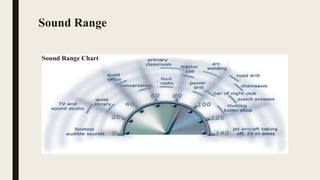

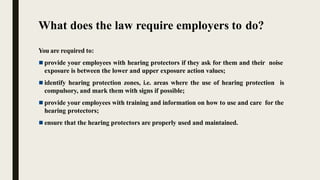

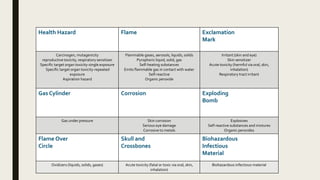

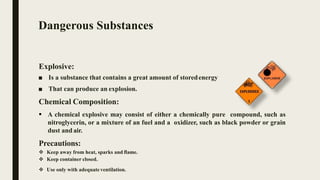

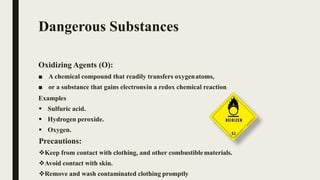

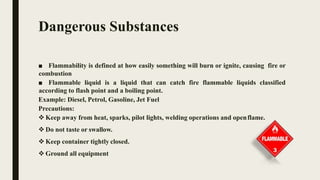

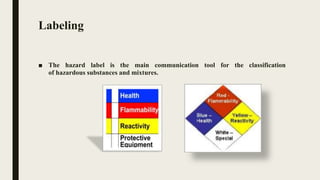

Noise exposure at work can cause temporary or permanent hearing loss. The CDC estimates that 22 million workers are exposed to potentially damaging noise levels each year. Employers are required to provide hearing protection to employees exposed to noise levels above certain limits and conduct health surveillance. Proper ventilation systems are important for removing airborne contaminants and maintaining a safe work environment. Hazardous substances must be properly stored, handled, and their dangers communicated through labeling according to established hazard classes.