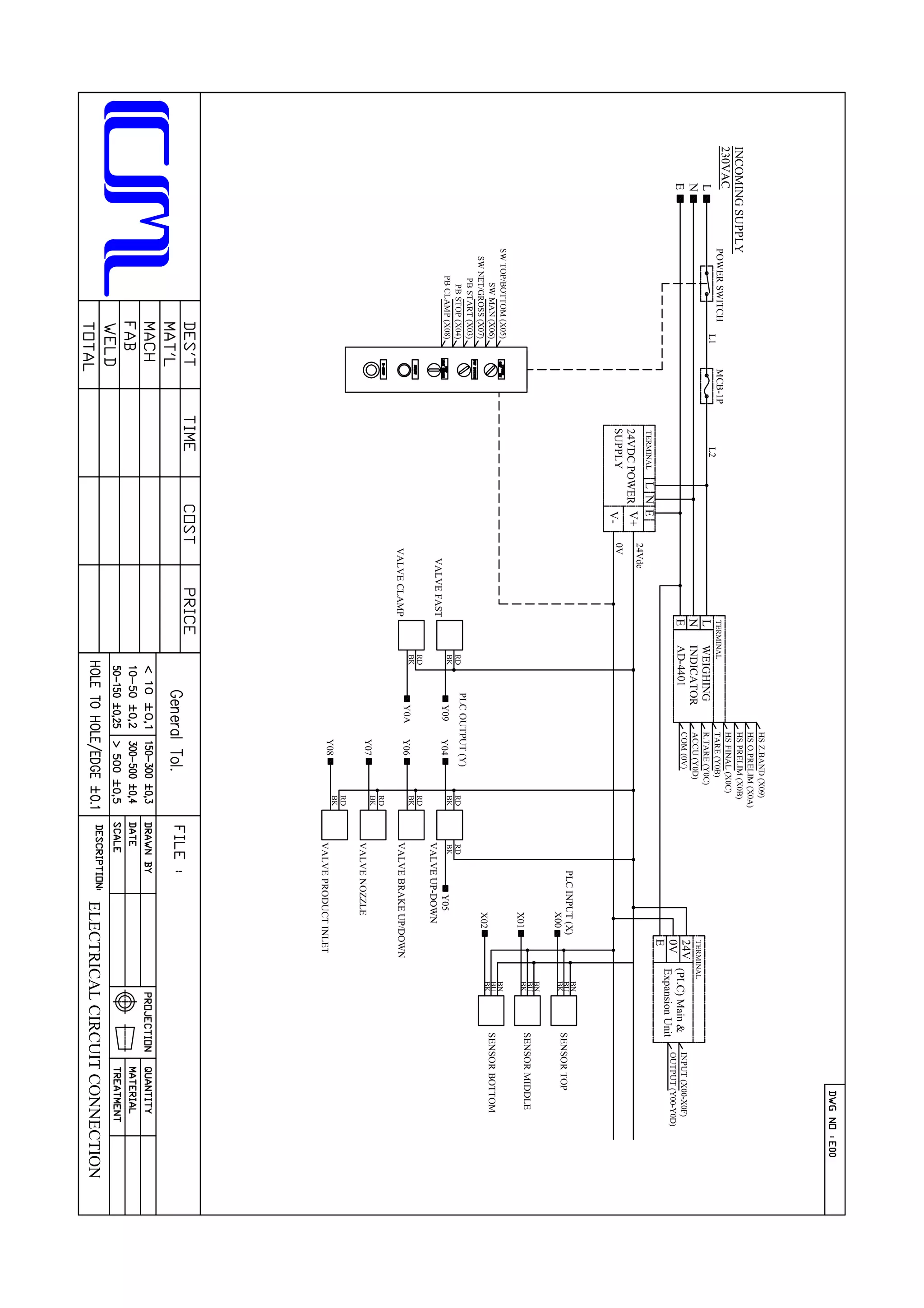

![CHAPTER 1 - INTRODUCTION TO AF-3

11

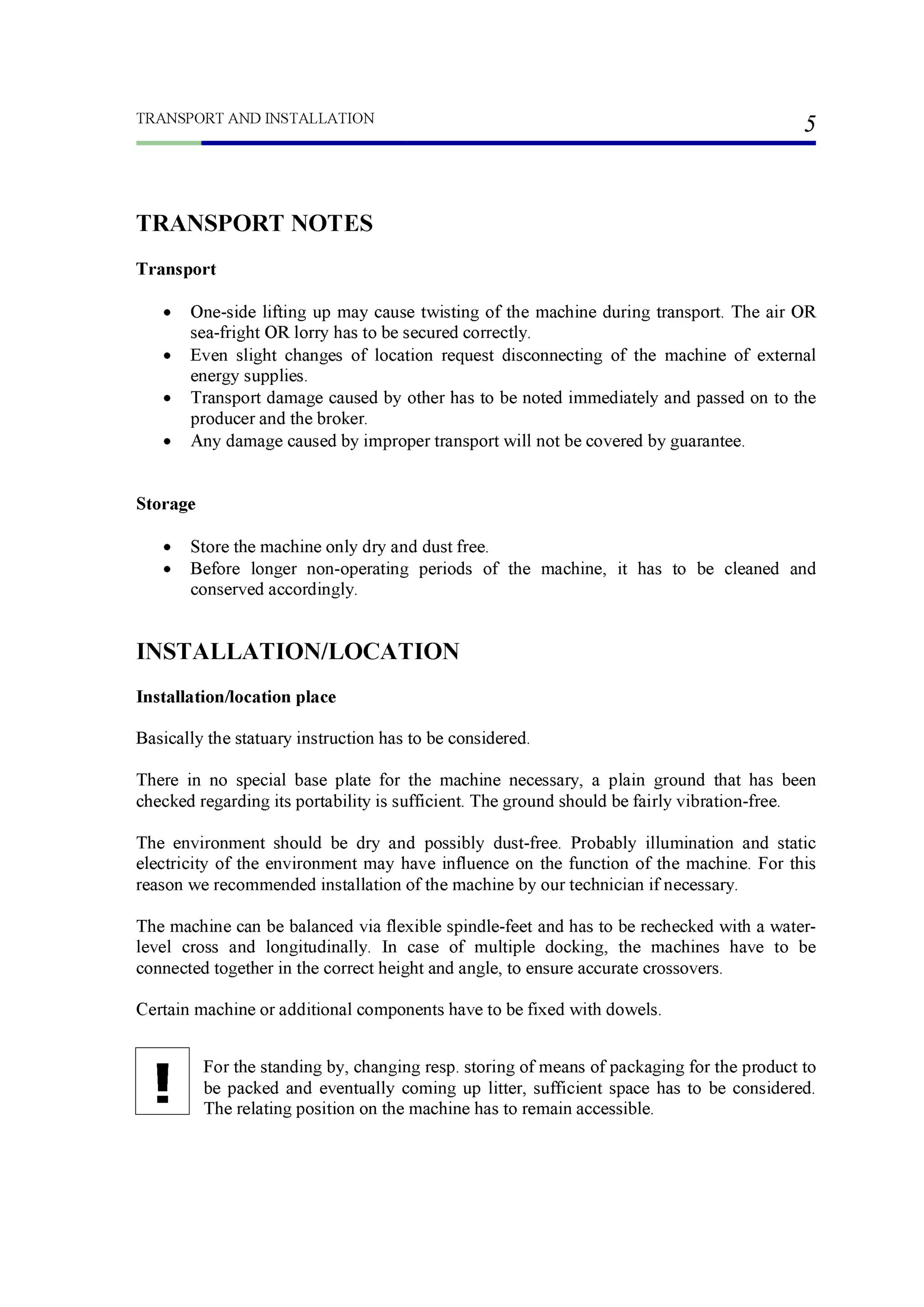

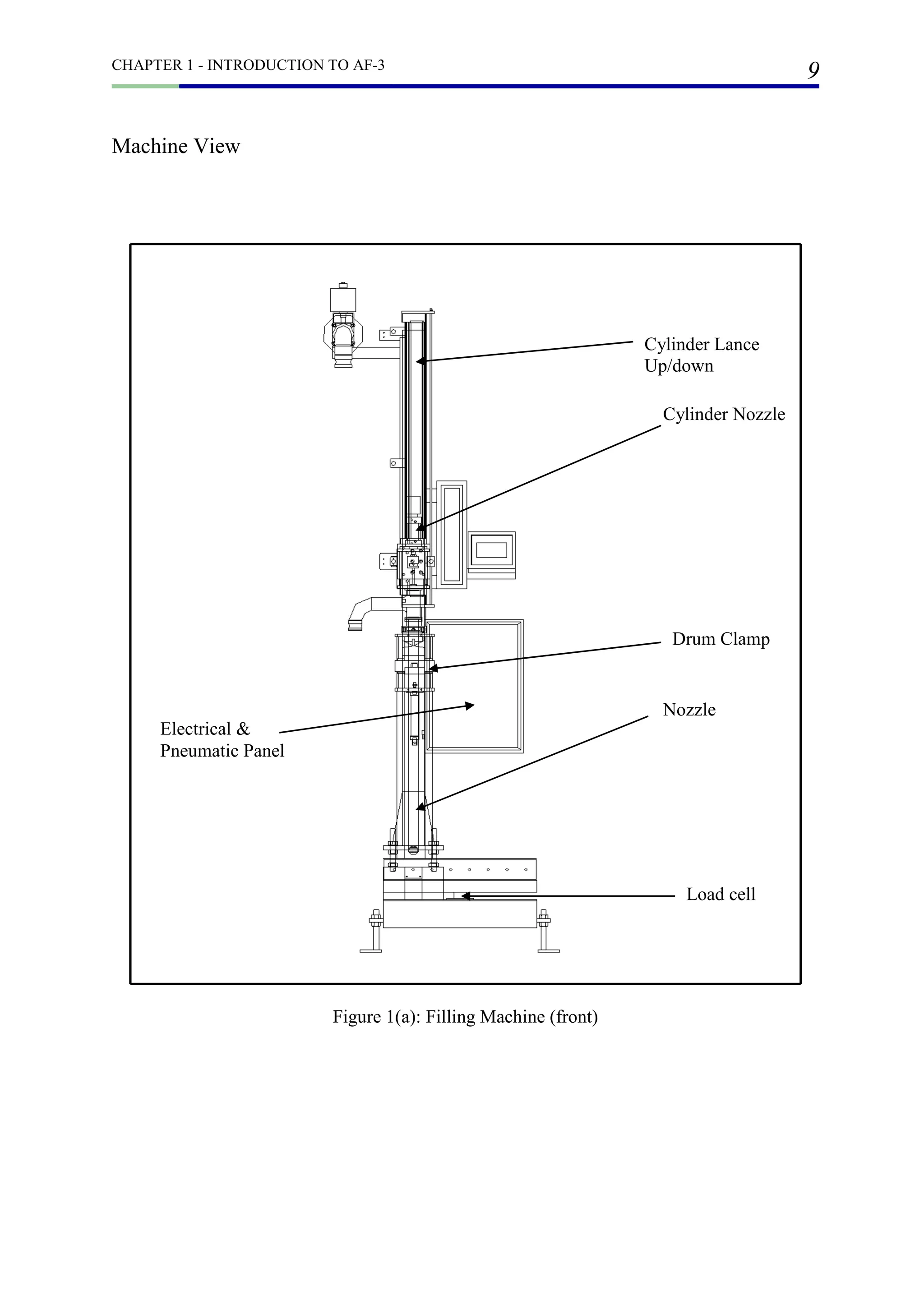

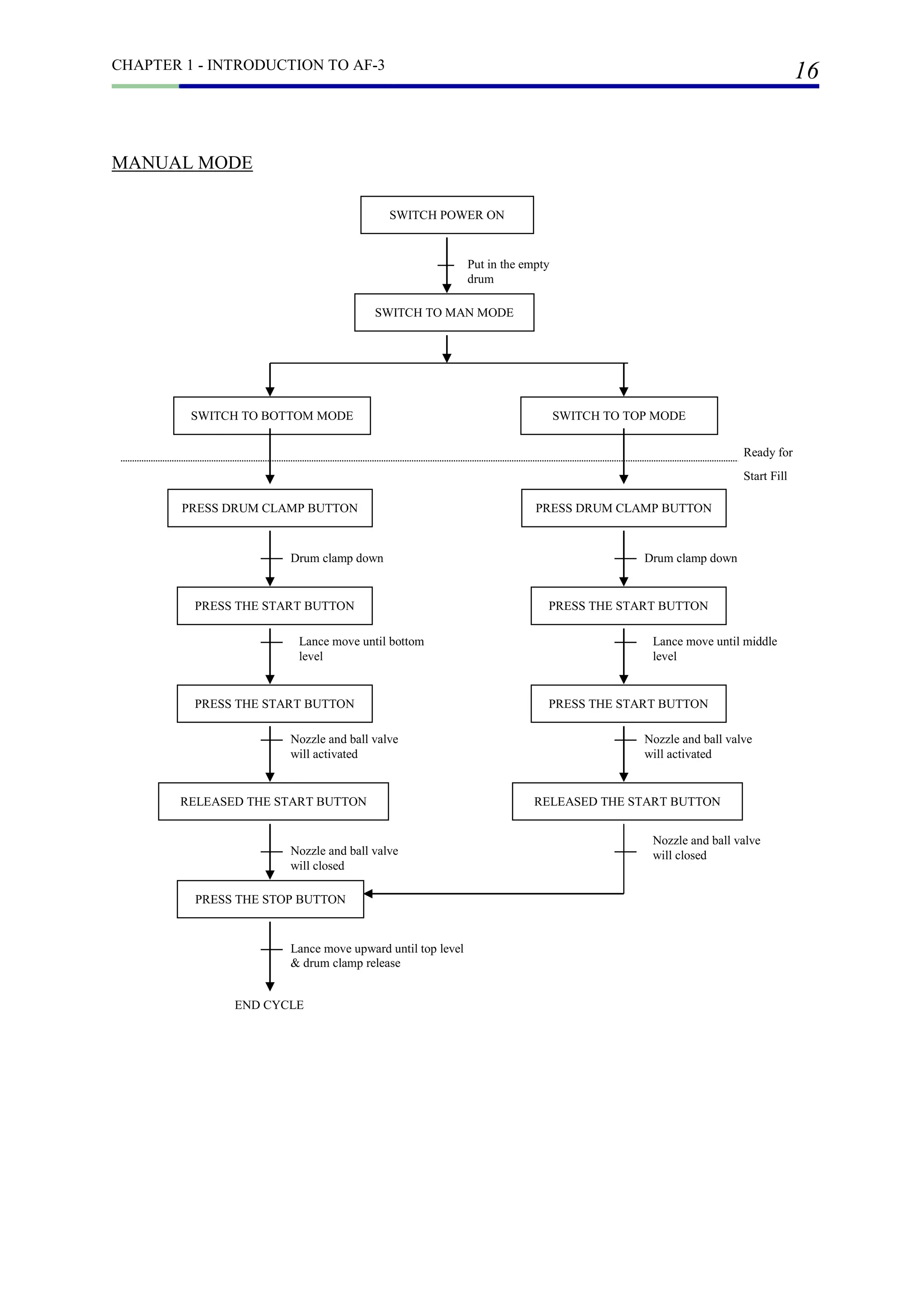

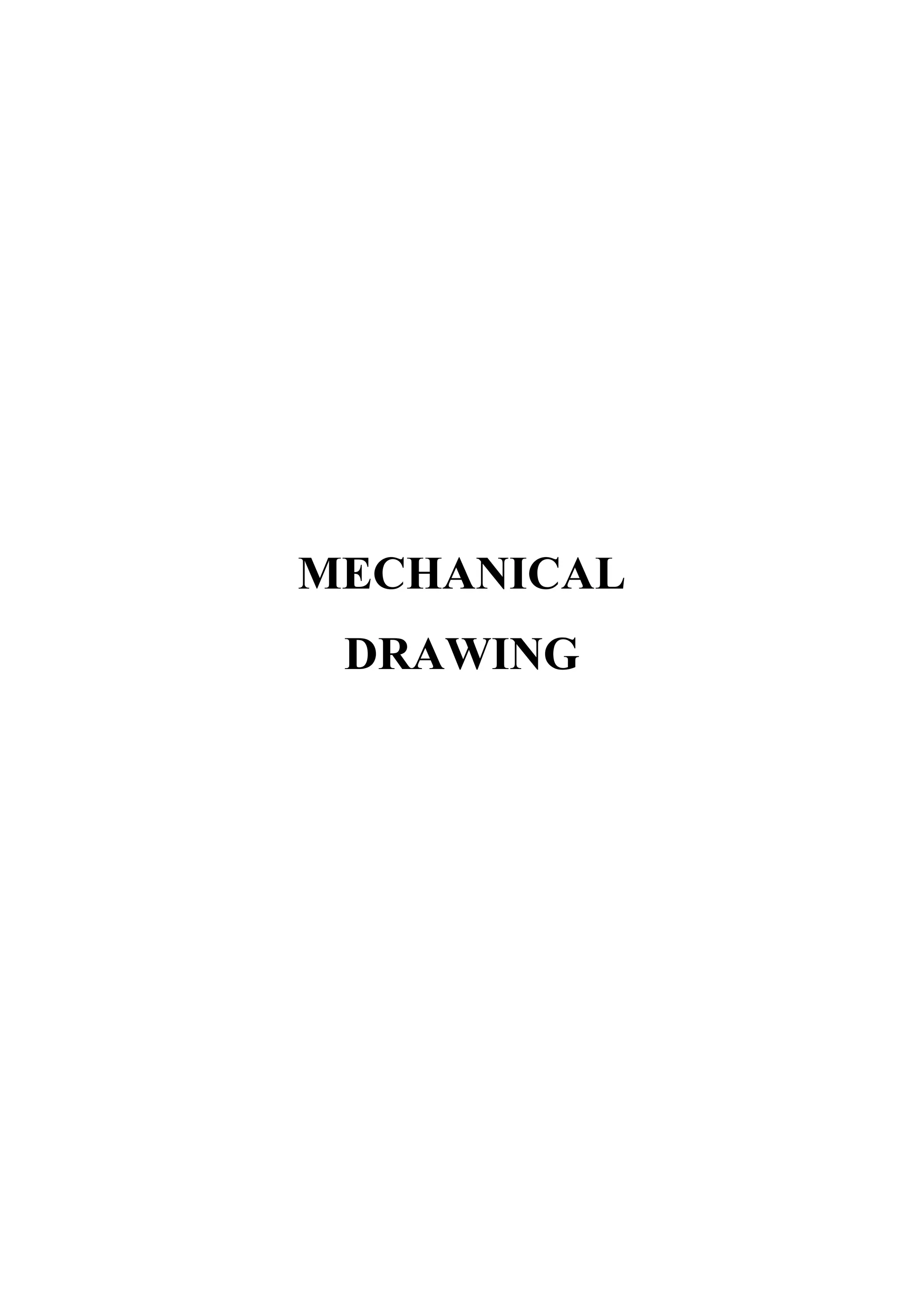

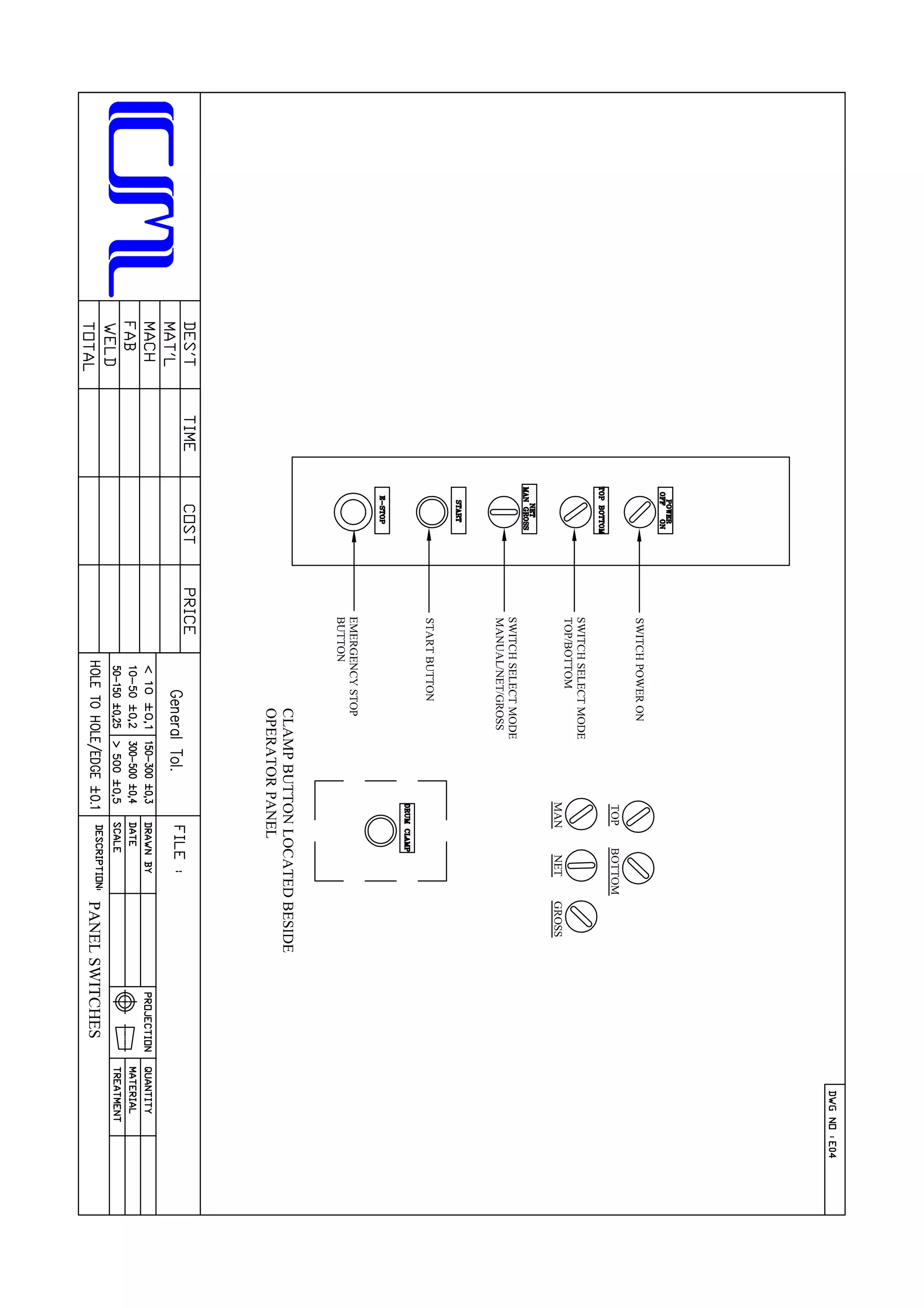

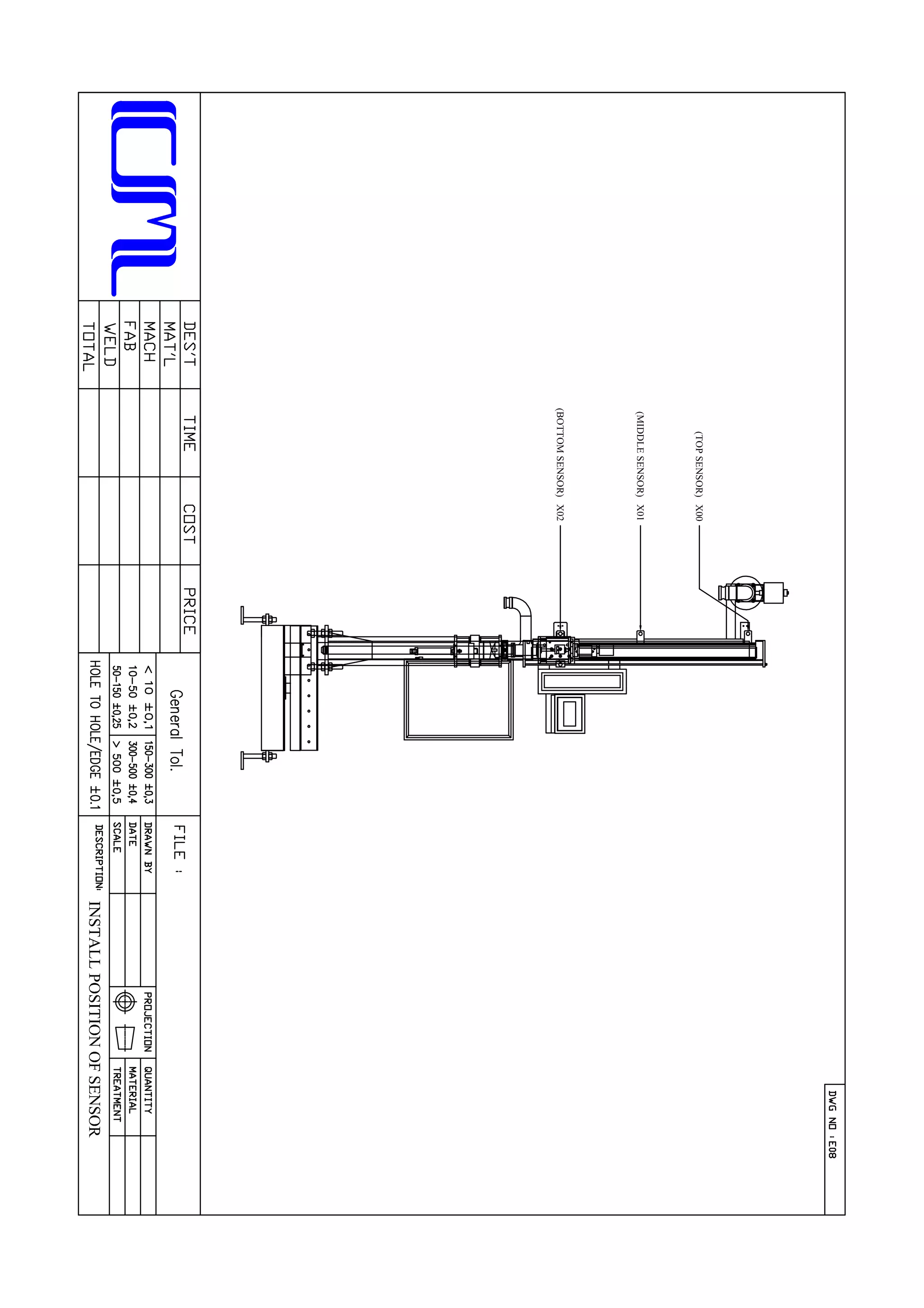

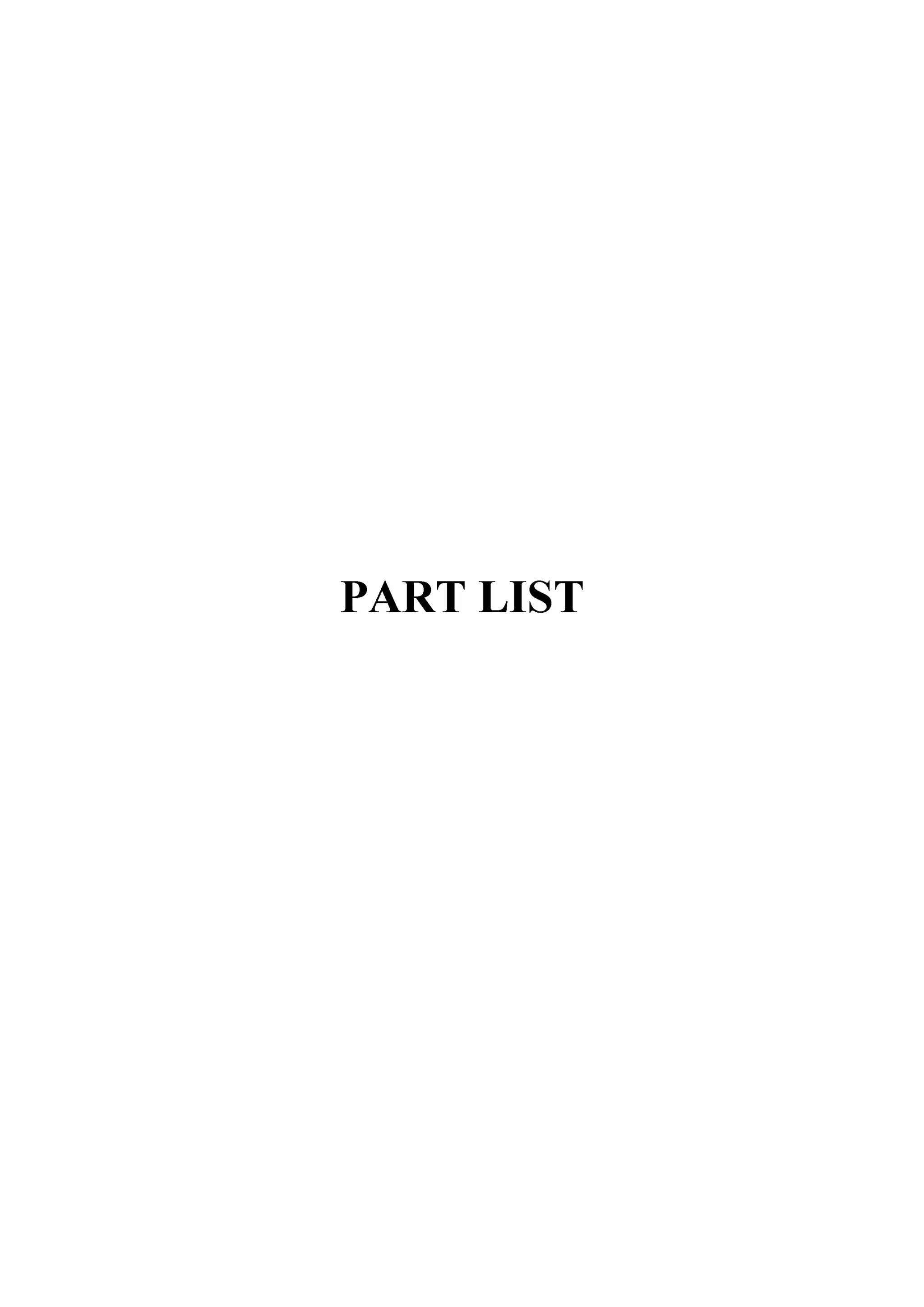

When depressed [START] button, it will start filling operation in auto.

START

TOP

Top mode is mean when the filling action start the lance descends to “MIDDLE” position

(under bunghole) until final weight reached.

BOTTOM

Bottom mode is mean when the filling action start the lance descends to “BOTTOM”

position of drum. While the optional prelim weight is reached, the lance will ascend to

“MIDDLE” position (under bunghole).

When switched ‘ON’, the switch is illuminated and power is applied to the MCB (switched

‘ON’). The 230V AC power has applied to weighing indicator and 24V DC power supply.

POWER

OFF ON

MODE

TOP BOTTOM

NET

MAN GROSS

MAN

This is manual mode when operator depressed [START] button, the lance will descends

down to position. Then depressed and hold the [START] button, the nozzle and ball valve

will open. When [START] button is released, the nozzle and ball valve will close. If [E-

STOP] button depressed, the lance will ascends to “UP” or “HOME” position.

NET

This is “NET” fill with auto tare. When empty drum placed into the weighing platform, the

weighing indicator will register the empty drum weight. When in this mode after depressed

the [START] button, the indicator will tare the empty drum weight and display will return

to 0.0KG but it is at “NET” reading.

GROSS

This is “GROSS” fill without tare. The empty drum weight is not tare and the display is at

“GROSS” reading.](https://image.slidesharecdn.com/af3-instructionmanual-cmspecialist-180919151900/75/Af3-instruction-manual-cm-specialist-14-2048.jpg)

