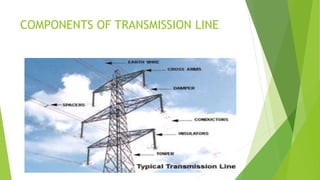

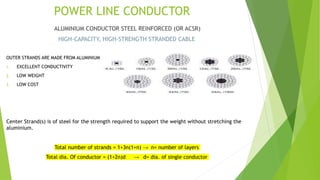

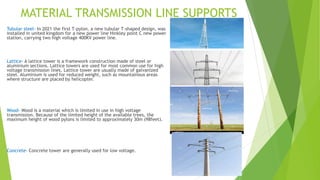

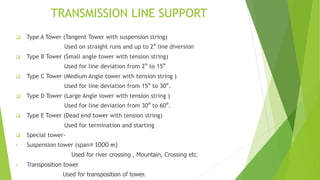

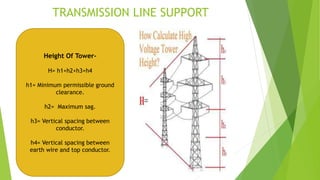

This document provides an overview of electrical power transmission in India. It discusses the components of transmission lines including conductors, spacers, and supports. It also covers transmission line design considerations such as voltage levels, ground clearances, conductor spacing, and tower heights. The document outlines India's existing transmission system and some issues in further developing the system such as right of way, regulation of power flows, and integration of new technologies like HVDC transmission and gas insulated substations.