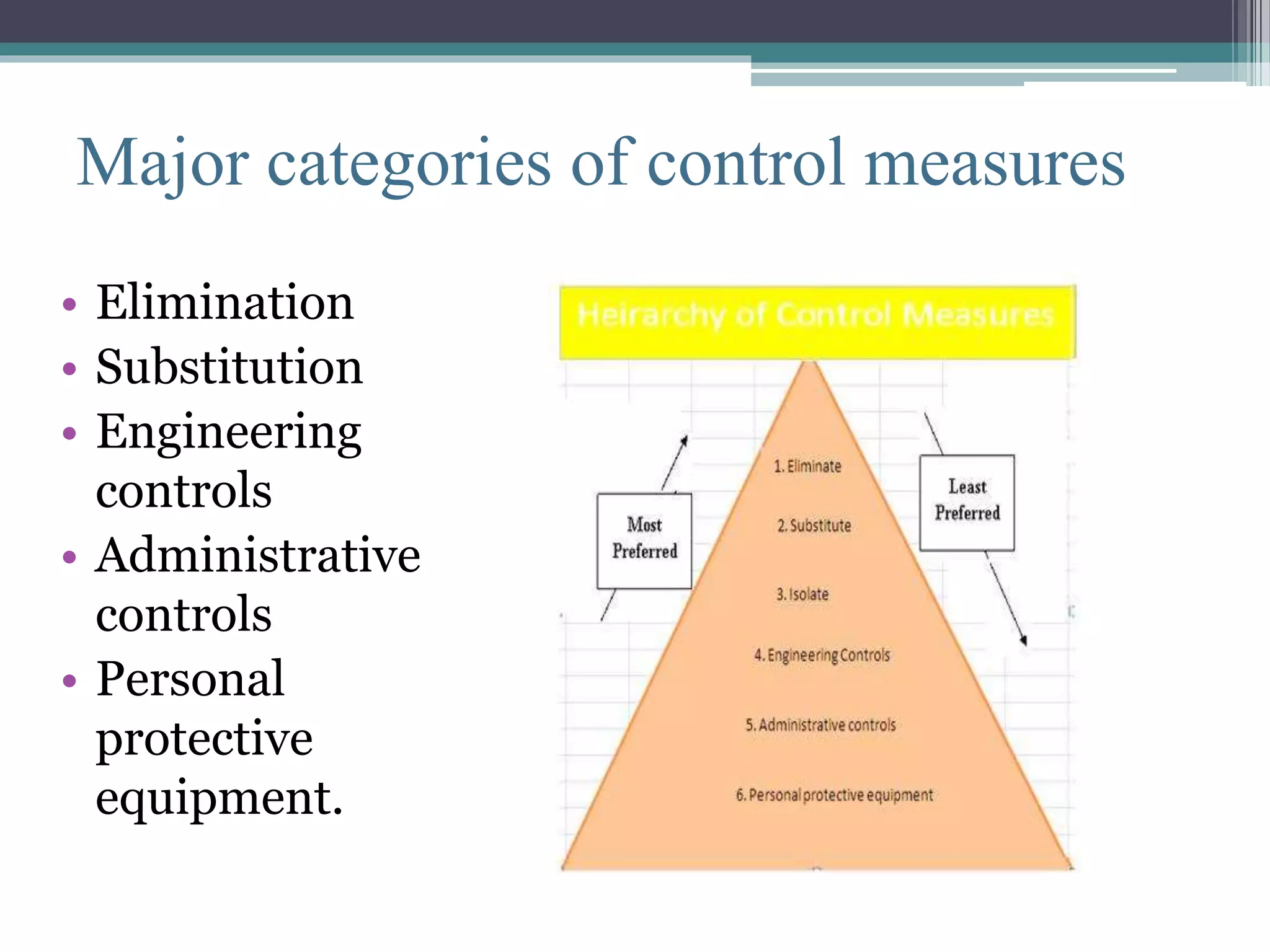

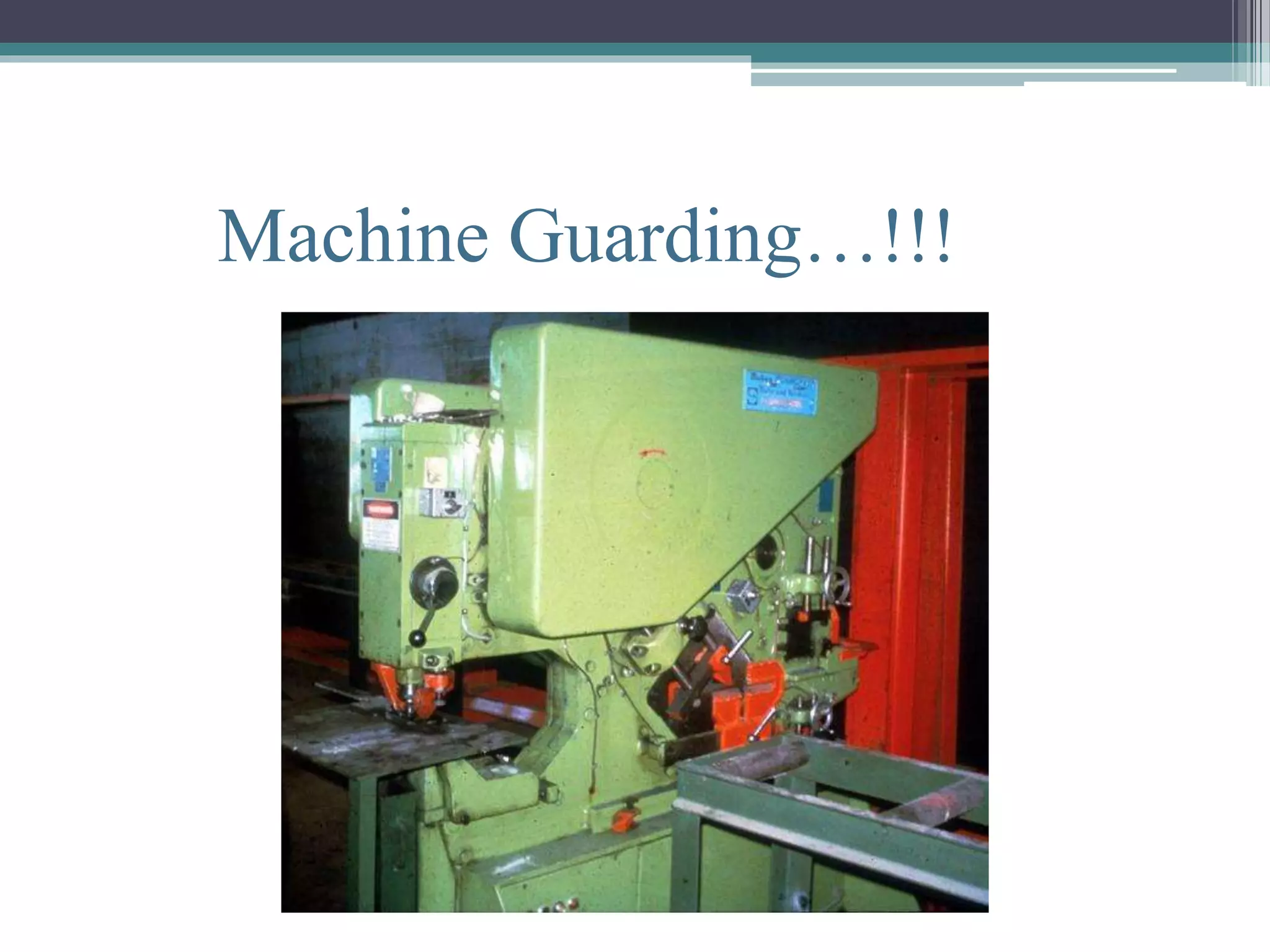

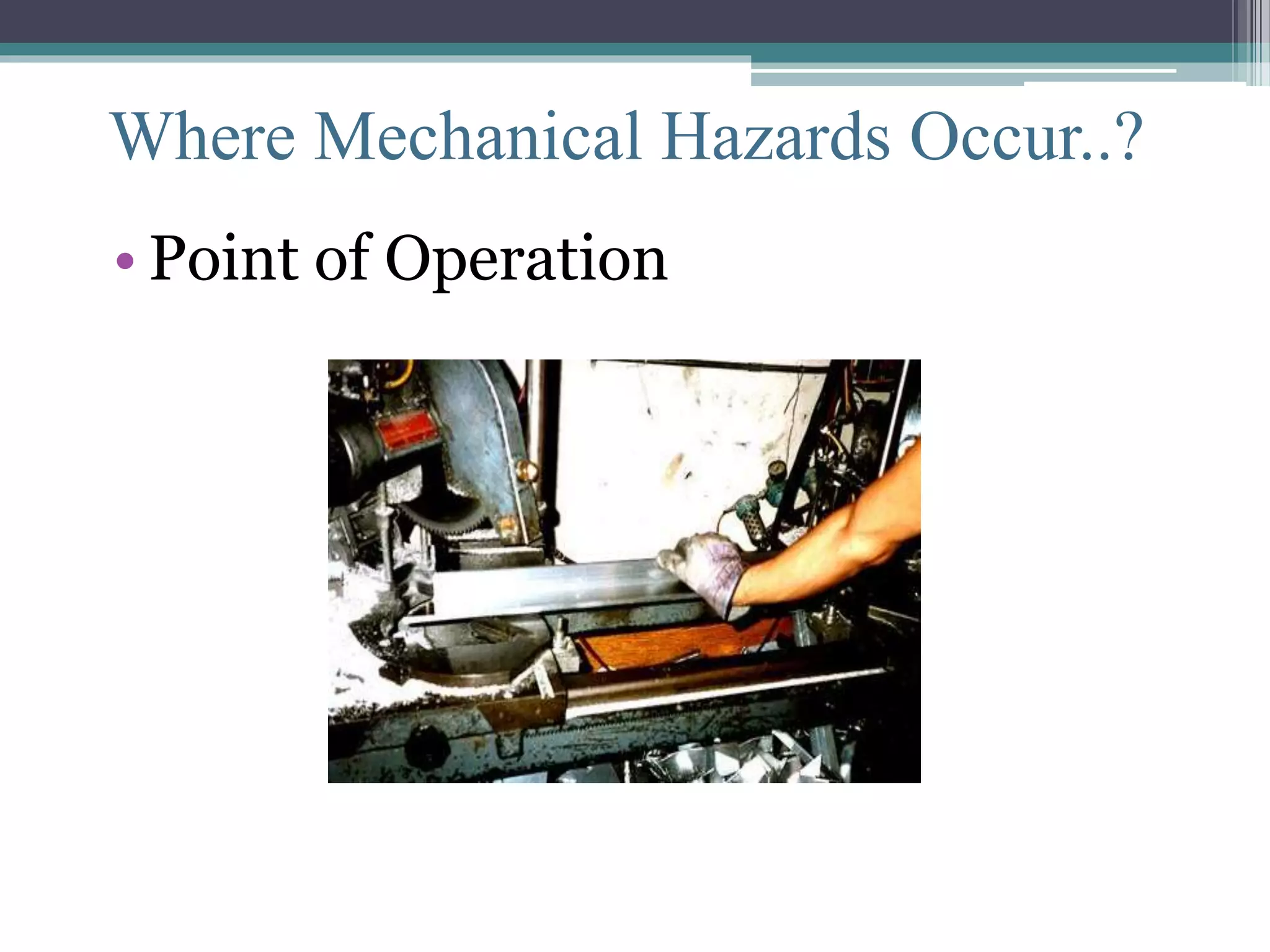

