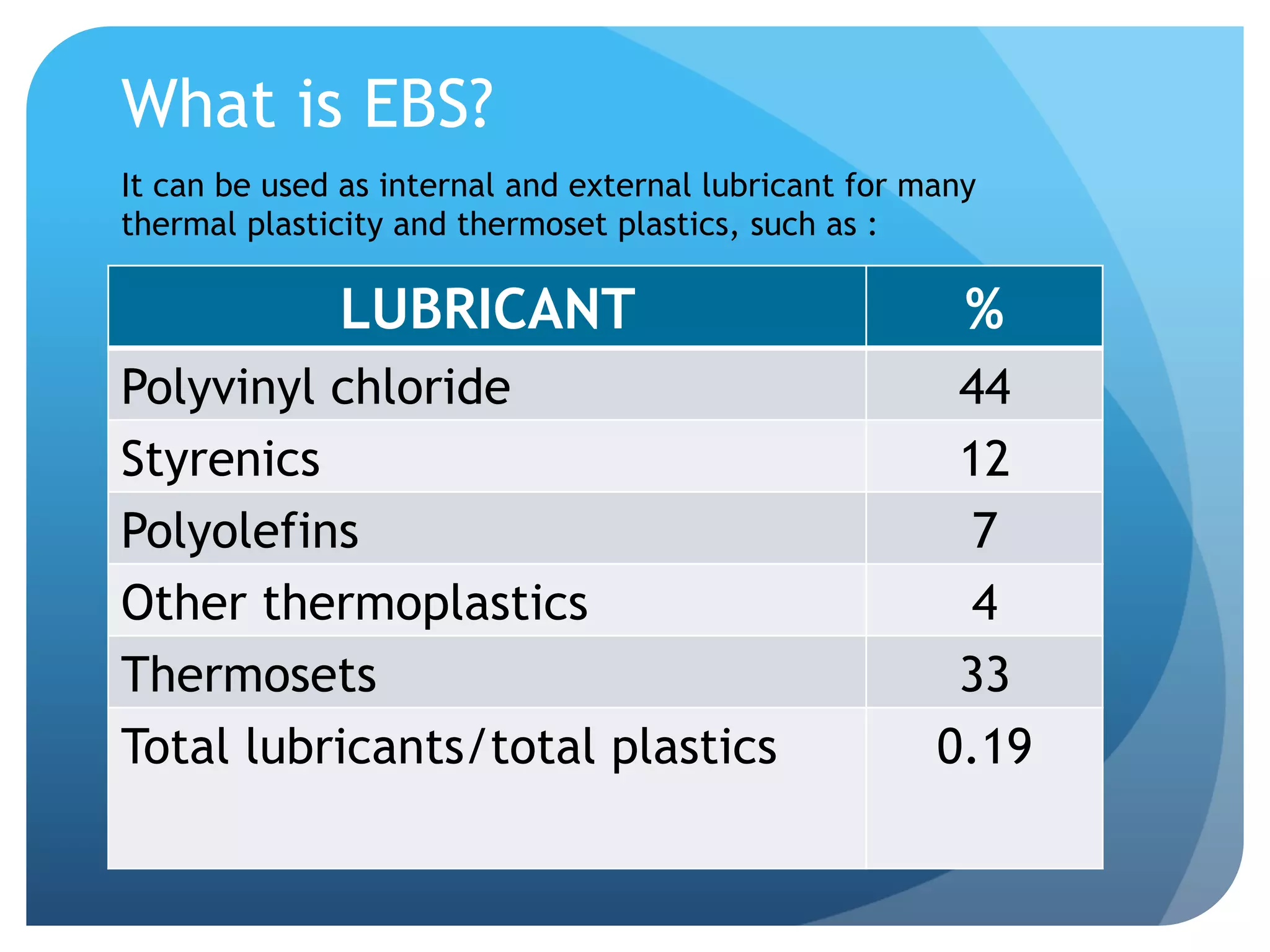

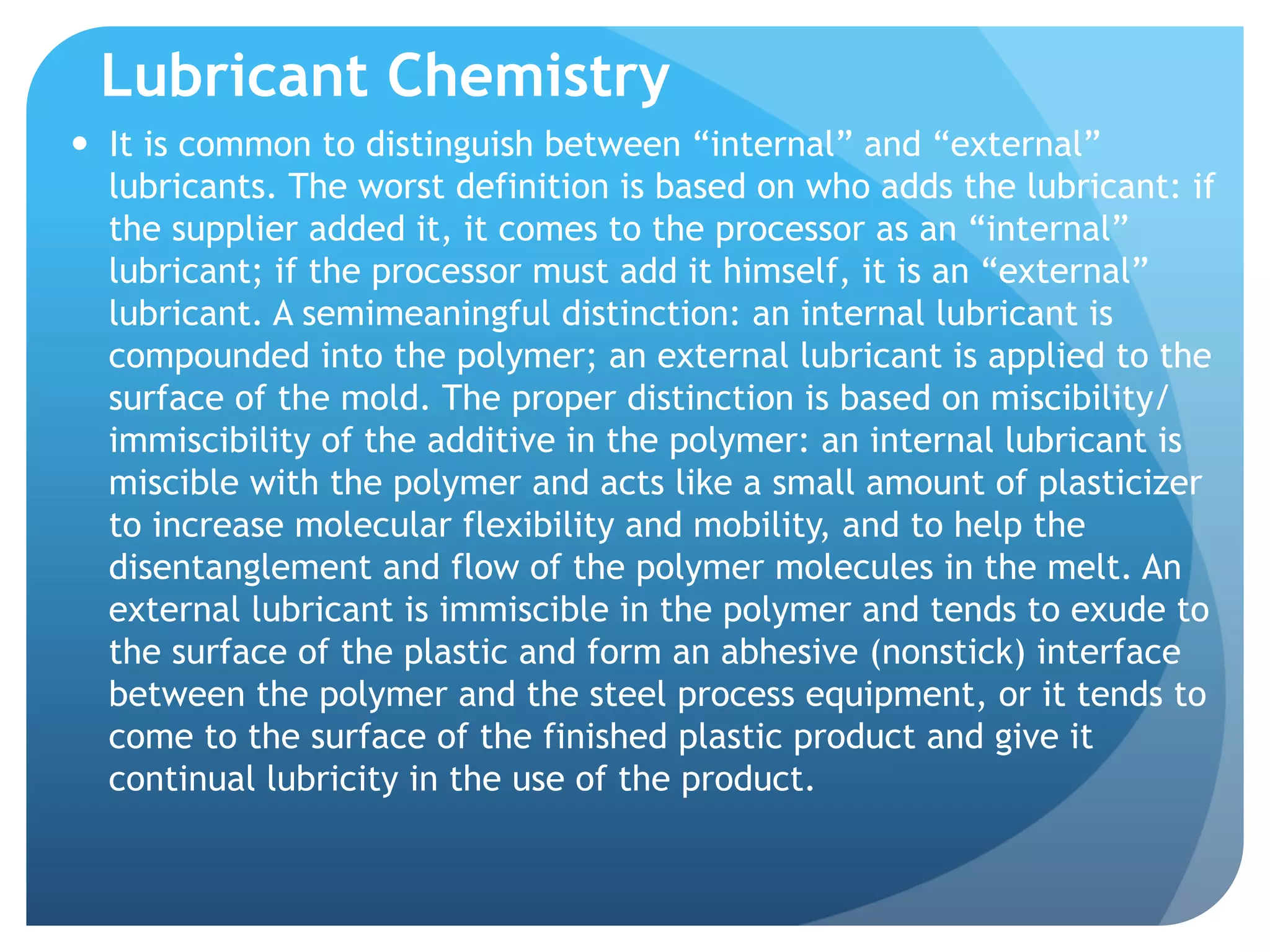

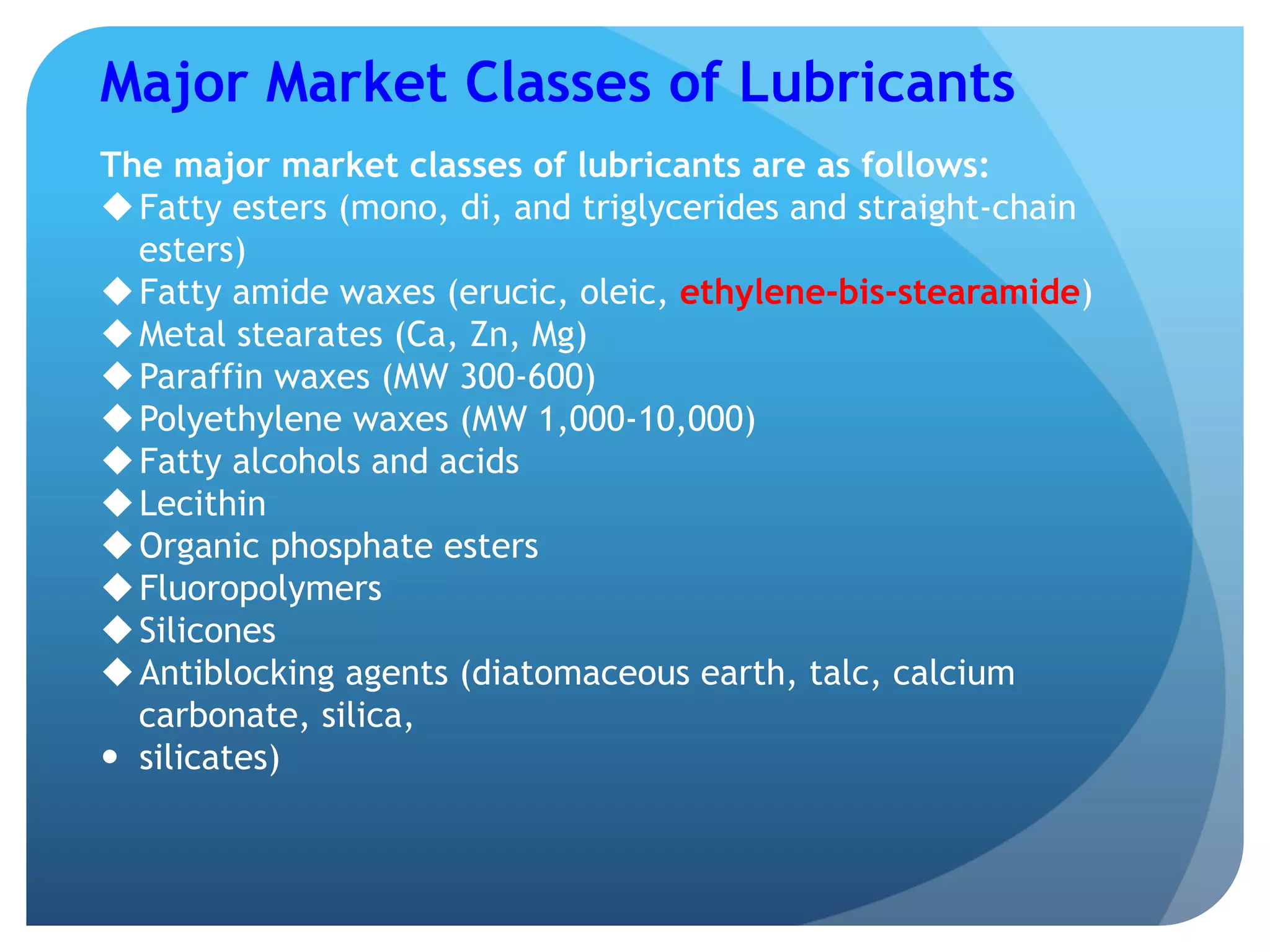

