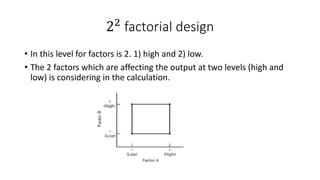

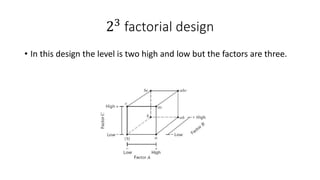

This document discusses the application of design of experiments (DOE) in welding technology. It explains why industrial engineers need to study DOE to push quality higher and focus on quality management. It also describes different types of experimental design methods like full factorial, fractional factorial, and Taguchi's method. Finally, it provides an overview of various welding processes classified based on the energy source used like gas, arc, resistance, solid state, and radiant energy welding.