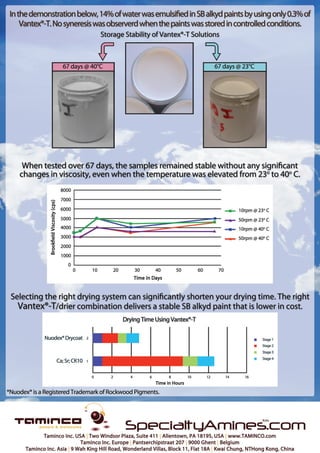

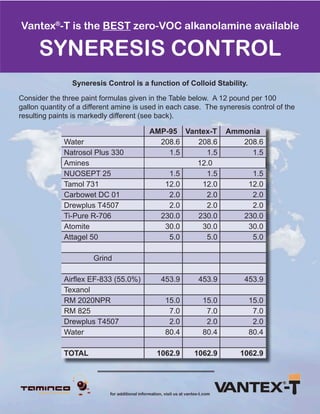

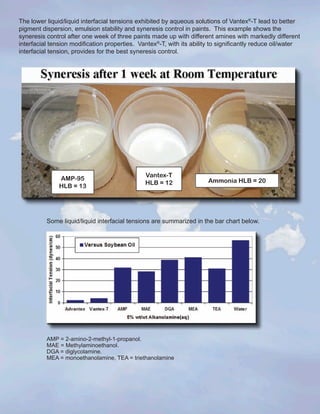

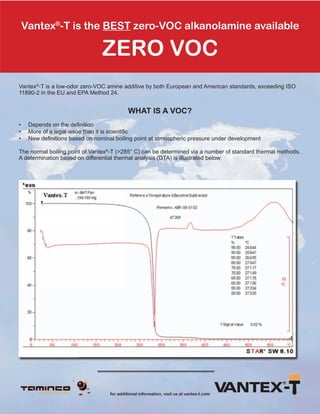

The document describes vantex® -t, a low-odor, zero-VOC alkanolamine that effectively reduces interfacial tensions, enhancing pigment dispersion, emulsion stability, and syneresis control in paints. It also includes details on specific paint formulations and their performance metrics, which demonstrate the additive's superior qualities compared to other amines. Additional information on the chemical properties and applications of vantex® -t is available on the company's website.