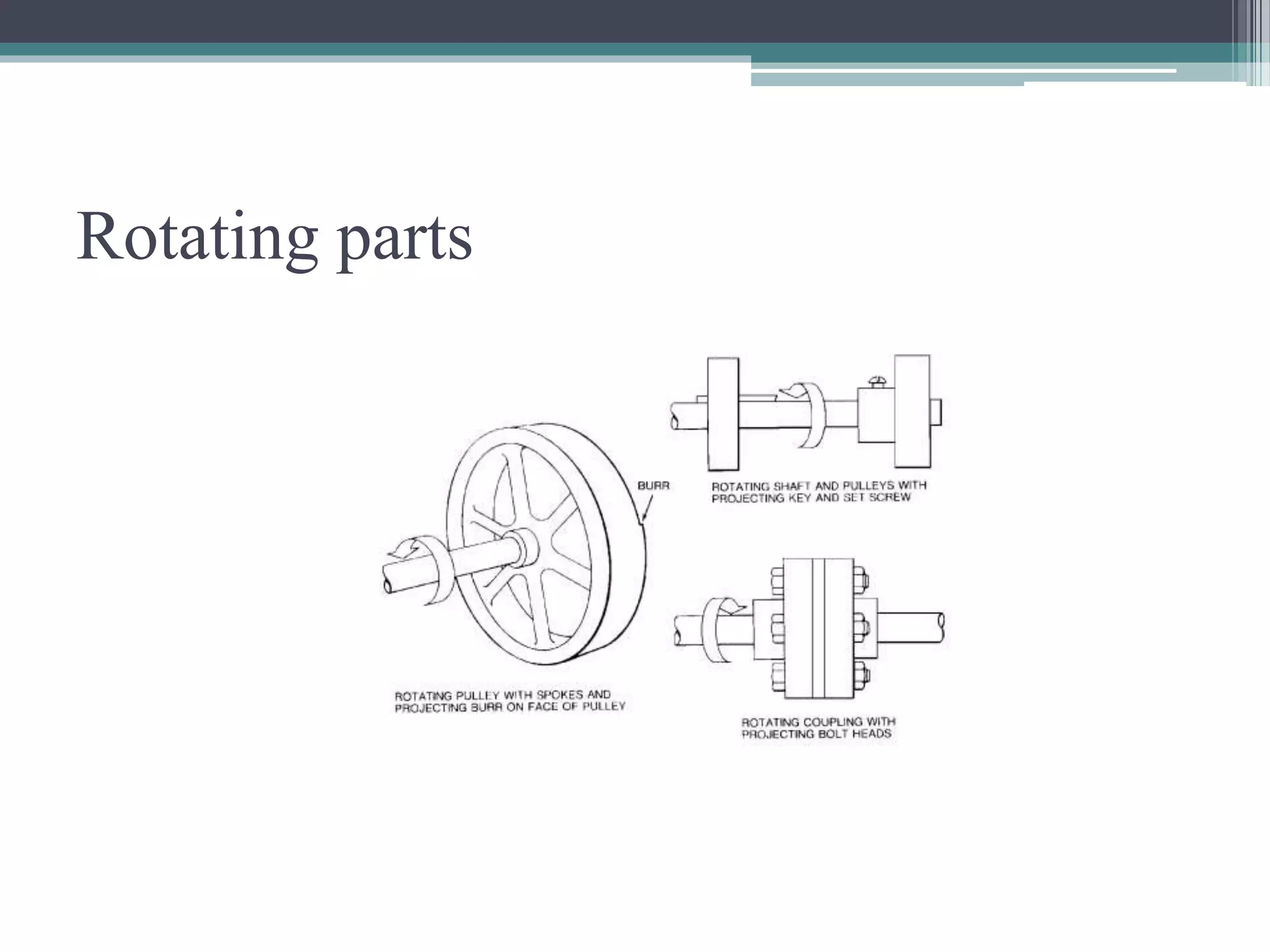

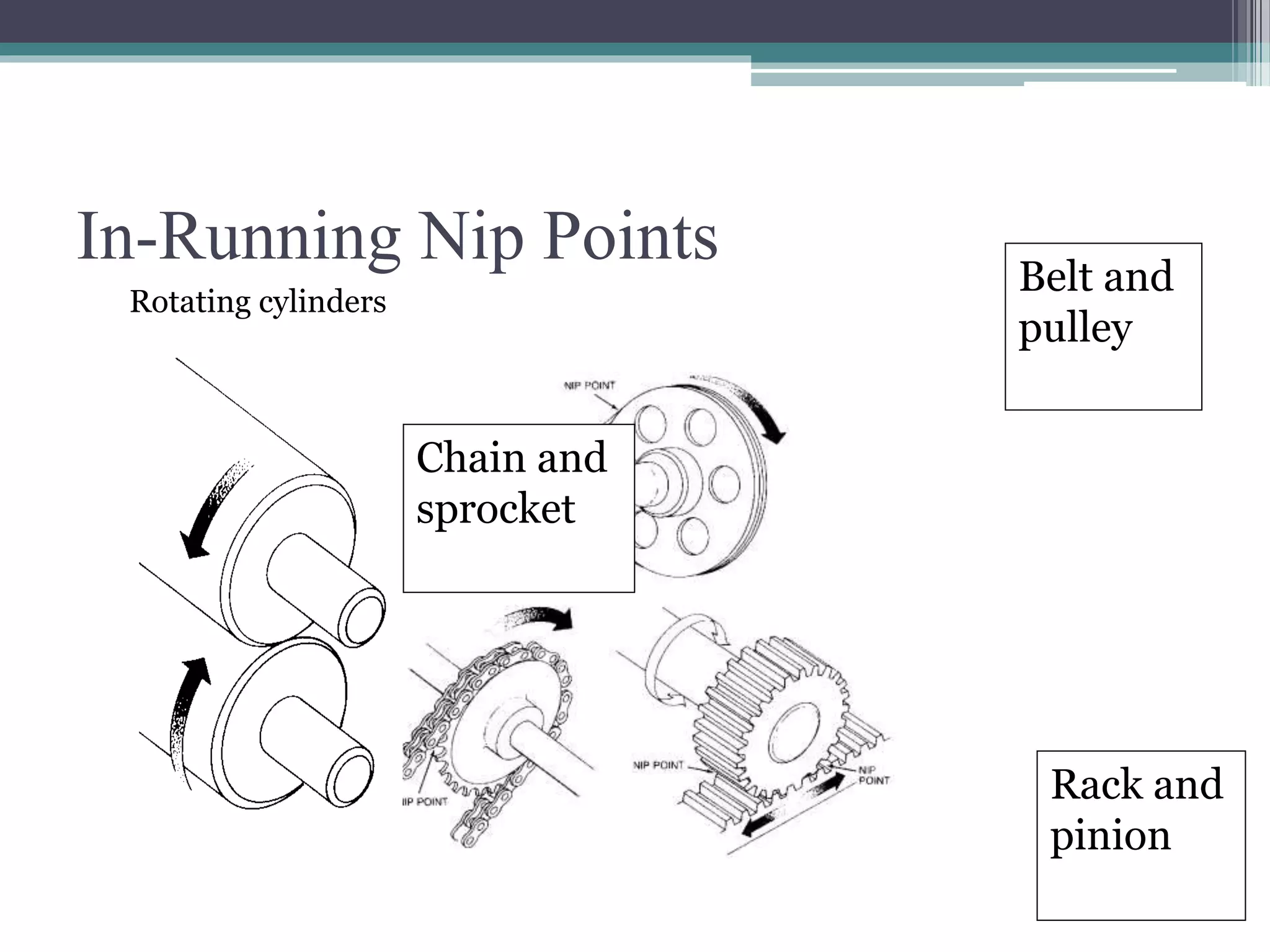

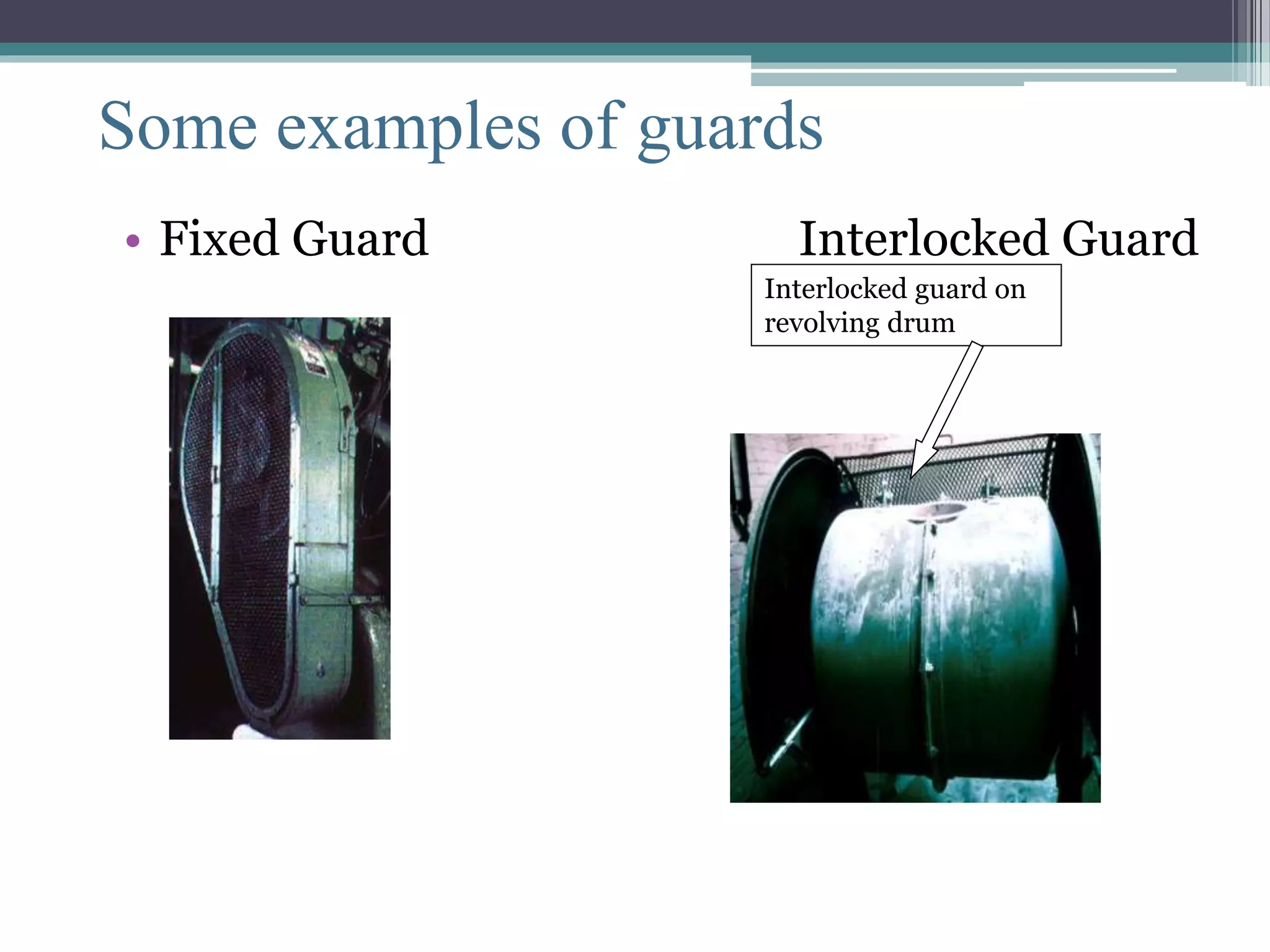

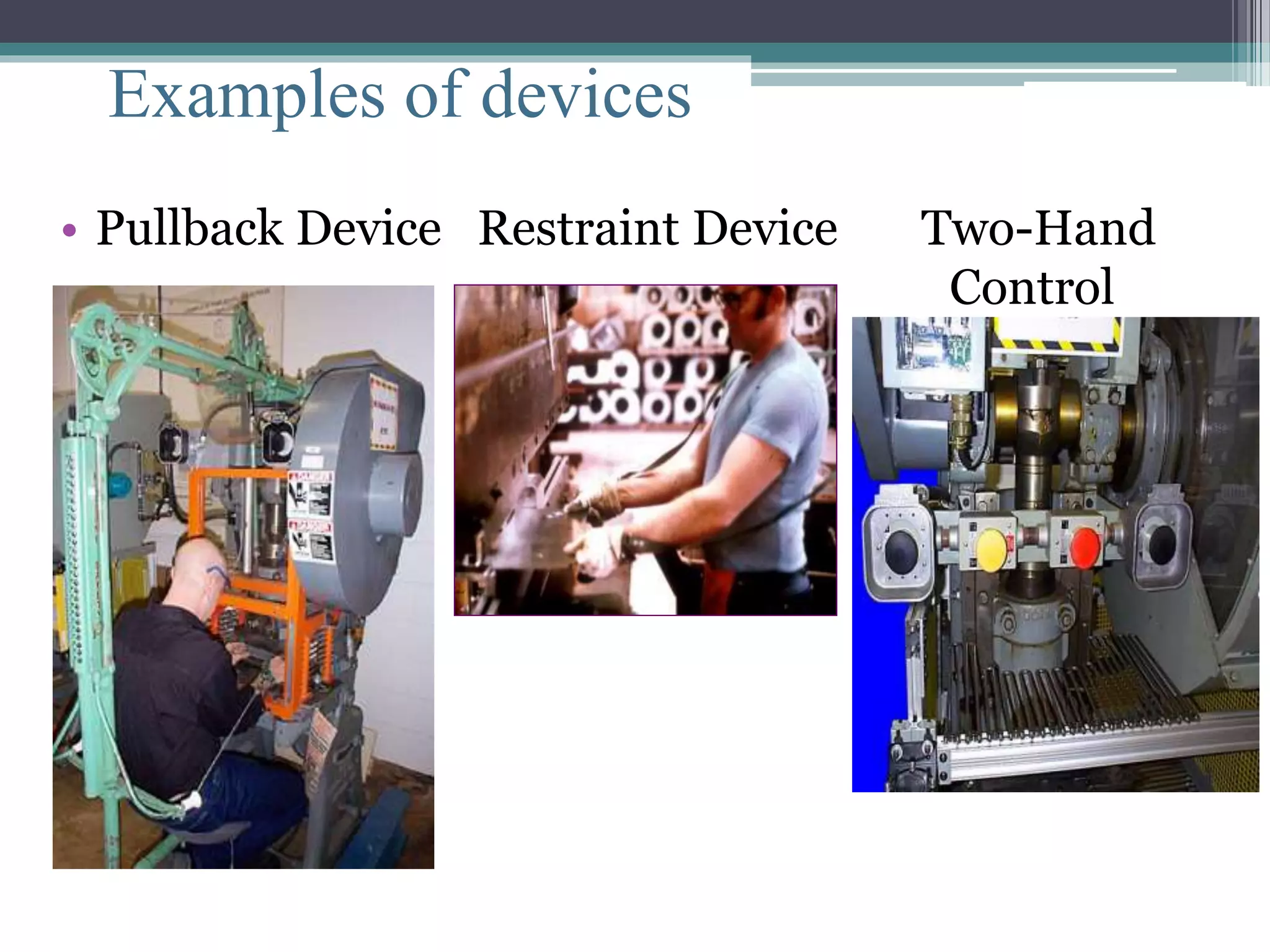

