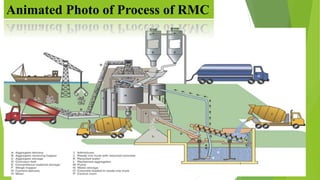

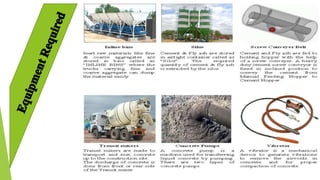

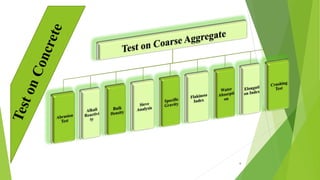

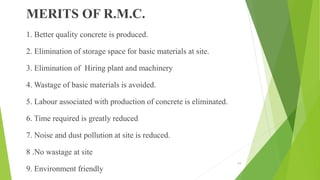

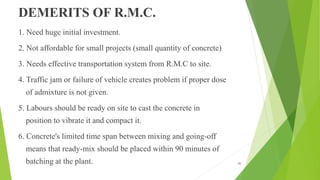

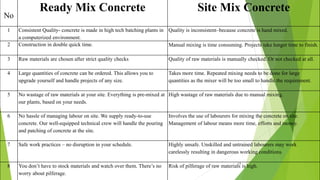

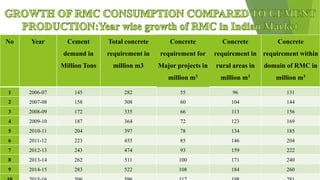

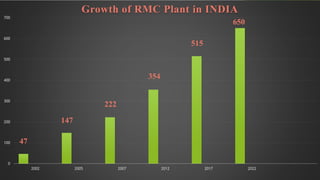

The document discusses ready mixed concrete (RMC), detailing its merits, such as consistent quality and reduced construction time, as well as demerits like high initial investment and transportation challenges. RMC is particularly beneficial for large projects in congested areas, providing better durability and lower environmental impact. It emphasizes the advantages of RMC over traditional site-mixed concrete in terms of efficiency, cost-effectiveness, and quality control.

![Ready Mixed Concrete

(RMC)

.

1

BIRLA

VISHVAKARMA

MAHAVIDHYALAYA

Prepared By:

Abhishek.S.Shah

ENROLLMENT NO: 130080714018

FIRST SEMESTER

CIVIL ENGINEERING DEPARTMENT

B.V.M ENGINEERING COLLEGE

Guide By:

PROF. JAYESHKUMAR R. PITRODA

ASSISTANT PROFESSOR & RESEARCH SCHOLAR

CIVIL ENGINEERING DEPARTMENT

B.V.M ENGINEERING COLLEGE

V.V.NAGAR

M.E. [ CONSTRUCTION ENGINEERING

& MANAGEMENT ]

CONSTRUCTION TECHNIQUES (711402) GUJARAT

TECHNOLOGICAL

UNIVERSITY](https://image.slidesharecdn.com/rmcumrakh-150809075243-lva1-app6891/75/Ready-Mix-Concrete-1-2048.jpg)