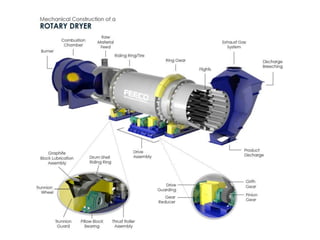

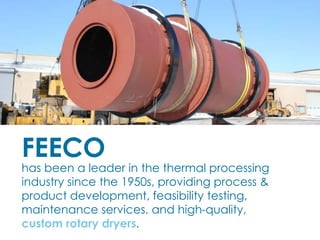

The document discusses the components and customization options of rotary dryers. Rotary dryers are used to process materials across many industries and consist of standard components like a dryer shell, combustion chamber, burner, feed system, drive assembly, and flights. The dryer shell, burner, and flights can be customized. Rotary dryers offer a robust and customizable solution for drying bulk solids.