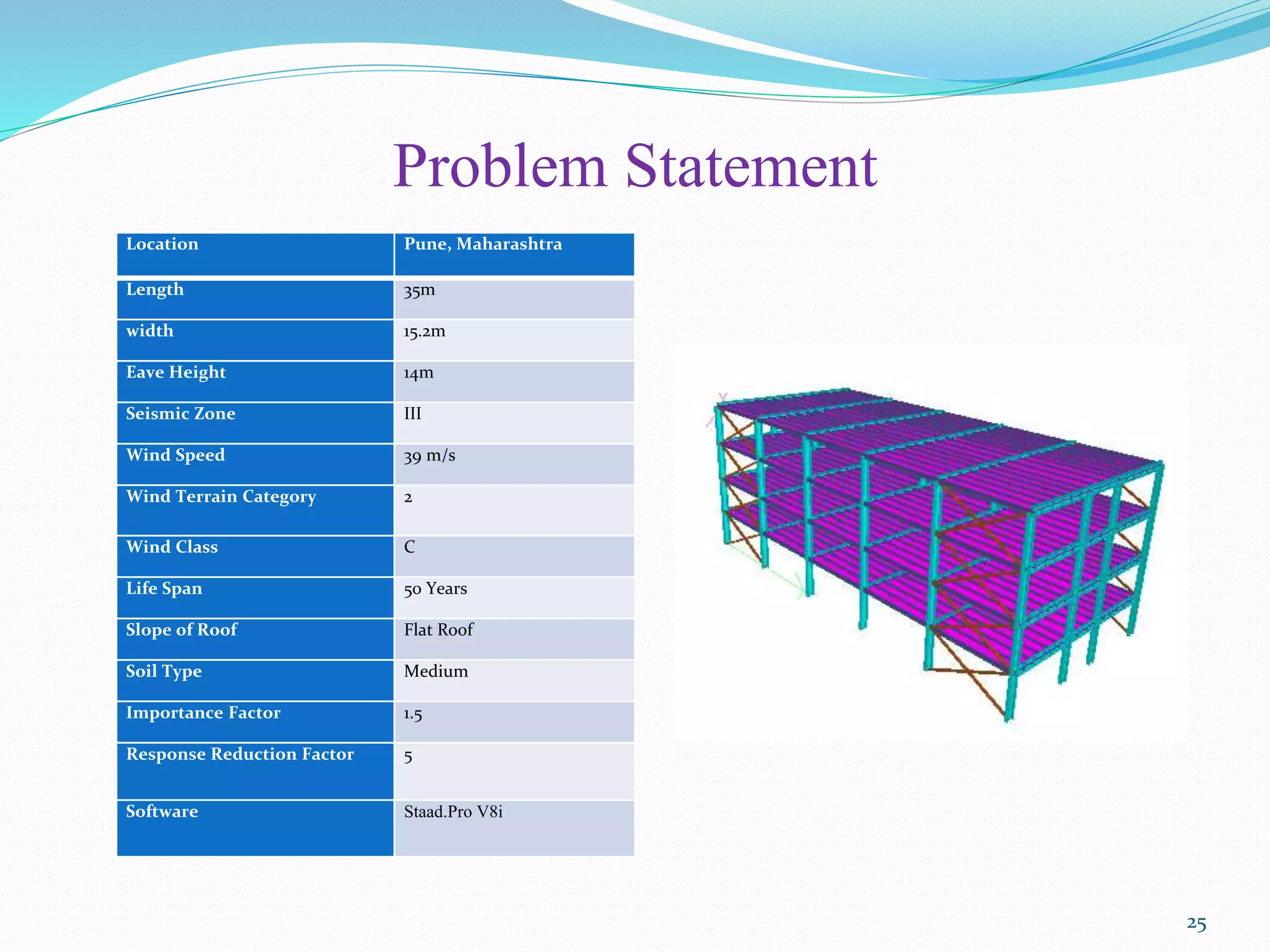

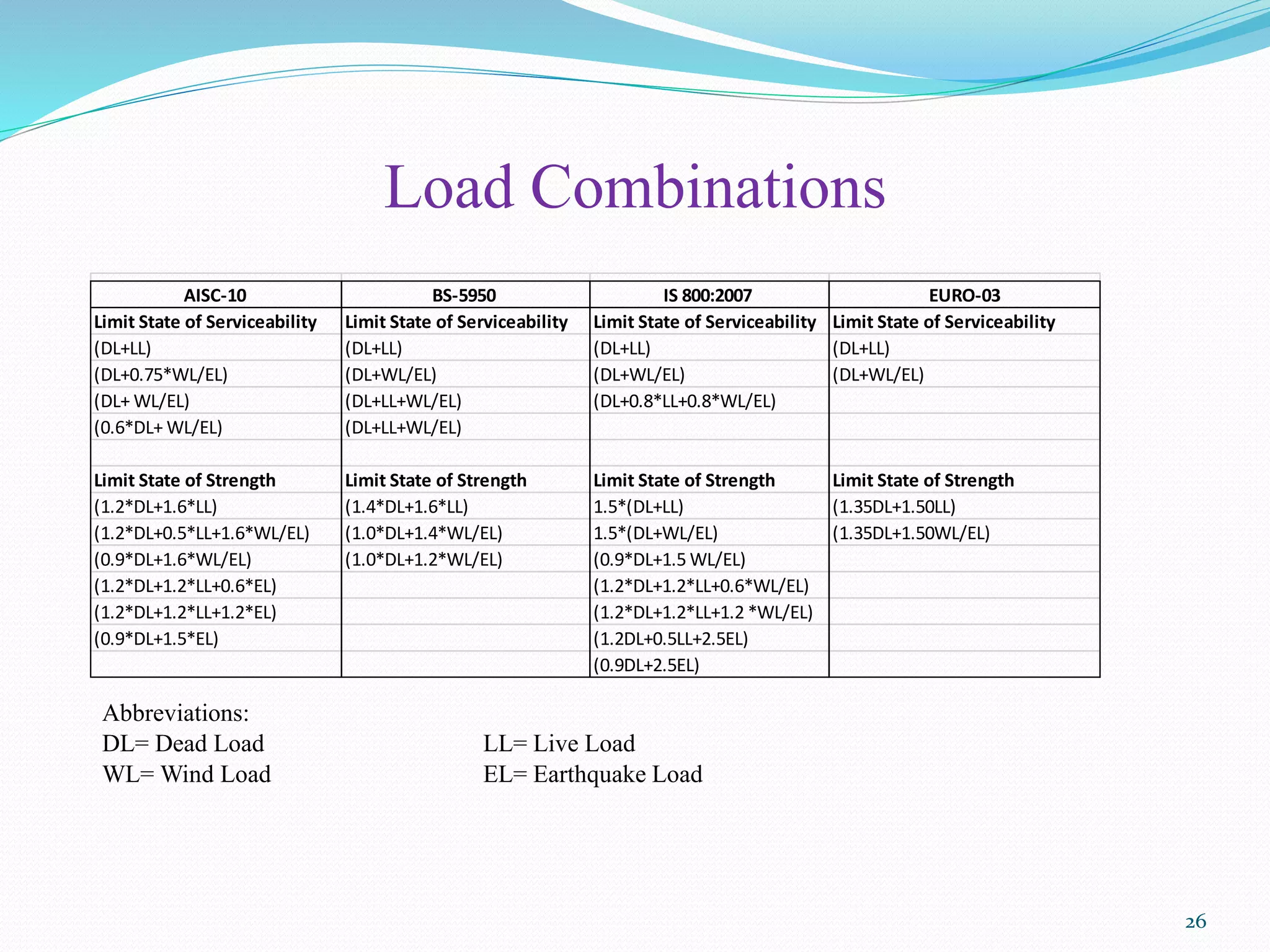

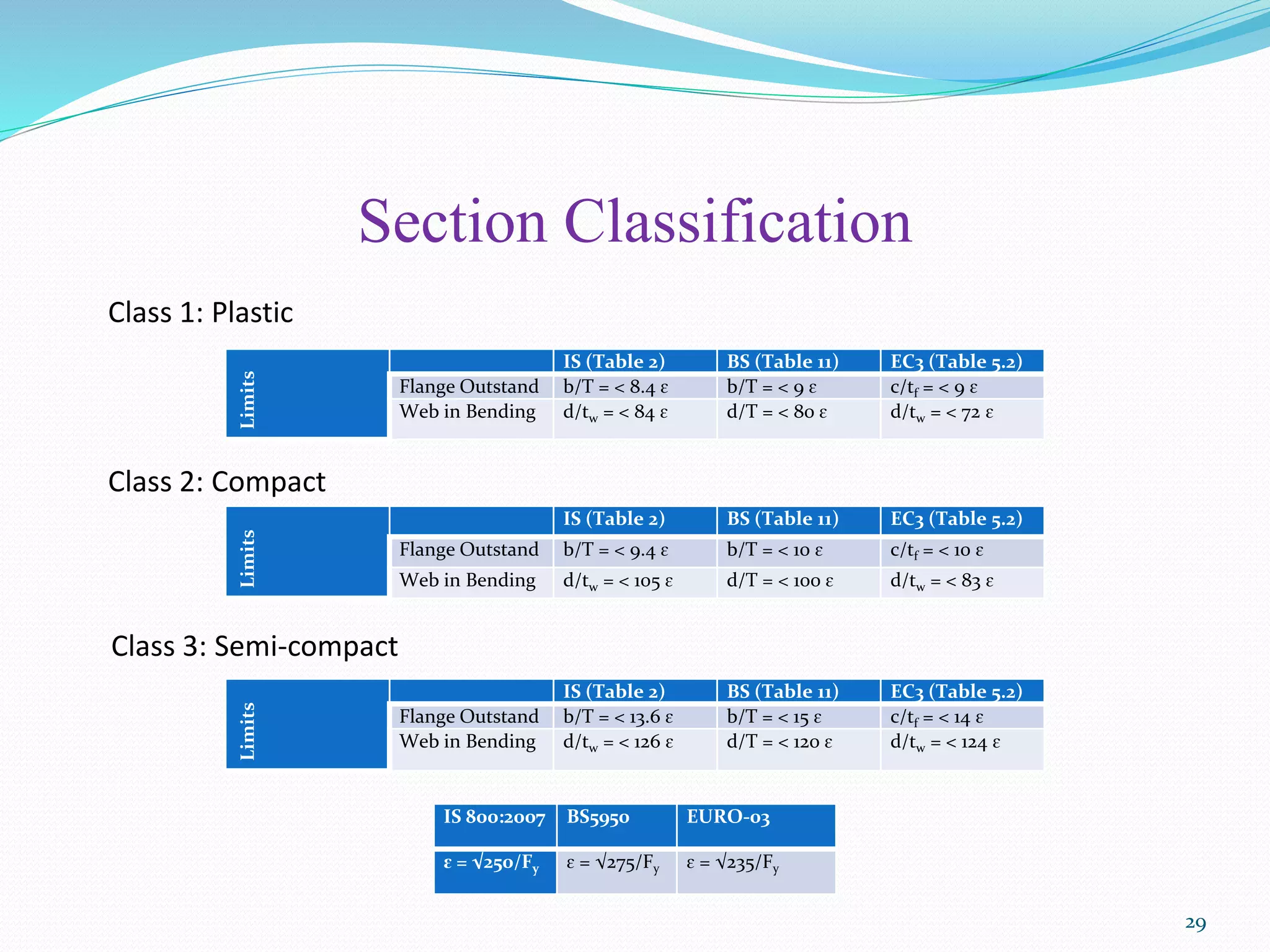