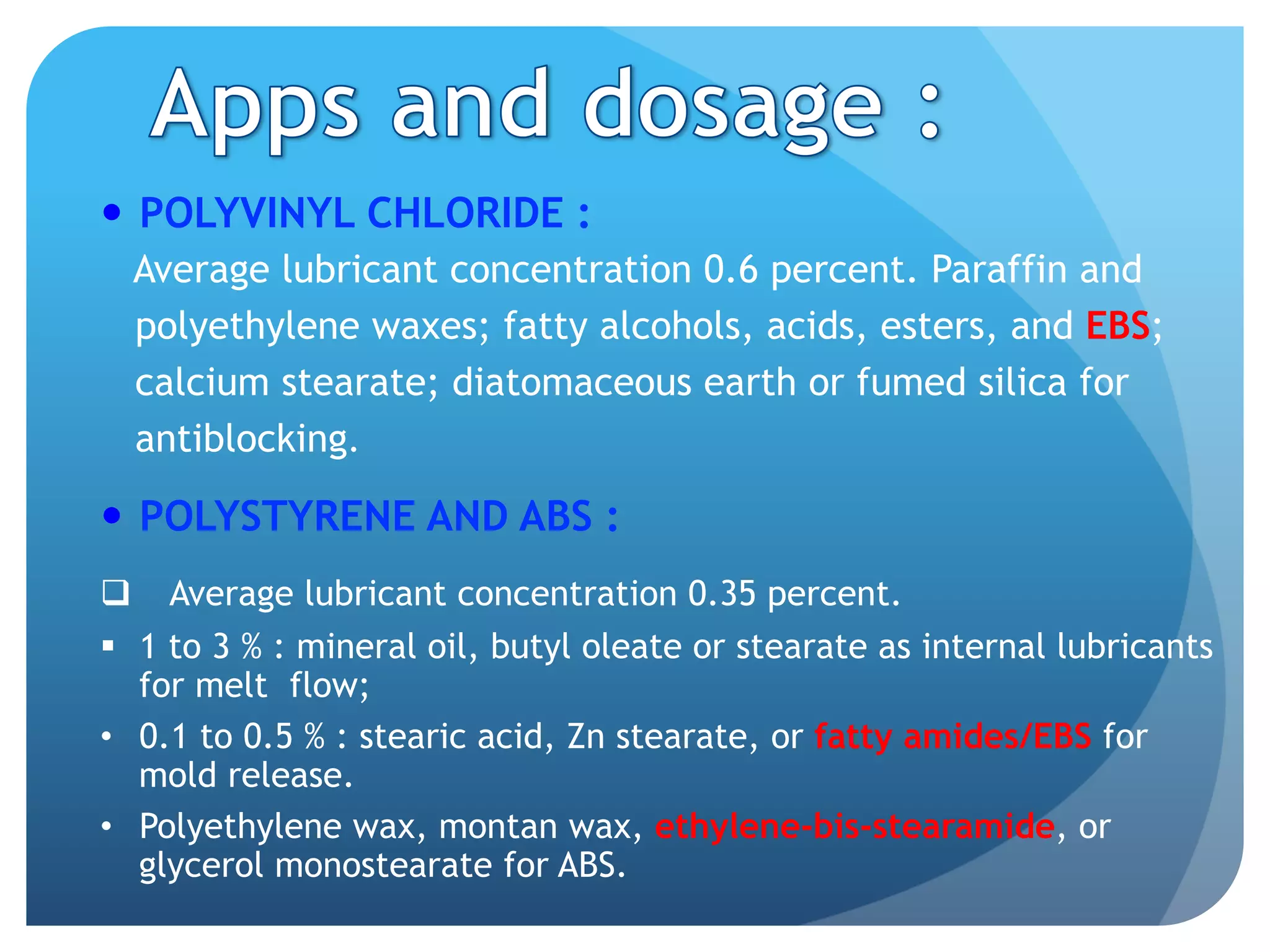

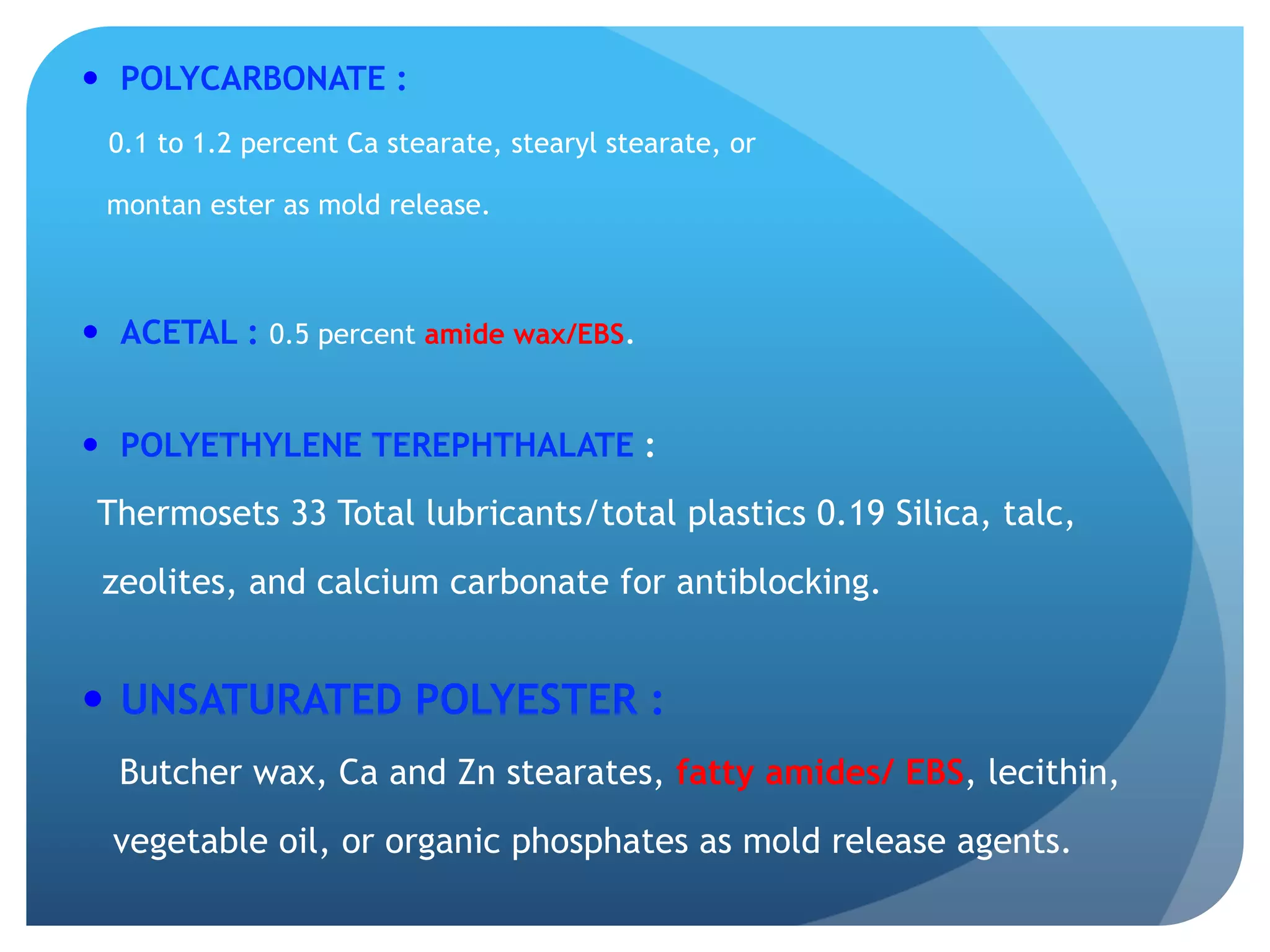

Ethylene bis-stearamide (EBS) is a versatile lubricant used in various plastics, categorized as either internal or external based on its miscibility with the polymer. Internal lubricants are mixed into the polymer for improved flow, while external lubricants form a non-stick interface on the surface. The document details different types of lubricants, their concentrations in specific plastics, and emphasizes the balance between internal and external properties based on the relative polarity of the lubricant and polymer.