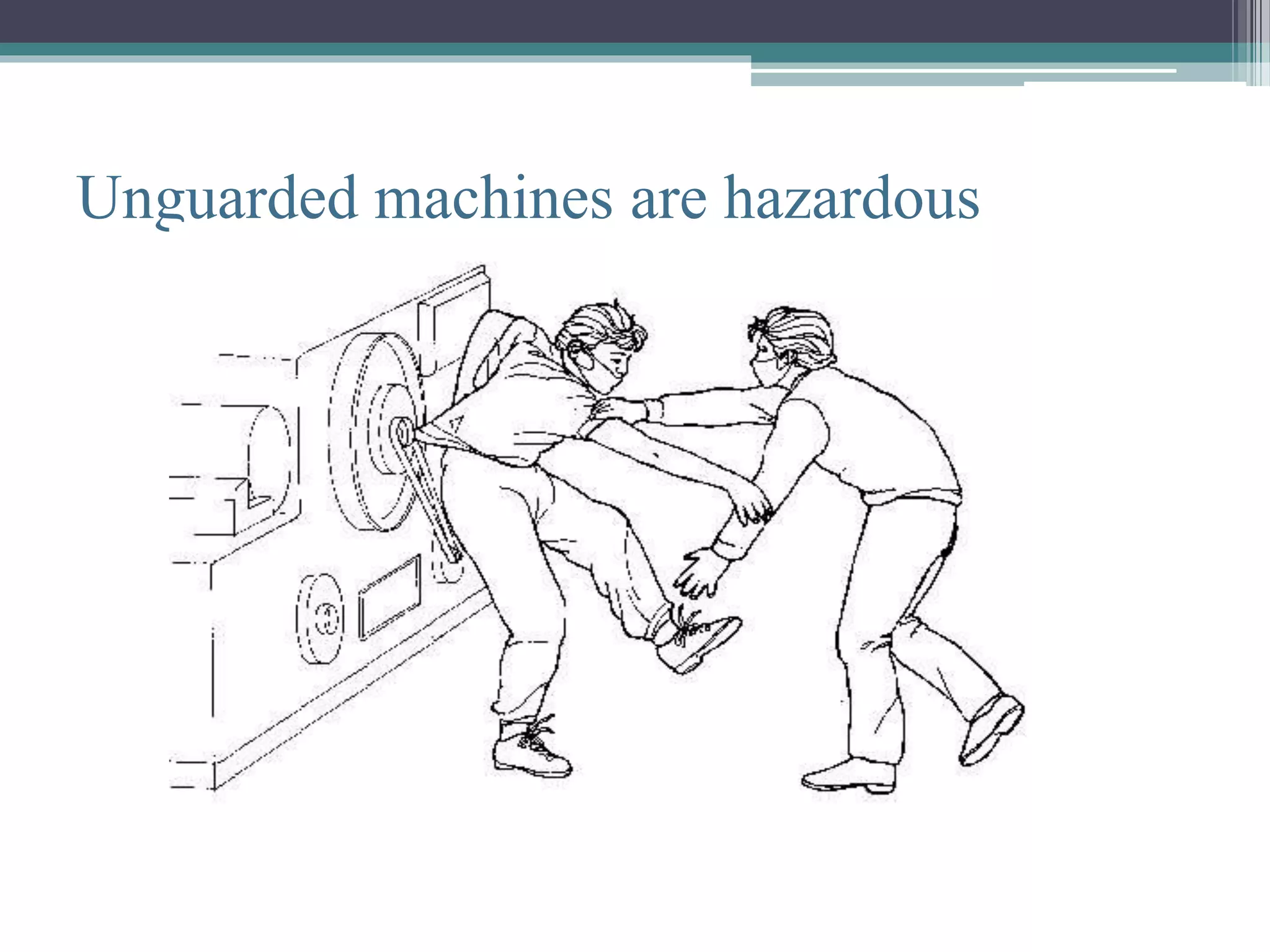

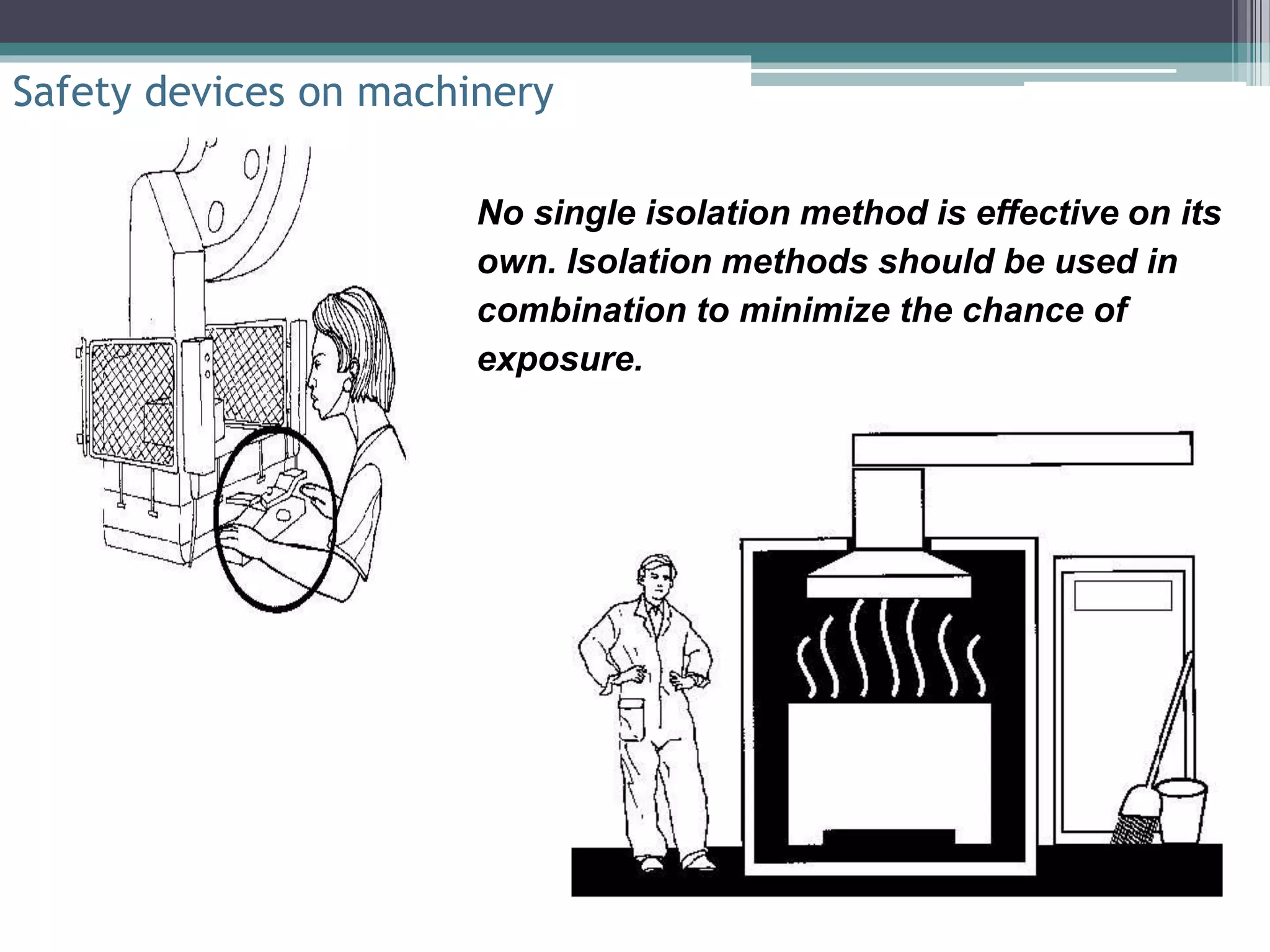

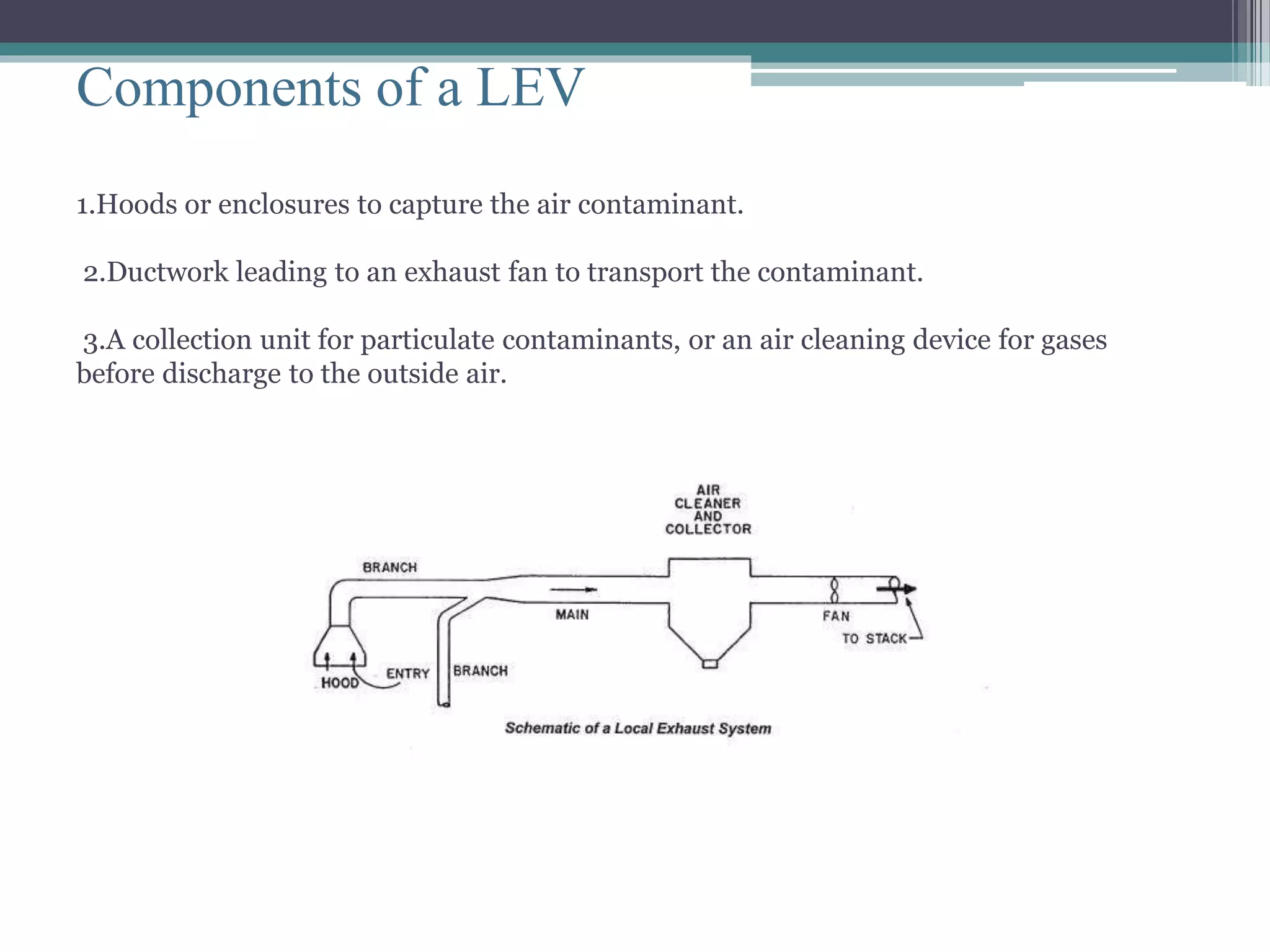

