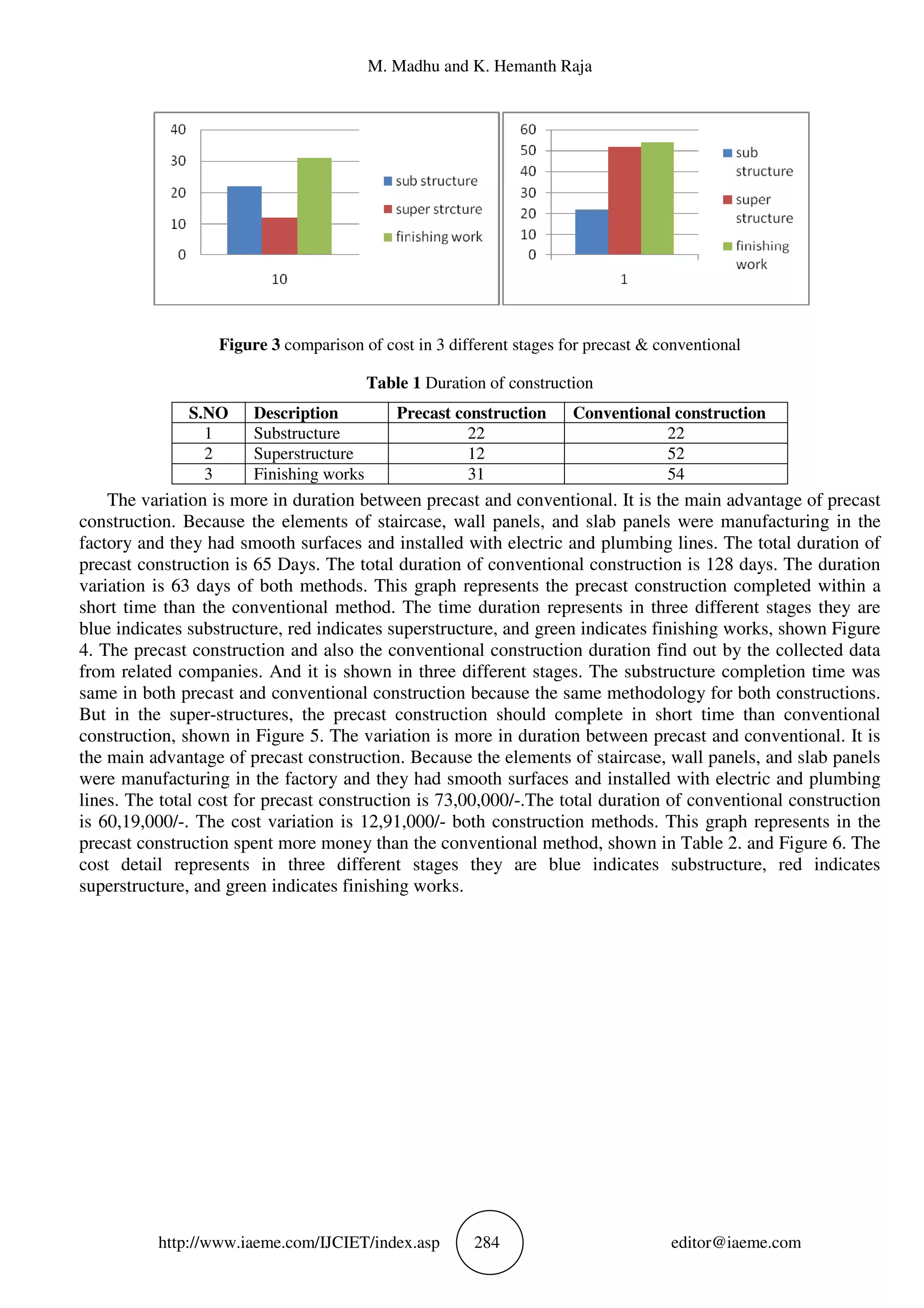

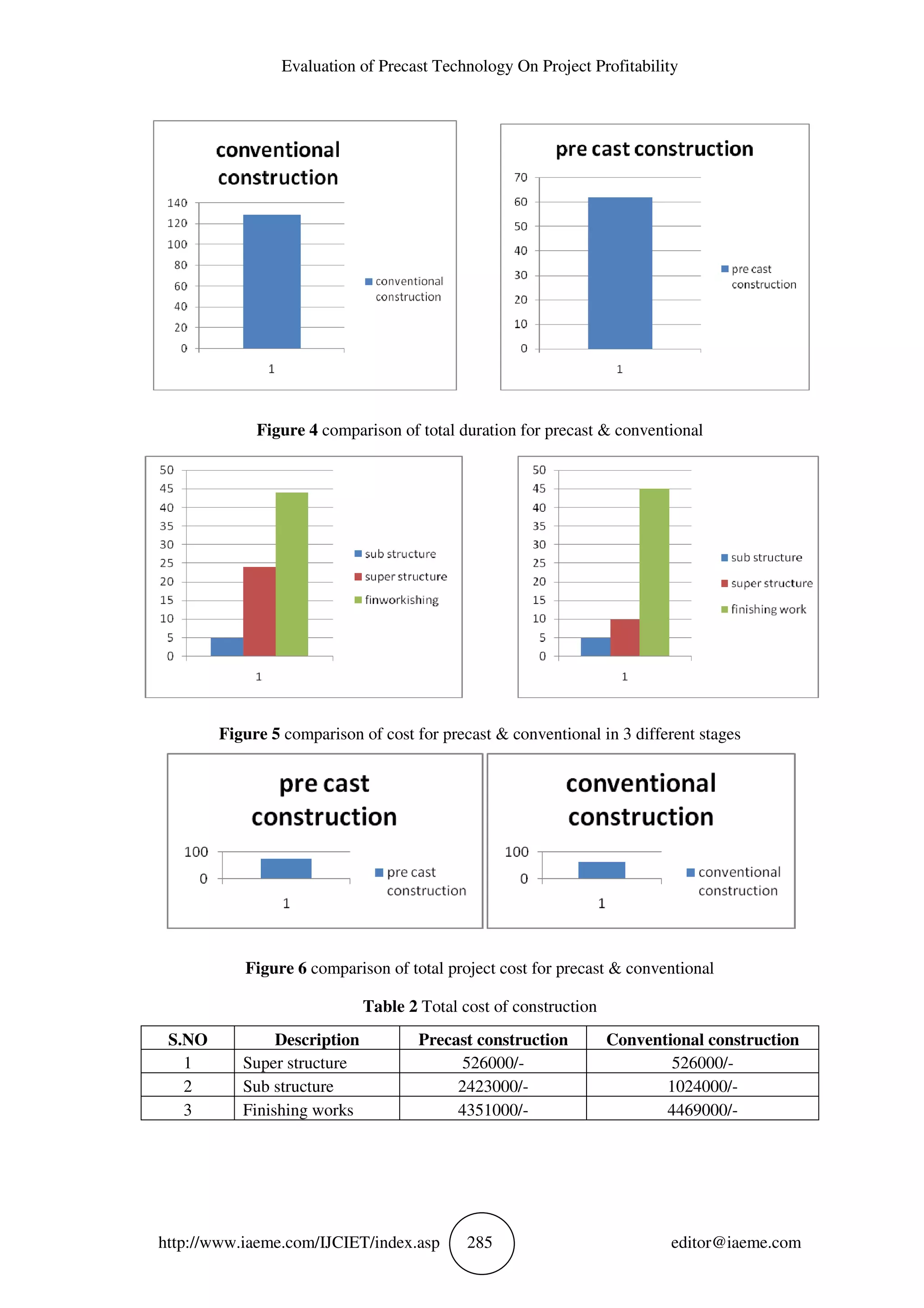

This study evaluates precast technology against conventional construction methods in terms of project profitability, highlighting that while precast construction is faster and reduces labor costs, it is more expensive overall. Data collected indicated that the construction duration for precast technology is significantly shorter, with a 63-day difference compared to conventional methods. Despite its advantages in speed and efficiency, conventional construction proves to be more cost-effective for individual houses.

![M. Madhu and K. Hemanth Raja

http://www.iaeme.com/IJCIET/index.asp 286 editor@iaeme.com

5. CONCLUSION

This paper represents to find out double-storey residential building project duration and project cost in both

construction methods, and compare the both precast construction and conventional construction method.

The building was completed within a short time by precast construction, easy to work and helpful in labor

shortage than the conventional construction. And the time of duration is reduced to 63 days by precast

construction. It is the main advantage of precast construction. But in the cost analysis, the conventional

construction was better than the precast construction in individual houses.

REFERENCES

