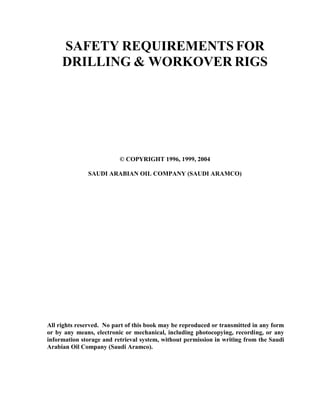

This document outlines safety requirements for drilling and workover rigs operated on behalf of Saudi Aramco. It establishes Saudi Aramco's safety rules for drilling and workover activities, and a uniform set of safety requirements applicable to both contractor and company-owned rigs. The objectives are to minimize risks to personnel and property through application of best petroleum industry loss control programs. Compliance with these requirements and cooperation of all personnel are necessary to fulfill the company's commitment to safety.

![condition, the RIG OPERATOR shall conduct a physical inspection of its rig and all

auxiliary equipment on a regular basis – no less than once per month.

The RIG OPERATOR will implement a comprehensive preventive maintenance

program to keep equipment in good working condition.

SECTION B: GENERAL

B-1 MEDICAL

1. Each RIG OPERATOR shall comply with the Saudi Arabian Ministry of Labor

and Social Affairs Decision Number 404, dated 7 July 1974, entitled "First Aid

Facilities at Work Sites". A copy of this document or an English language

translation is available from the Drilling and Workover Operations Manager or

from Dhahran Area Loss Prevention.

2. The RIG OPERATOR, with the assistance of the COMPANY as required,

prior to the start of drilling or workover operations, shall identify the nearest

trauma clinic or physician or hospital and shall make provisions for the

PROMPT transportation of a victim of injury or sudden illness to the

physician, hospital or clinic or to summon emergency medical personnel to

the location. Also, prior to the start of operations, the COMPANY shall

provide an effective communication system for contacting necessary medical

and emergency agencies with written posted procedures for medical

evacuation [Medivac].

3. The RIG OPERATOR, with the assistance of the COMPANY as required,

shall furnish to any person injured in his employment who is in need of

medical attention immediate transportation to a hospital, physician, or clinic

for the purpose of treatment.

4. Telephone numbers of the physician, hospital, ambulance, and helicopter

services shall be conspicuously posted by the COMPANY in the

Representative‟s office, Rig Manager's office, the rig medic station, and the

radio room. These numbers are to be posted as soon as possible after

moving to a new location.

5. The vehicle or conveyance used for transport of the injured shall in addition to

contractual requirements:

(a) Be of sufficient size and suitable to accommodate a stretcher and

accompanying person entirely within the body of the vehicle or

conveyance.

(b) Be clean and well maintained.

(c) Protect the injured worker and the accompanying person.

REV. JUNE 2004 Safety Requirement for

Drilling & Workover Rigs

-- Page 8 of 95 --](https://image.slidesharecdn.com/safetydrillingslideshow-120505211245-phpapp01/85/Safety-drilling-slide-show-15-320.jpg)

![coordinating activities when working under a SCBA. [Note: Dry eraser

boards may be substituted for chalk boards].

L. Flashlights - explosion proof with an extra set of batteries and extra

bulb for each (number to be at least one for each two persons in the

operation but not less than five).

NOTE:

All safety equipment with rubber, plastic or other parts likely to

deteriorate shall be stored in a dark air conditioned room near the

Foremen's office. Adequate supplies of sanitizing materials shall be

available for sanitizing face masks and other body contact equipment.

Section B-7 Appendix III:

SAUDI ARAMCO STANDARD SAFETY EQUIPMENT FOR H2S

OPERATIONS ON ALL OFFSHORE DRILLING AND WORKOVER RIGS

1. A continuous monitoring system with eight sensors and six beacon

lights/siren alarm systems, each with conductor cable, shall be provided. All

personnel shall be informed by the RIG OPERATOR of the hazards relating

to Hydrogen Sulphide and shall receive instruction in the correct use of any

personal safety equipment, Hydrogen Sulphide detectors, and warning

systems associated with the RIG OPERATOR‟S H2S equipment.

(a) All sensors must have protective housings capable of protecting the

sensor from accidental spray from rig wash down hoses and accidental

mud and/or oil splashes.

(b) Sensors shall be located as near as practical to:

1. The top of the bell nipple.

2. The flowline opening to the shale shaker.

3. The Drillers position and about three feet above the rig floor.

4. The mud pit in the pump area.

5. The motorman's work area in the motor room.

6. The living quarters area nearest the most likely source of

hydrogen sulfide.

7. The breathing apparatus compressor package, near the rig

floor.

8. A spare sensor system with 200 feet of cable on portable reel

shall be extra and will be used to monitor any other potential

source of hydrogen sulfide or kept on standby in designated

safety equipment storage area.

