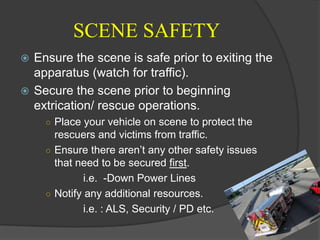

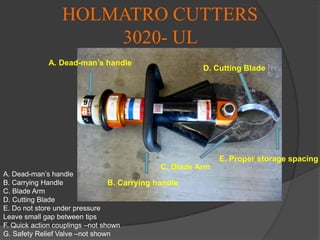

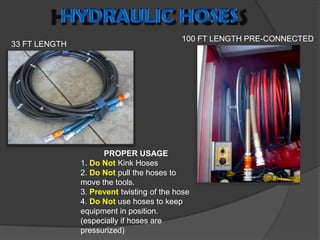

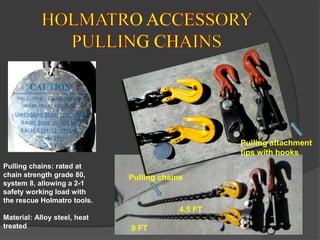

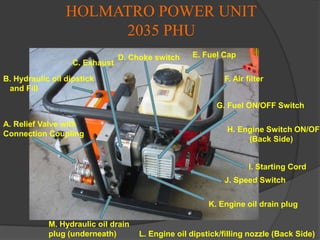

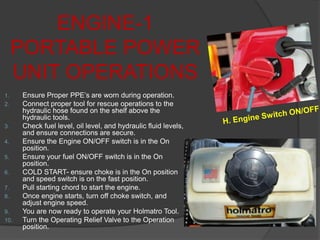

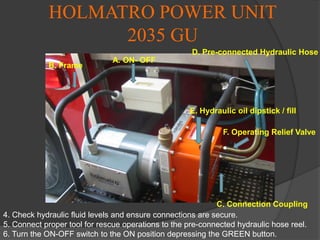

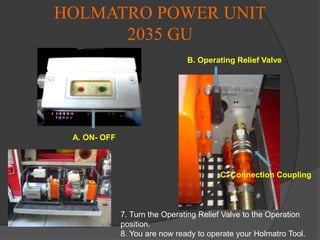

This document provides information on Holmatro rescue tools and how to operate them safely. It describes personal protective equipment firefighters should wear and safety procedures for securing the scene. It then details several Holmatro rescue tools - spreaders, a combi tool, cutters, and a ram - listing their specifications. It explains how to connect the tools to hydraulic hoses and power units, maintain connections, and use the tools properly while pressurized. The document emphasizes the importance of safety in all operations.