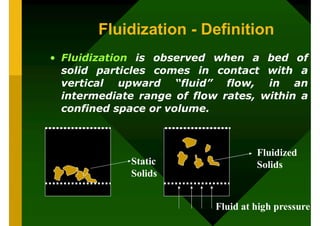

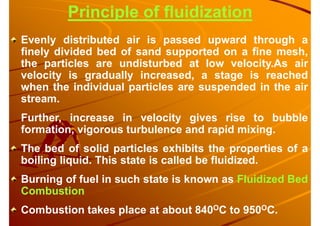

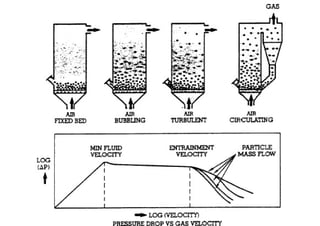

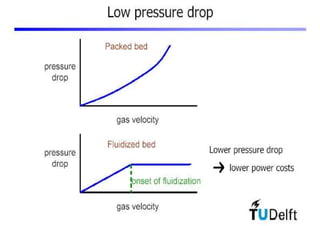

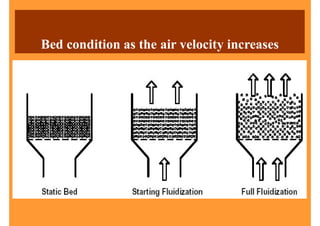

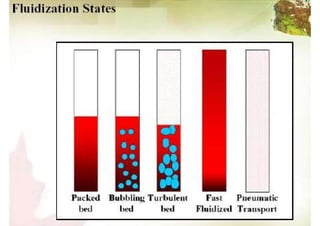

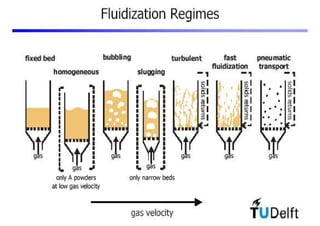

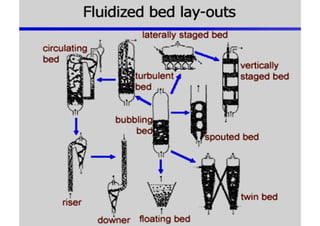

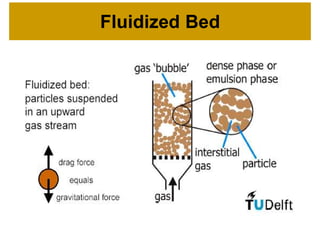

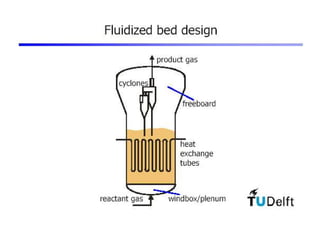

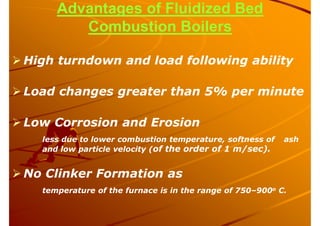

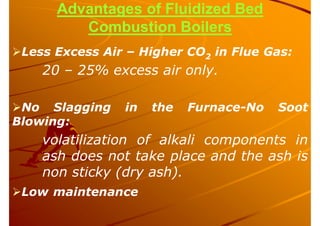

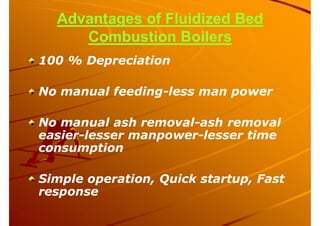

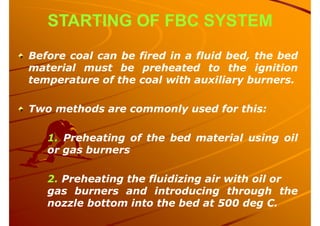

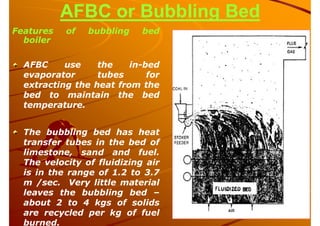

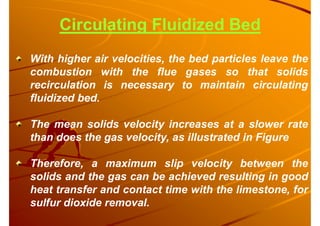

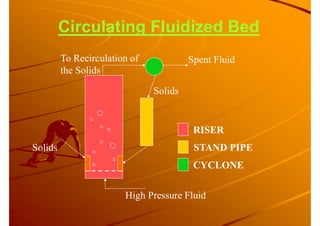

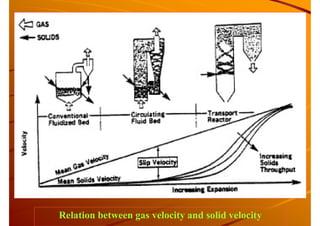

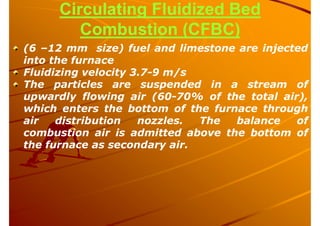

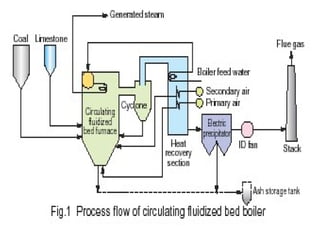

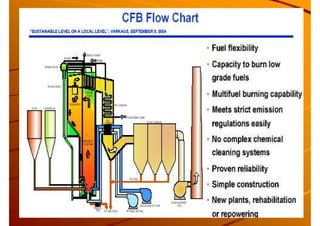