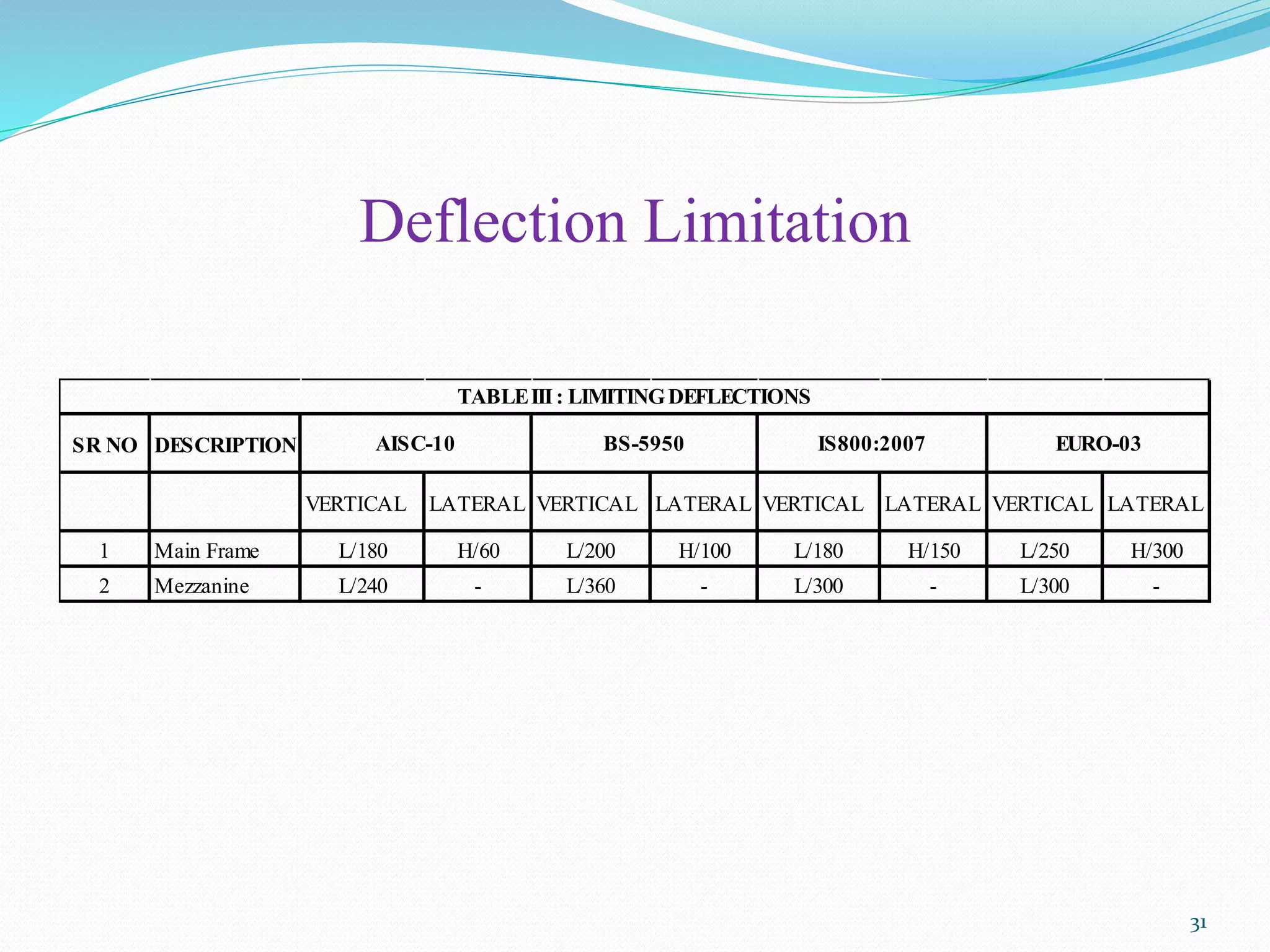

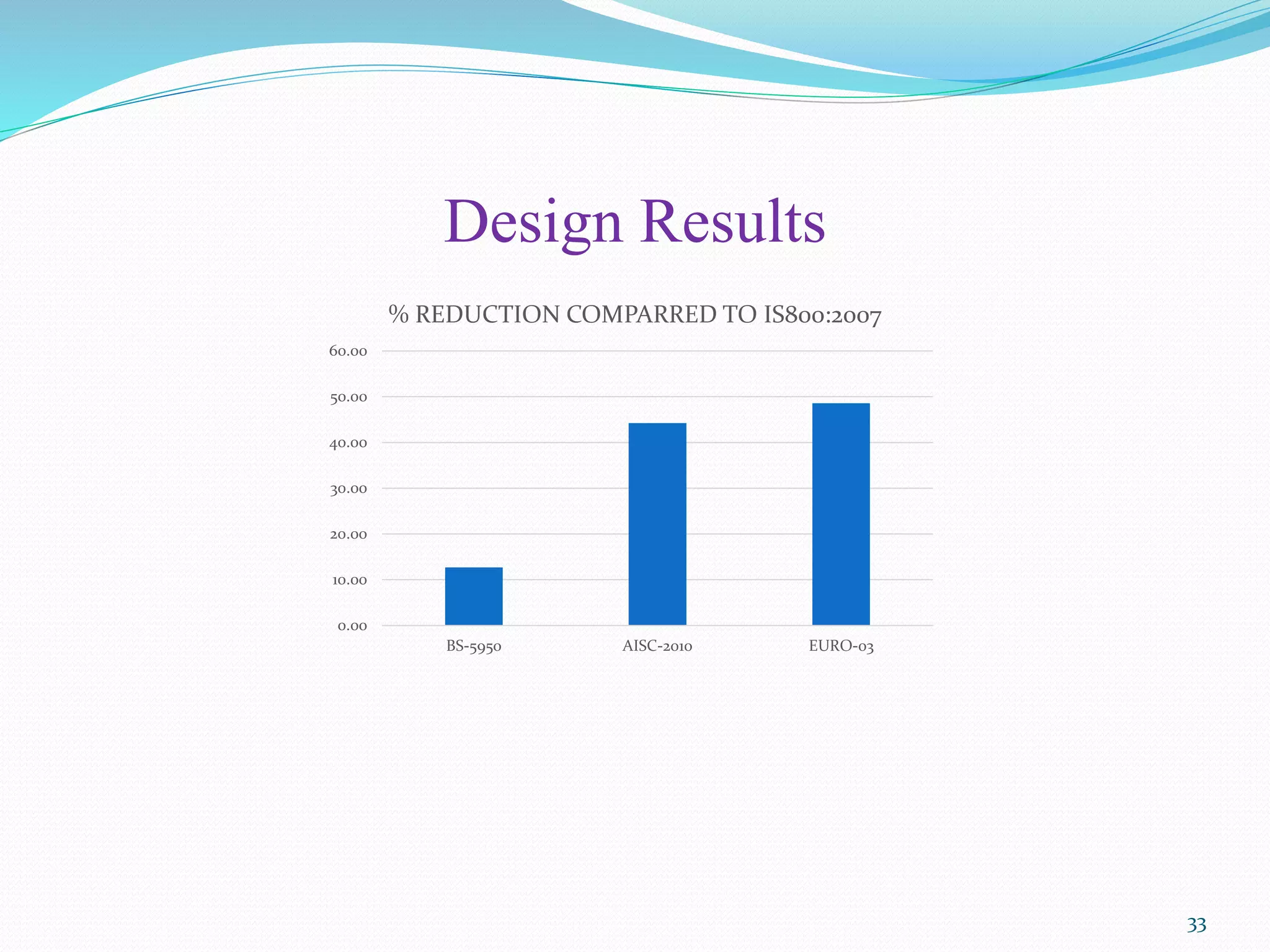

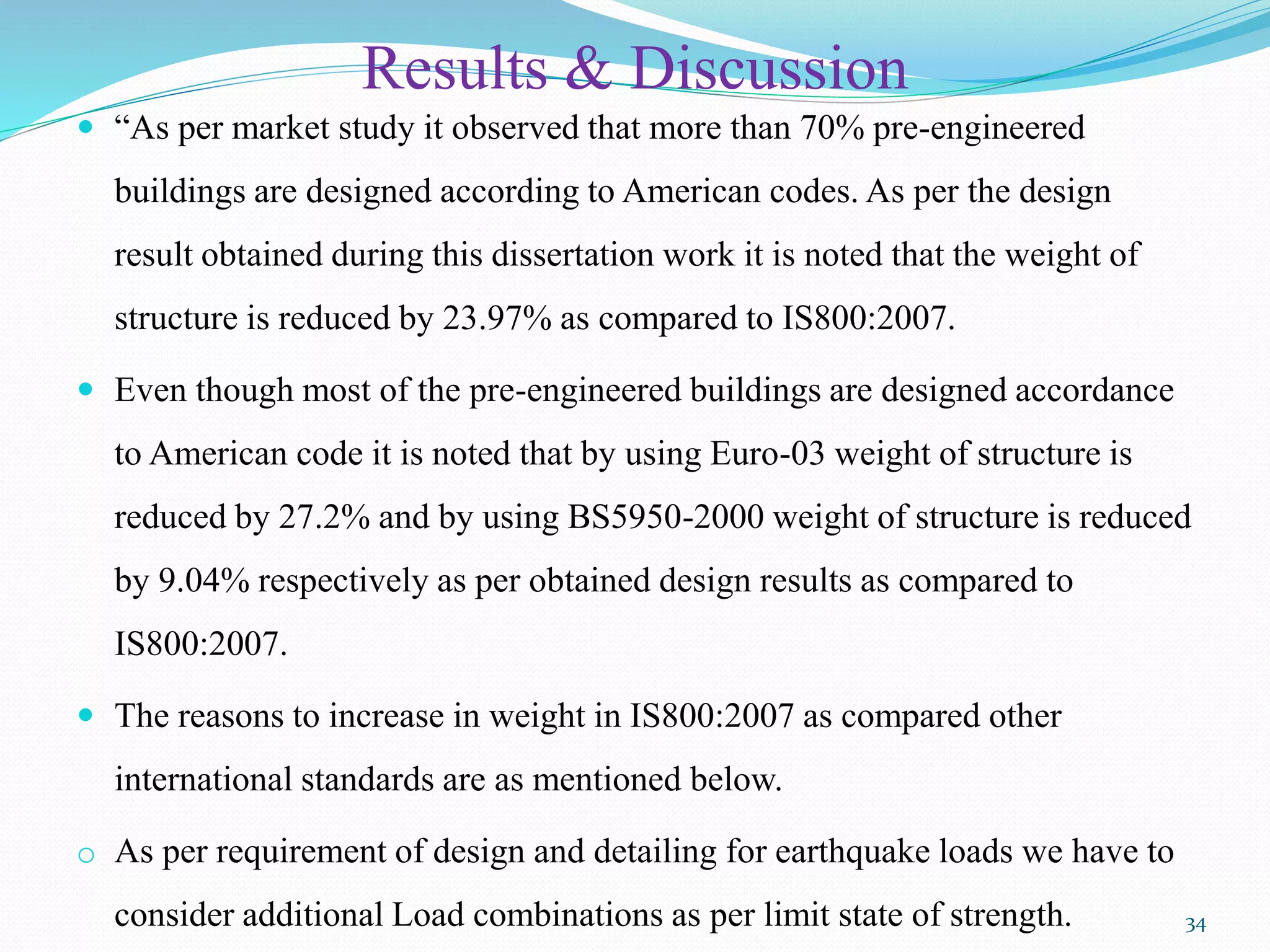

