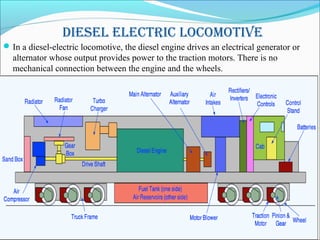

The document is a summer training report on Diesel Locomotive Works (DLW) in Varanasi, detailing its establishment, operations, and locomotive manufacturing processes. It describes the types of locomotives produced, classification codes, and various engineering divisions involved in the assembly and testing of diesel-electric locomotives. Additionally, it covers the welding and machine shop processes, highlighting techniques like SMAW, MIG welding, and CNC machining used in the manufacturing process.

![claSSification of locomotiveS

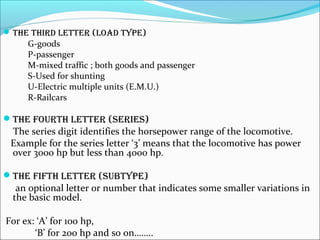

Locos, except the older steam ones, have classification codes that

identify them. This code is of the form

WDG5A “ [ gauge ][ power ][load ][ series ][ sub type ]”

the firSt letter (gauge)

W- Indian broad gauge

Y- meter gauge

Z- narrow gauge(2.5 ft)

N- narrow gauge (2 ft)

the Second letter (motive power)

D- Diesel

C- DC electric (can run under DC traction only)

A- AC electric (can run under AC traction only)

CA- Both DC and AC (can run under both AC and DC tractions)

B- Battery electric locomotive (rare)](https://image.slidesharecdn.com/dlwreport-170425193447/85/DLW-varanasi-summer-training-report-5-320.jpg)

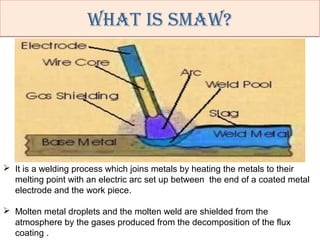

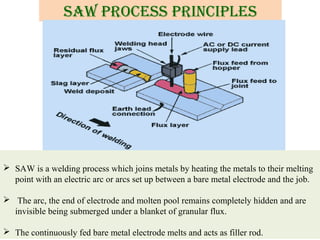

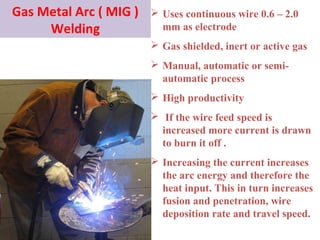

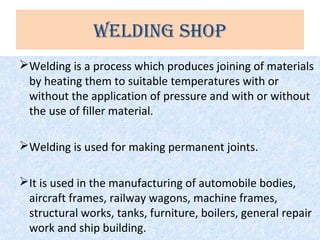

![Shielded Metal Arc Welding [SMAW]

Submerged Arc Welding [SAW]

Gas Shielded Metal Arc Welding [MIG]

Flux Cored Arc Welding [FCAW]

Shielded Metal Arc Welding [SMAW]

Submerged Arc Welding [SAW]

Gas Shielded Metal Arc Welding [MIG]

Flux Cored Arc Welding [FCAW]

Types Of Welding Used in dlWTypes Of Welding Used in dlW](https://image.slidesharecdn.com/dlwreport-170425193447/85/DLW-varanasi-summer-training-report-10-320.jpg)