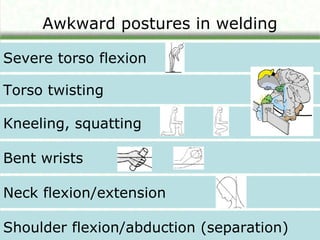

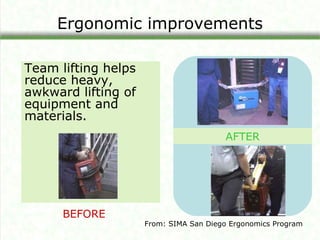

Welding operations present various occupational hazards including work-related musculoskeletal disorders (WMSDs) from awkward postures and heavy lifting. Common WMSDs among welders include back injuries, shoulder pain, and carpal tunnel syndrome. Implementing ergonomic solutions such as powered tools, lifting aids, and adjustable workstations can help reduce physical demands and prevent WMSDs. Failure to address ergonomic hazards may result in injuries, lost time, and reduced productivity.

![More resources Shipyard Ergonomics for purchase at Shipbuilders Council of America at www.Shipbuilders.org NIOSH’s Ergonomic Interventions in the Building, Repair, and Dismantling of Ships SHARP Program Easy Ergonomics . A practical approach for improving the workplace OR OSHA & CAL OSHA Services. www.cbs.state.or.us/osha/pdf/pubs/3347.pdf On WMSD hazardous exposures visit the WISHA webpage at: www.lni.wa.gov/Safety/Topics/Ergonomics Example Template of an accident prevention program : www.lni.wa.gov/Safety/Basics/Programs/Accident Ideas to reduce hazardous exposures can be found at the Ergonomics Ideas Bank You may also write us at: [email_address]](https://image.slidesharecdn.com/ergonomics6-110509101528-phpapp01/85/Ergonomics-6-30-320.jpg)