[1] Nahmens I, Michael A. Mullen’s Lean Homebuilding: Lessons Learned from a Precast Concrete

Panelizer. Journal of architectural engineering. 2011 January; 17(4), 155-161.

[2] Neville B, Khalfan M A, Maqsood T. Off-Site Construction of Apartment Buildings. Journal of

Architectural engineering. 2013 March; 19(1), 51-57.

[3] Alistair G F G, Andrew R J D. Strategies for Integrating the Use of Off-Site Production Technologies in

House Building. Journal of Construction Engineering and Management. 2012 November; 138(11),

1331-1340.

[4] Warszawski A, Moshe A, Carmel D. Utilization of precast concrete elements in building. Journal of

American Society of Civil Engineers. 1984 December; 110(4), 476-485.

[5] Christian T, Lars H. Rethinking the business model in construction by the use of off-site "system

deliverance" the shaft project. Journal of Architectural Engineering. 2013 December; 19(4), 279-287.

[6] Jeong Y S, Eastman C M, Sacks R, Kaner I. Benchmark tests for BIM data exchanges of precast

concrete. Journal of Automation in Construction. 2009 July, 18(4), 469-484.

[7] Vacharapoom B, Nashwan D. Intelligence approach to production planning system for bespoke precast

concrete products. Automation in Construction. 2006 November; 15(6), 737-745.](https://image.slidesharecdn.com/ijciet0801030-170304074651/75/EVALUATION-OF-PRECAST-TECHNOLOGY-ON-PROJECT-PROFITABILITY-6-2048.jpg)