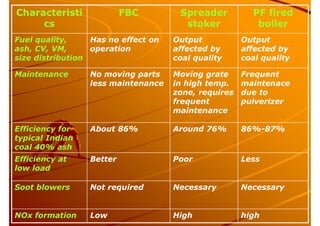

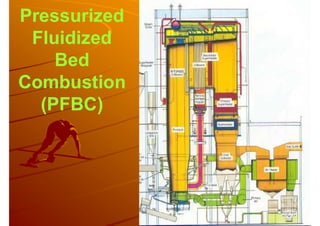

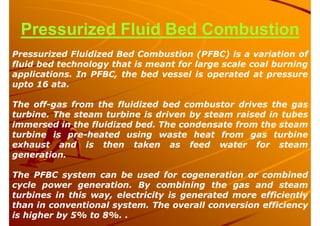

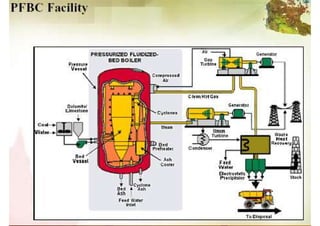

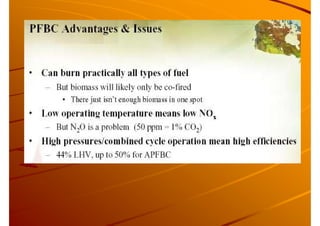

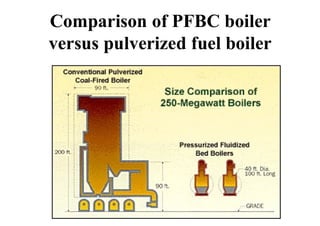

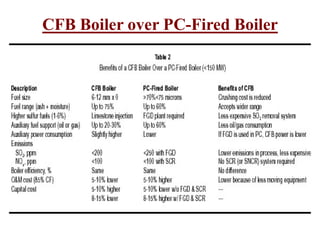

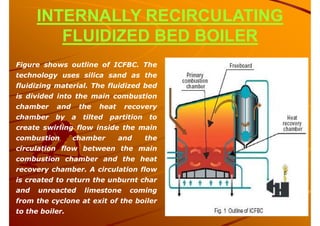

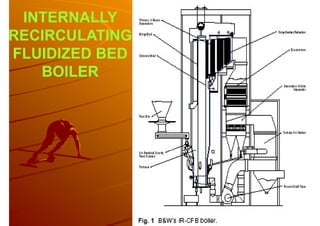

The document discusses fluidized bed combustion (FBC) boilers. It describes the mechanism of FBC, including how fluidization works. It outlines the main types of FBC boilers: atmospheric fluidized bed combustion, circulating fluidized bed combustion, and pressurized fluidized bed combustion. The document highlights the advantages of FBC boilers such as their ability to burn a wide range of low-grade fuels efficiently with low emissions. It also discusses operational features, retrofitting FBC systems, and challenges like corrosion.