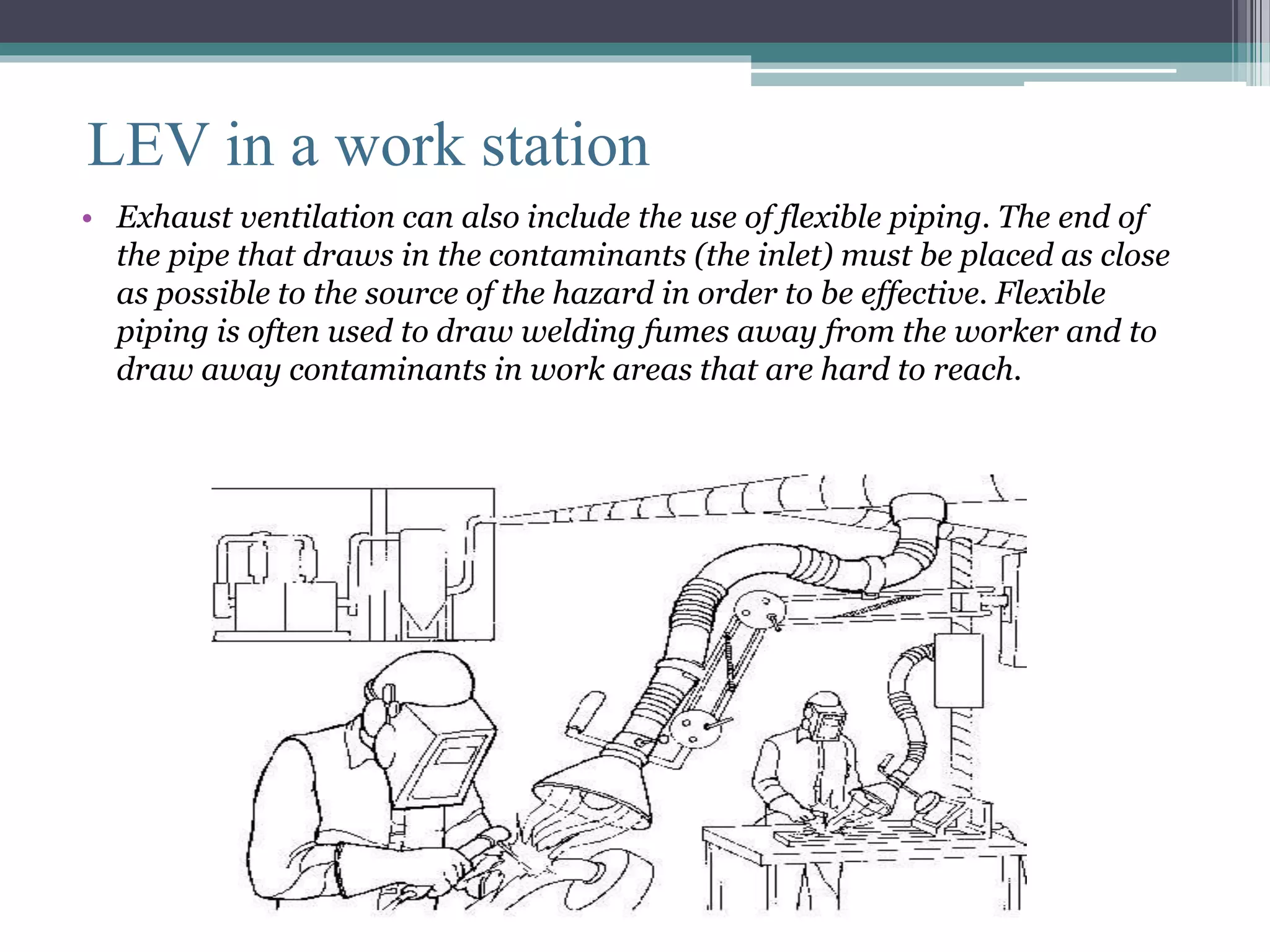

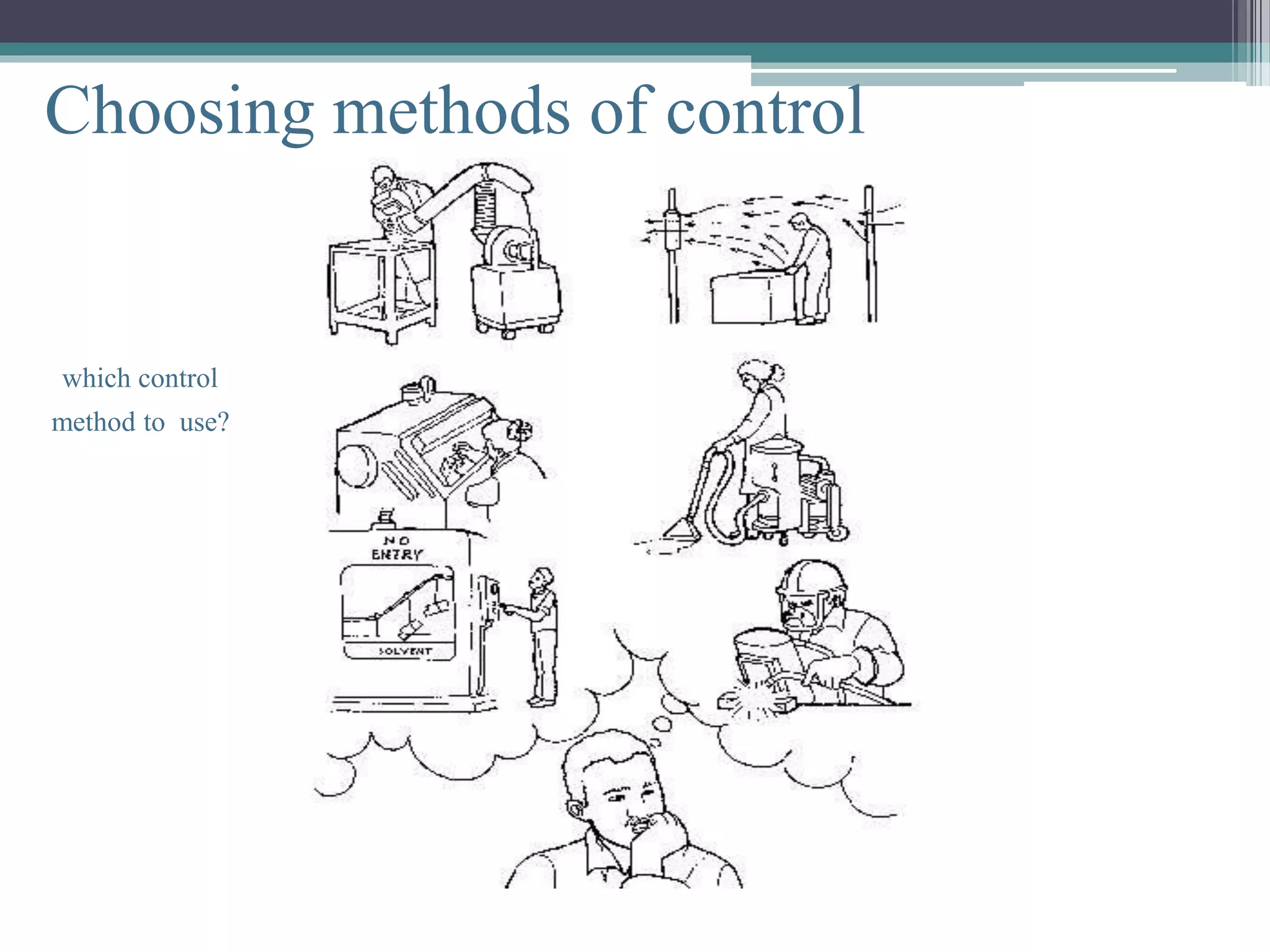

This document addresses various methods for controlling workplace hazards, emphasizing the importance of eliminating hazards at the source and using a combination of control measures like engineering controls, isolation, and ventilation. It outlines specific strategies for machine safeguarding and identifying health and safety concerns, highlighting roles for health and safety representatives in ensuring proactive hazard management. Effective control techniques include enclosure, isolation, ventilation, and the use of personal protective equipment, with the goal of preventing occupational exposure to hazards.