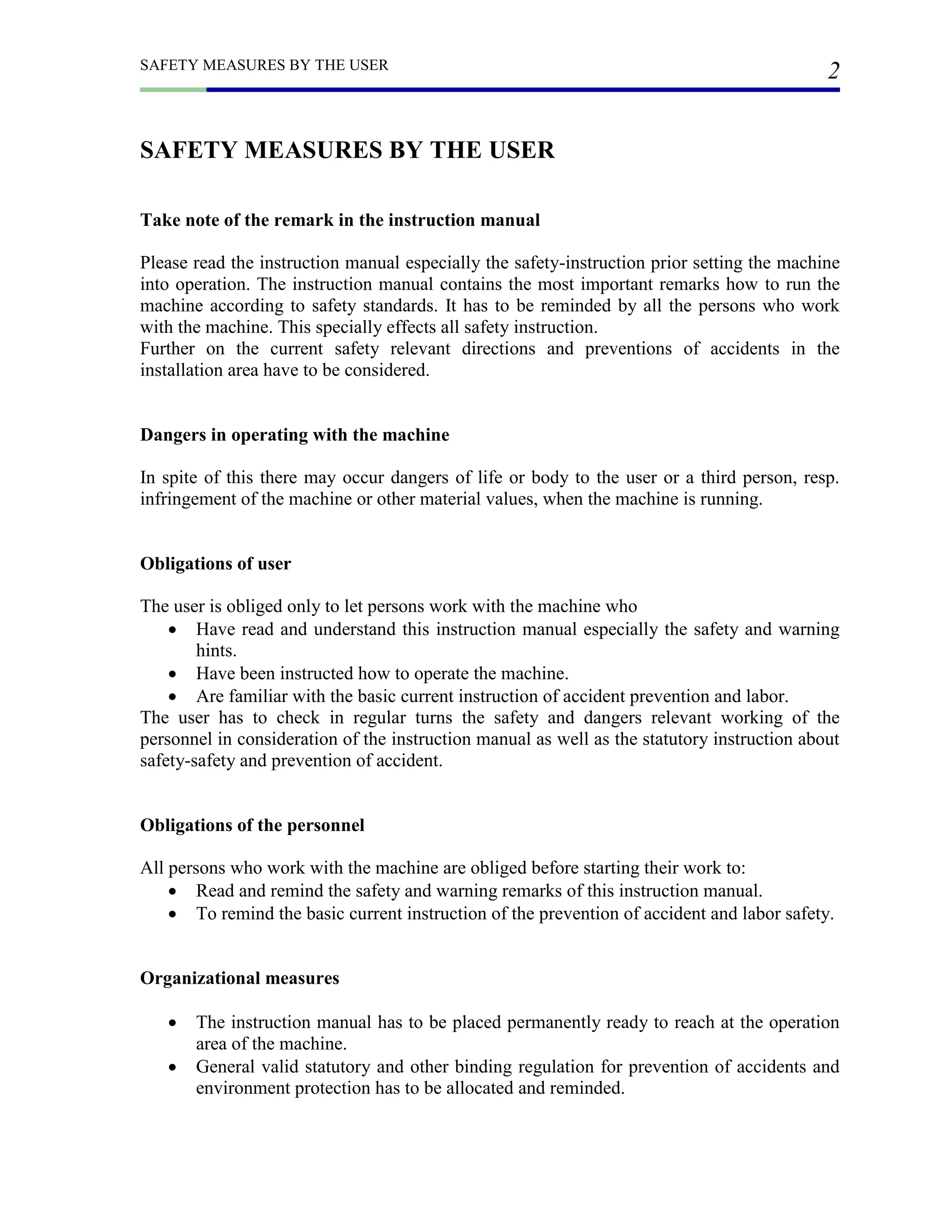

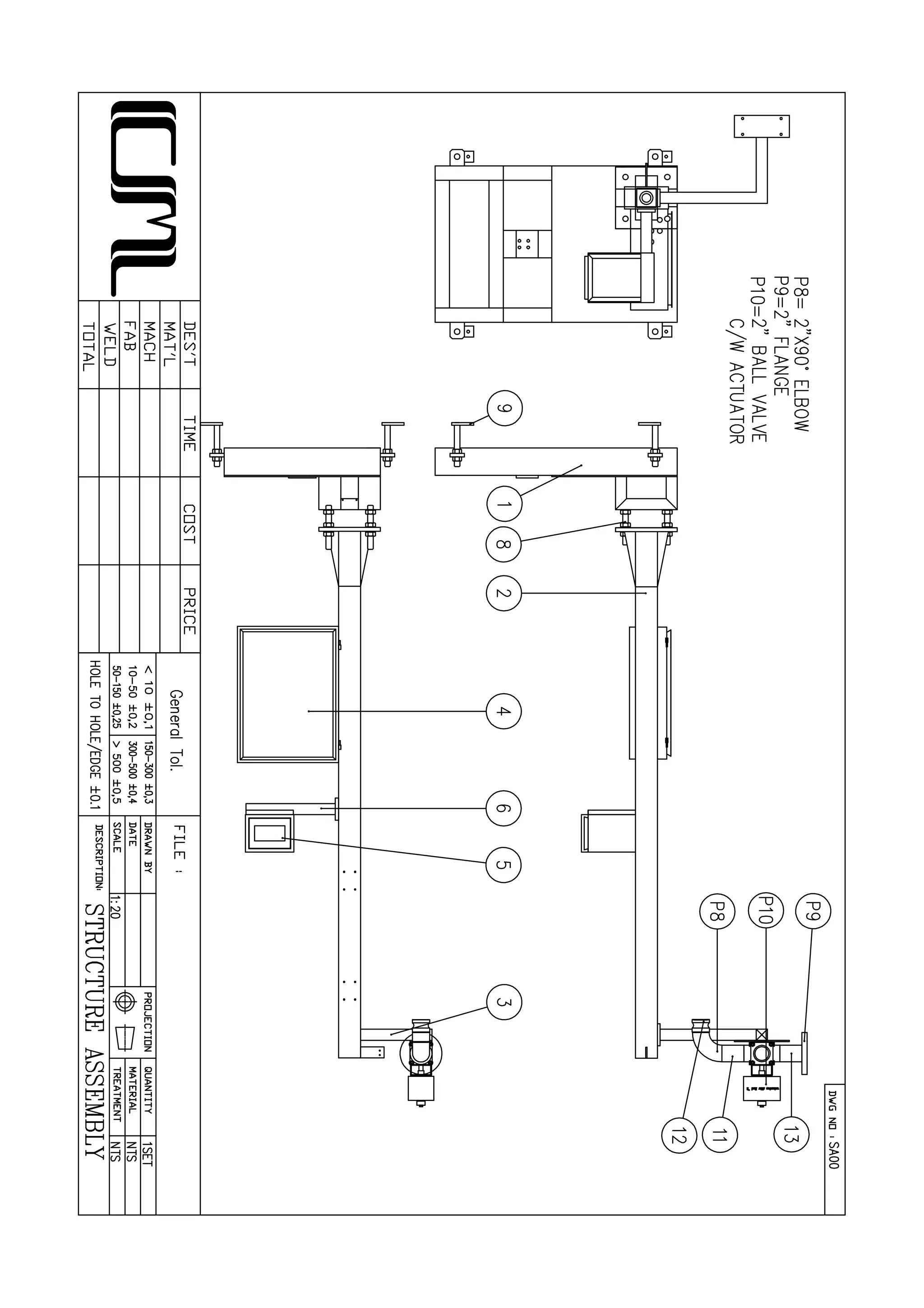

![CHAPTER 1 - INTRODUCTION TO AF-3

12

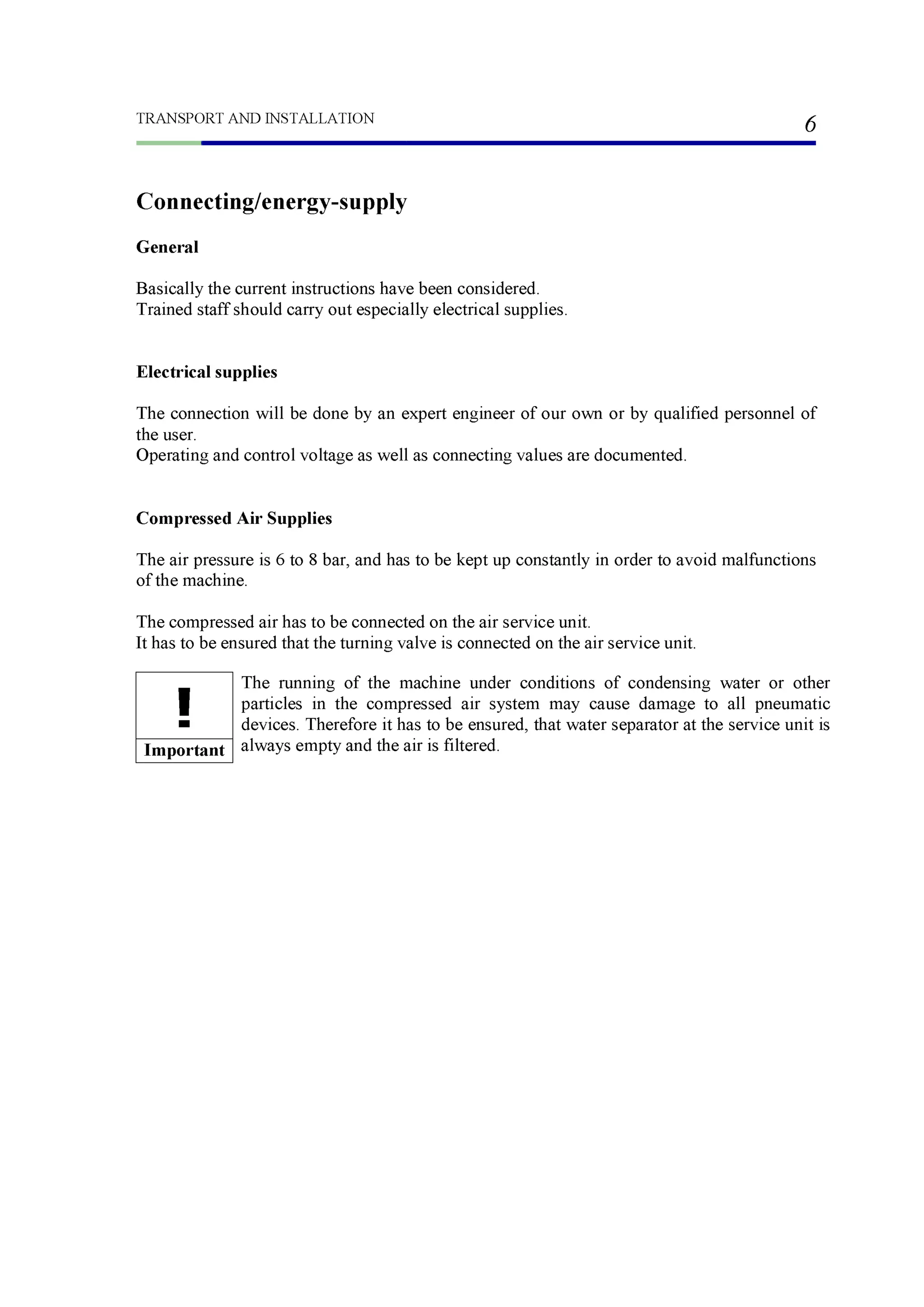

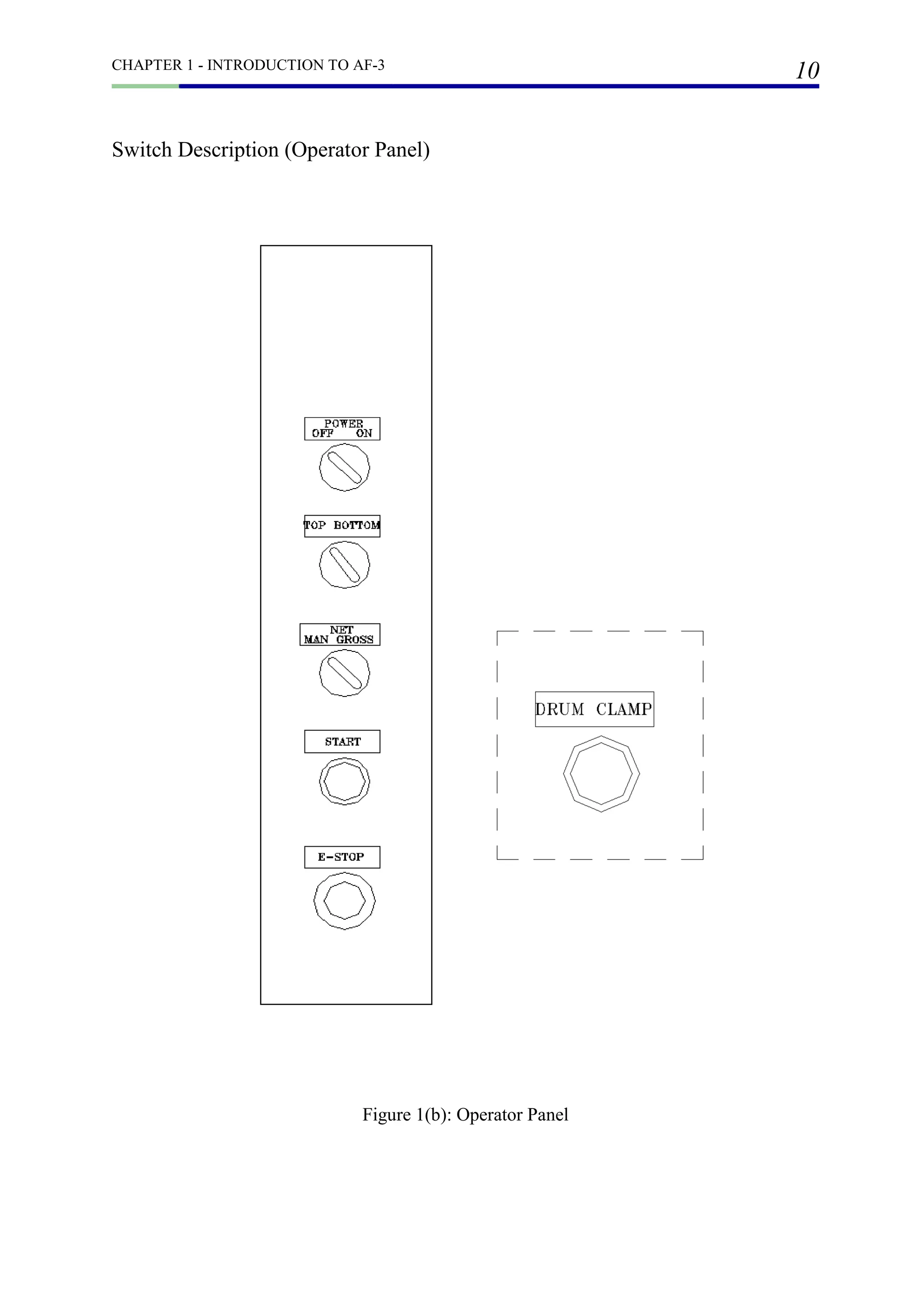

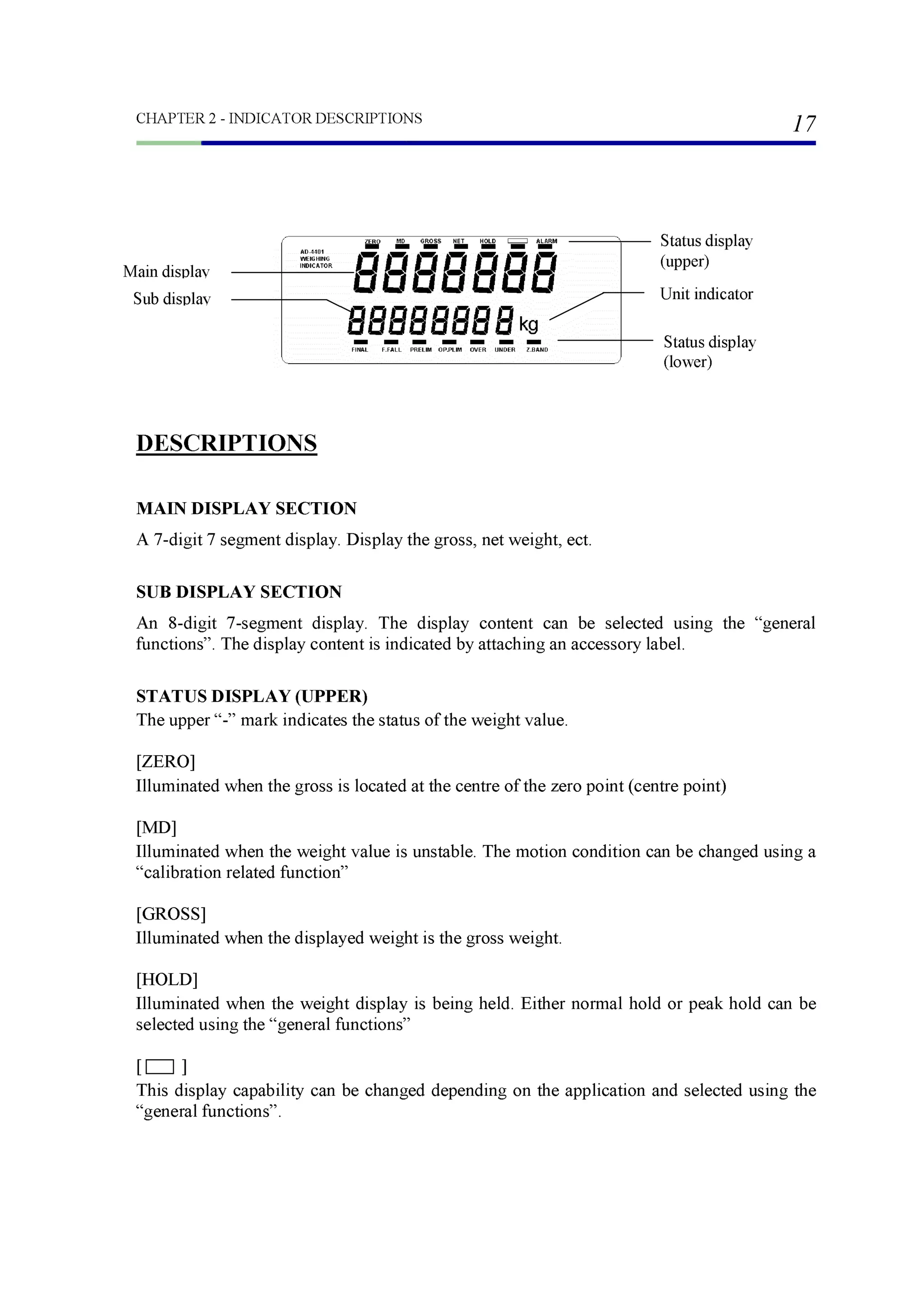

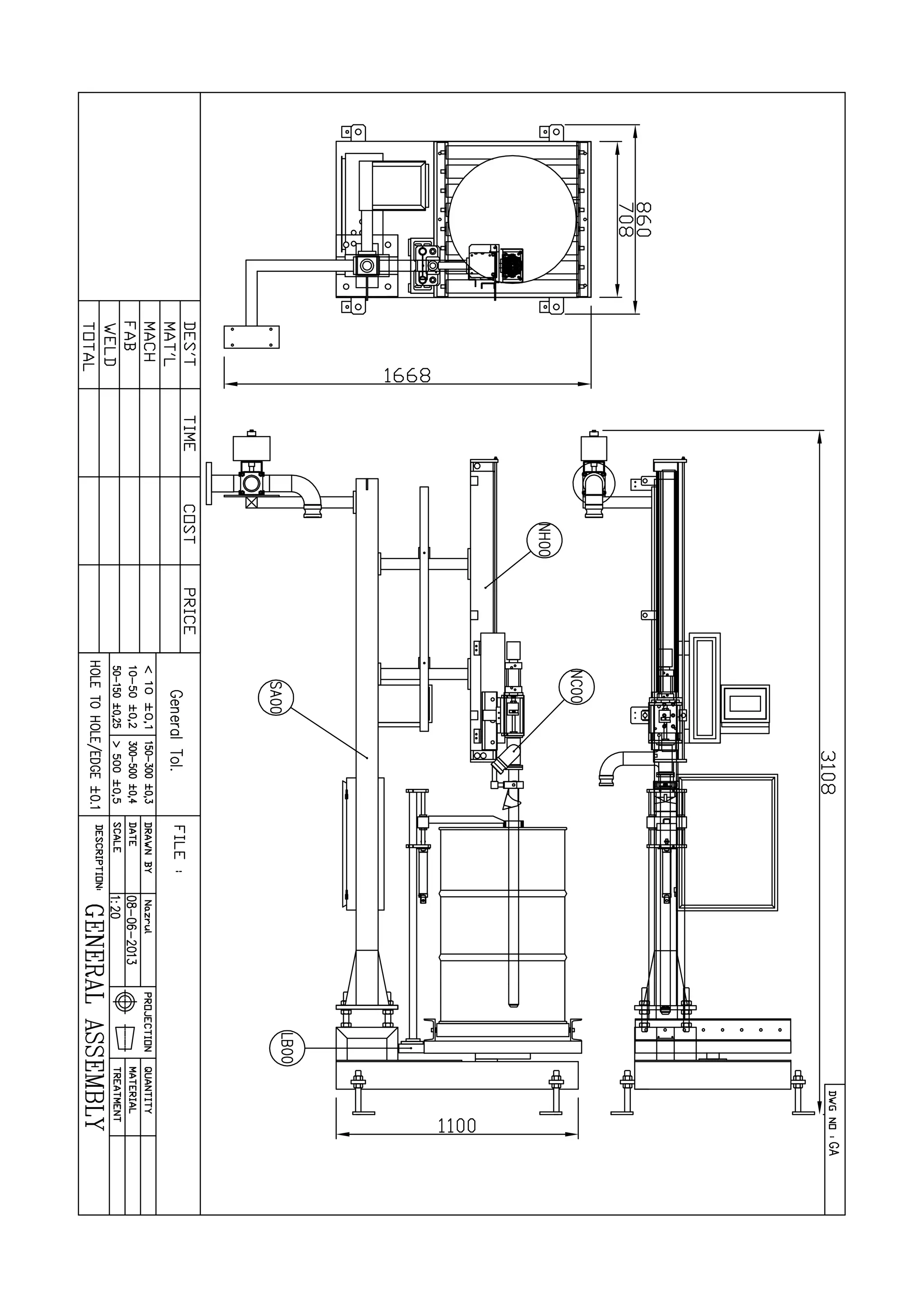

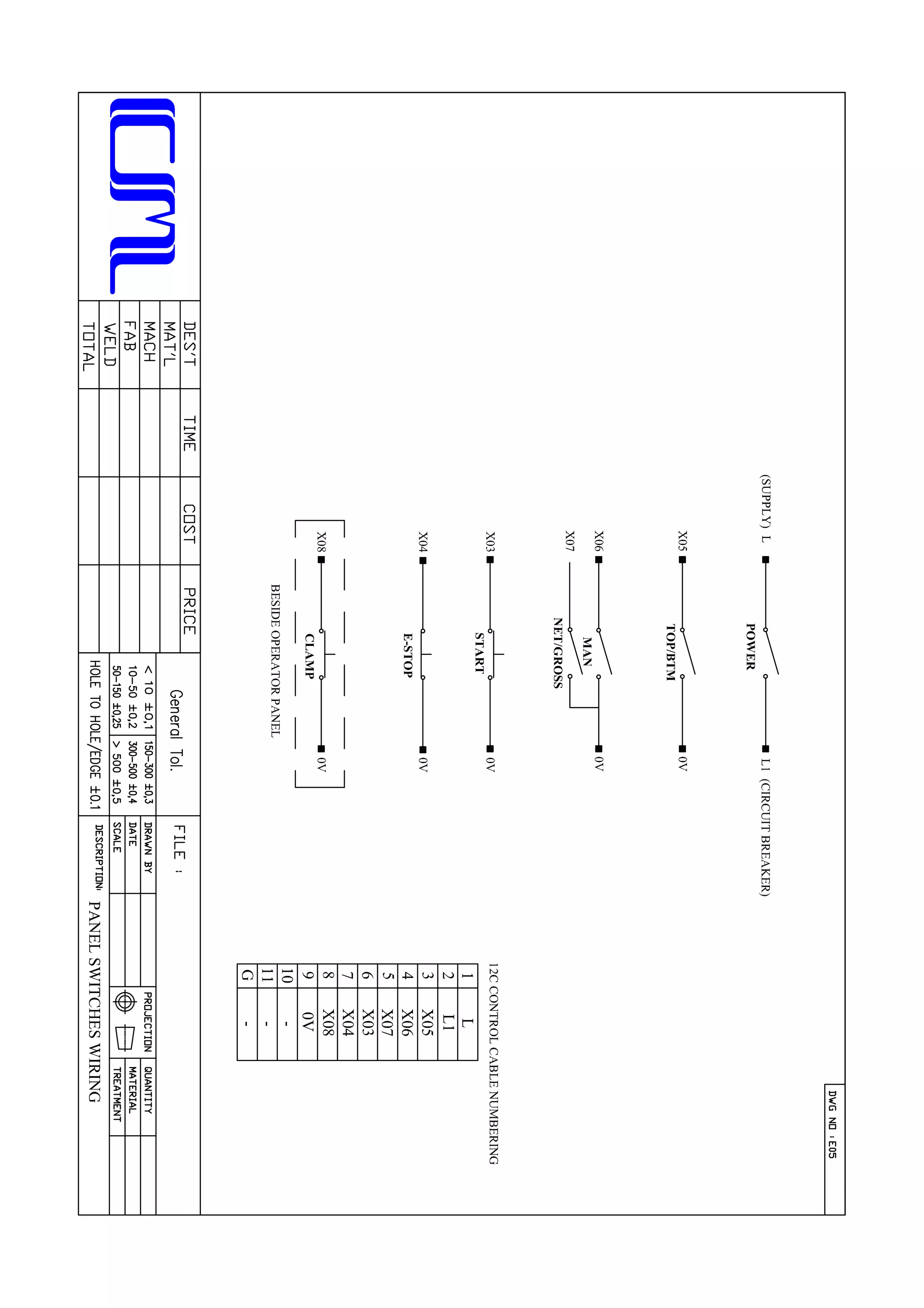

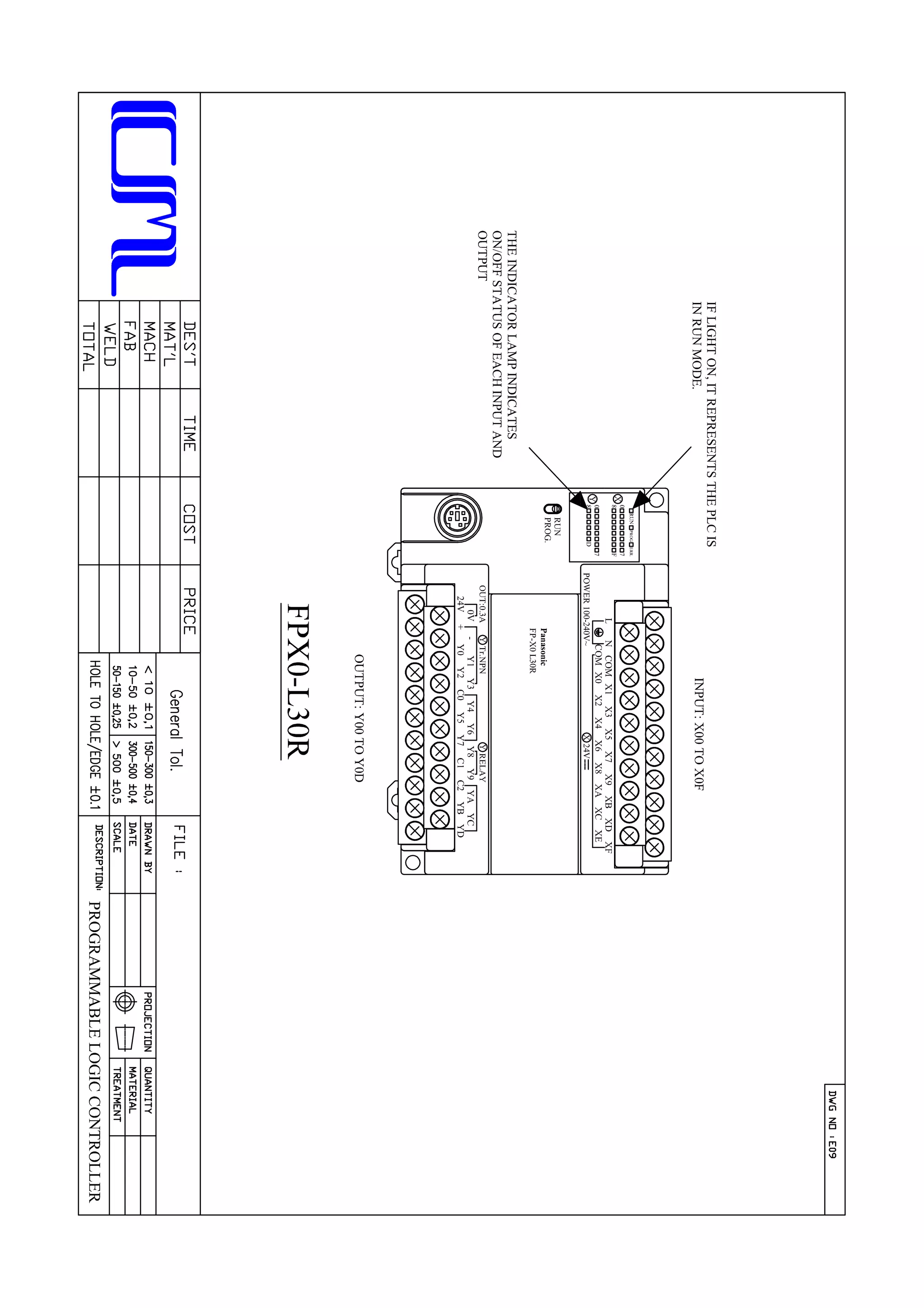

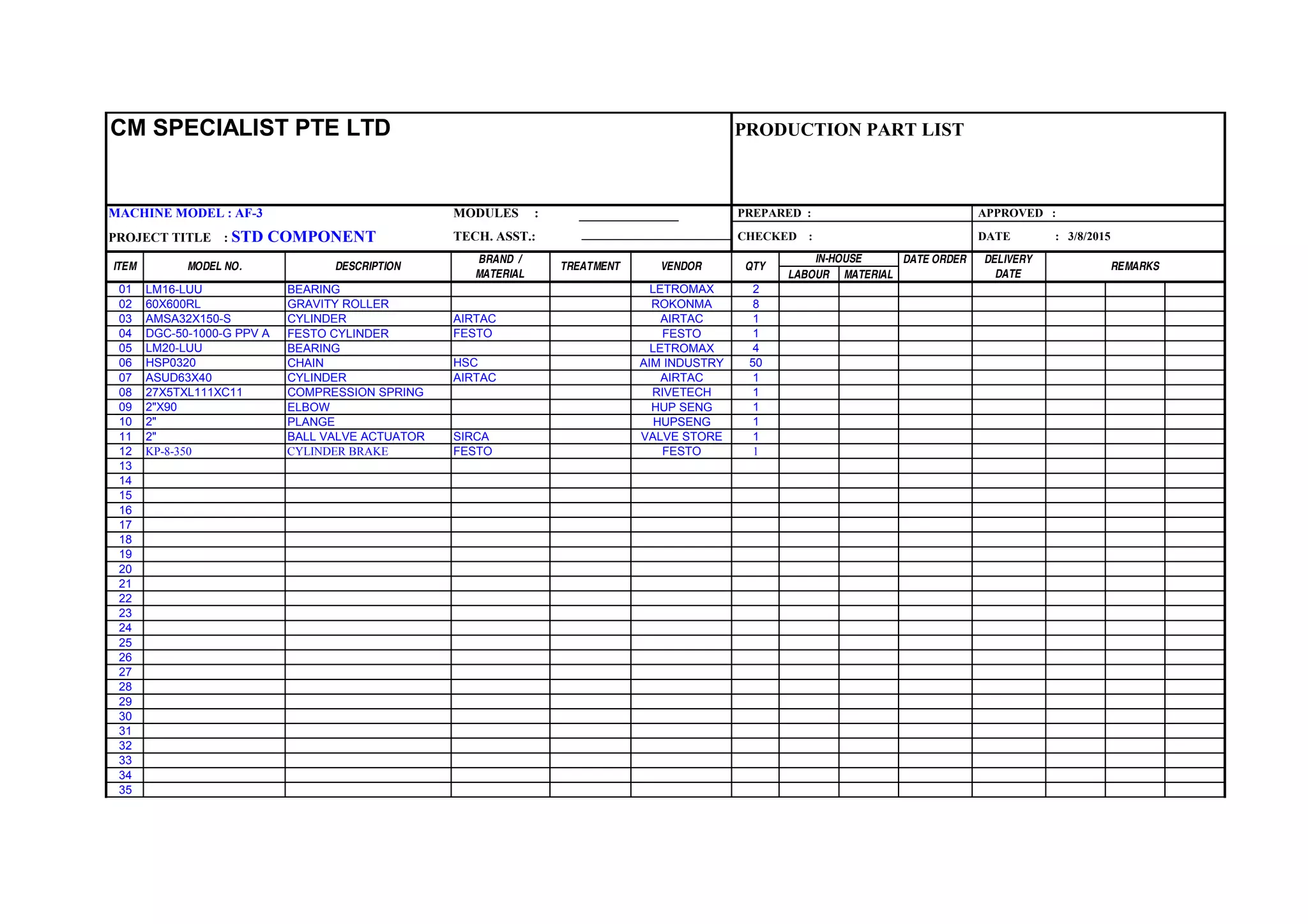

In case of emergency, when depressed [E-STOP] button, entire machine will stop all the

operation. The nozzle and ball valve will close; the lance will retract back to “UP” or

“HOME” position.

E - STOP

DRUM CLAMP

When depressed [DRUM CLAMP] button, the drum clamp device will clamp the

bunghole of drum.](https://image.slidesharecdn.com/af3-instructionmanual-cmspecialist-180919151900/75/Af3-instruction-manual-cm-specialist-15-2048.jpg)

