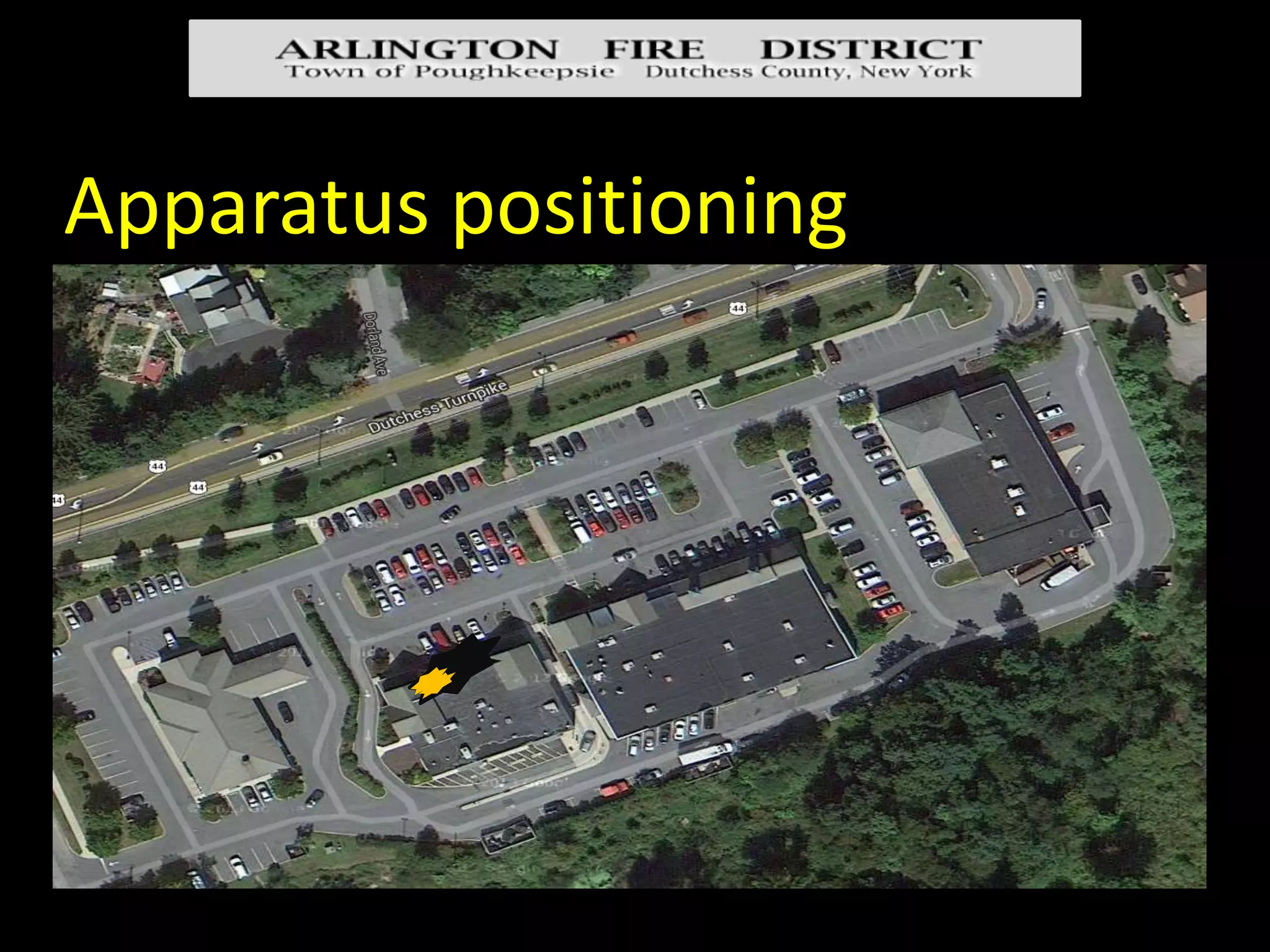

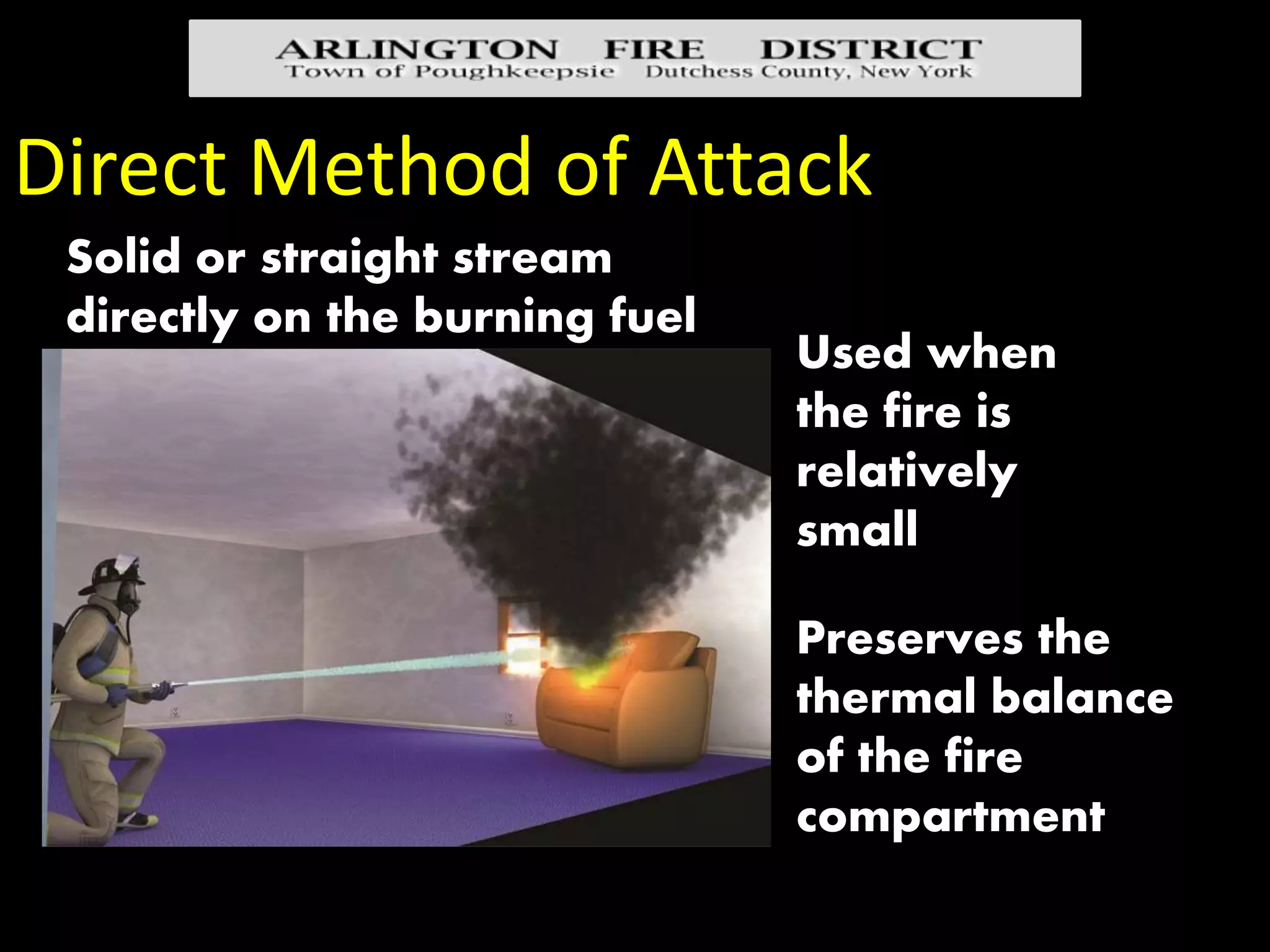

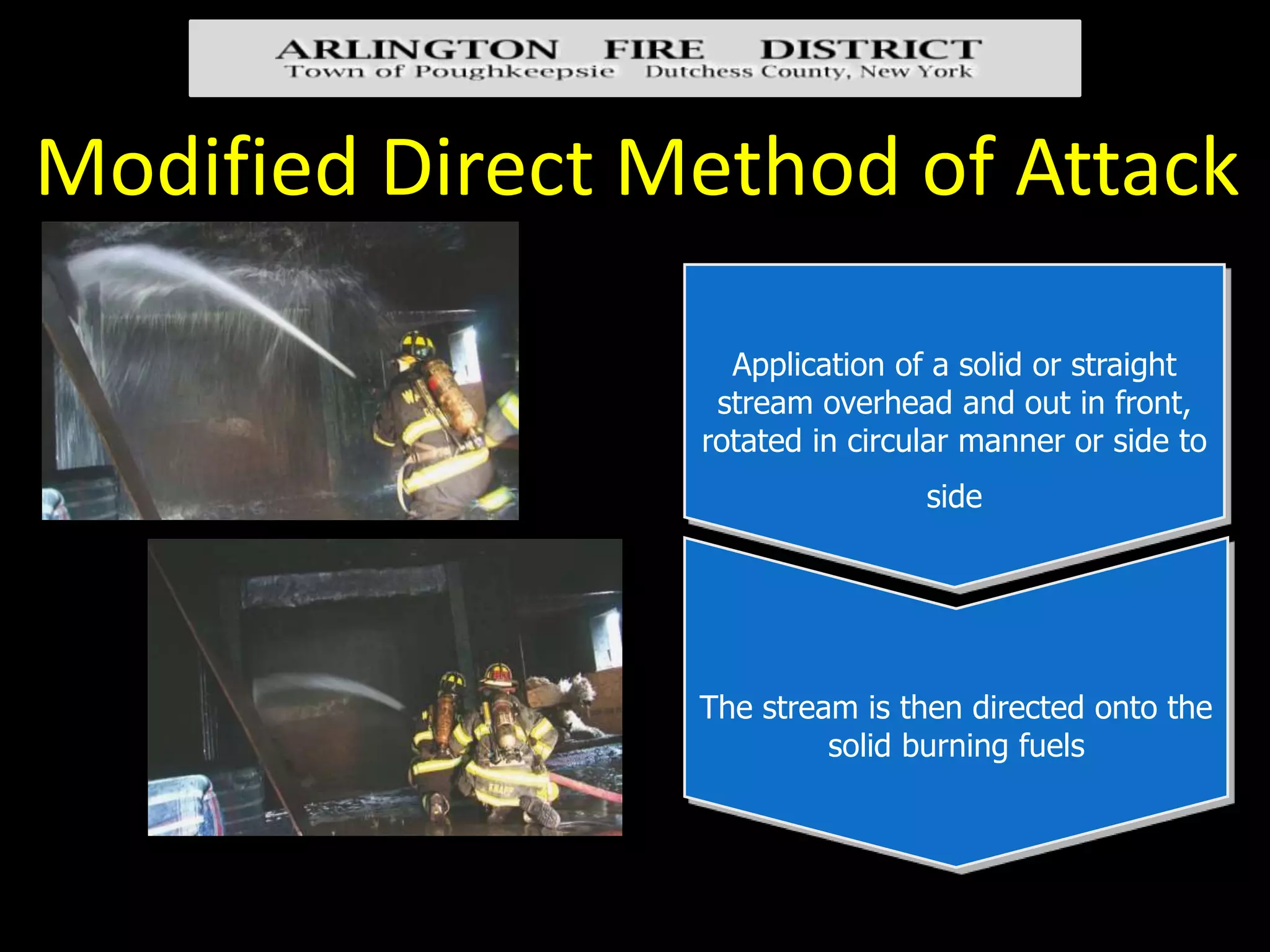

The document discusses RECEO, which outlines the priority sequence of firefighting operations as rescue, exposures, confinement, extinguishment, and overhaul. It also discusses apparatus positioning, hose selection and placement, water flow requirements, and methods of fire attack including direct, indirect, modified direct, and transitional. Key considerations for engine company operations include pre-planning duties and communications, protecting occupants and firefighters, and choosing the appropriate attack based on life safety and fire conditions.