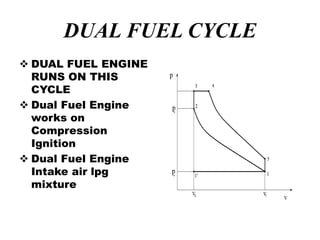

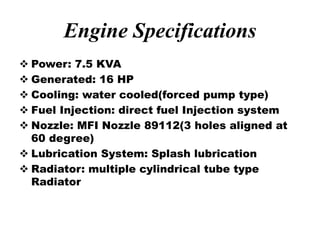

This document summarizes a student project to operate a diesel engine using both diesel fuel and liquefied petroleum gas (LPG). The project aims to utilize the compression ignition properties of diesel to ignite LPG, allowing a diesel engine to run on both fuels. Key findings include that this approach could provide cost savings by reducing dependence on fuel price fluctuations and allow the use of biofuels. Testing showed the engine generated 16 horsepower but further work is needed to reduce knocking and optimize the fuel mixture. Overall, the project demonstrates the potential for dual-fuel engine technology but more testing and advancement is still required.