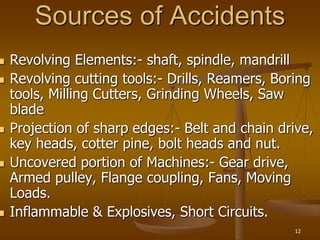

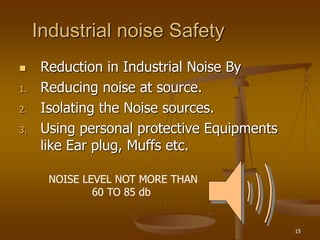

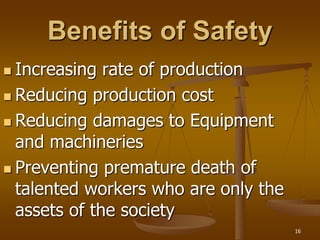

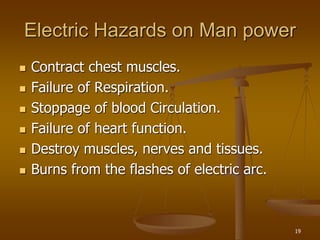

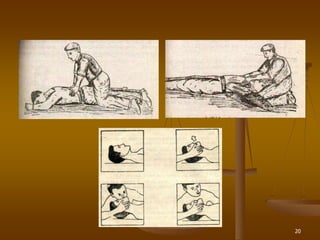

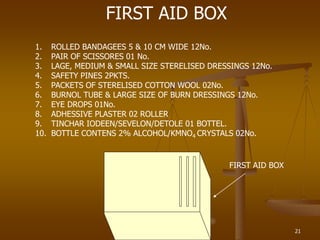

The document discusses various aspects of safety in industries, focusing on mechanical safety, causes of accidents, and preventive measures. It highlights the importance of following safety rules, using appropriate tools, and maintaining safe working conditions to reduce accidents and improve productivity. Additionally, it mentions the need for personal protective equipment, the risks associated with industrial noise and electric hazards, and outlines first aid essentials.