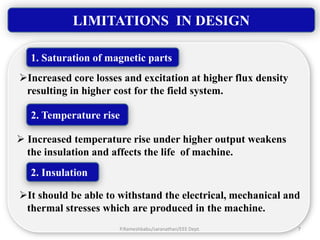

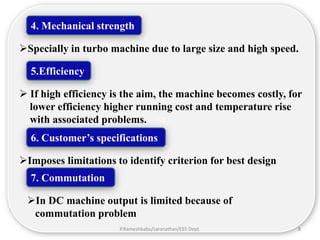

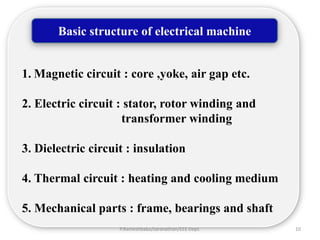

This document contains lecture notes on the fundamentals of electrical machine design from the EE-1352 ELECTRICAL MACHINE DESIGN course. It defines electrical machine design as the creative physical realization of theoretical concepts to produce machines that perform specified tasks with optimum economy and efficiency. The notes discuss basic considerations in developing a design including the design base, specifications, design transfer, and information updating. It also outlines major considerations like lower cost, durability, and meeting performance criteria, as well as limitations in design such as magnetic saturation, temperature rise, insulation, and customer specifications. Finally, it describes the basic structure of electrical machines including the magnetic, electric, dielectric, thermal, and mechanical circuits.