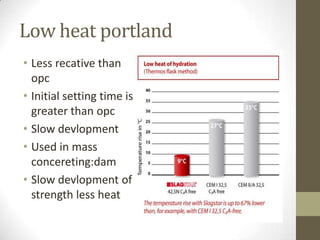

There are two main types of cement: ordinary portland cement and non-portland cement. Ordinary portland cement can be further broken down into rapid hardening cement, low heat portland cement, sulphate resisting cement, masonry cement, waterproof portland cement, white portland cement, and colored portland cement. Non-portland cement includes high alumina cement and super sulphate cement. Each type of cement has different properties making it suitable for different uses depending on setting time, strength development, chemical resistance, and heat generation.