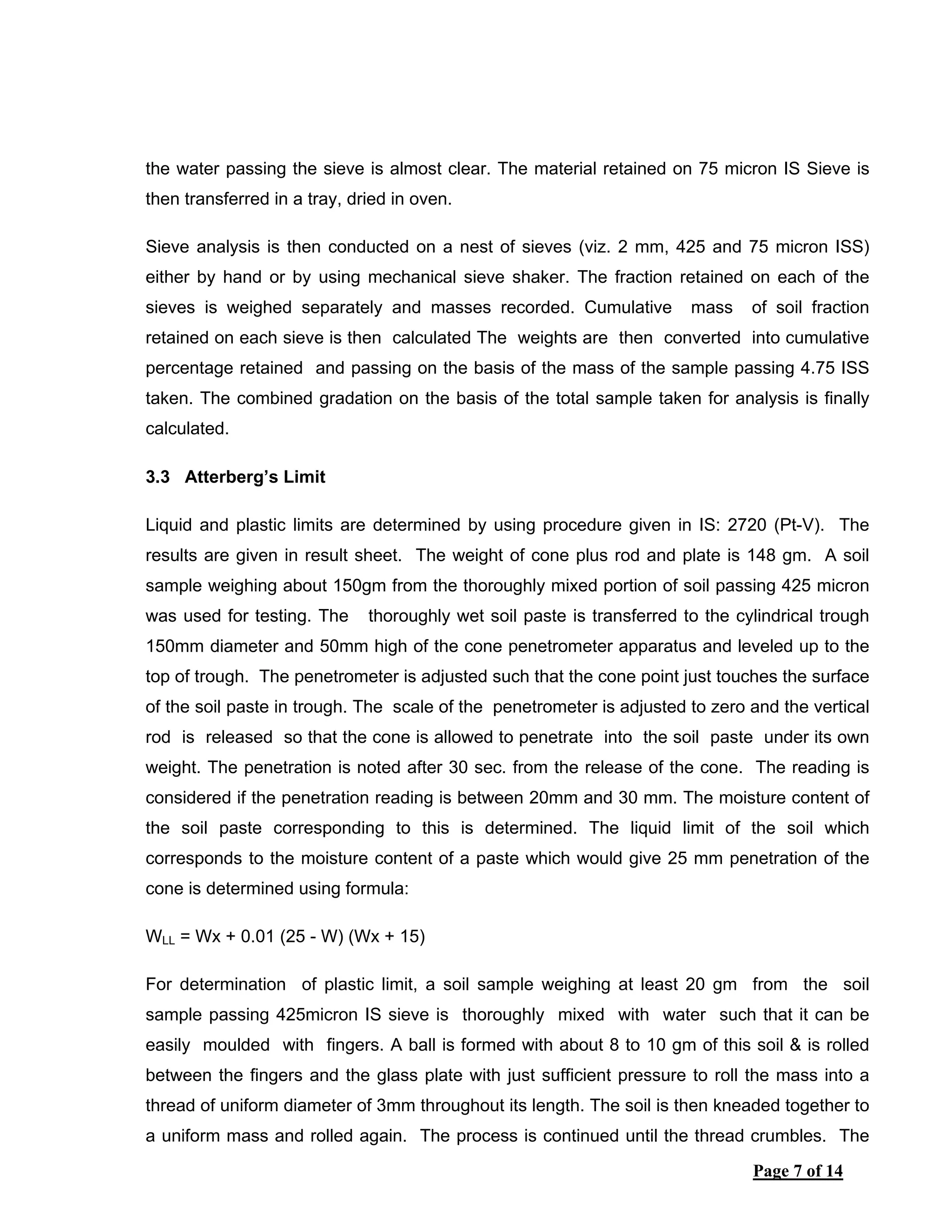

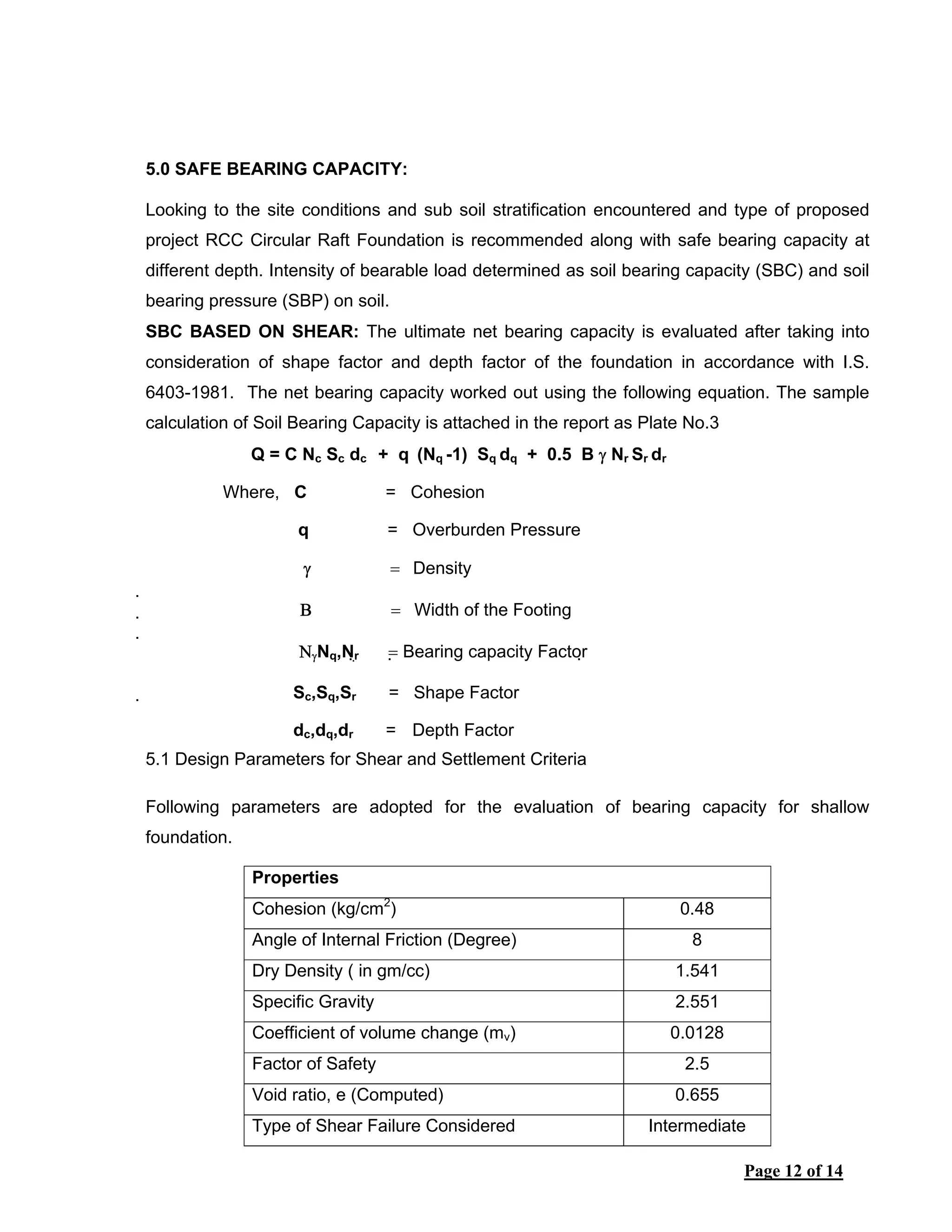

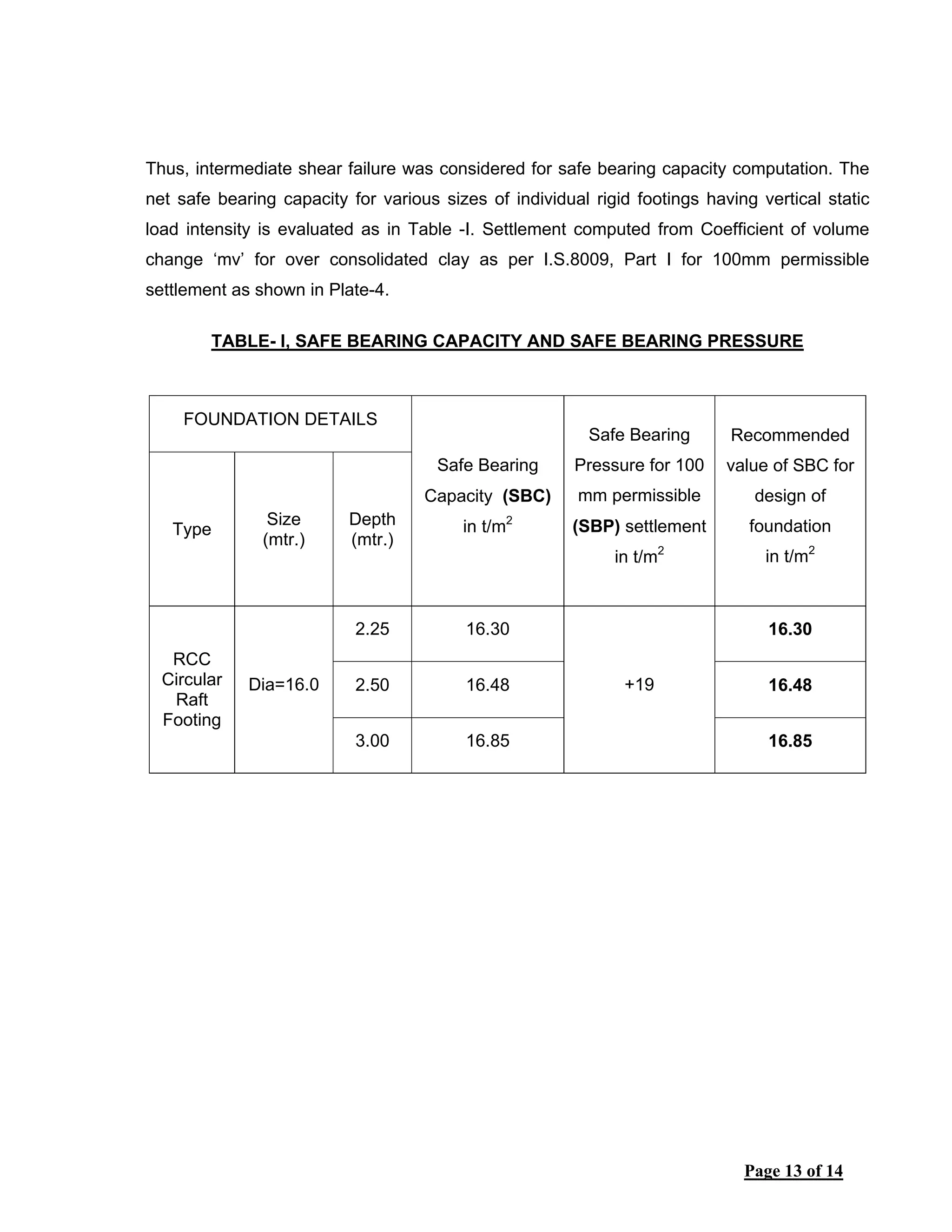

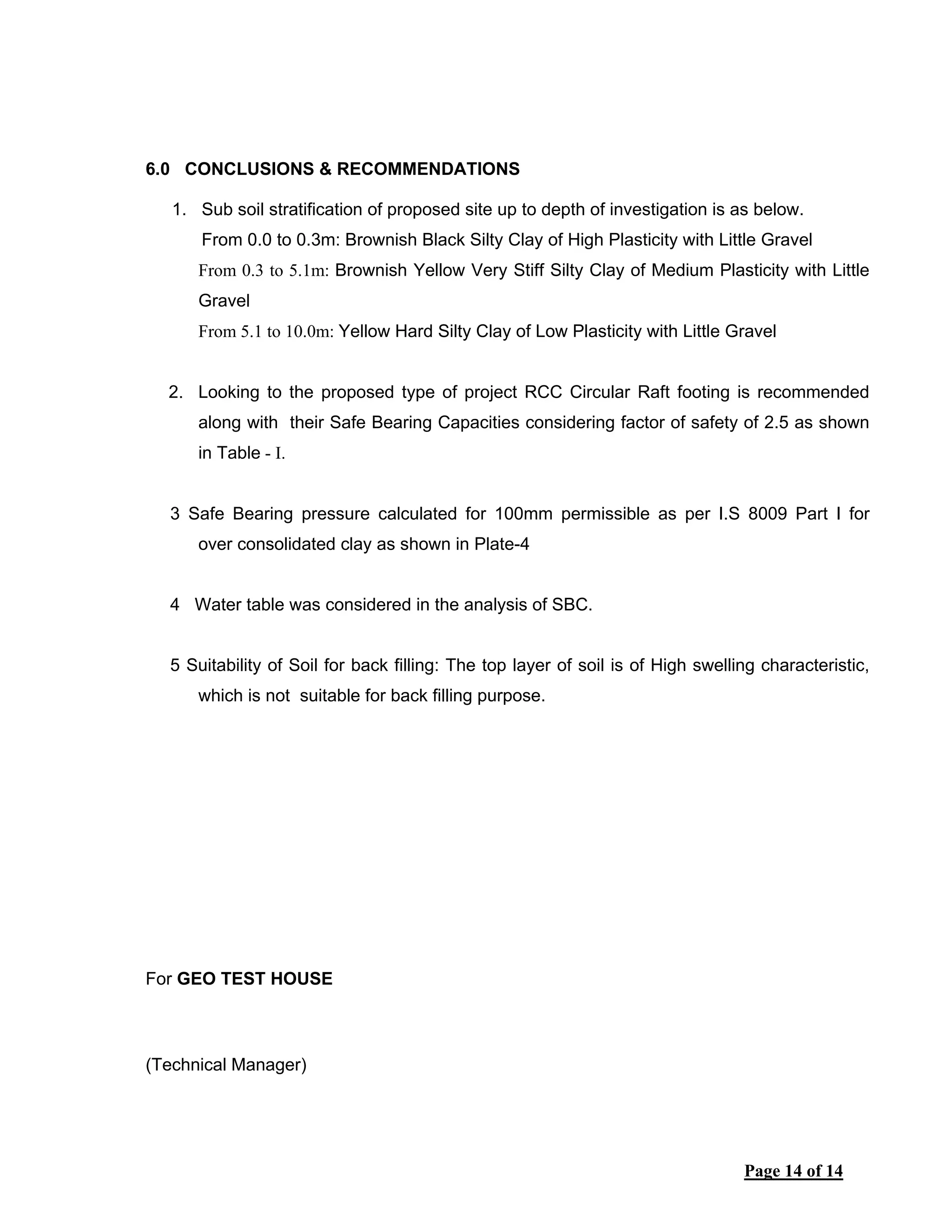