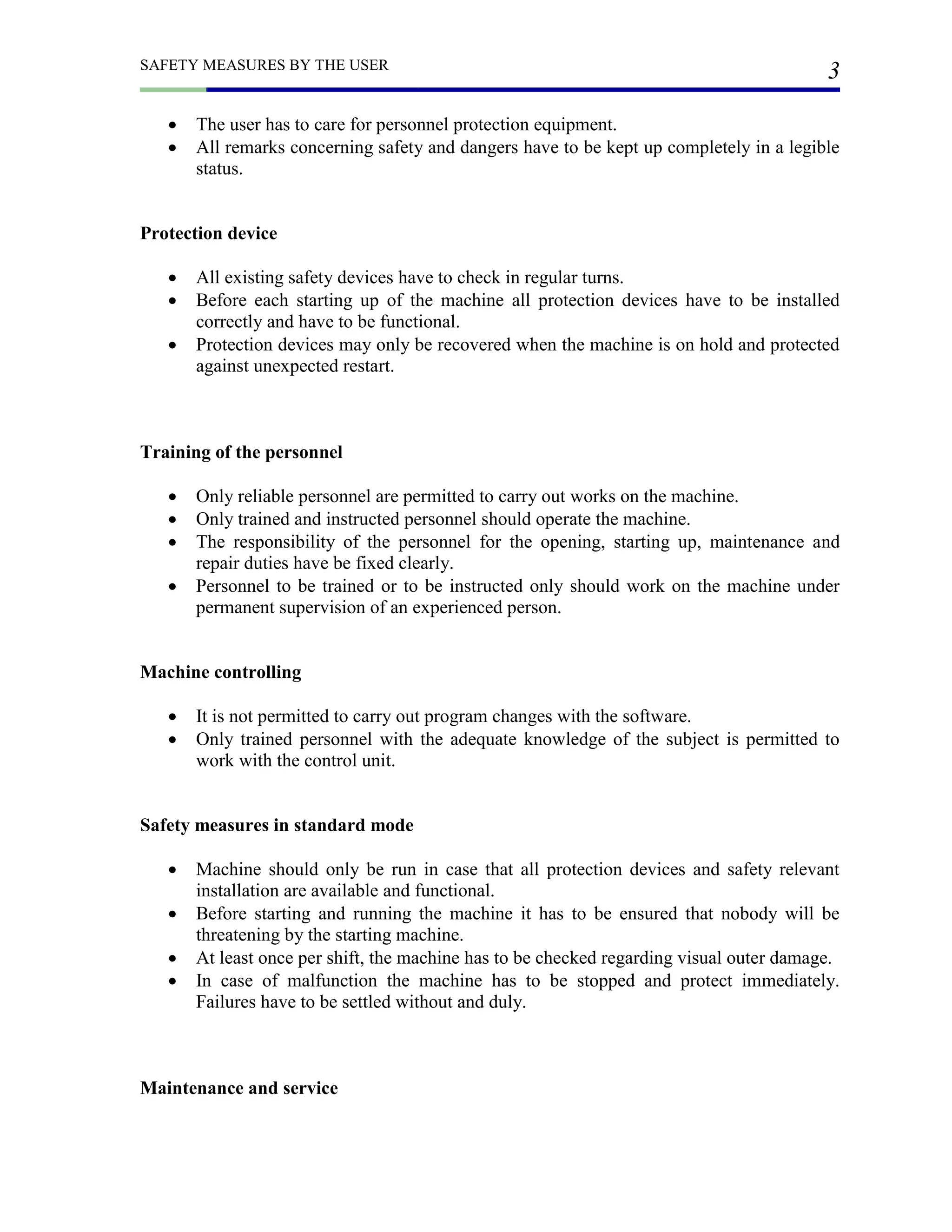

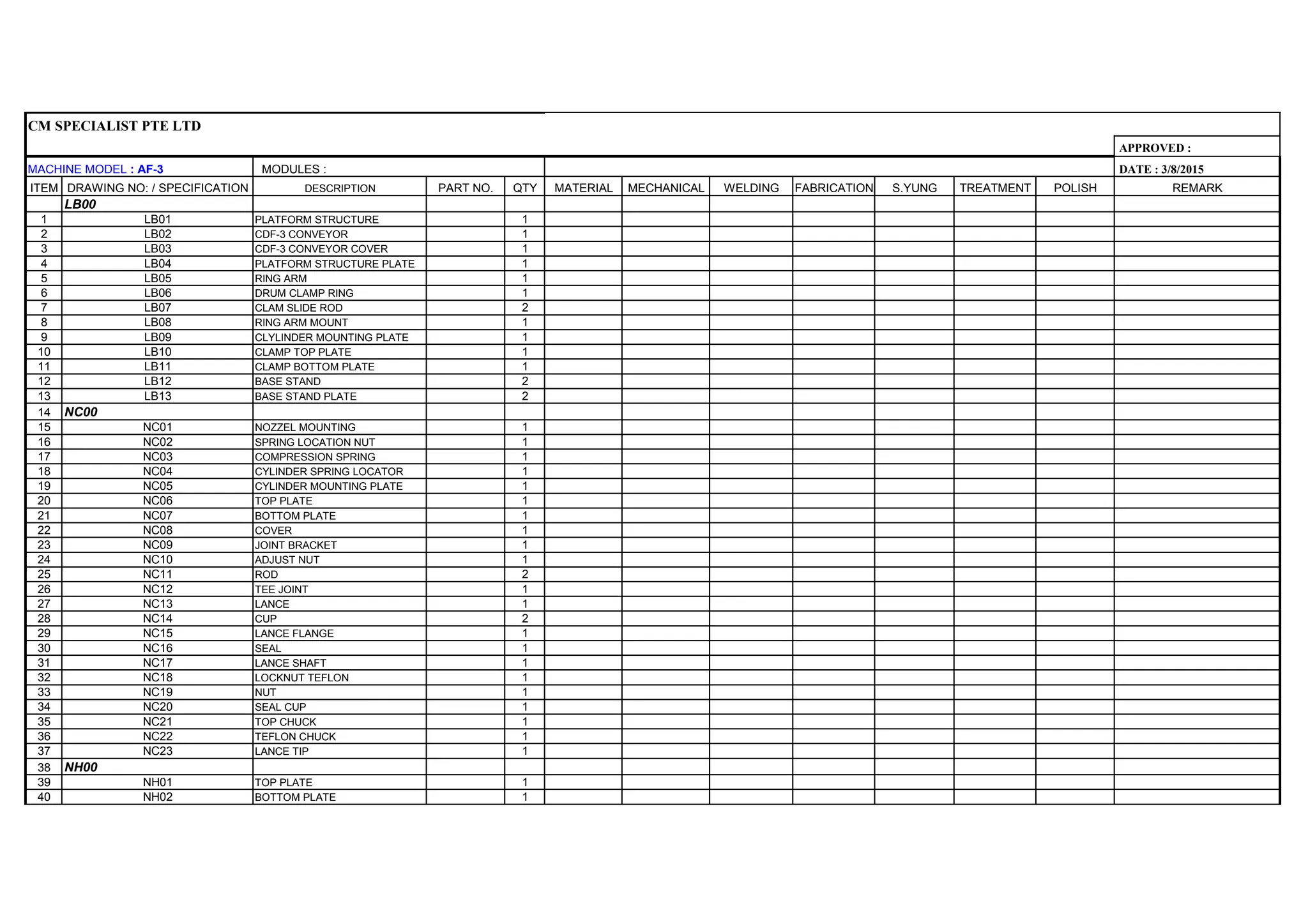

![CHAPTER 1 - INTRODUCTION TO AF-3

13

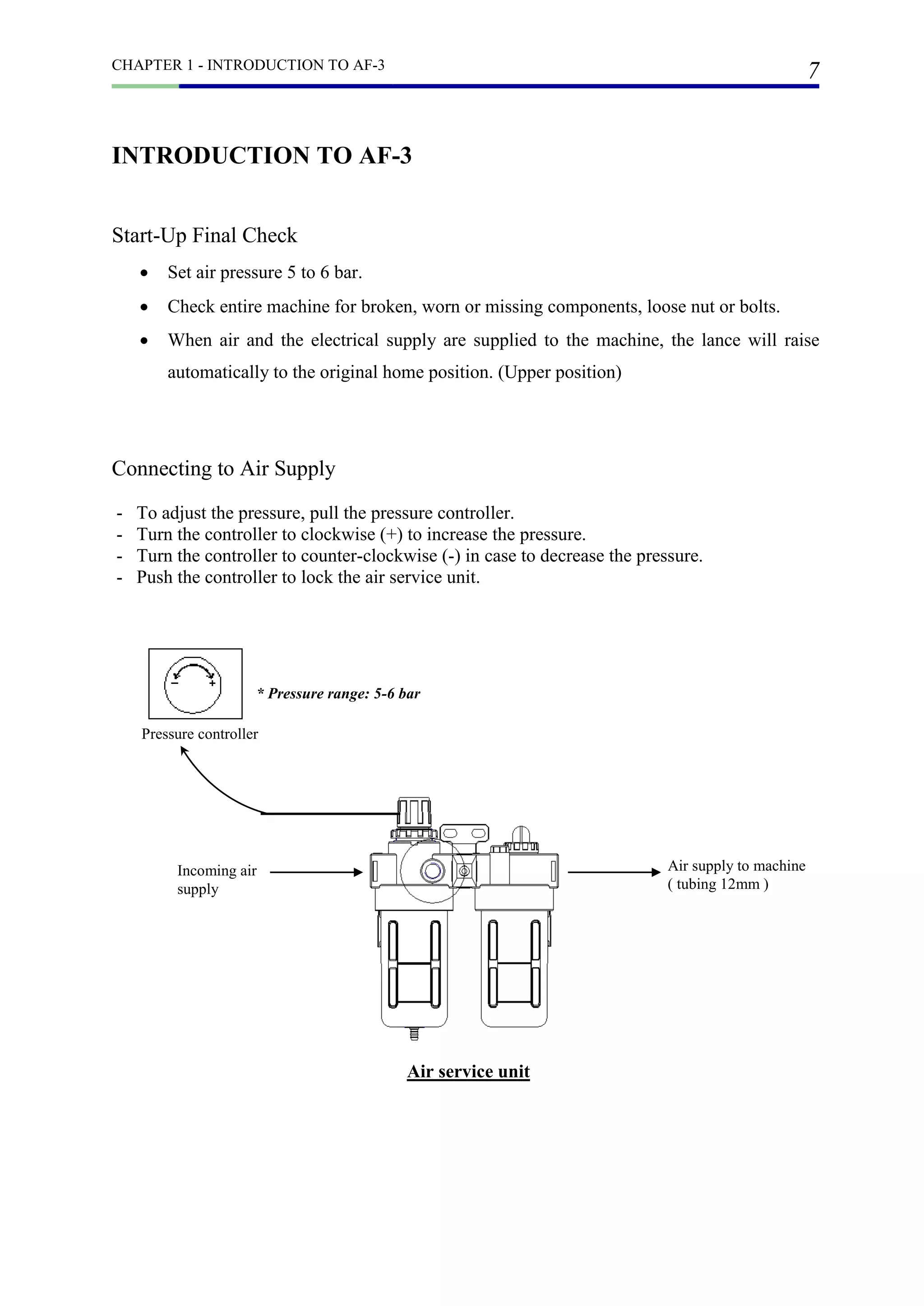

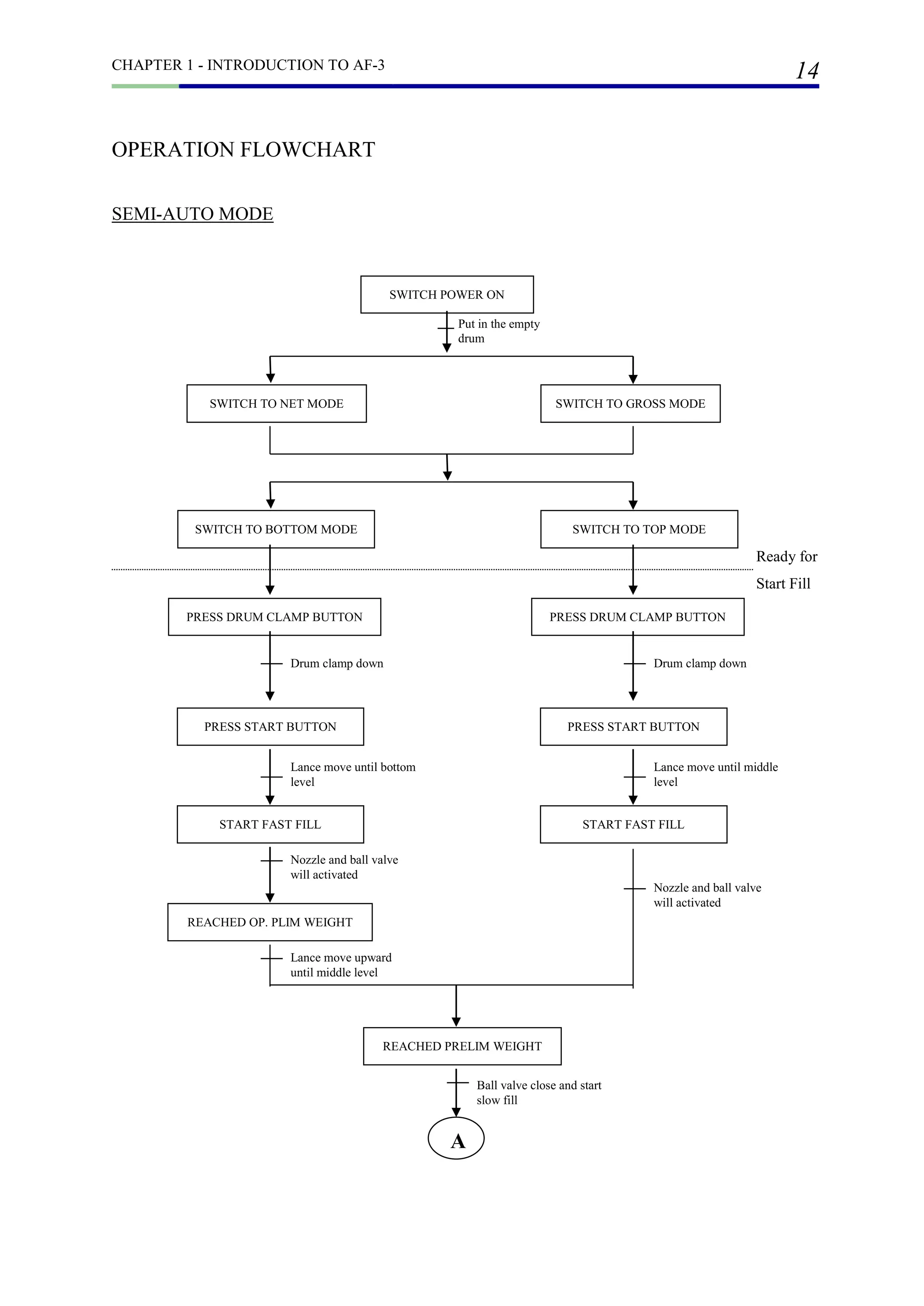

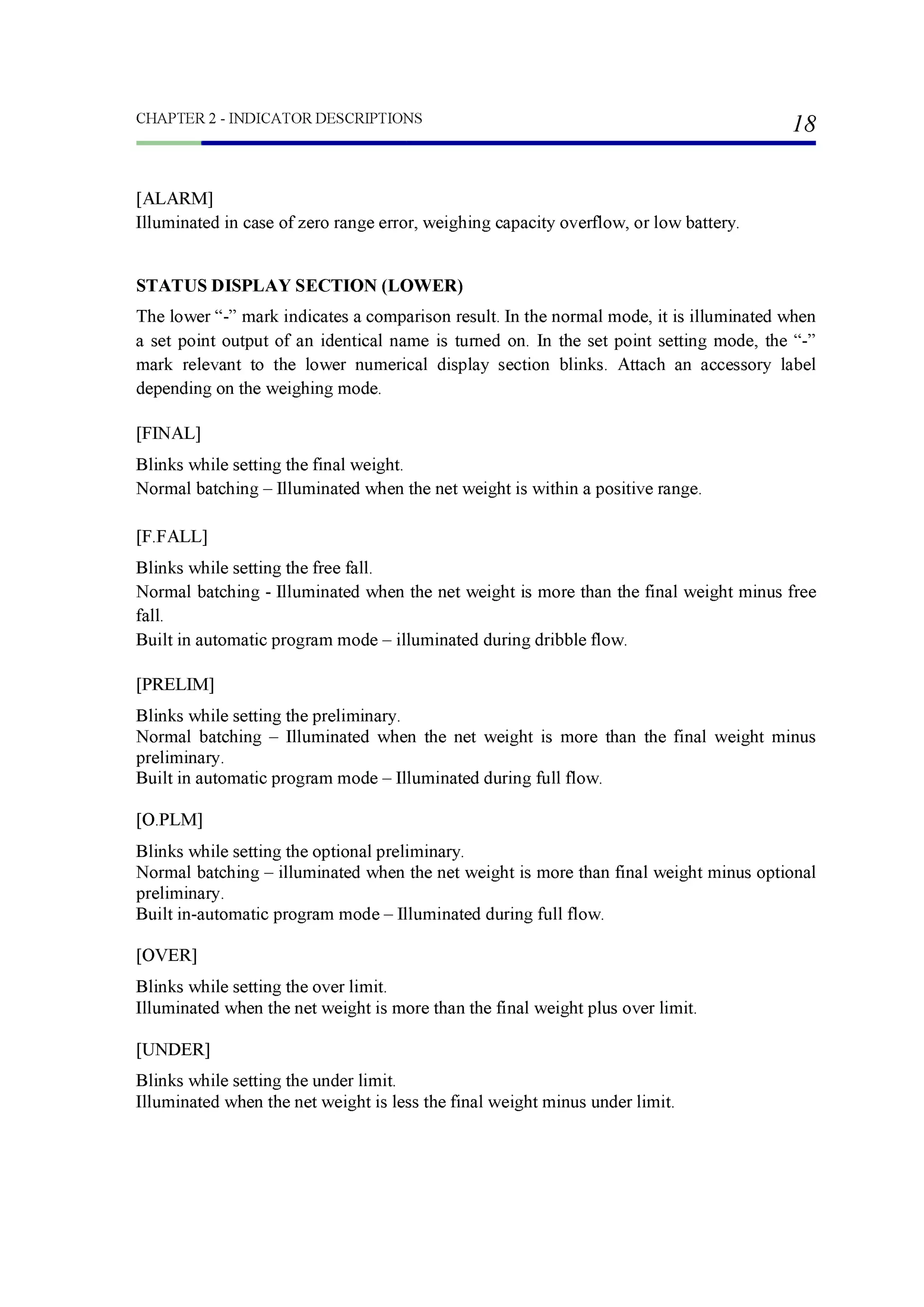

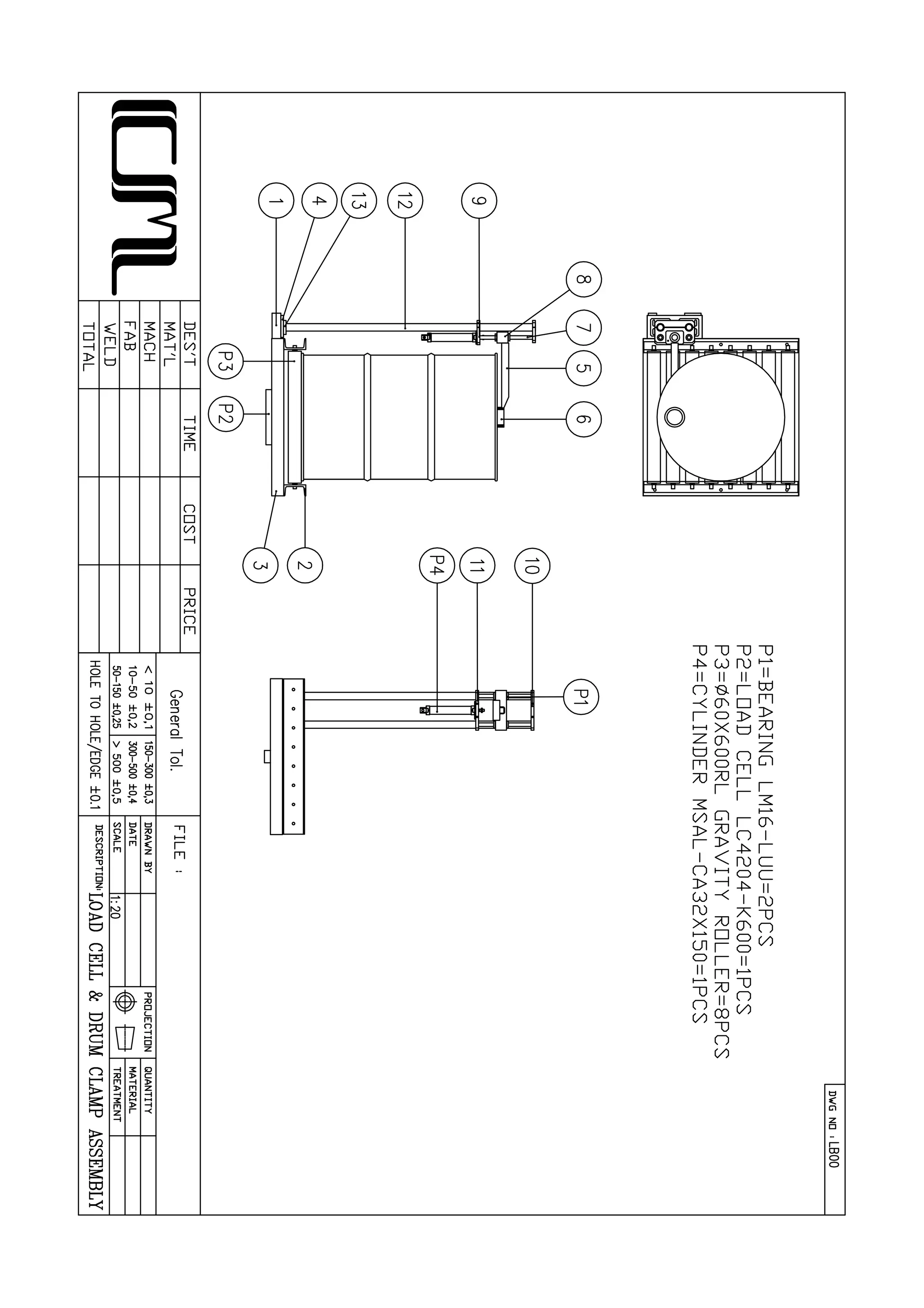

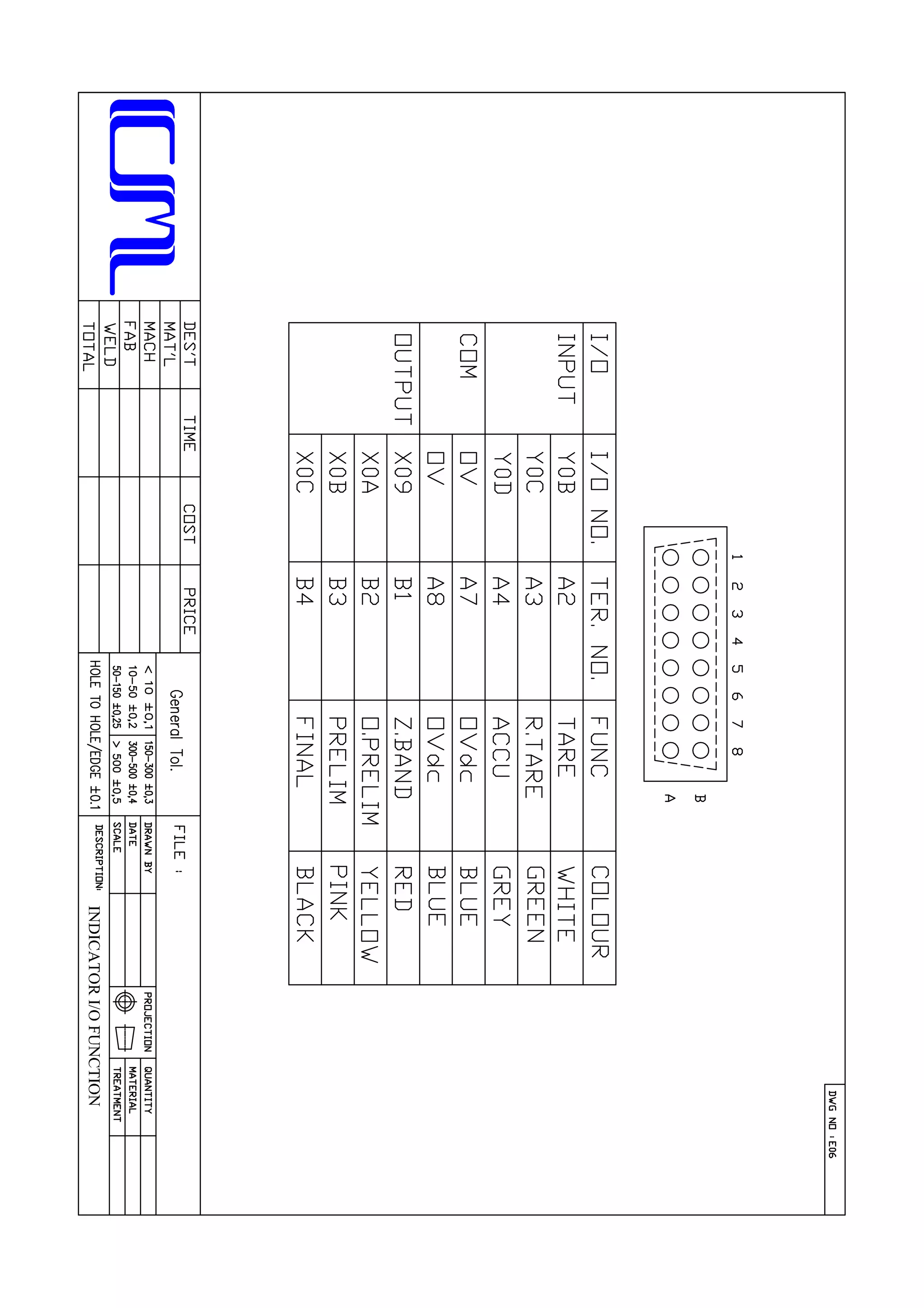

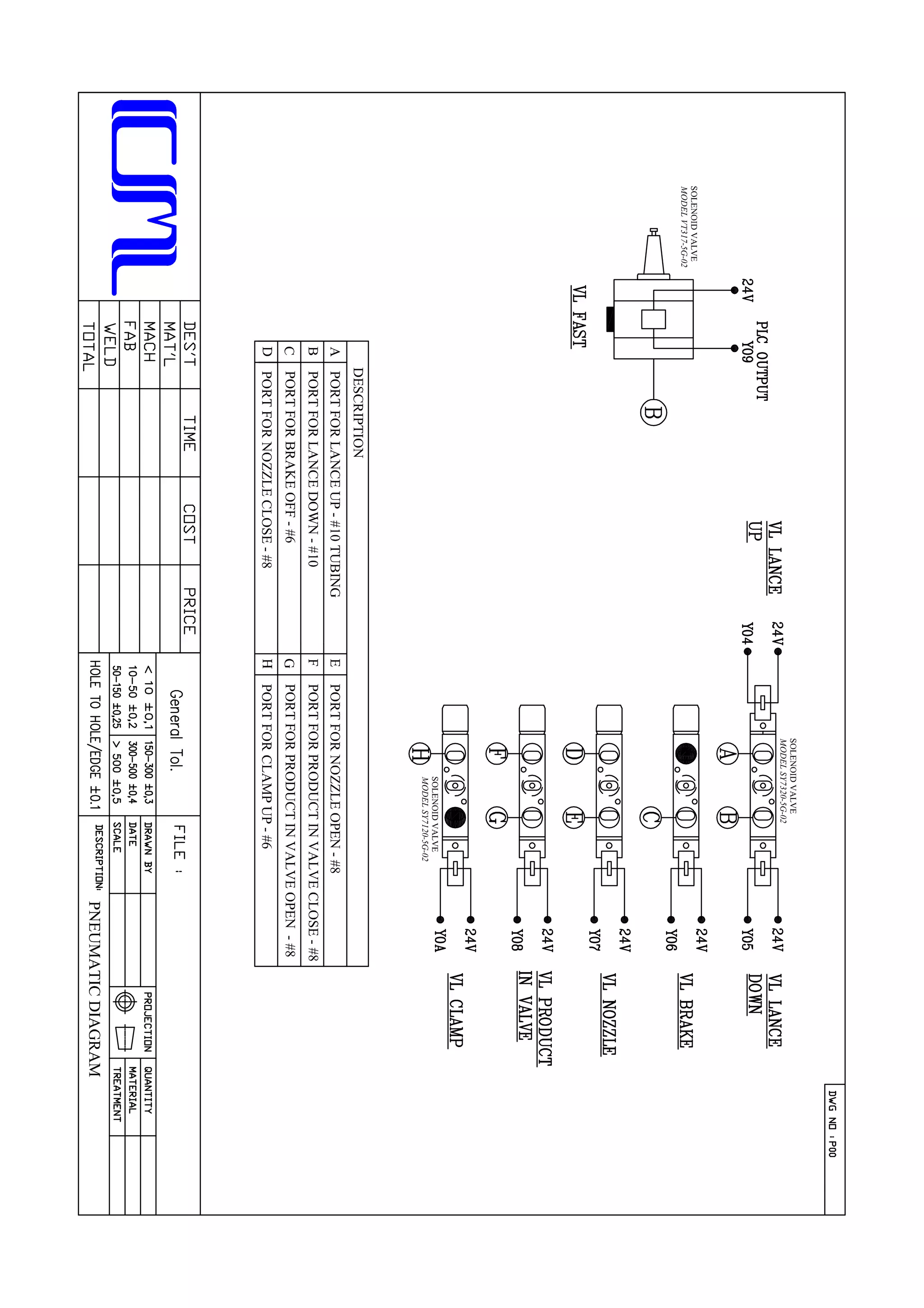

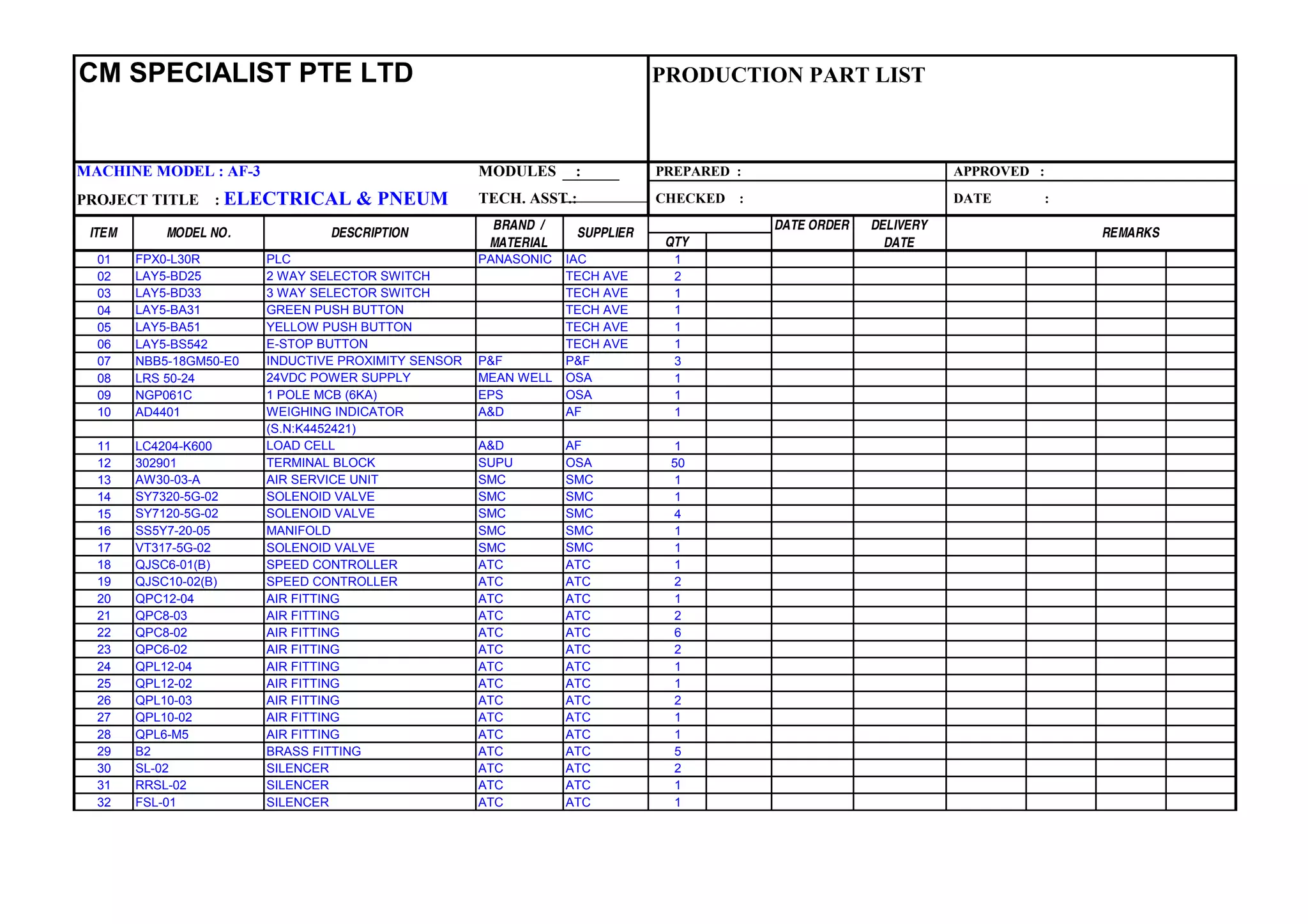

Operation Procedures

With nothing on the weighing platform, the digital weighing indicator should indicate

0.0kg. If the display is not at 0.0kg, press the [ZERO] button on the weighing indicator

to get 0.0kg.

Operator preset on weighing indicator for desired “ZERO BAND”, “OPTIONAL

PRELIM”, “PRELIM”, “FINAL” and “FREE FALL” (if needed) value for filling.

When the empty drum placed into the weighing platform, the operator will depress

[DRUM CLAMP] button to locate the bunghole position. Then press [START] button.

If bottom mode, the lance will descend to “BOTTOM” position or if top mode, the

lance will descends to “MIDDLE” position. If the operation in “GROSS” modes, the

empty drum wills not tare and indicator display is at “GROSS” reading. If the

operation in “NET” mode, the empty drum weight will auto tare to 0.0kg before start

filling, but it is “NET” reading.

At the top mode, the filling operation start fill product into drum, while the lance

descends to “MIDDLE” position which is approx. 50mm below the bunghole.

At the bottom mode, the filling operation start fill product into drum, while the lance

descends to bottom position of the drum, and raise to middle position, when the

optional prelim weight was reach.

When the “PRELIM” weight is reached, the ball valve will close and slow fill will be

activated to reduce the flow rate.

When the “FINAL” weight is reached, the nozzle will close completely. And the lance

device will ascend back to “UP” or “HOME” position.](https://image.slidesharecdn.com/af3-instructionmanual-cmspecialist-180919151900/75/Af3-instruction-manual-cm-specialist-16-2048.jpg)