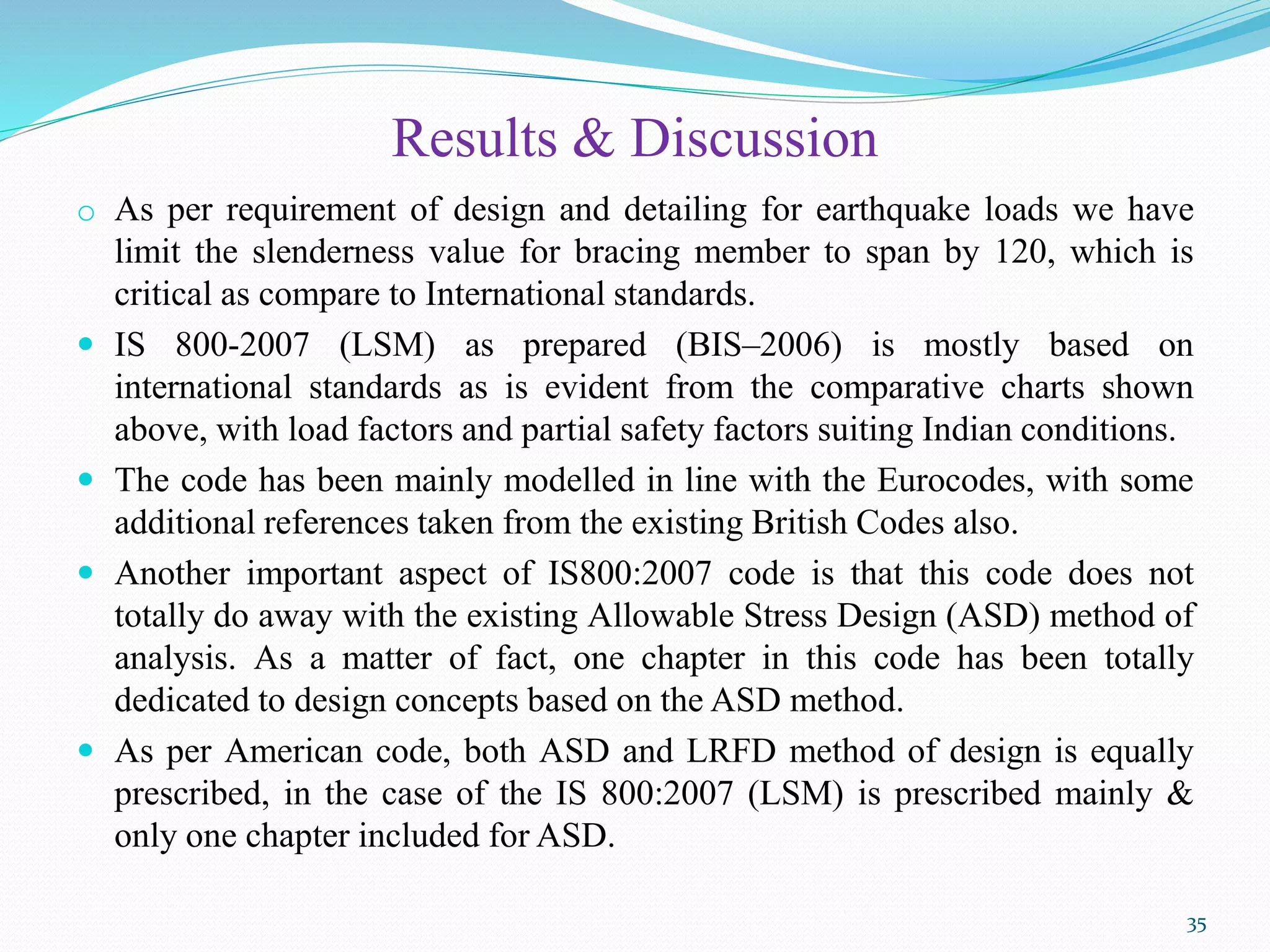

The document discusses the analysis and design of a pre-engineered building (PEB) using IS800:2007 and international standards. It summarizes literature on PEBs and their advantages over conventional buildings. The objective is to design a G+3 school building using different codes and compare the structural weight. Load combinations and section classifications according to different codes are presented. The design is carried out for the building and results show the structural weight is reduced by 9.04% under BS5950, 23.97% under AISC-2010, and 27.19% under Eurocode 3, compared to IS800:2007.

![Literature Review

Kumar et al [2014]

