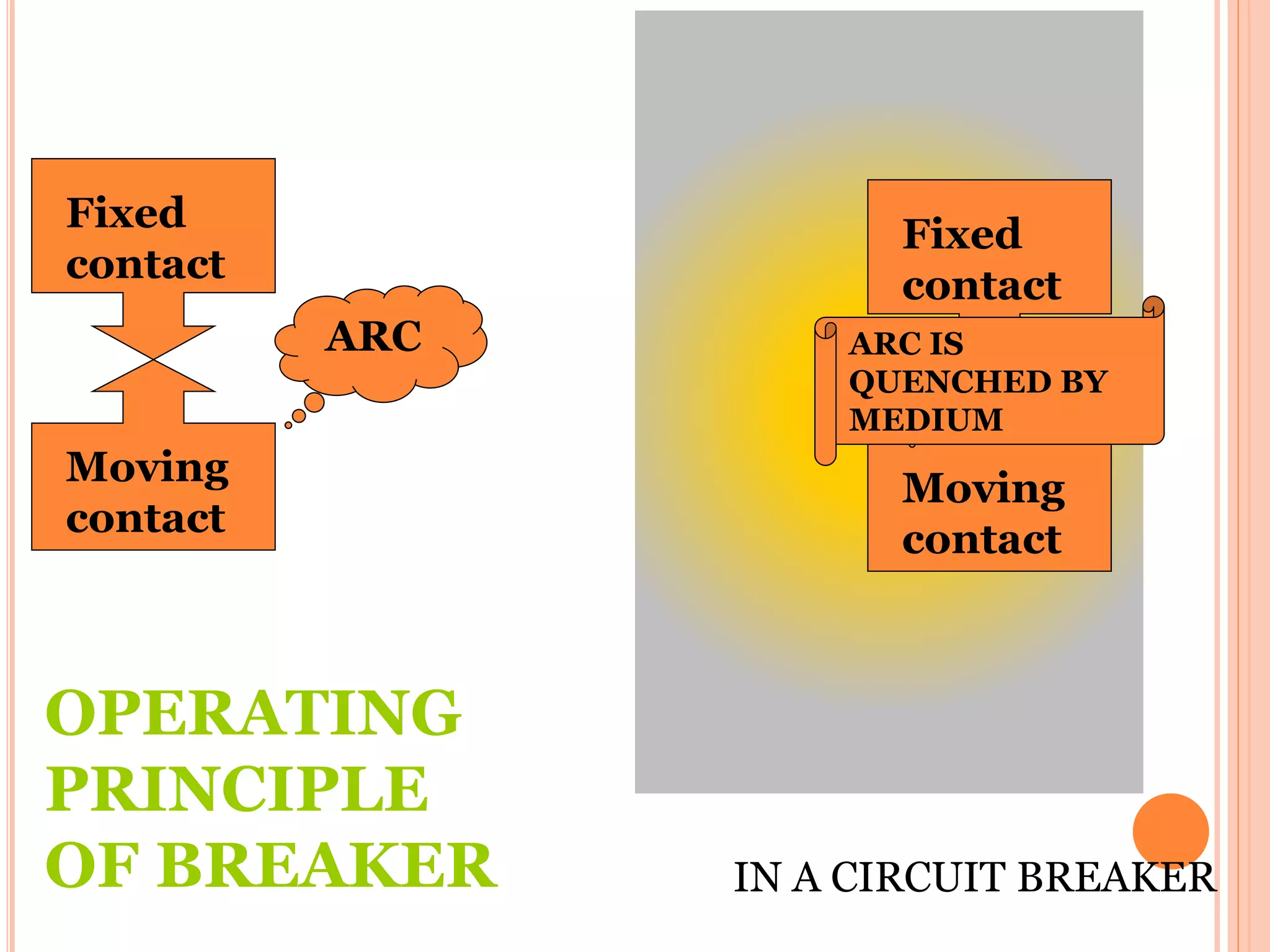

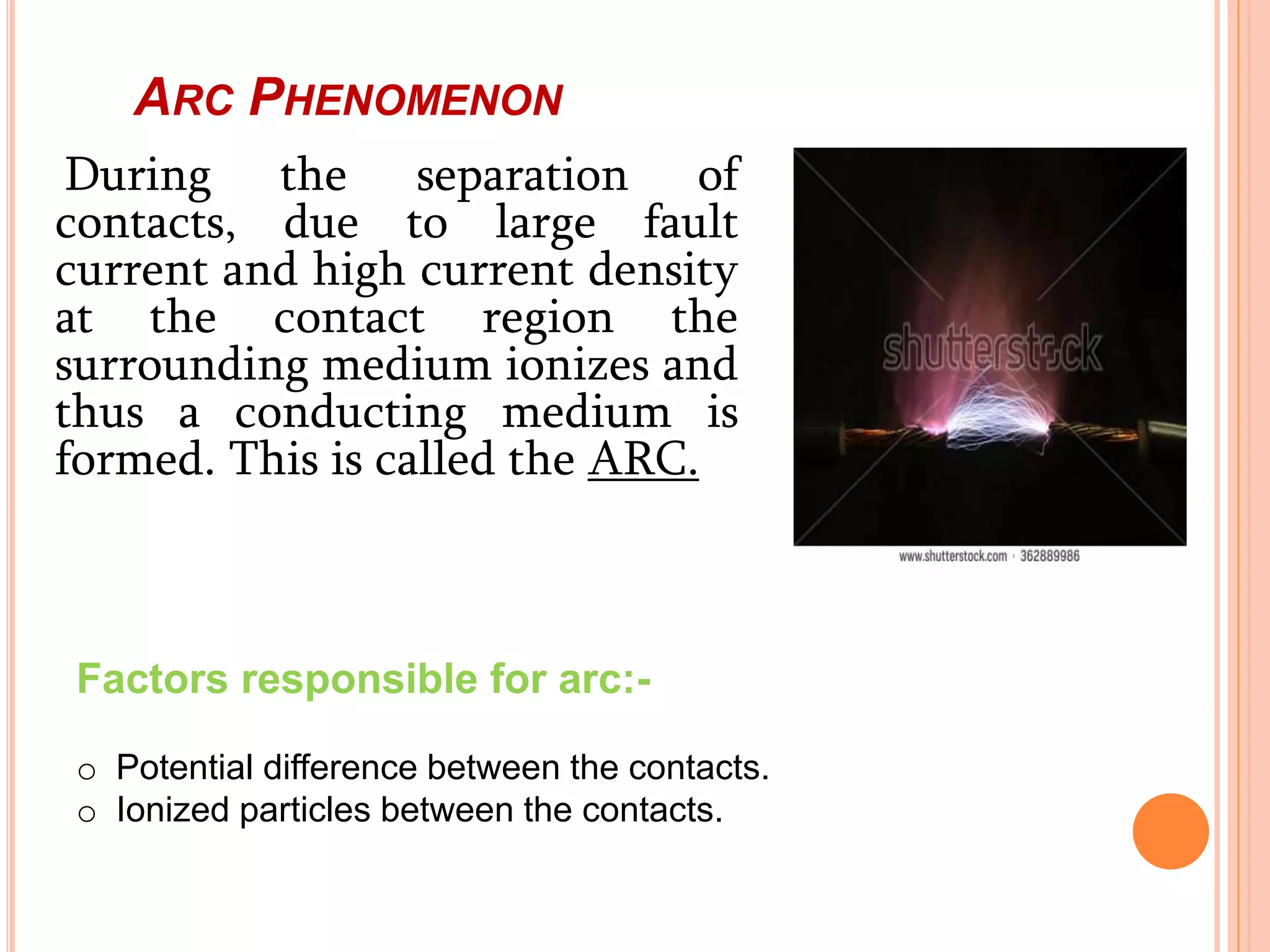

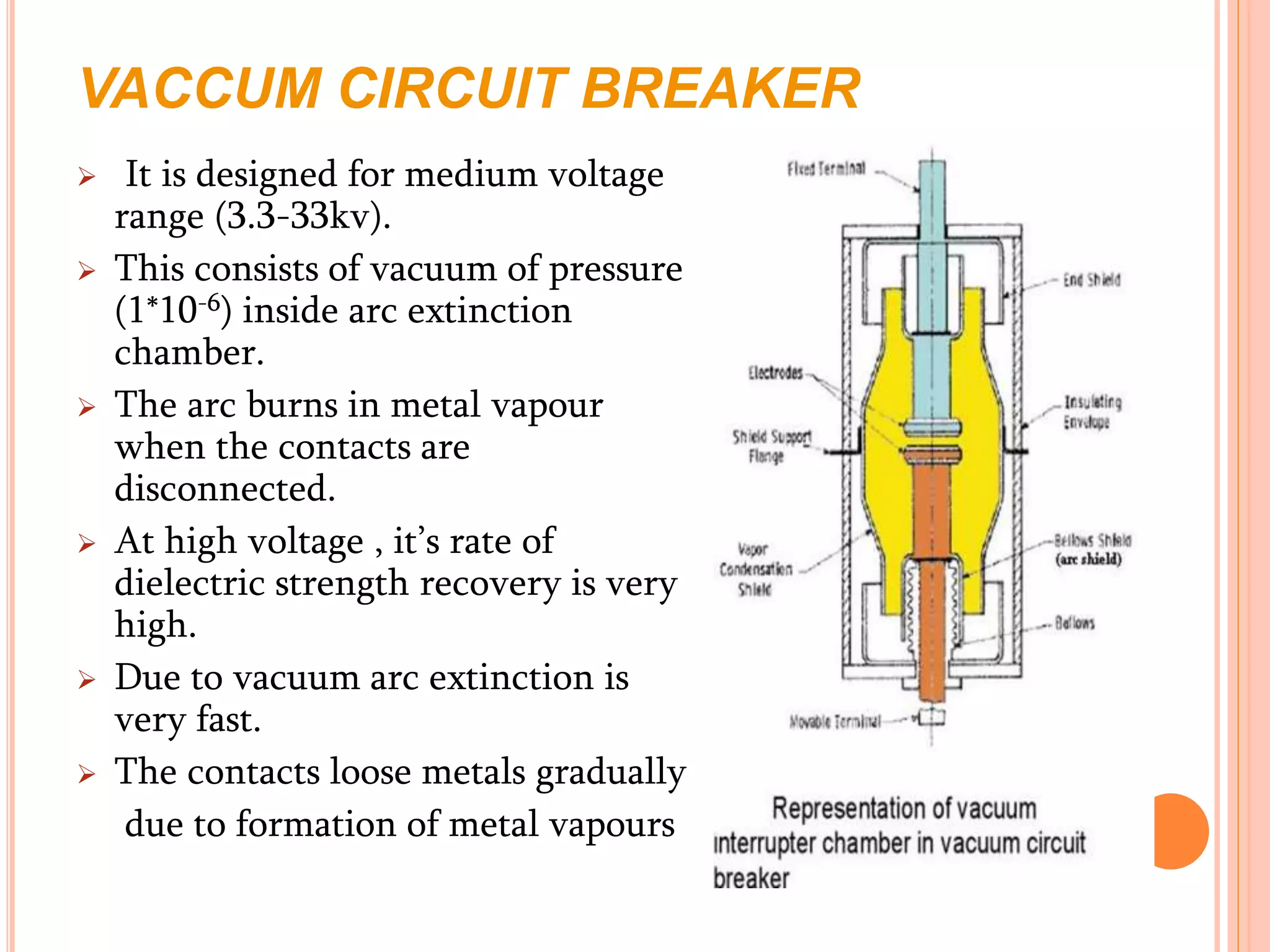

The document discusses different types of circuit breakers, including air blast, vacuum, oil, and SF6 circuit breakers. It explains that a circuit breaker breaks a circuit manually or automatically under various load conditions. The operating mechanism involves two contacts that separate when a trip coil is energized during a fault. Different circuit breakers use various mediums like oil, air, vacuum, or SF6 gas to quench the arc formed during contact separation. Modern circuit breakers widely use vacuum or SF6 breakers due to their reliable and fast operation.