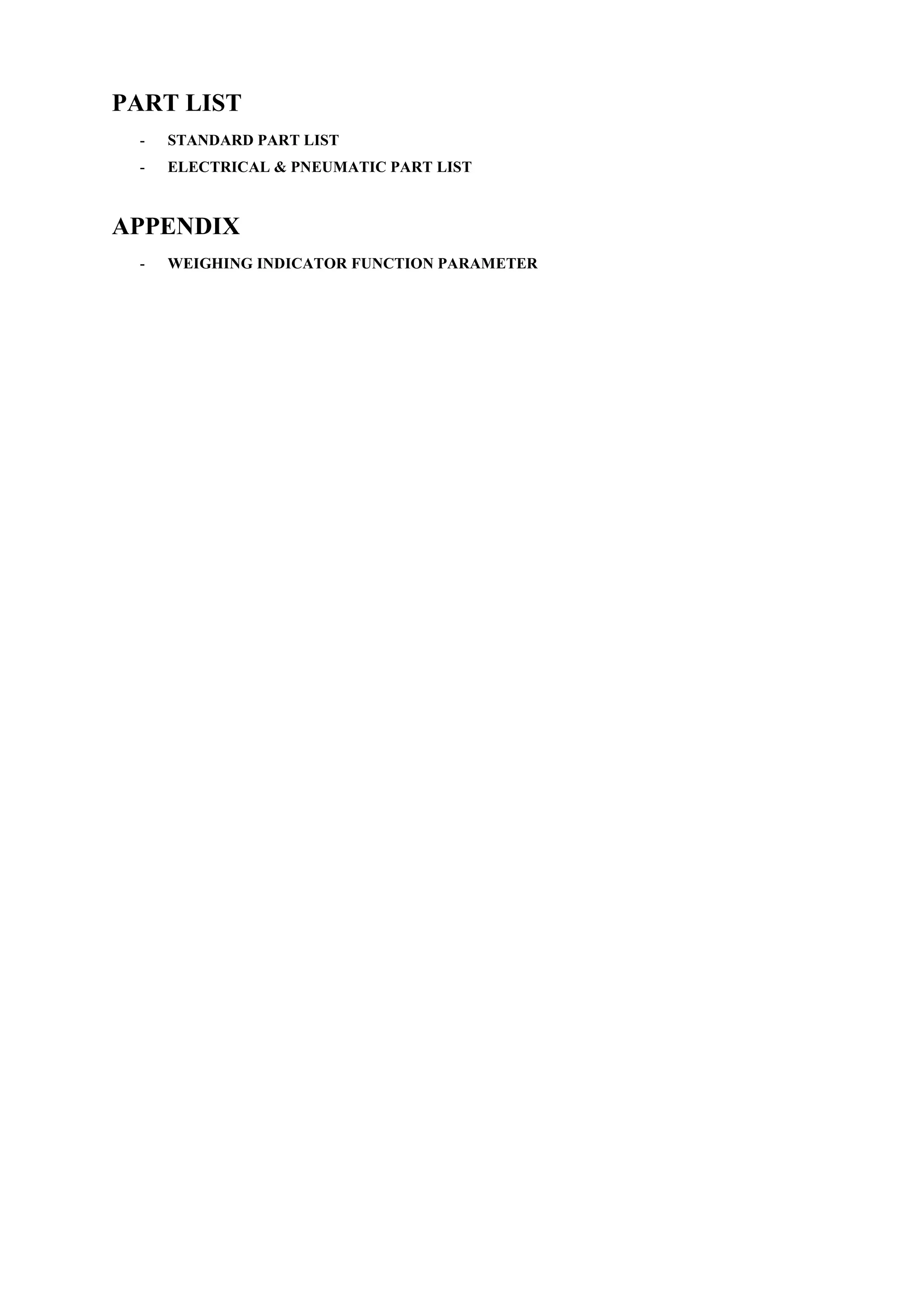

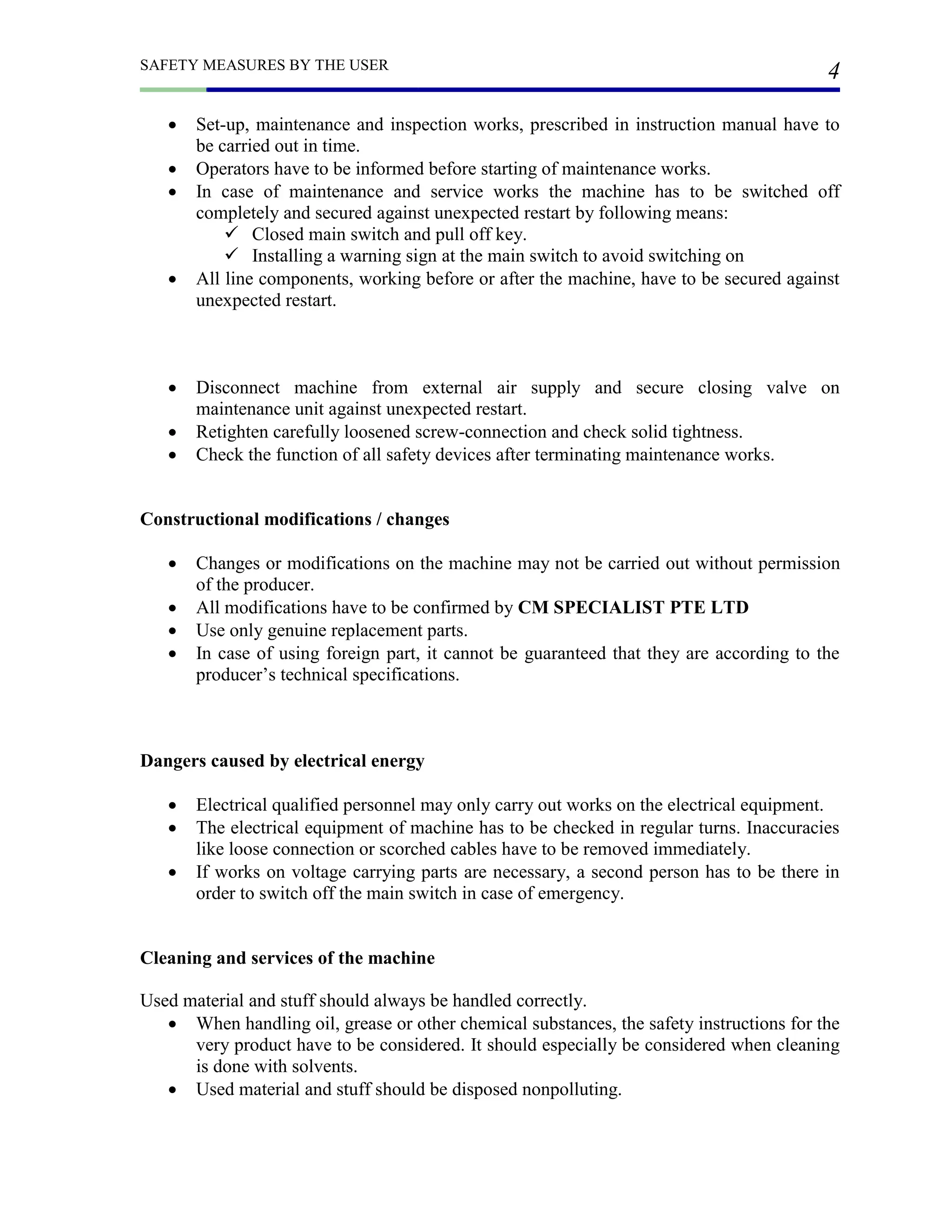

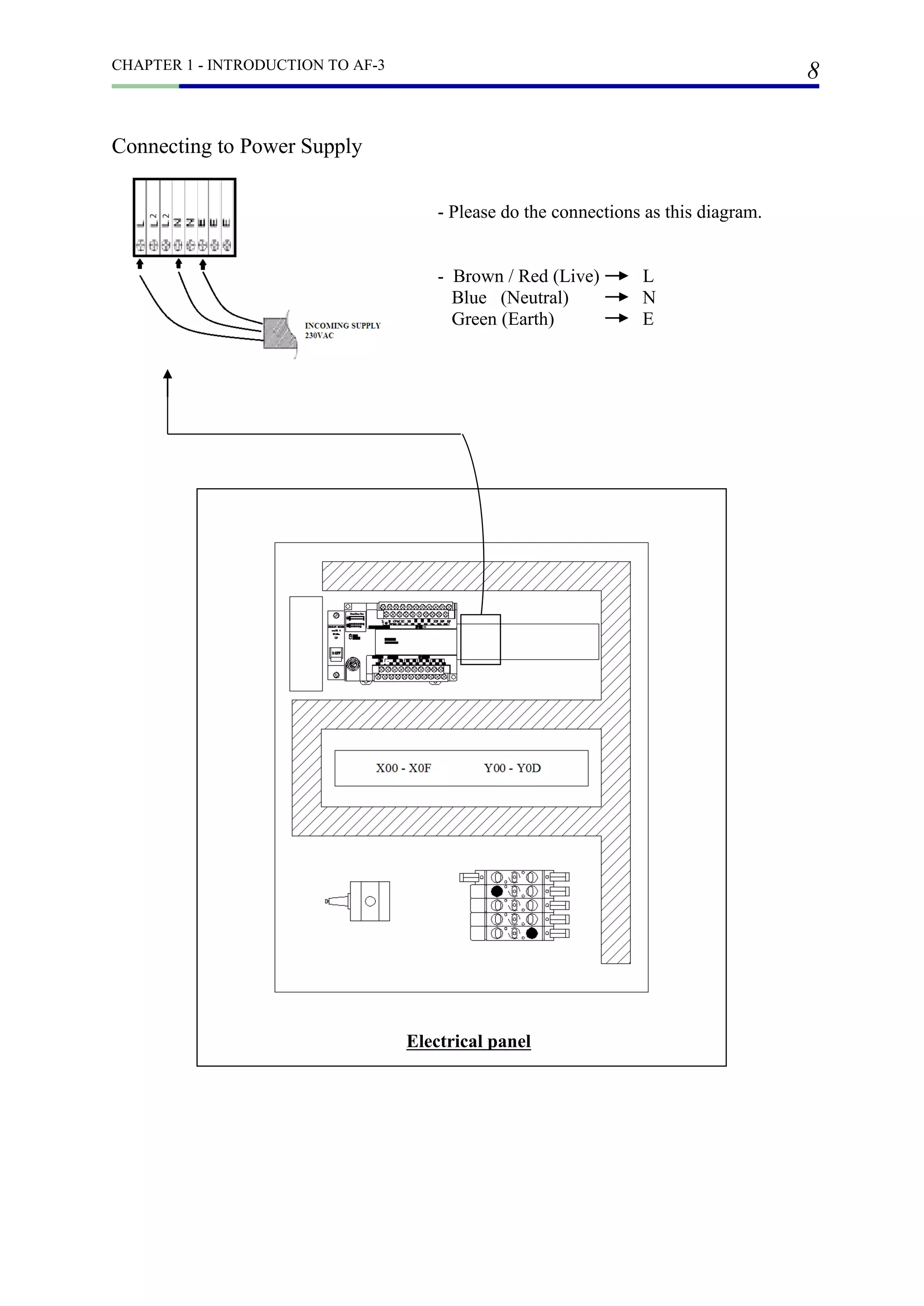

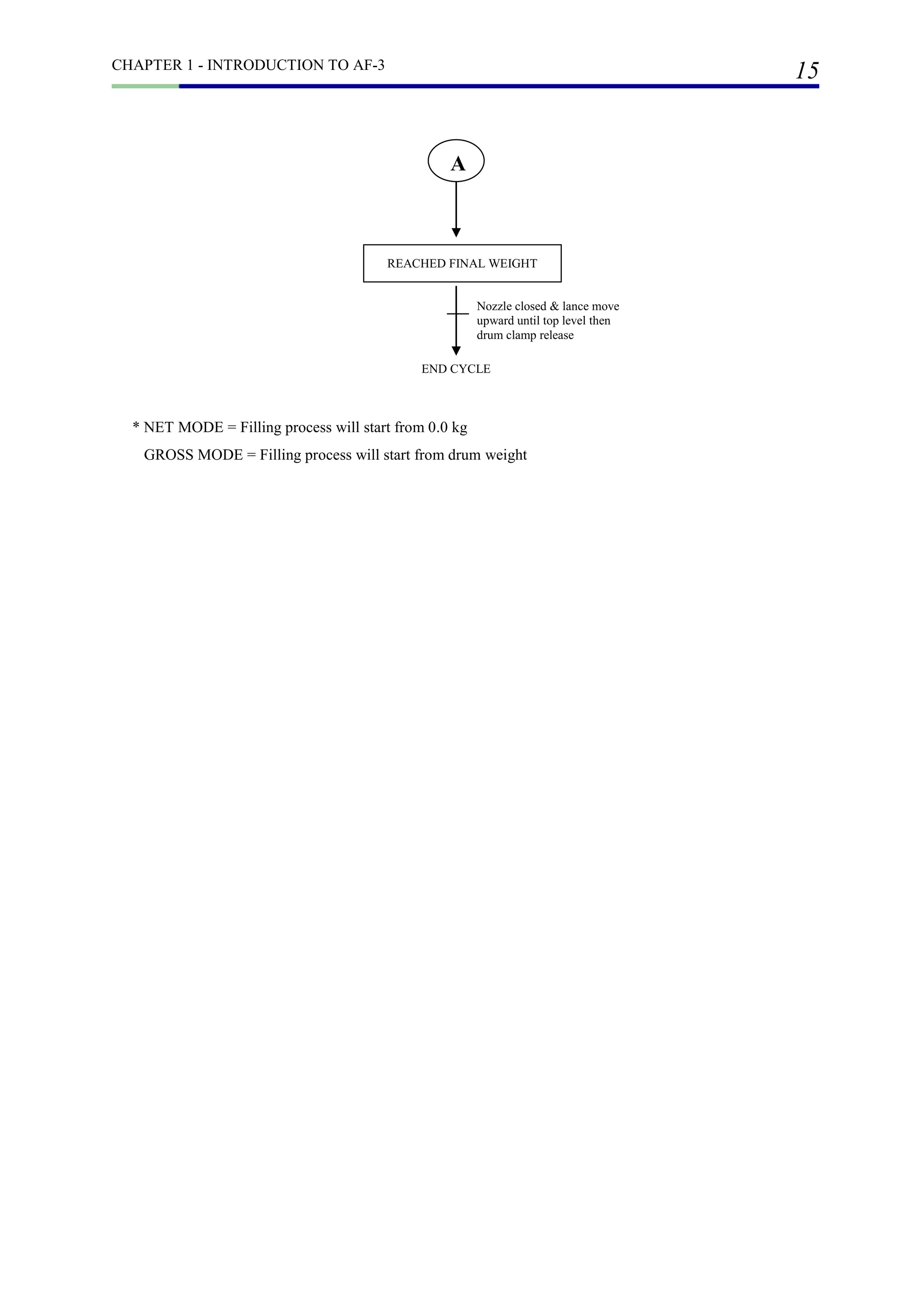

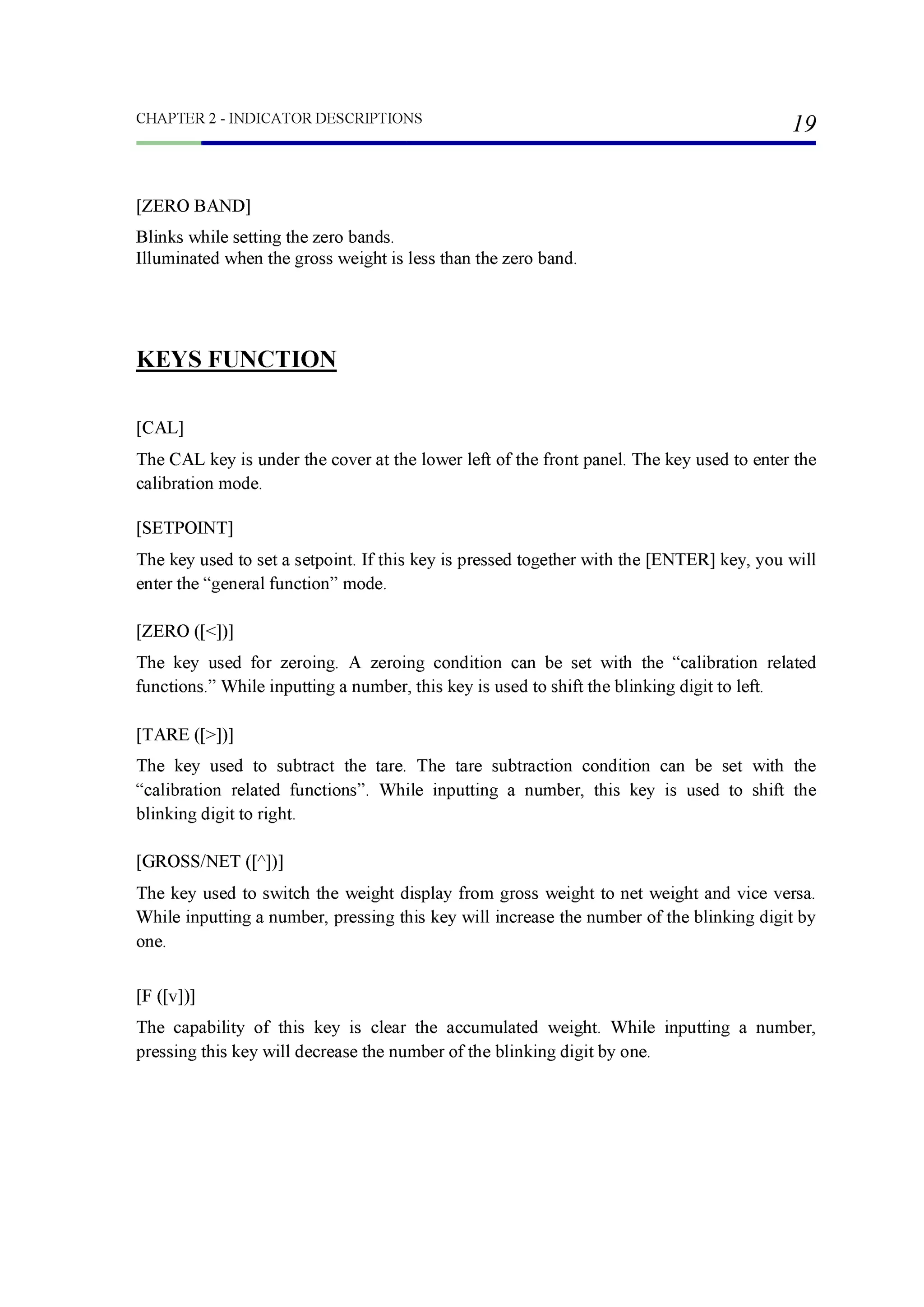

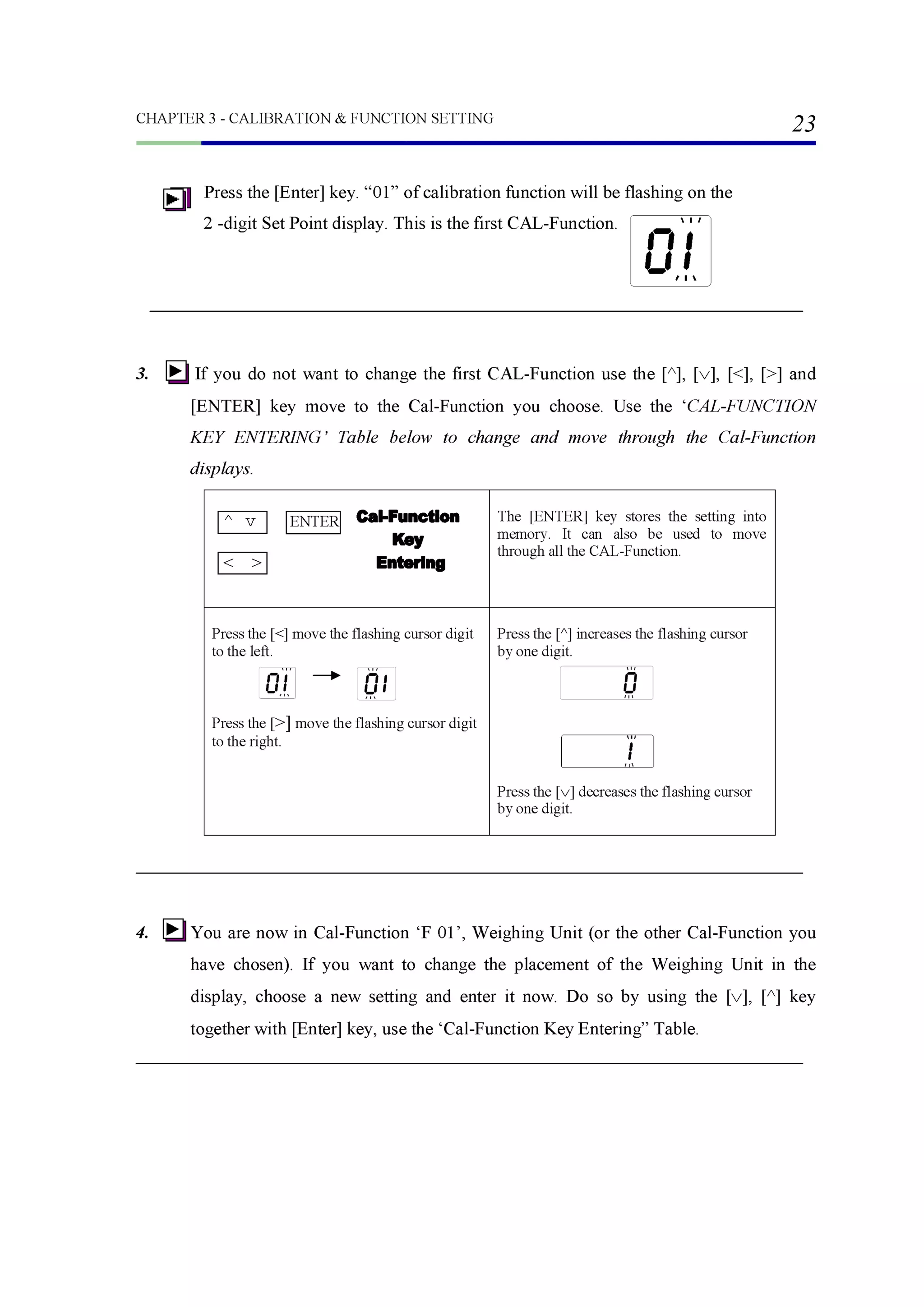

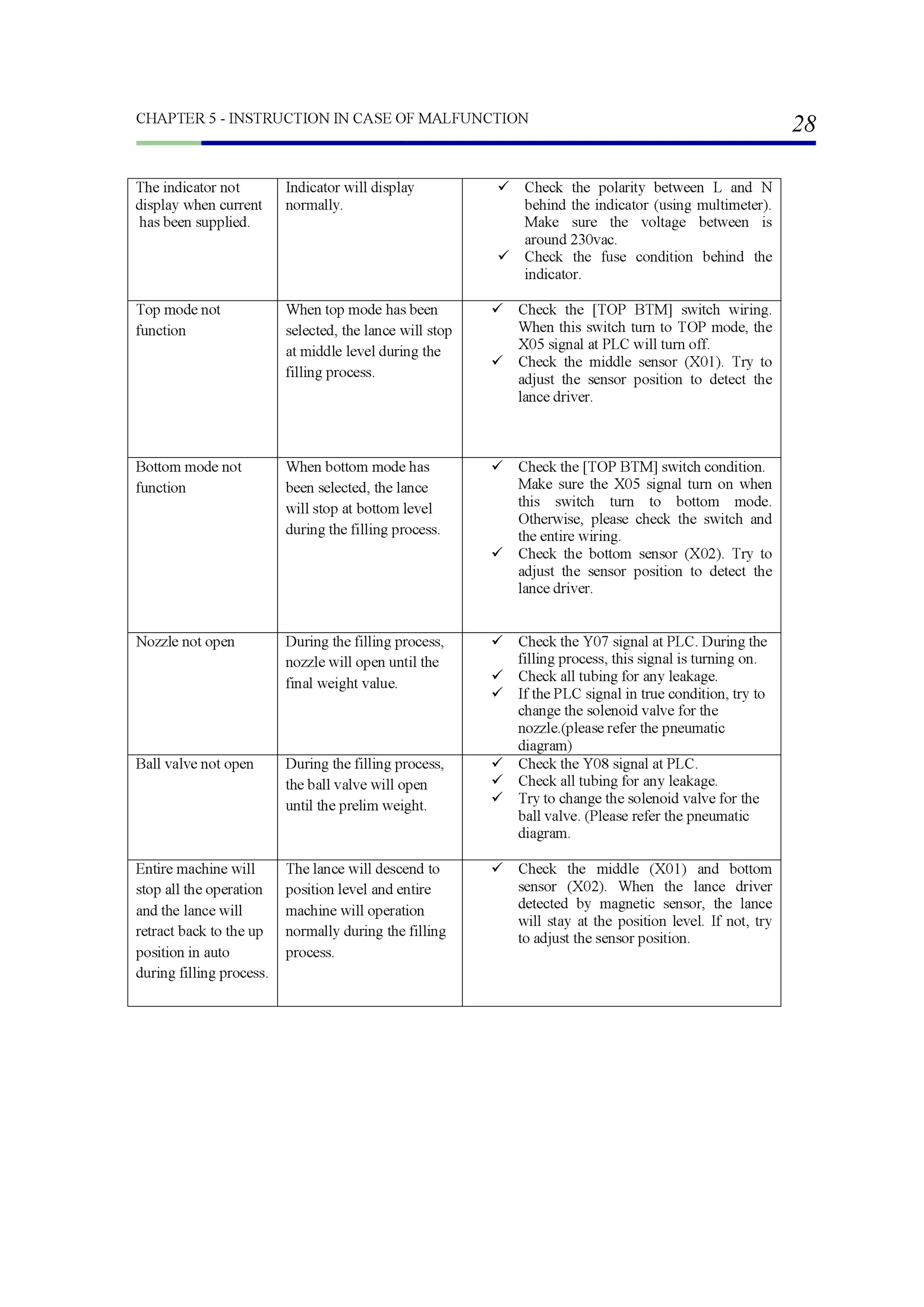

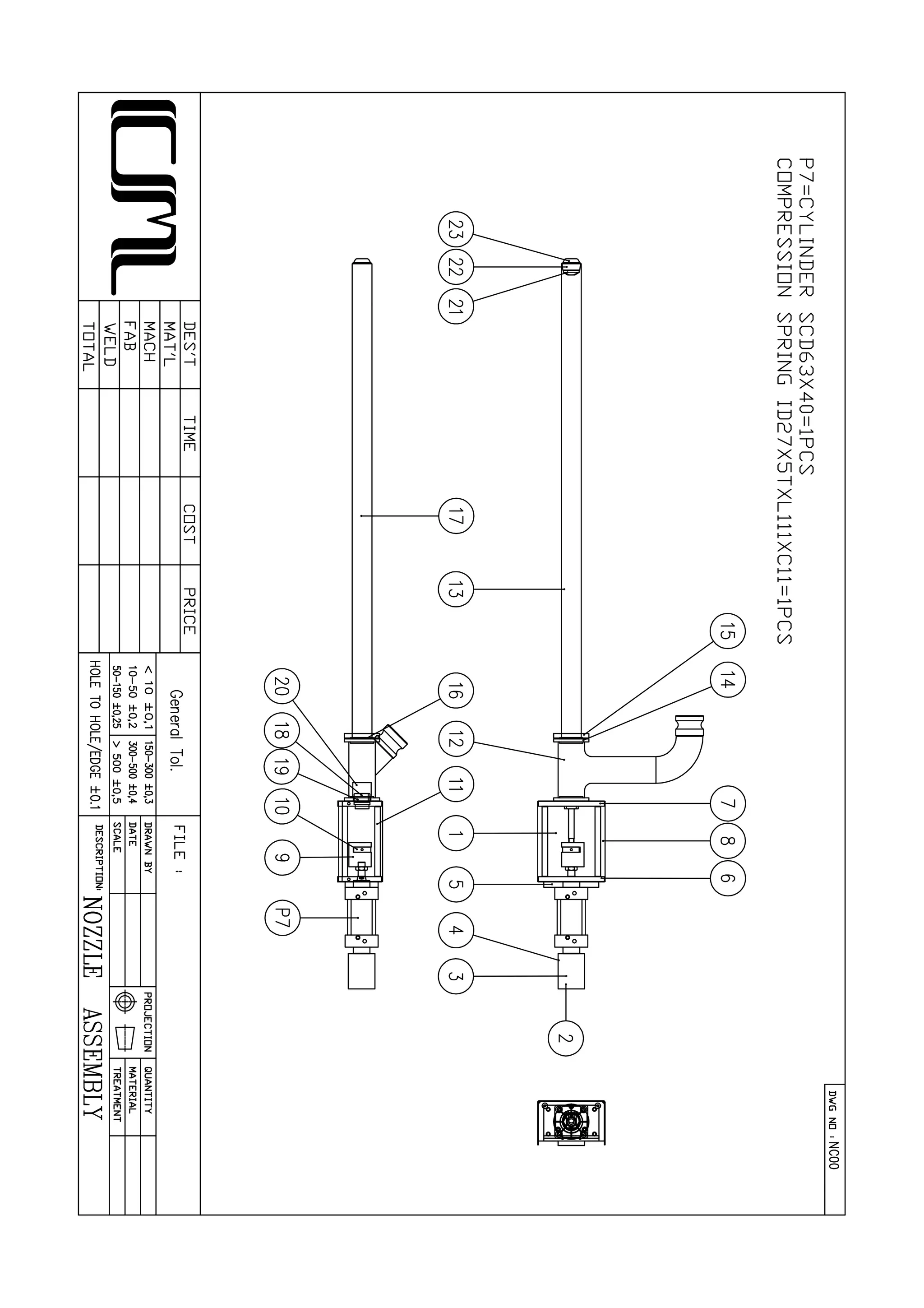

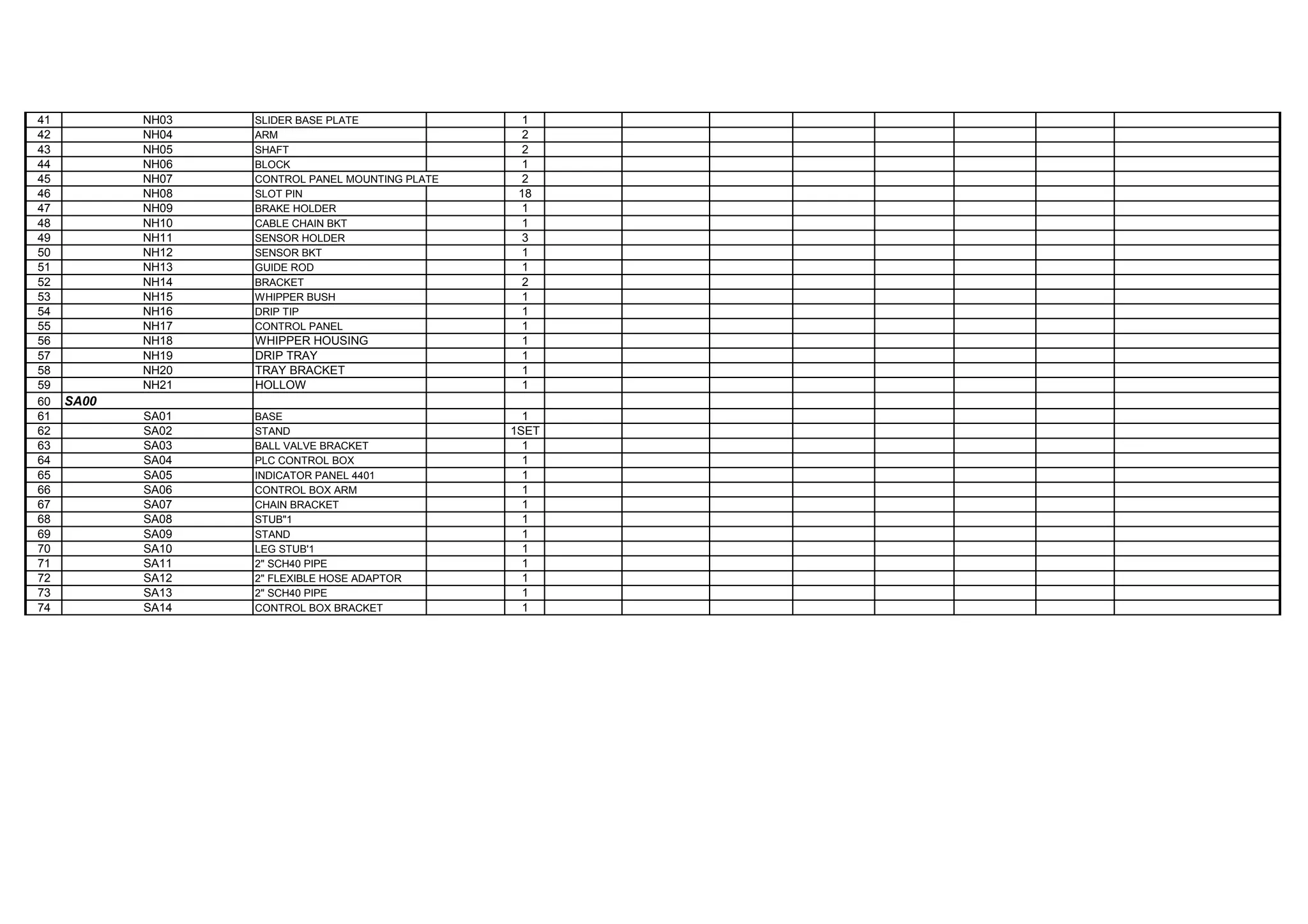

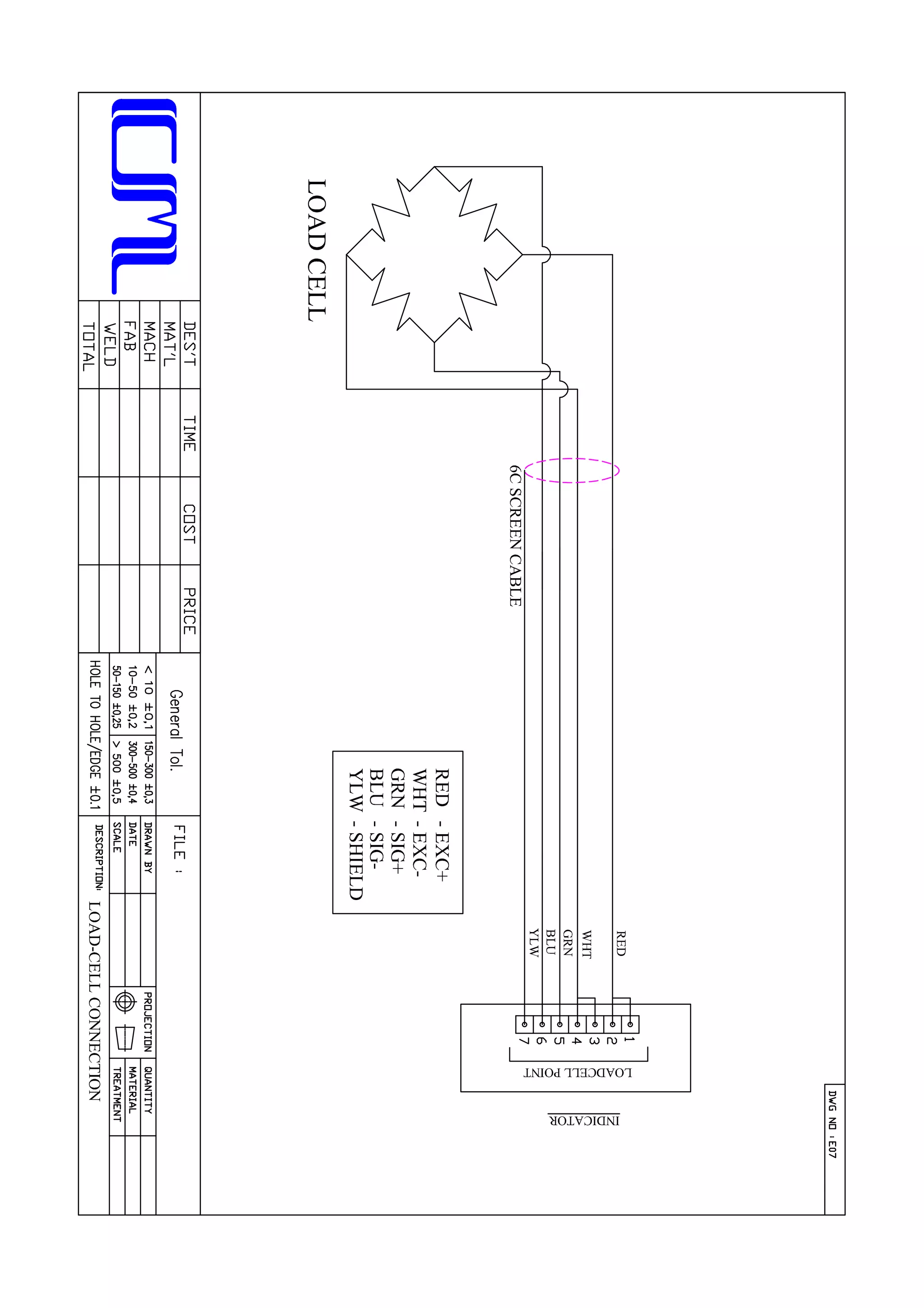

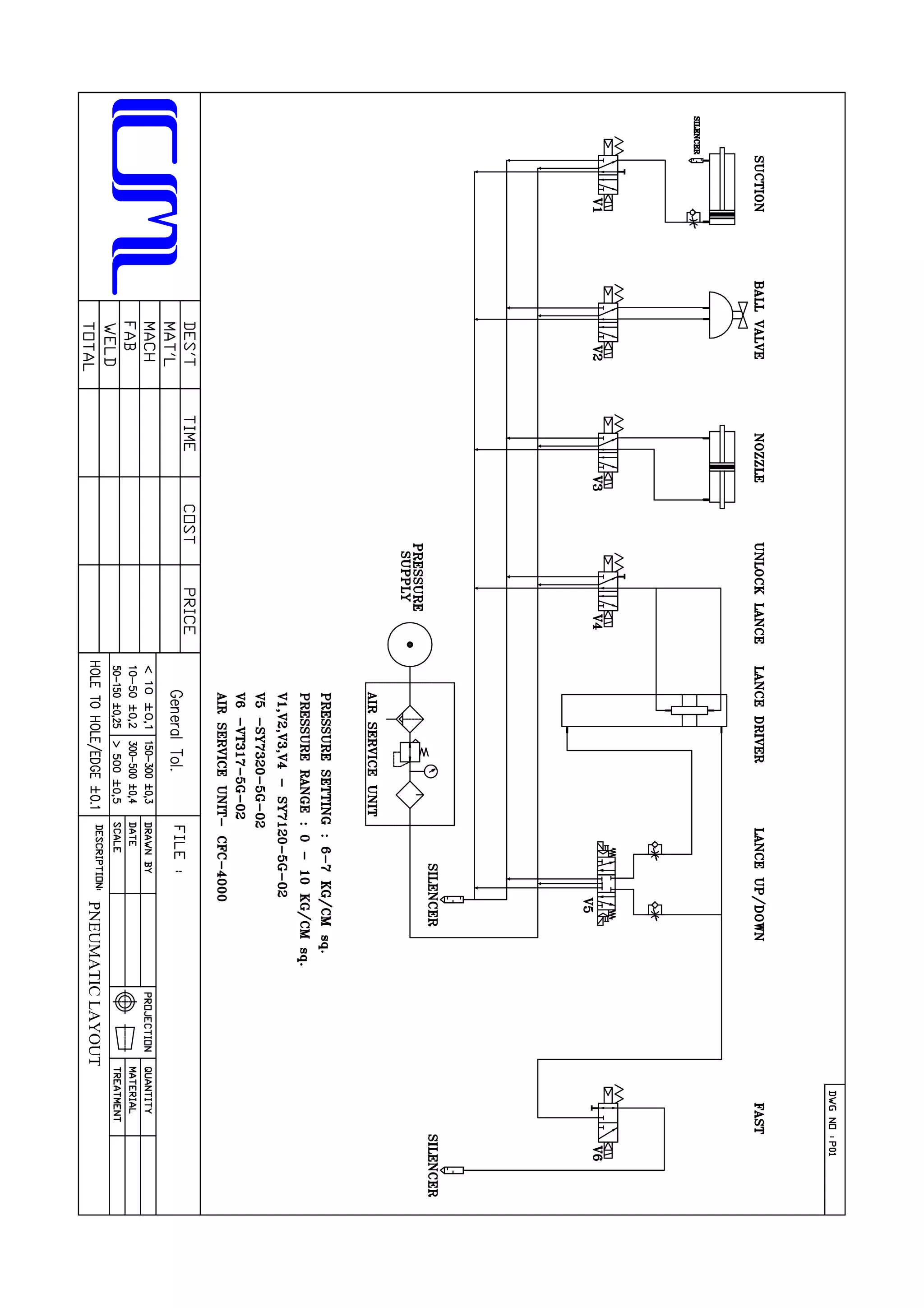

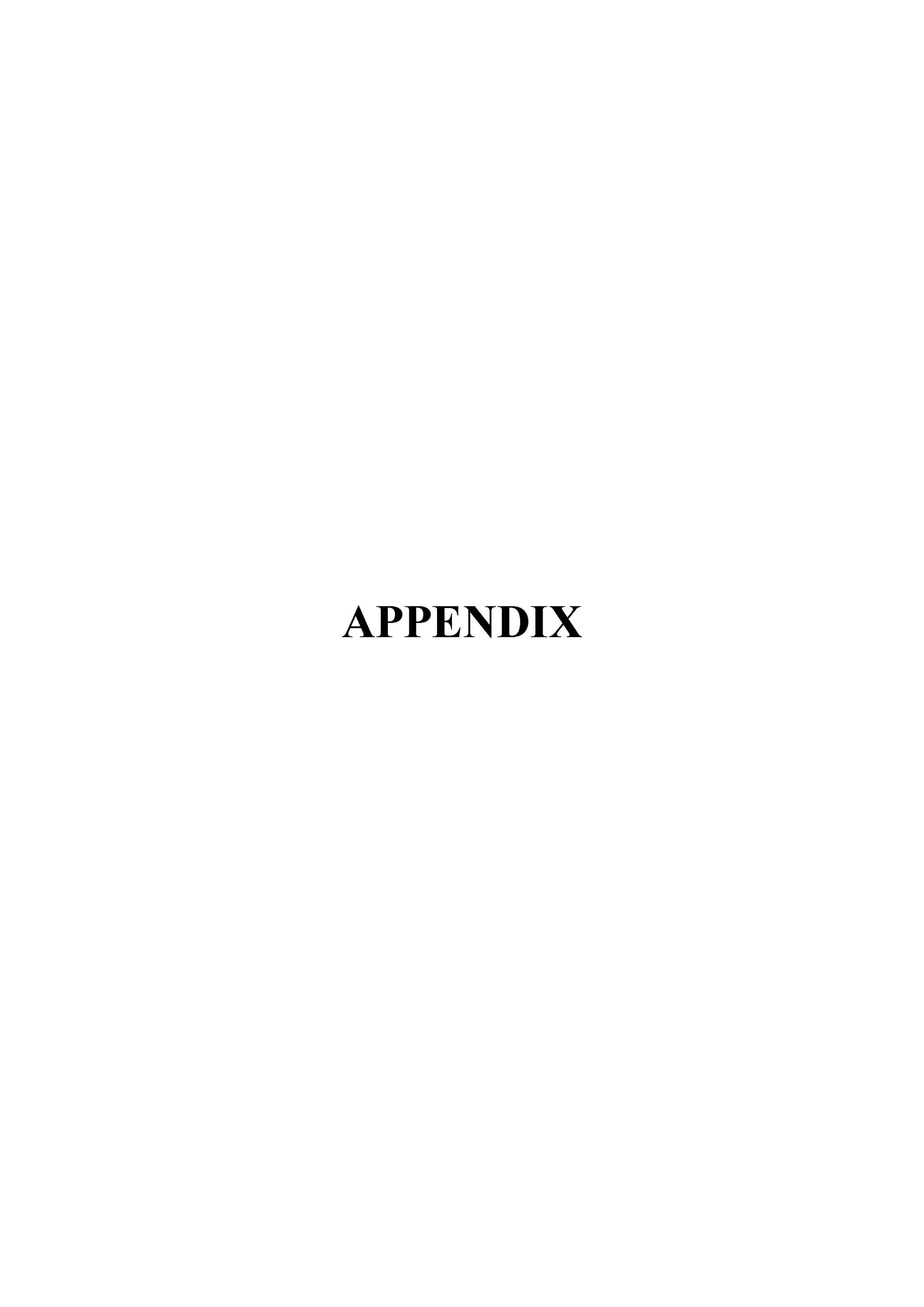

![(A) WEIGHING INDICATOR FUNCTION PARAMETER

CALF- DESCRIPTION SETTING

VALUE

F01 Weighing Unit 2

F02 Decimal Point Position 1

F03 Minimum Division 0.1

F04 Capacity 300.00

F05 Set Zero Range 10

F10 Tare and Zero at Unstable Weight Value 1

F11 Tare at Negative Gross 1

F14 Weighing Mode 1

FNCF- DESCRIPTION SETTING

VALUE

F02 Capabilities of [F] Key 0

F04 Display Content of Subdisplay Section 4

INF- DESCRIPTION SETTING

VALUE

INF-02 Capabilities of Input Terminal A2 2

INF-03 Capabilities of Input Terminal A3 9

INF-04 Capabilities of Input Terminal A4 10

CALIBRATION RELATED FUNCTION SETTING VALUE

BASIC CAPABILITIES FUNCTION RELATED SETTING VALUE

CONTROL I/O INPUT RELATED SETTING VALUE](https://image.slidesharecdn.com/af3-instructionmanual-cmspecialist-180919151900/75/Af3-instruction-manual-cm-specialist-57-2048.jpg)