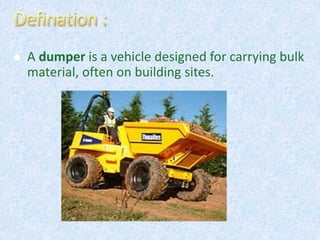

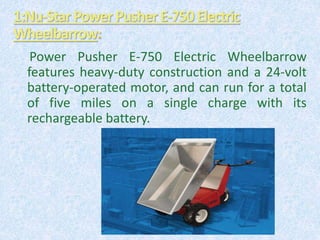

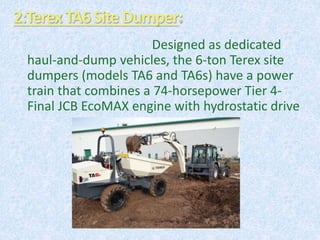

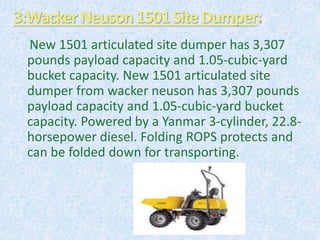

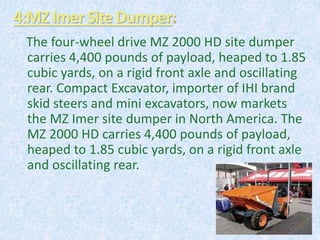

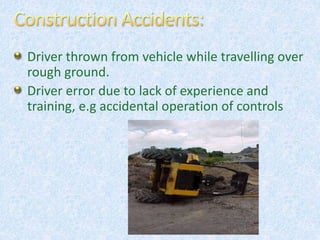

Group 7's project focuses on site dumpers. Site dumpers are open vehicles used to carry bulk materials on construction sites. They have the load skip in front of the driver and can tip the skip to dump loads. The group evaluates several common site dumper models from manufacturers like Nu-Star, Terex, Wacker Neuson, and MZ Imer. These dumpers have payloads from 2,200 to 13,000 pounds and are powered by diesel engines. Proper training and safety precautions are needed when operating site dumpers to prevent overturning, which is a major cause of accidents.