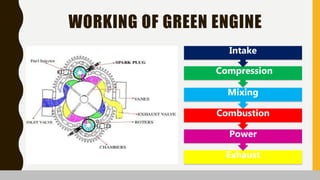

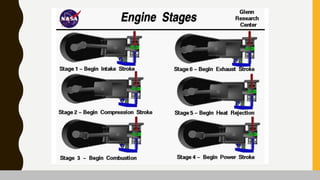

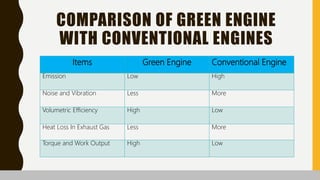

This document provides information about a green engine, which is a type of internal combustion engine that aims to reduce emissions. It has a six-phase working principle of intake, compression, mixing, combustion, power, and exhaust. This allows for complete fuel mixing and burning, resulting in near-zero emissions. The green engine has higher efficiency than conventional engines and can run on multiple fuel types. It has benefits like reduced size, weight, emissions, and noise compared to piston engines. Research is ongoing but it shows potential for use in various industries and applications.