REV. JUNE 2004 Safety Requirement for

Drilling & Workover Rigs

-- Page 26 of 95 --](https://image.slidesharecdn.com/safetydrillingslideshow-120505211245-phpapp01/85/Safety-drilling-slide-show-33-320.jpg)

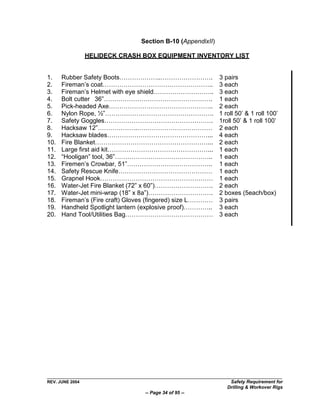

![15. Four stretchers (Stokes litter - Navy type basket or equivalent) with blankets

and securing straps.

16. Four first aid kits (each 25 man size).

17. Four Quick-Air splint kits or equivalent.

18. Six portable electronic bull horn speakers with six extra battery packs.

19. Six small chalk boards with clamps for mounting with an adequate supply of

chalk and erasers. Boards can be utilized as visual means of coordinating

activities when working under a SCBA. [Note: Dry eraser boards may be

substituted for chalk boards.]

20. Flashlights - explosion proof with extra set of batteries and extra bulb for each

(minimum number shall be 10 flashlights).

Note: All safety equipment with rubber, plastic or other parts like to

deteriorate shall be stored in an air conditioned, dark and designated area,

near the Supervisor's office. Adequate supplies of sanitizing material shall be

available for sanitizing face masks and other body contact equipment.

B-8 HOUSEKEEPING

1. Work areas, stairs and walkways shall not be obstructed by debris or stored

materials.

2. All walking and working surfaces shall be kept in good repair and free from

oil, mud, and other potentially slippery material.

3. The area around the base of the derrick ladder shall be kept clear to provide

unhampered access to the ladder.

4. The area around the rotary table shall be kept clear of obstacles; clean, and

free of tools, materials and any accumulation of oil, water, or circulating fluids.

5. Storage of material shall not create a hazard. Bags, containers, bundles, etc.,

stored in tiers shall be stacked, blocked, and limited in height so they are

stable and secure against sliding or collapse.

6. Storage areas shall be kept free from accumulation of materials that

constitute hazards from tripping, fire, or explosion.

7. Combustible materials, such as oily rags and waste, shall be stored in

approved covered metal containers.

REV. JUNE 2004 Safety Requirement for

Drilling & Workover Rigs

-- Page 30 of 95 --](https://image.slidesharecdn.com/safetydrillingslideshow-120505211245-phpapp01/85/Safety-drilling-slide-show-37-320.jpg)

![3. Except during drilling with automatic driller engaged, drawworks controls shall

not be left unattended while the hoisting drum is in motion. When drilling with

an automatic driller, it is permissible for the driller to step out of arms reach of

the controls; however, he must always be in a position to simultaneously see

the drilling controls, associated gauges, and drill floor.

4. Before putting the drawworks in motion, the worker in charge of the

drawworks shall ensure that all other workers are clear of the machinery and

lines.

5. When there is a danger of the controls being engaged by accidental contact

with catlines or other equipment, the controls shall be protected by a guard.

6. There shall be an emergency kill switch at the driller's console for the

emergency shutdown of the rig motors and mud pumps. This switch shall be

checked periodically by the rig electrician and functioned quarterly to ensure

that it is ready for immediate use.

7. All instrumentation at the driller's console, including pit level indicator, mud

rate return flow, and pump stroke counter, shall be installed, used and

maintained according to its manufacturer's specifications. All warning alarms

shall be kept turned on and noted daily on the pre-tour checklists.

C-14 BRAKES

1. The RIG OPERATOR shall ensure that the brakes on the drawworks of every

drilling rig are tested by each driller when he comes on tour to determine

whether they are in good working order. Both the mechanical brake and the

auxiliary brake shall also be examined by the toolpusher at weekly intervals to

determine the condition of the brake blocks, linkage, seals, and other

operating parts.

2. Unless the drawworks is equipped with an automatic driller, the brake shall

not be left unattended without first being tied down. [Note: Meaning of

"unattended" in context of automatic usage]

3. Where a hold down chain is used in securing the drawworks brake handle,

the slot for holding the chain shall be provided with a seat or, where a side lug

is provided, it shall be curved upwards to prevent accidental disengagement

of the hold down chain.

C-15 ROTARY TABLE

1. Water hoses, lines, or chains shall not be handled or used near a rotary table

while it is in motion.

2. When visibility on a rig floor is obscured, personnel shall not be required or

permitted to work on the rig floor while the rotary table is in motion.

3. The rotary table shall not be engaged until all personnel and materials are

clear of it.

REV. JUNE 2004 Safety Requirement for

Drilling & Workover Rigs

-- Page 59 of 95 --](https://image.slidesharecdn.com/safetydrillingslideshow-120505211245-phpapp01/85/Safety-drilling-slide-show-66-320.jpg)