This document discusses the key components and design considerations for extra high voltage (EHV) AC transmission lines. It covers:

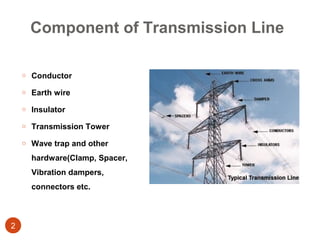

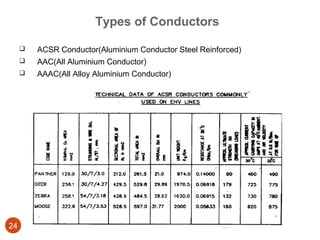

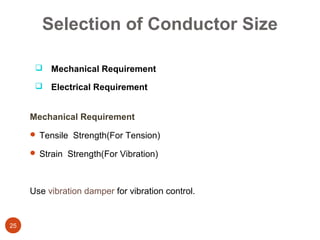

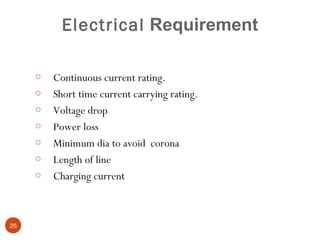

1. The main components of transmission lines including conductors, earth wires, insulators, towers, and hardware.

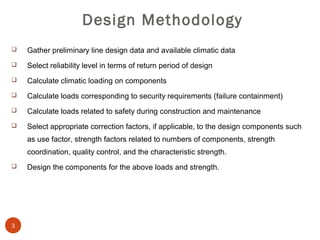

2. The design methodology which involves calculating loads from climatic conditions, reliability requirements, and safety factors before designing each component.

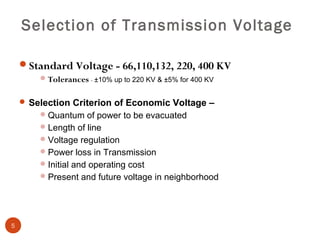

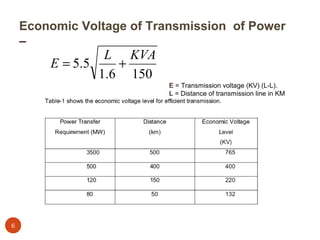

3. Factors involved in selecting the transmission voltage level based on the power level, line length, voltage regulation needs, and costs.

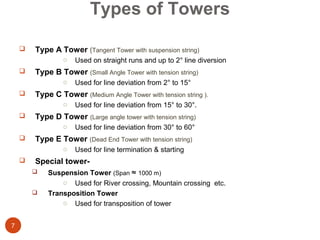

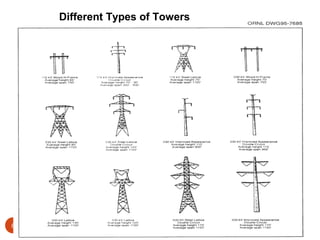

4. The types of transmission towers used for different line angles and situations like river crossings.

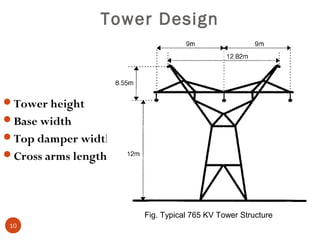

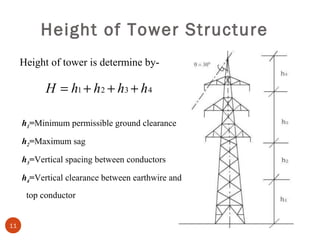

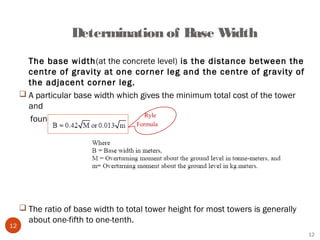

5. Design of the tower structure including height, base width, cross arm length based

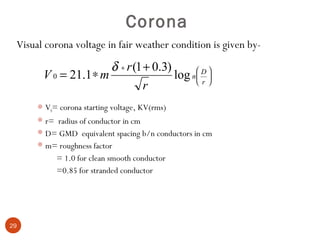

![Optimization of Conductor

When more than one conductor satisfied the requirement of current

capacity and corona performance than study required for conductor

optimization

C= cost in Rs. Per Km of 3-ø line

A= Annual fixed charge on capital in Rs./ Rupees of capital cost(interest

14%+depreciation 5%+ operation and maintenance cost 1-3%)

Pm= Maximum demand(KW)

Annual energy generated

LF=

V= Line voltage(KV) 8760*maximum demand

R= Resistance of conductor/Km/phase L= Energy charge in Rs/Kwh

M= Demand charge in Rs/Kwh

Cosø=Power factor

H= Loss load factor

= 0.3[LF+0.7(LF)2] (For normal load variation)

= 0.2[LF+0.8(LF)2] (For more uniform load variation)

31](https://image.slidesharecdn.com/ehvactransmissionline-130205053535-phpapp02/85/Ehv-ac-transmission-line-31-320.jpg)

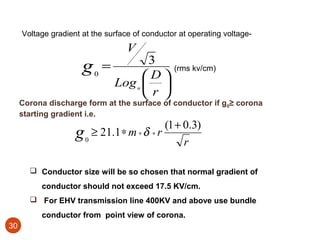

![J =

12 M ( LF ) +8760 ∗L ∗H

2

1000

Total annual fixed charge (C1)=C*A

Total annual running charges(C2)= (P2m*R*J)/(V2 Cos2 ø)

Total charges(T)= C*A + (P2m*R*J)/(V2 Cos2 ø)

Conductor giving minimum T will be optimum

Cost/KW/Km will be minimum i.e. T/Pm will be minimum when

Pm = V cos φ

[C ∗ A] 1/ 2

R

32](https://image.slidesharecdn.com/ehvactransmissionline-130205053535-phpapp02/85/Ehv-ac-transmission-line-32-320.jpg)