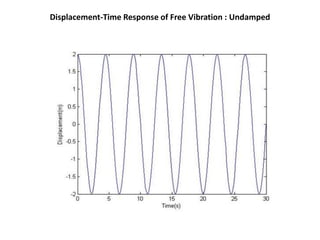

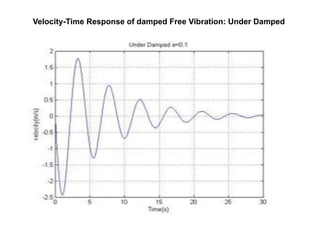

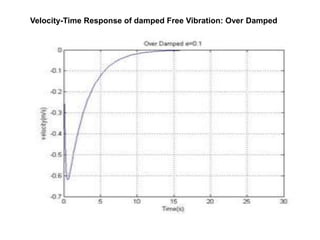

The document presents an analysis of mechanical vibrations in spring mass damper models and machining processes for a Bachelor of Technology thesis in Mechanical Engineering. It discusses types of vibrations, damping influences, and includes experimental results comparing various vibration scenarios and their analysis using MATLAB. Key findings emphasize the significance of vibration monitoring in machining and the use of devices like VibXpert for effective vibration analysis.

![• Vibration can be regarded as a branch of dynamics that deals with periodic

and oscillatory motion. Common example of vibration problems are the

response of civil engineering structures to dynamic loading, ambient

condition and earthquakes, vibration of the unbalanced rotating machines

and vibration of power line due to wind excitations, and aircraft wings

[11].

• Vibrations are produced in machine having unbalanced masses. These

vibrations will be transmitted to the foundation upon which the machine

is installed. This is usually undesirable. To diminish the transmitted

vibration, machines are usually mounted on spring or dampers, or on

some other vibration isolating material [12].

• Phani Srikantha A., Woodhouse J. [9] studied parametric identification of

viscous damping models in the context of linear vibration theory.

Frequency domain identification methods based on measured frequency

response functions (FRFs) are considered.](https://image.slidesharecdn.com/finalppt-141214102413-conversion-gate01/85/Mechanical-Vibration-9-320.jpg)

![•Jiao Chunwang, Liu Jie, Guo Dameng and Wang Qianqian [10] studied that

It is of paramount importance to acquire the response of many nonlinear

forced vibration system. They developed a new method to explore the

approximate analytical solution of forced vibration system which is named

harmonic iteration method (HIM).

•Hao Jiang, Xinhua Long, and Guang Meng [13] said Cutting vibration is

unavoidable during a machining process and has great impact on the

machined surface. With the increase of the demand on the highquality of

surface finish, the effects of cutting vibrationon surface generationattract a

lot of attentions.

•A great deal of research has been carried out on the chatter problem since

the late 1950s, when Tobias and Fishwick [3], Tlusty and Polacek [6] and

Merrit [7] presented the first research results focused on this phenomenon.

Lots of significant advances have been made over the years. Advances in

computers, sensors and actuators have increased understanding of the

phenomena, and developed and improved strategies to solve the problem

[2].](https://image.slidesharecdn.com/finalppt-141214102413-conversion-gate01/85/Mechanical-Vibration-10-320.jpg)

![Bibliography

[1]. Tobias, S.A. Machine Tool Vibration. Spain : UMRO, 1961.

[2]. Chatter in machining process: A review. Guillem Quintana, Joquim Ciurana. 2011, International Journal of

Machine tools and Manufacture, pp. 363-376.

[3]. S.A. Tobais, W. Fishwick. Theory of regenerative machine tool chatter. s.l. : The Engineer, 1958.

[4]. A review of chatter vibration research in turning. M. Siddhpura, R. Paurobally. 1, s.l. : ELSEVIER, 2012,

International Journal of machine tools and manufacture, Vol. 61, pp. 27-47.

[5]. On the art of cutting metals. F.Taylor. 1907, Transactions of ASME , Vol. 28.

[6]. The stability of machine tools against self-excited vibrations in machining. J. Tlusty, M. Polacek. 1963,

International Research in Production Engineering, pp. 465–474.

[7]. Theory of self-excited machine-tool chatter-contribution to machine tool chatter research—1. Merrit, H.E.

1965, ASME Journal of Engineering for Industry, pp. 447-454.

[8]. Robust Analysis of Stability in Internal Turning. Giovanni Totis, Marco Sortino. Udine, Italy : ELSEVIER, 2014.

24th DAAAM International Symposium on Intelligent Manufacturing and Automation. Vol. 69, pp. 1306-1315.

[9]. Viscous damping identification in linear vibration. S. Adhikari, J. Woodhouse. 2007, Journal of Sound and

Vibration , Vol. 303, pp. 475-500.

[10]. Jiao Chunwang, Liu Jie, Guo Dameng and Wang Qianqian. A New Method for Solving Nonlinear Forced

Vibration System Response. 2010.

[11]. Wahab, M. A. Dynamics and Vibration: An Introduction. s.l. : John Wiley & Sons Ltd., 2008.

[12]. Rattan, S.S. Theory of Machines. 3. New Delhi : McGraw Hill Education (India) Private Ltd., 2009.

[13]. Study of the correlation between surface generation and cutting vibrations in peripheral milling. Hao

Jiang, Xinhua Long, Guang Meng. Shanghai, China : s.n., 2008, journal of materials processing technology, Vol.

208, pp. 229-238.](https://image.slidesharecdn.com/finalppt-141214102413-conversion-gate01/85/Mechanical-Vibration-45-320.jpg)