This document discusses switchgear technology, specifically focusing on different types of circuit breakers (CBs). It describes:

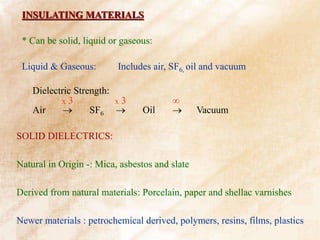

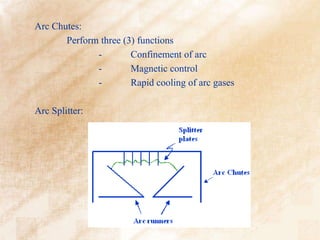

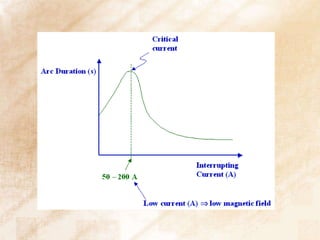

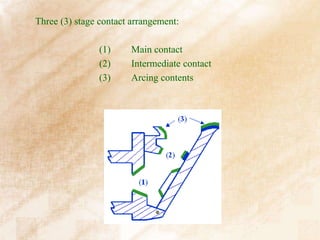

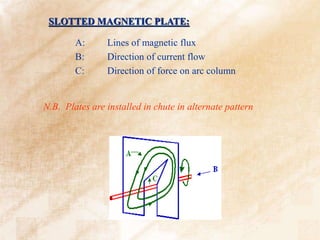

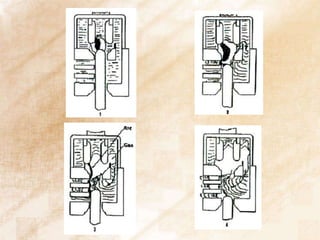

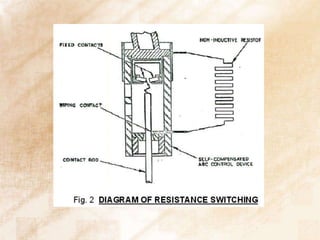

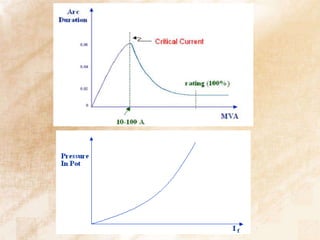

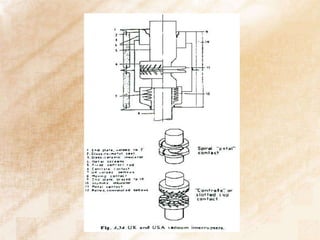

1. The basic physics of arcs in CBs and how they are controlled through insulating materials, arc chutes that confine and cool arcs, and contact arrangements.

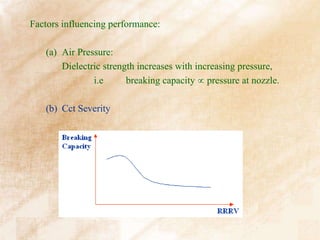

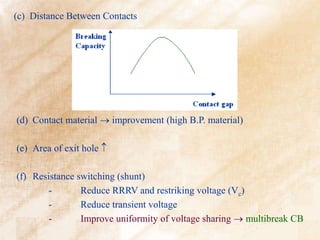

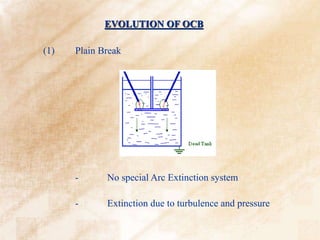

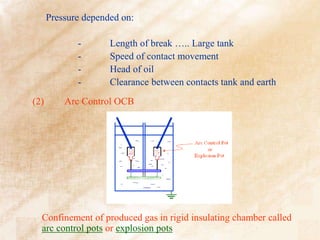

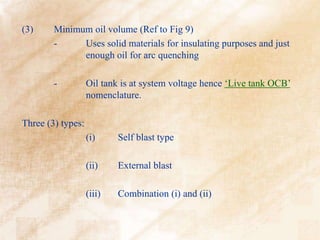

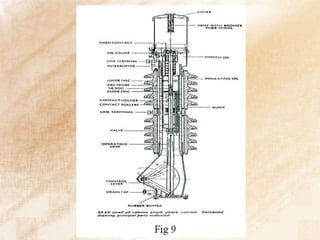

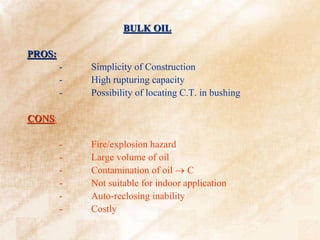

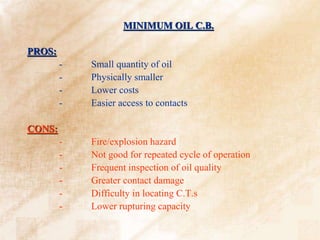

2. How air circuit breakers (ACBs) and air blast CBs interrupt arcs naturally or through injected air, while oil circuit breakers (OCBs) rely on oil to cool arcs.

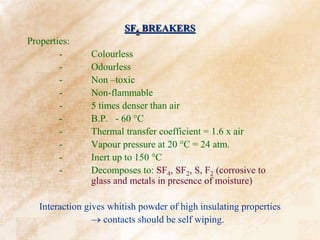

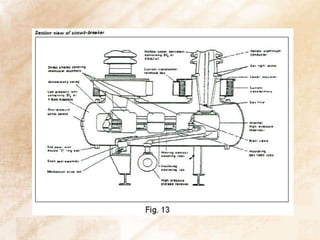

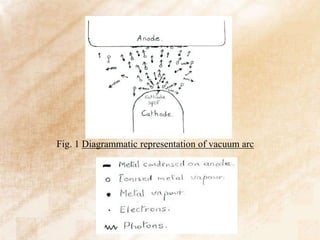

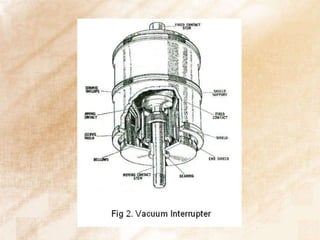

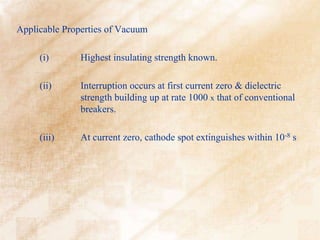

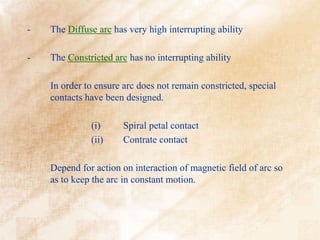

3. SF6 and vacuum breakers, which use insulating gases and high vacuum respectively to rapidly deionize arcs at current zero.