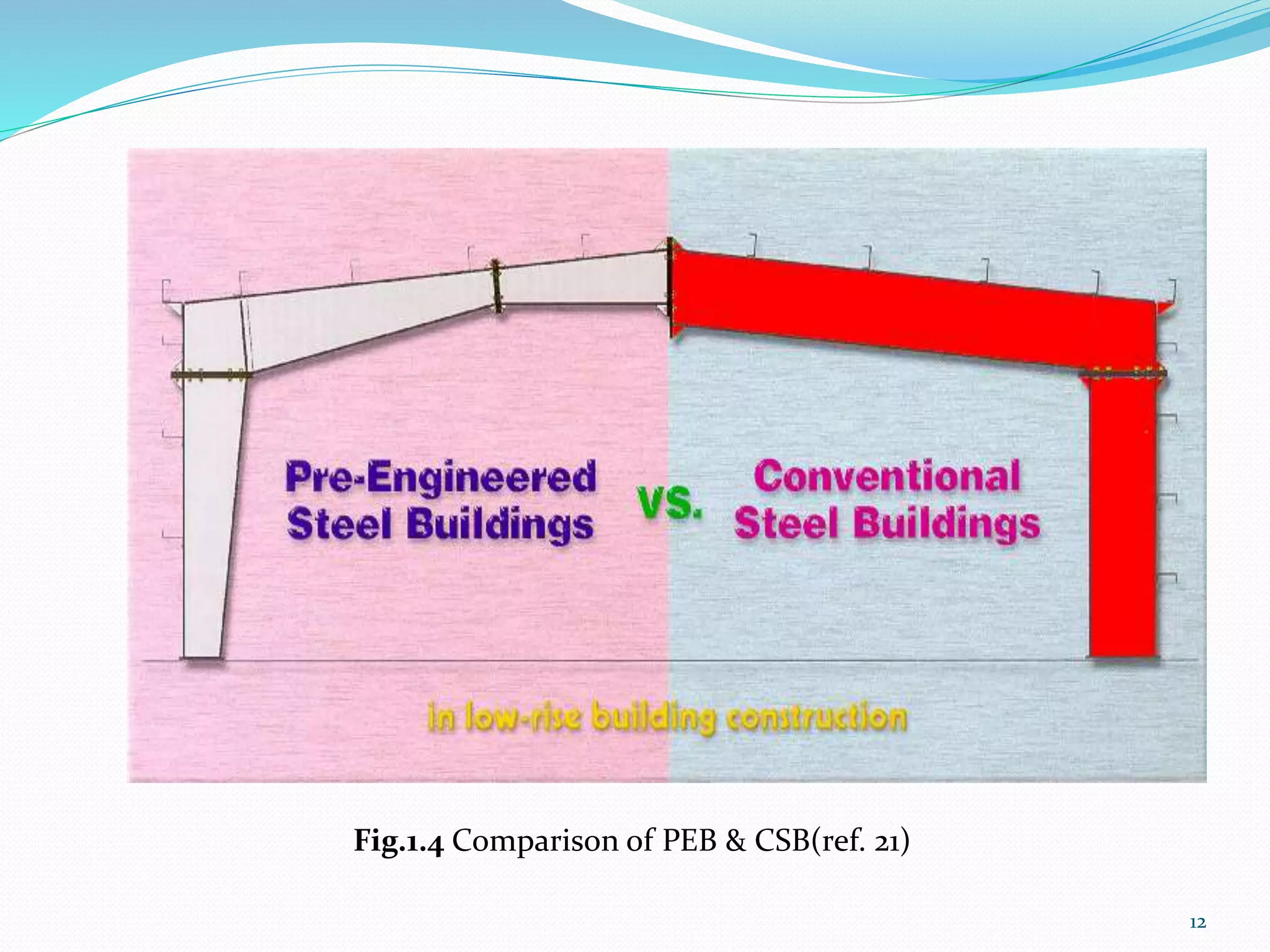

o Studied the Pre-Engineered Building (PEB) concept in the design of structures

which helped in optimizing design.

o The ability of PEB in the place of Conventional Steel Building (CSB) design

concept resulted in many advantages, including economy and easier fabrication.

o The economy of the structure is discussed in terms of its weight comparison,

between Indian codes (IS800-1984, IS800-2007) & American code (AISC-89)

& between Indian codes (IS800-1984, IS800-2007).

Chavan et al [2014]

o Evaluated the economic significance of the Hollow Structural Sections (HSS) in

contrast with open sections.

o This study was carried out to determine the percentage economy achieved using

Hollow Structural Sections (HSS) so as to understand the importance of cost

effectiveness.

16](https://image.slidesharecdn.com/analysisdesignofpre-engineeredbuildingusingis8002007internationalstandards-00-180408081553/75/Analysis-and-design-of-pre-engineered-building-using-is-800-2007-and-International-standards-16-2048.jpg)

![Literature Review

Anbuchezian et al [2013]

o studied behaviour of cold formed sections.

o Cold formed steel purlins are the widely used structural elements in

India.

o Practically ‘Z’ sections are provided, where the span of the roof purlins is

sloped and the length of the span is maximum.

Saleem [2013]

o Presented research work on, minimum weight buildings that are targeted

with simple fabrication process and easy erection to have maximum

structural efficiency.

o and to verify suitability and applicability of concept of PEB, a sample

steel building is first analyzed and designed by using conventional steel

hot rolled sections and then by using pre-engineered tapered and cold

formed sections.

17](https://image.slidesharecdn.com/analysisdesignofpre-engineeredbuildingusingis8002007internationalstandards-00-180408081553/75/Analysis-and-design-of-pre-engineered-building-using-is-800-2007-and-International-standards-17-2048.jpg)

![Literature Review

Satpute et al [2012]

o He has done the detailed analysis of Industrial building with Cold

formed concept is carried out.

o A comparative study has also been carried out between Hot Roll steel

Industrial building and Cold formed Industrial building and a conclusion

has been drawn.

o In Industrial building the material & cost of the building is minimized in

case of cold formed steel while in case of conventional building it was be

higher both in two cases. The saving in material and cost is about 25%.

18](https://image.slidesharecdn.com/analysisdesignofpre-engineeredbuildingusingis8002007internationalstandards-00-180408081553/75/Analysis-and-design-of-pre-engineered-building-using-is-800-2007-and-International-standards-18-2048.jpg)