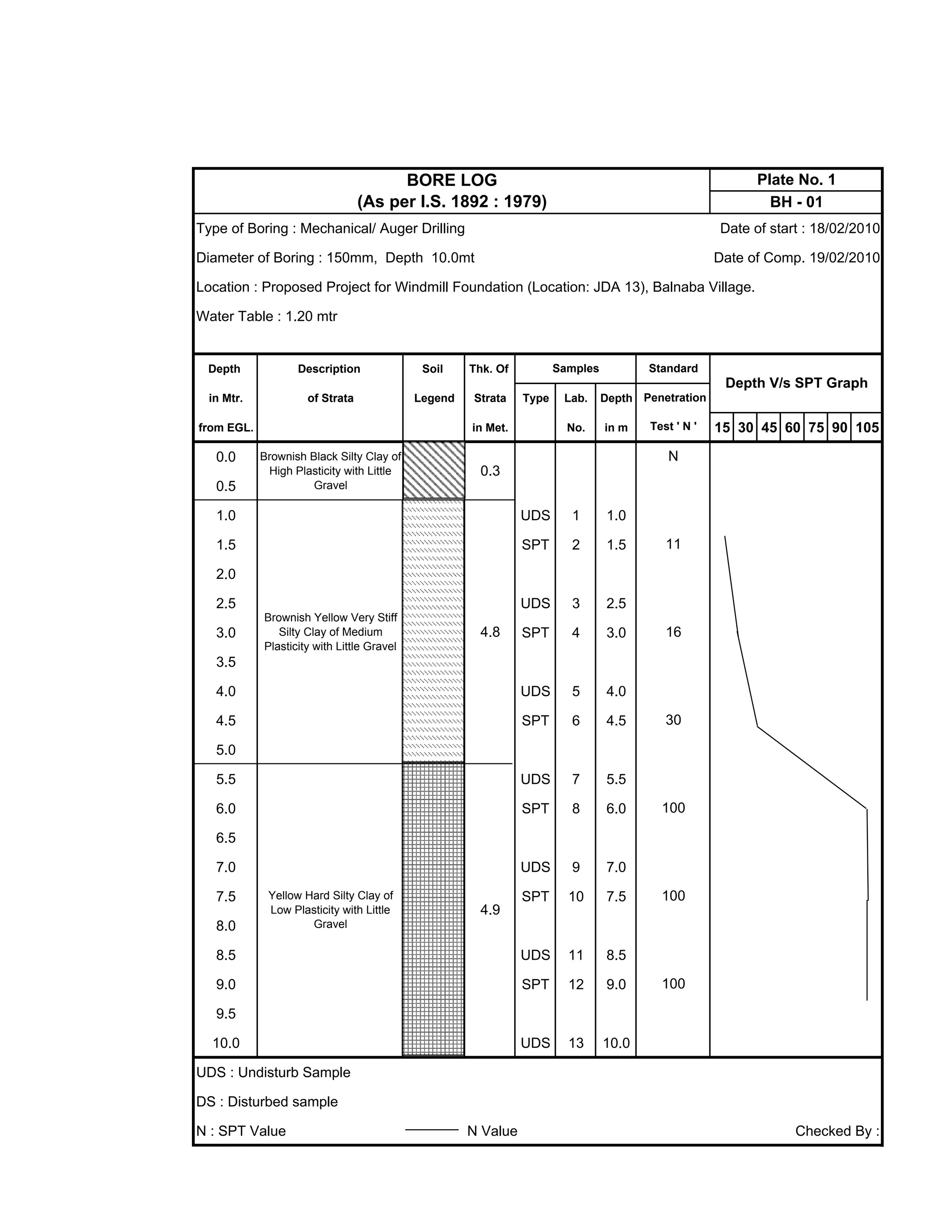

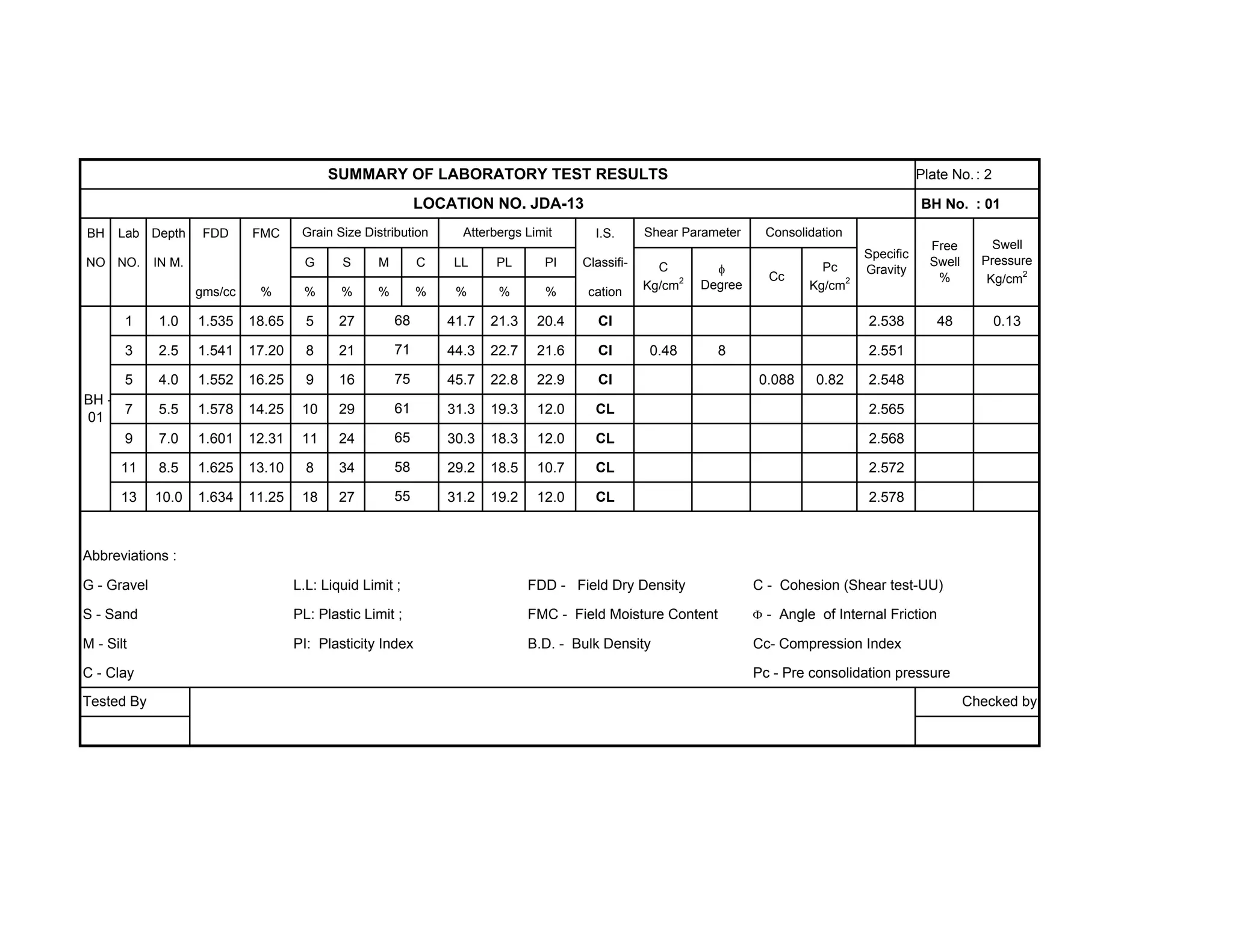

This soil investigation report summarizes subsurface exploration and laboratory testing conducted for a proposed wind turbine foundation project. One borehole was drilled to a depth of 10 meters and standard penetration and sampling tests were performed. Undisturbed and disturbed soil samples were collected and subjected to various laboratory tests to determine physical and engineering properties. These included dry density, particle size analysis, Atterberg limits, shear strength, consolidation, and free swell tests. The results were analyzed to evaluate the subsurface conditions and provide a safe bearing capacity for foundation design of the wind turbine.