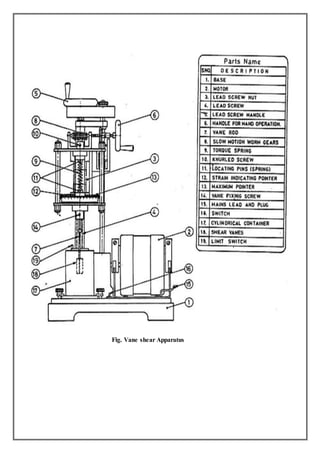

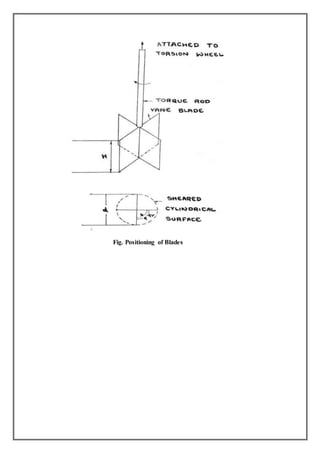

This experiment aims to determine the undrained shear strength of remolded cohesive soil using a vane shear test. The vane shear test involves pushing a four-bladed vane into a soil sample and rotating it until shear failure occurs along a cylindrical surface. The torque required to cause failure is measured and converted to a unit shear resistance. This test is suitable for soft soils where other shear tests may not work accurately, and it can be used to find both the undisturbed and remolded shear strengths to estimate soil sensitivity. The procedure involves filling a container with soil at a set density and water content, inserting the vane, and rotating it until failure while recording the applied torque and calculated shear strength.