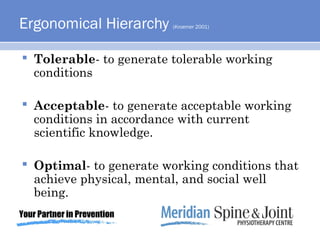

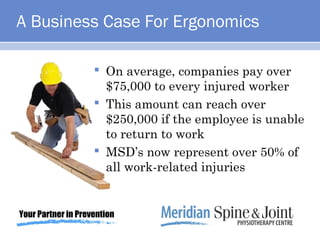

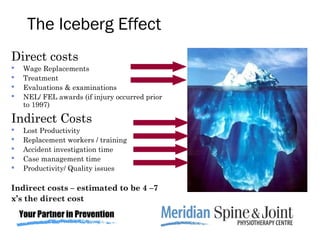

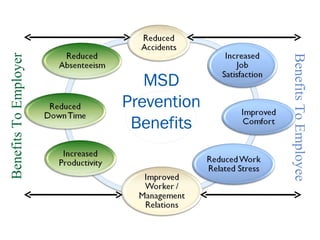

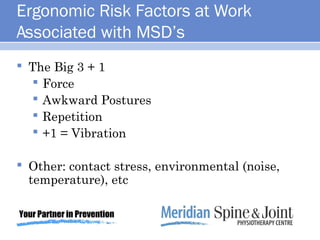

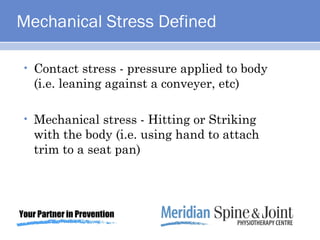

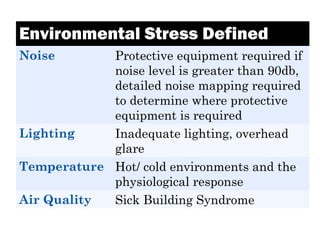

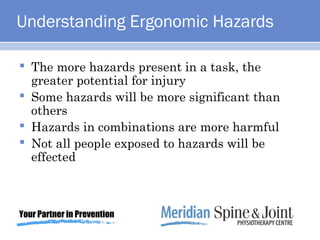

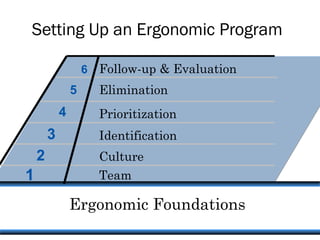

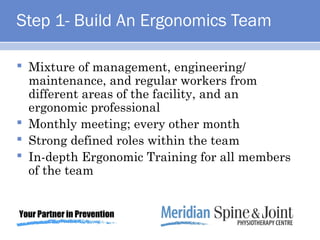

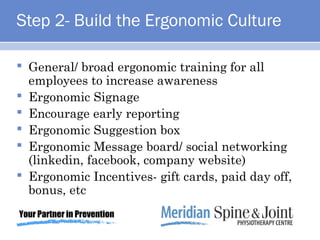

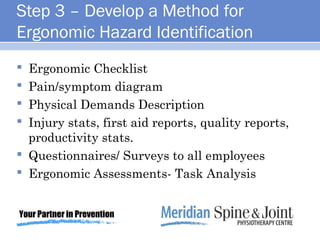

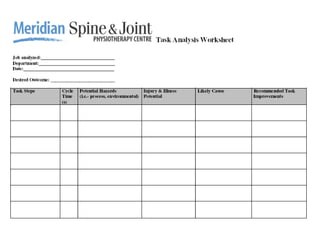

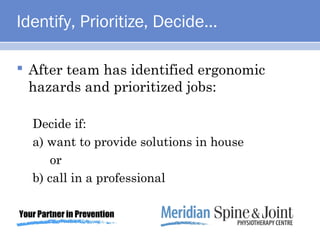

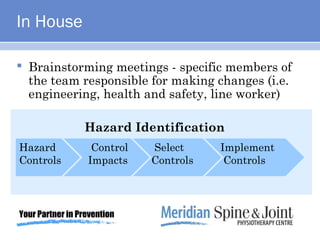

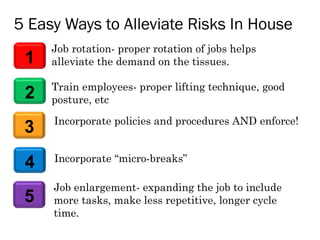

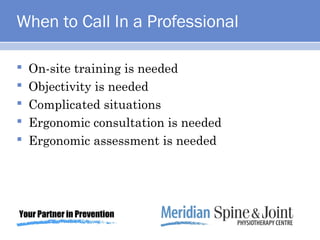

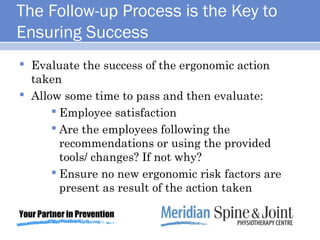

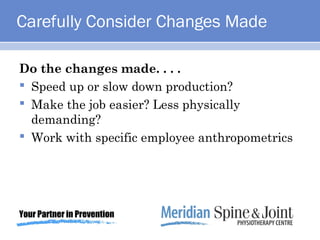

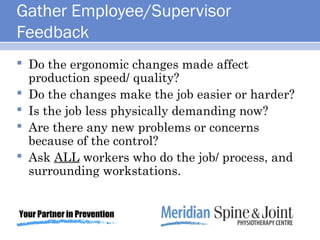

The document outlines how to set up an effective musculoskeletal disorder (MSD) prevention program. It discusses what MSDs are, why prevention programs are important, getting company buy-in, ergonomics basics, and how to set up and ensure success of an MSD prevention program. The key steps include building an ergonomics team, developing a culture of prevention, identifying hazards, prioritizing issues, implementing controls, follow-up evaluations, and communicating results.